Waterproof steel comb plate expansion joint system

A technology of expansion joints and tooth plates, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of unsustainable monitoring, waste of manpower and material resources, missed judgment, etc., achieve accurate and reliable monitoring results, great flexibility, and solve the problem of water accumulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

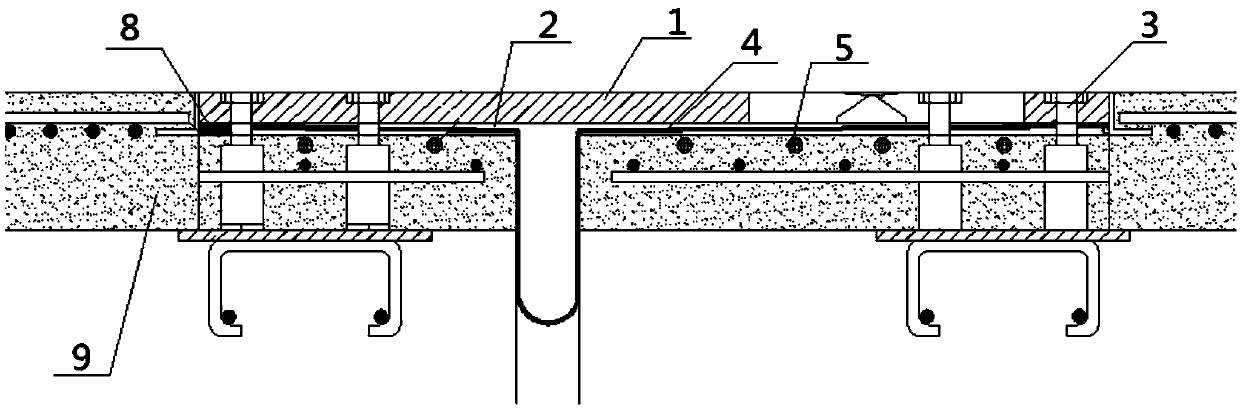

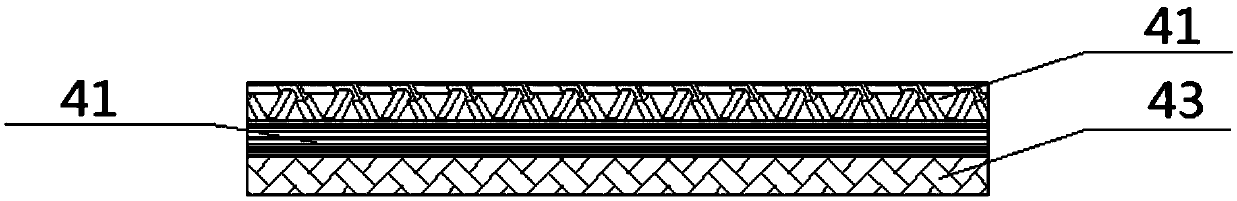

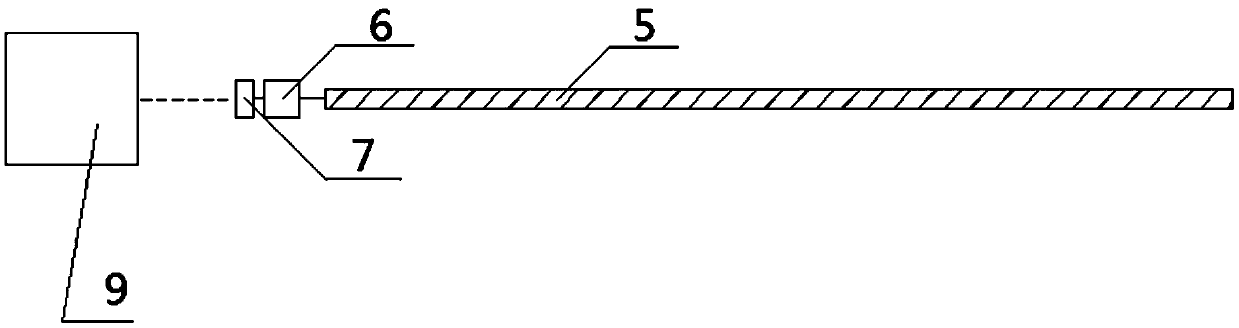

[0031] A waterproof steel comb plate expansion joint system see figure 1 , The expansion joint system is set at the expansion joints of two concrete beams and on the concrete beams on both sides of the expansion joints. The concrete beams are sequentially provided with C40 fiber concrete layer 9, waterproof layer 4, stainless steel slide plate 2 and Comb-tooth steel plate 1, the C40 fiber concrete layer 9 is provided with a gap of the same width at the corresponding position of the expansion joint, the waterproof layer 4 covers the C40 fiber concrete layer 9 and the expansion joint, the waterproof layer 4 Extend downwards at the expansion joint to form a "U-shaped" section, so that the cross-section of the concrete beam and C40 fiber concrete layer 9 at the expansion joint is covered by the waterproof layer 4. The concrete beam is equipped with pre-embedded steel bars. A pre-embedded steel plate is connected above the steel bar. The pre-embedded steel plate fastens the C40 fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com