Preparation method of ferrite europium antiferromagnetic ceramics

An antiferromagnetic and ceramic technology, applied in antiferromagnetic materials, magnetic materials, magnetic objects, etc., to achieve the effects of low price, significant reduction, and strong activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

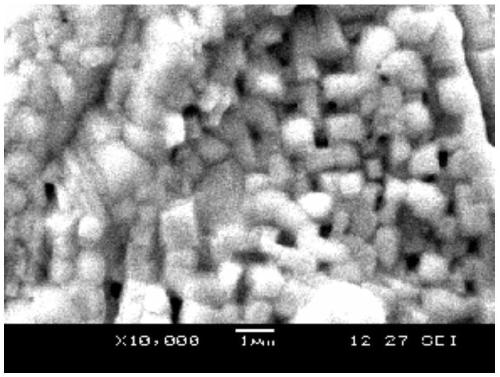

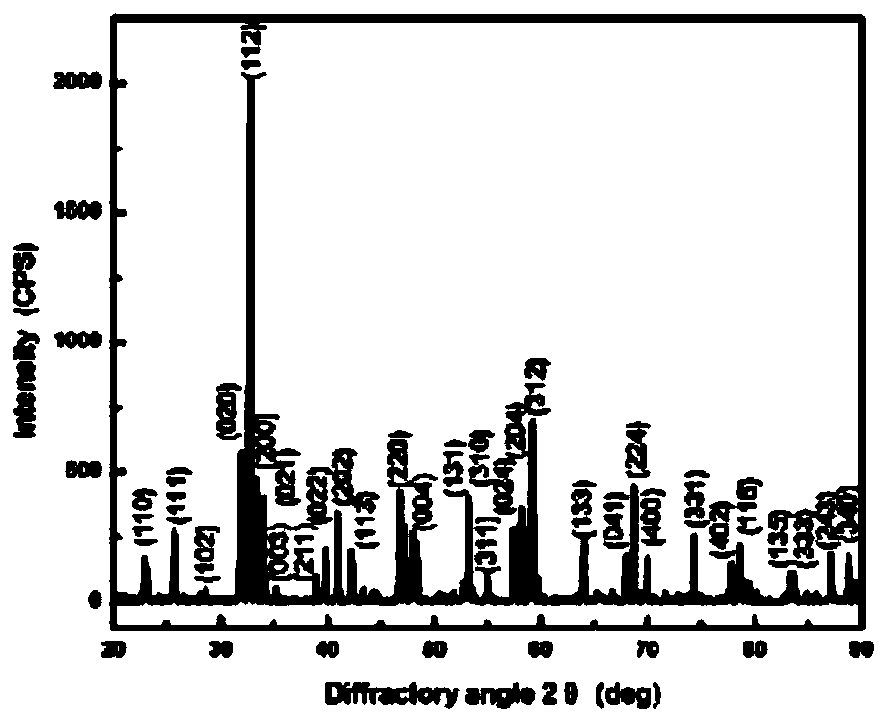

Examples

Embodiment 1

[0027] According to the formula, the chemical formula is EuFeO 3 Weigh raw materials, molecular weight 255.81, batching quality 50.00 grams; weigh required raw materials Fe 2 o 3 Mass is 15.638 grams, Eu 2 o 3 The mass is 34.397 grams.

[0028] The preparation method is:

[0029] Weigh Fe according to stoichiometric ratio 2 o 3 、Eu 2 o 3 After each powder raw material is placed in a ball mill jar, add an appropriate amount of distilled water as a solvent, and after 16 hours of planetary ball milling, it is at 100 o Dry in the drying box of C temperature for 24 hours, pulverize and pass through 80 mesh sieves, obtain the mixed powder of raw material;

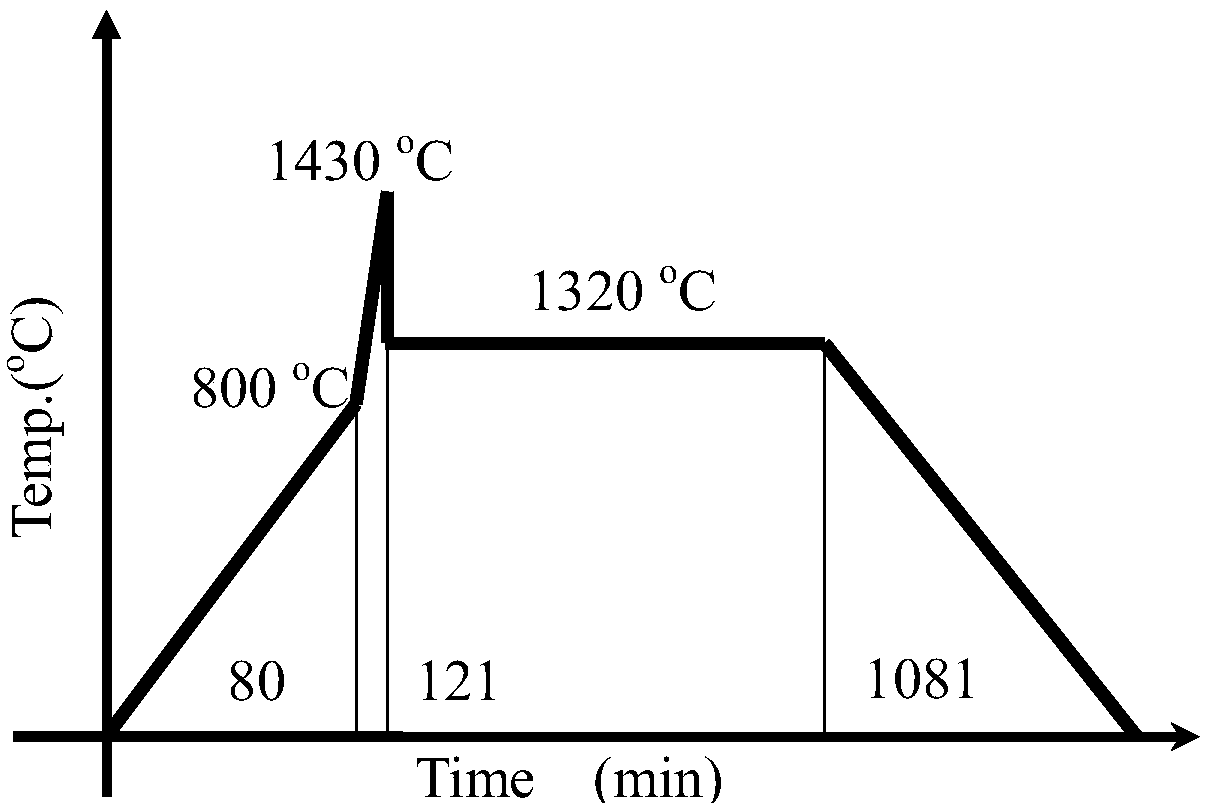

[0030] The resulting mixed powder, through 900 o C, 6 hours low temperature and long time pre-synthesis of mixed powder precursor;

[0031] To the synthesized precursor powder, add PVA binder with a concentration of 5 wt% accounting for 15 wt% of the powder material, mix and pre-press, crush and grind through an 80-mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com