Functional flame-retardant polymeric composition and preparation method and application thereof

A technology of flame retardant polymer and composition, applied in the field of functional flame retardant polymer composition and its preparation, can solve the problems of reduced material toughness, reduced impact strength, poor flame retardant effect, etc., and achieves excellent comprehensive performance and good The effect of technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

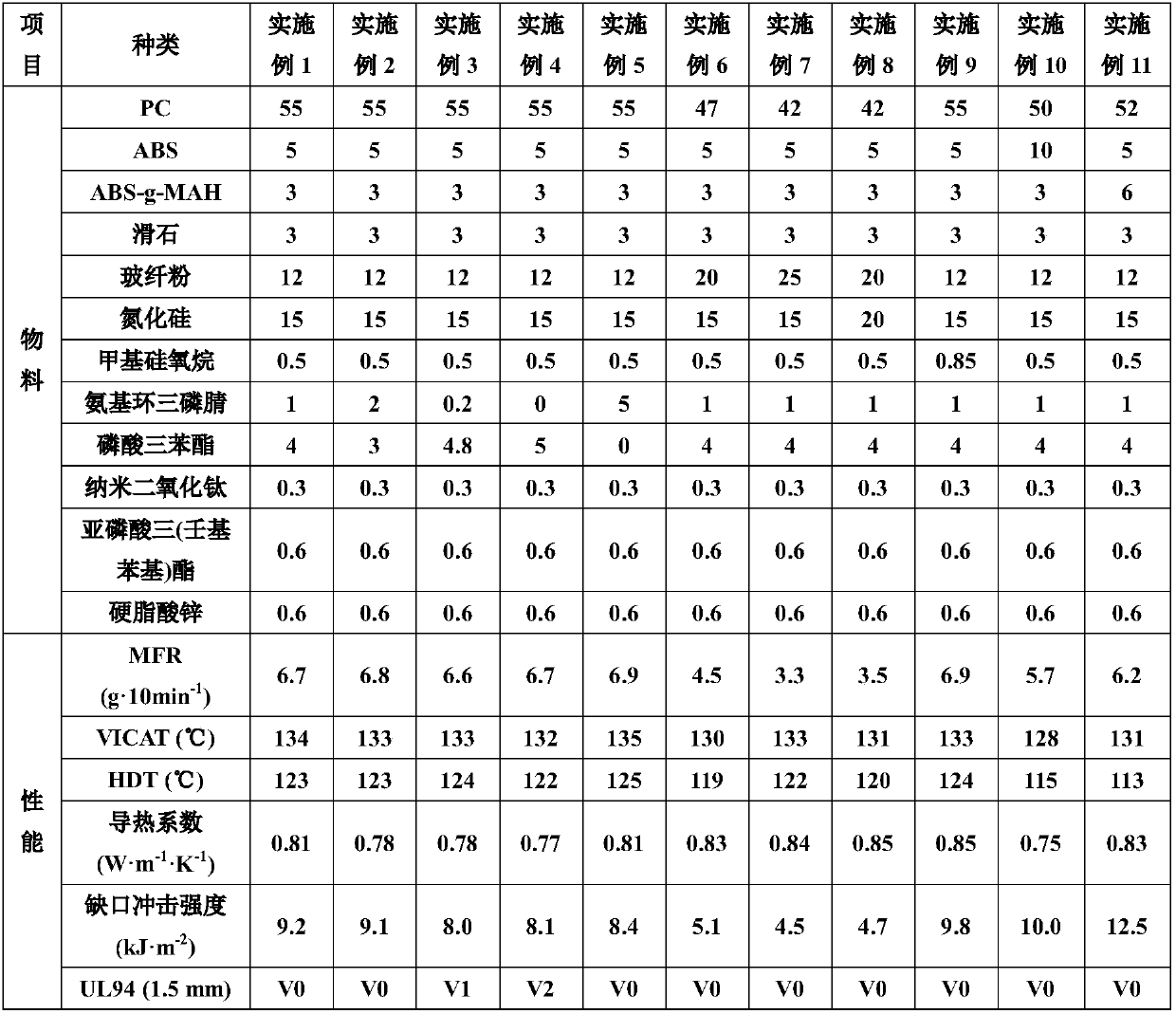

Embodiment 1-11

[0047] The preparation process of the functional filler pretreatment and the functional flame retardant polymer composition is as follows: Weigh the functional filler and the interface modifier and place them in a high-speed mixer. After mixing for 2 minutes, add the polymer matrix material and compatibilizer , flame retardant, additives, etc., continue to mix for 3 minutes. The mixed materials are introduced into a Leistritz twin-screw extruder for melting, kneading, extrusion, and granulation to obtain functional flame-retardant polymer compositions A1-A11. The temperature of each section of the twin-screw extruder is 150 to 180°C, 170 to 200°C, 200 to 250°C, 220 to 280°C, 250 to 300°C, and the screw speed is 100 to 300 rpm.

