Solvent-free two-component polyurethane adhesive for resisting aluminized film transferring and preparation method thereof

A two-component polyurethane, solvent-free technology, applied in the direction of polyurea/polyurethane adhesive, adhesive type, adhesive, etc., can solve the problems of aluminized film transfer, product spots, low composite strength, etc., and achieve construction Simple and easy, high composite strength, good slippery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

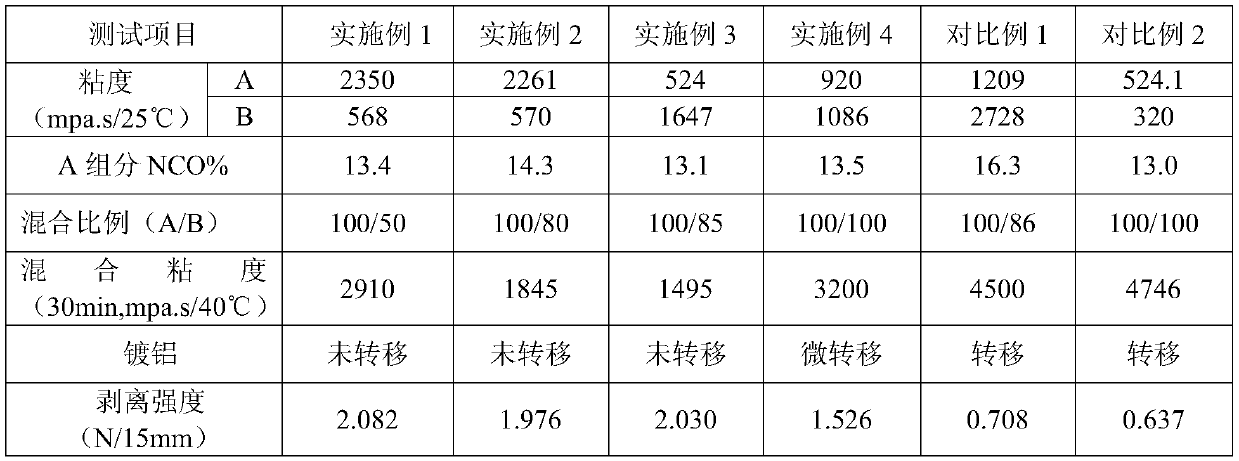

Embodiment 1

[0037] The solvent-free two-component polyurethane adhesive for aluminum plating transfer resistance provided in this example is prepared by the following method:

