Rust remover suitable for surface of metal material

A metal material and derusting agent technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve problems such as difficult to handle, labor-intensive, coating peeling off, etc., and achieve the effect of simple and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the examples, but the protection scope of the present invention will not be limited.

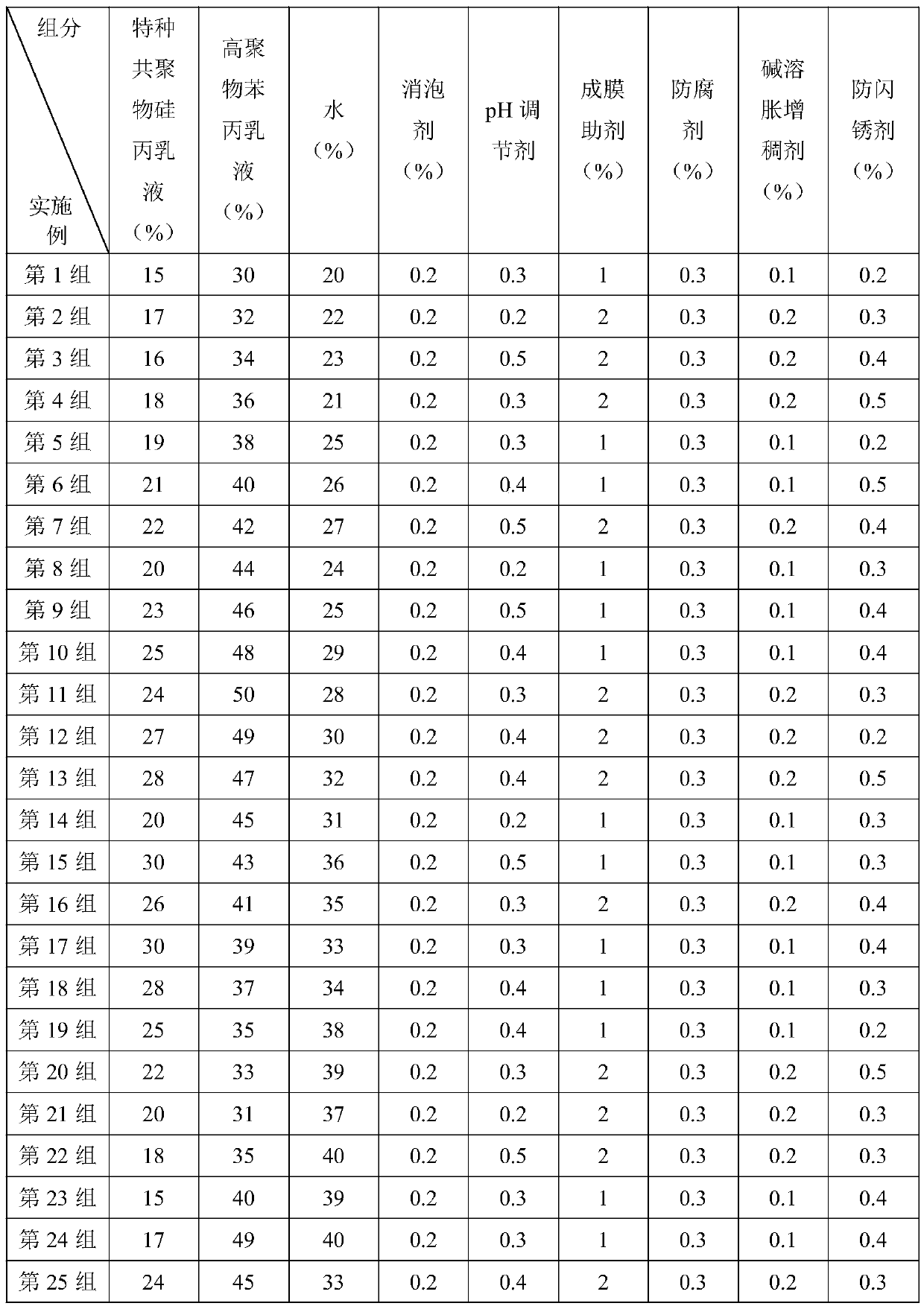

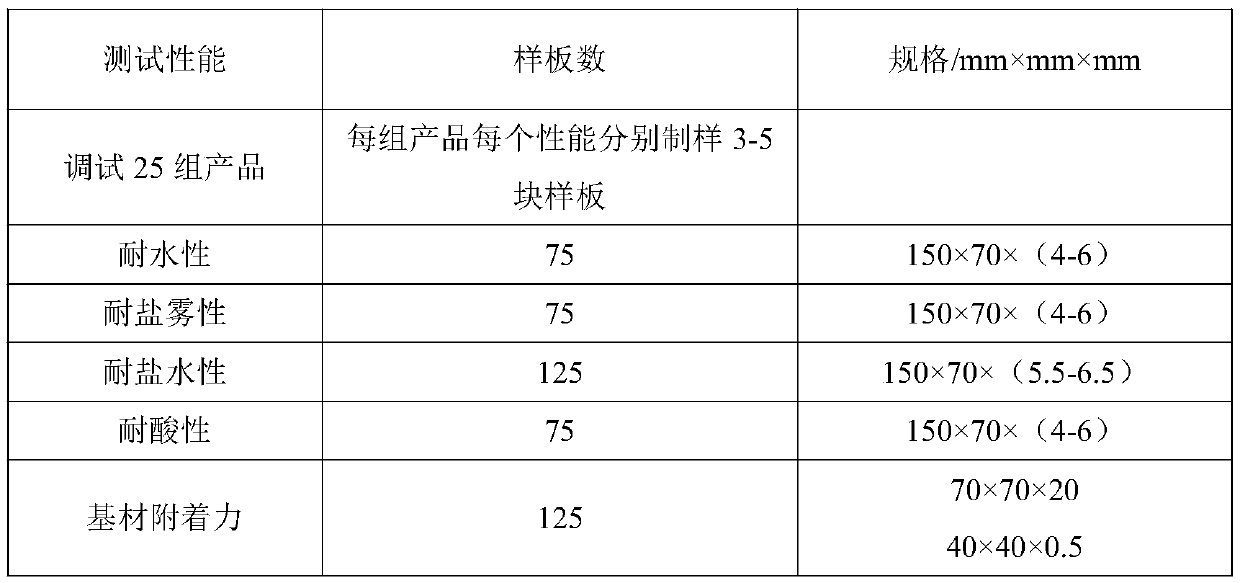

[0018] The invention provides a technical solution, a rust remover suitable for the surface of metal materials, which consists of the following ingredients in parts by weight: special copolymer silicon acrylic emulsion 15%-30%, high polymer styrene acrylic emulsion 30%-50% %, water 20%-40%, defoamer 0.2%, pH regulator amount, film-forming aid 1%-2%, preservative 0.3%, alkali swelling thickener 0.1%-0.2%, anti-flash rust agent 0.2%-0.5%.

[0019] Wherein, in the present embodiment, the preparation method of described rust remover is as follows:

[0020] S1: Before feeding, check whether the outlet at the bottom of the production kettle is closed, discharge the material according to the production formula sheet, take the special copolymer silicone acrylic emulsion by weighing, and put it into the production kettl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water resistance | aaaaa | aaaaa |

| Acid resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com