[0048] Sample injection molding: BOY 55M injection molding machine was used to inject A1-A11 into standard splines. Perform the test after constant temperature and humidity treatment according to the standard requirements. The performance test result...

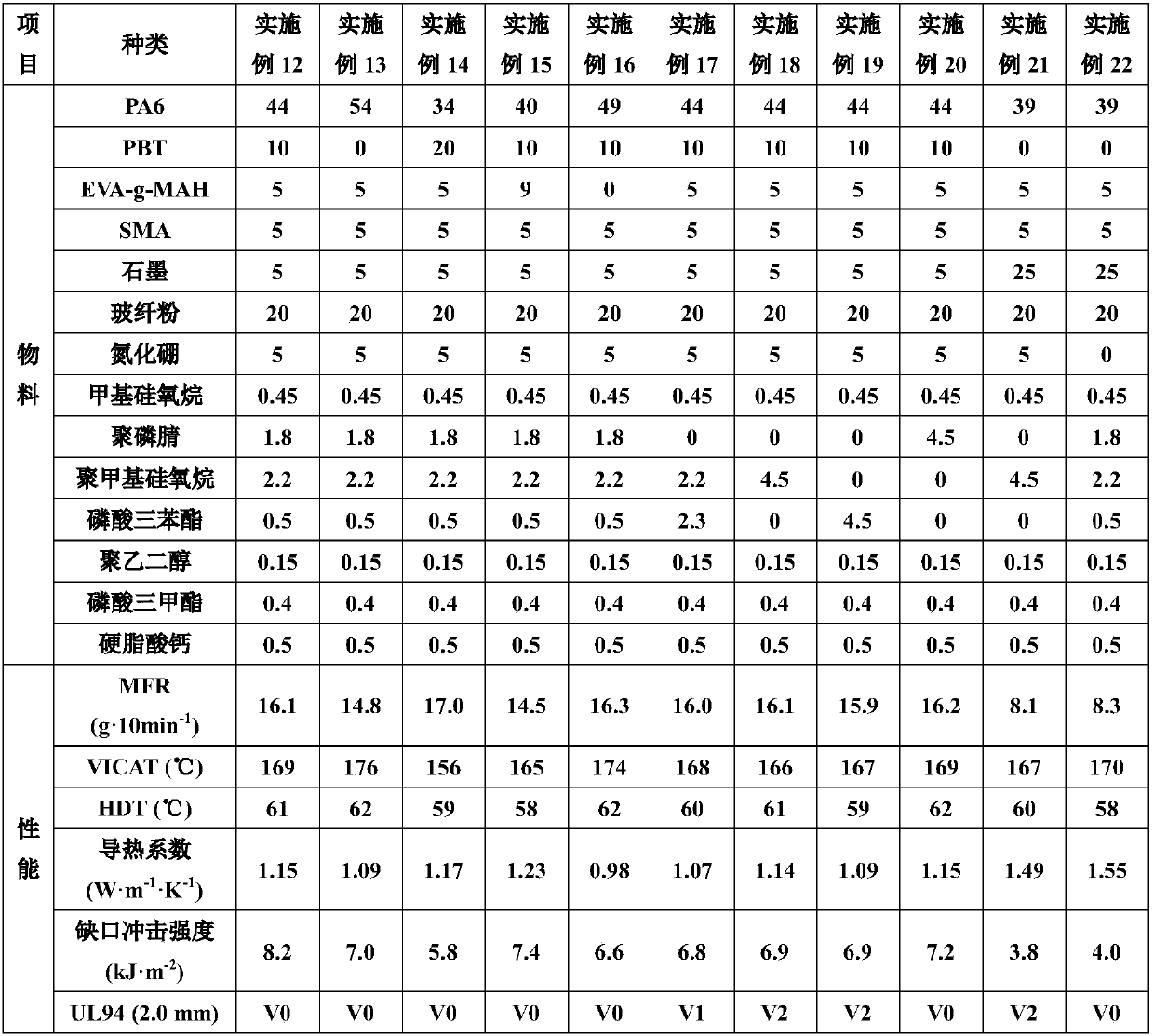

Embodiment 12-22

[0050] The preparation process of the functional filler pretreatment and the functional flame-retardant polymer composition is as follows: Weigh the functional filler and the interface modifier and place them in a high-speed mixer. After mixing for 3 minutes, add the polymer matrix material and compatibilizer , flame retardant, additives, etc., continue to mix for 2 minutes. The mixed materials are introduced into a Leistritz twin-screw extruder for melting, kneading, extrusion, and granulation to obtain functional flame-retardant polymer compositions A12-A22. The temperature of each section of the twin-screw extruder is 150 to 180°C, 170 to 200°C, 200 to 250°C, 220 to 280°C, 250 to 300°C, and the screw speed is 100 to 300 rpm.

[0051] Sample injection molding: BOY 55M injection molding machine was used to inject A12-A22 into standard splines. Perform the test after constant temperature and humidity treatment according to the standard requirements. The performance test resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com