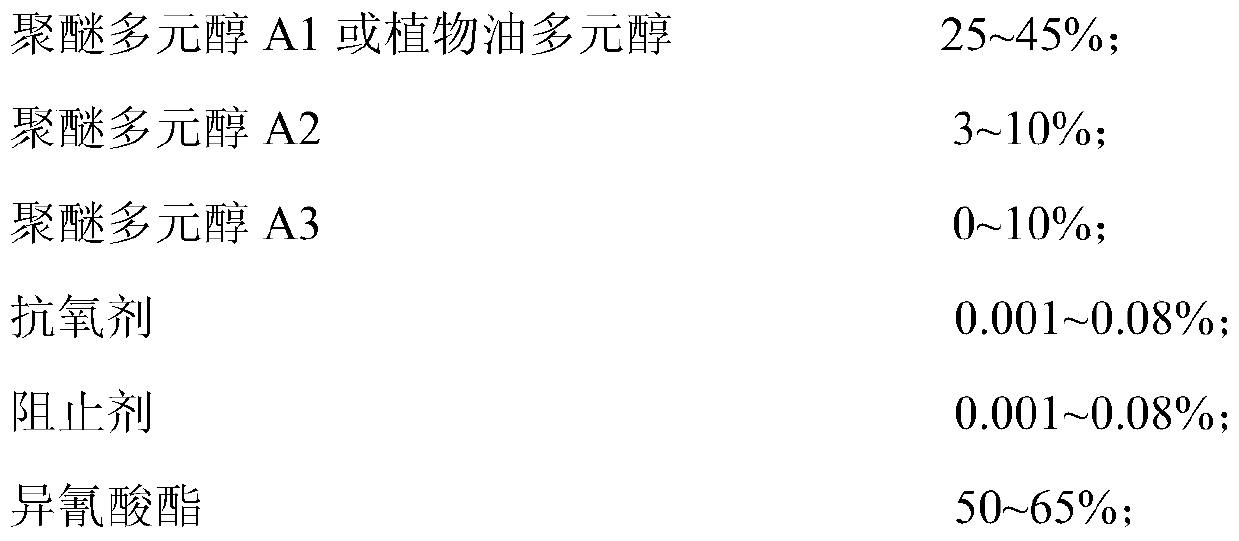

[0038] (1) Preparation of component A

[0039] Weigh respectively 40 parts of polyether polyol A1 (DDL-2000D) with a number average molecular weight of 2000, 8 parts of polyether polyol A2 (DL-400) with a number average molecular weight of 400, and 0.01 parts of antioxidant 1010 , the side reaction inhibitor (benzoyl chloride) is 0.05 parts, the reaction kettle is assembled, after the temperature is raised to 70 ° C, the stirring is started, the rotation speed is set to 60 rpm, the vacuum pump is turned on to keep the vacuum degree below -0.098Mpa, and after pumping for 1 hour, Stop vacuuming, stop stirring, add 52 parts of MDI-50, keep the temperature at 70°C, set the speed at 100 rpm, stir for 2 hours, turn on the vacuum pump, keep the vacuum degree below -0.098Mpa, vacuum for 20 minutes, stop vacuuming, and leav...

Embodiment 2

[0045] The solvent-free two-component polyurethane adhesive for aluminum plating transfer resistance provided in this example is prepared by the following method:

[0046] (1) Preparation of component A

[0047] Weigh respectively 38.3 parts of polyether polyol A1 (DL-2000D) with a number average molecular weight of 2000, 7.6 parts of polyether polyol A2 (DL-400) with a number average molecular weight of 400, and 0.01 parts of antioxidant 1010 , the side reaction inhibitor (phosphoric acid) is 0.05 parts, the reaction kettle is assembled, the temperature is raised to 70°C, and the stirring is started, the rotation speed is set to 60 rpm, the vacuum pump is turned on to keep the vacuum degree below -0.098Mpa, and after pumping for 1 hour, stop pumping Vacuum, stop stirring, add 41 parts of MDI-50, keep the temperature at 60 ° C, set the speed at 100 rpm, stir for 2 hours, add carbodiimide-modified diisocyanate MDI-100L to 13 parts, turn on the vacuum pump, the vacuum degree Wh...

Embodiment 3

[0053] The solvent-free two-component polyurethane adhesive for aluminum plating transfer resistance provided in this example is prepared by the following method:

[0054] (1) Preparation of component A

[0055] Weigh respectively 90 parts of castor oil, 10 parts of polyether polyol A2 (DL-400) with a number average molecular weight of 400, 0.01 part of antioxidant 1010, and 0.01 part of side reaction inhibitor (phosphoric acid). After the assembly is complete, heat up to 100°C and start stirring, set the rotation speed to 60 rpm, turn on the vacuum pump to keep the vacuum below -0.098Mpa, and after pumping for 1 hour, cool down to 50°C, stop vacuuming, stop stirring, and add MDI-50 For 134 parts, keep the temperature at 60°C, set the speed at 100 rpm, stir for 2 hours, turn on the vacuum pump, keep the vacuum degree below -0.098Mpa, vacuum for 20 minutes, stop vacuuming, and discharge the material for sealed storage.

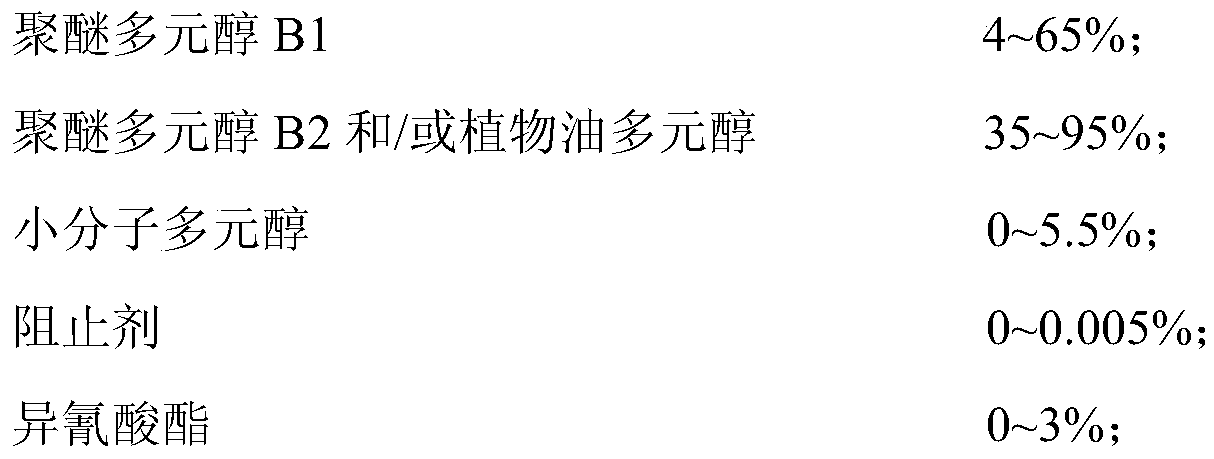

[0056] (2) Preparation of component B

[0057] 60 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com