Bridge transverse prestress tensioning bench

A technology of transverse prestressing and benching, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., which can solve problems such as inconvenient movement, low work efficiency, and complex structure, so as to facilitate transverse prestressing and tensioning operations and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

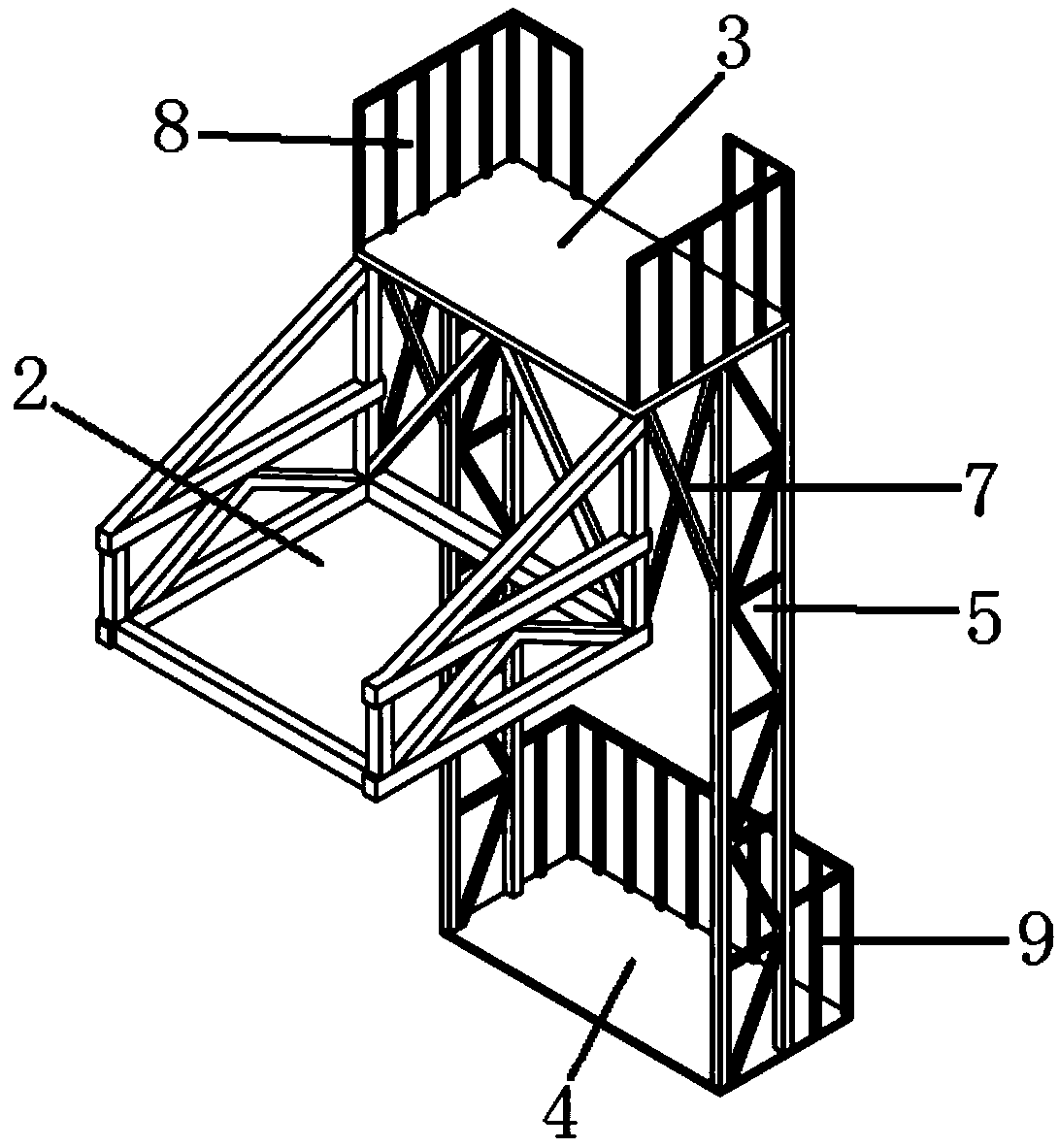

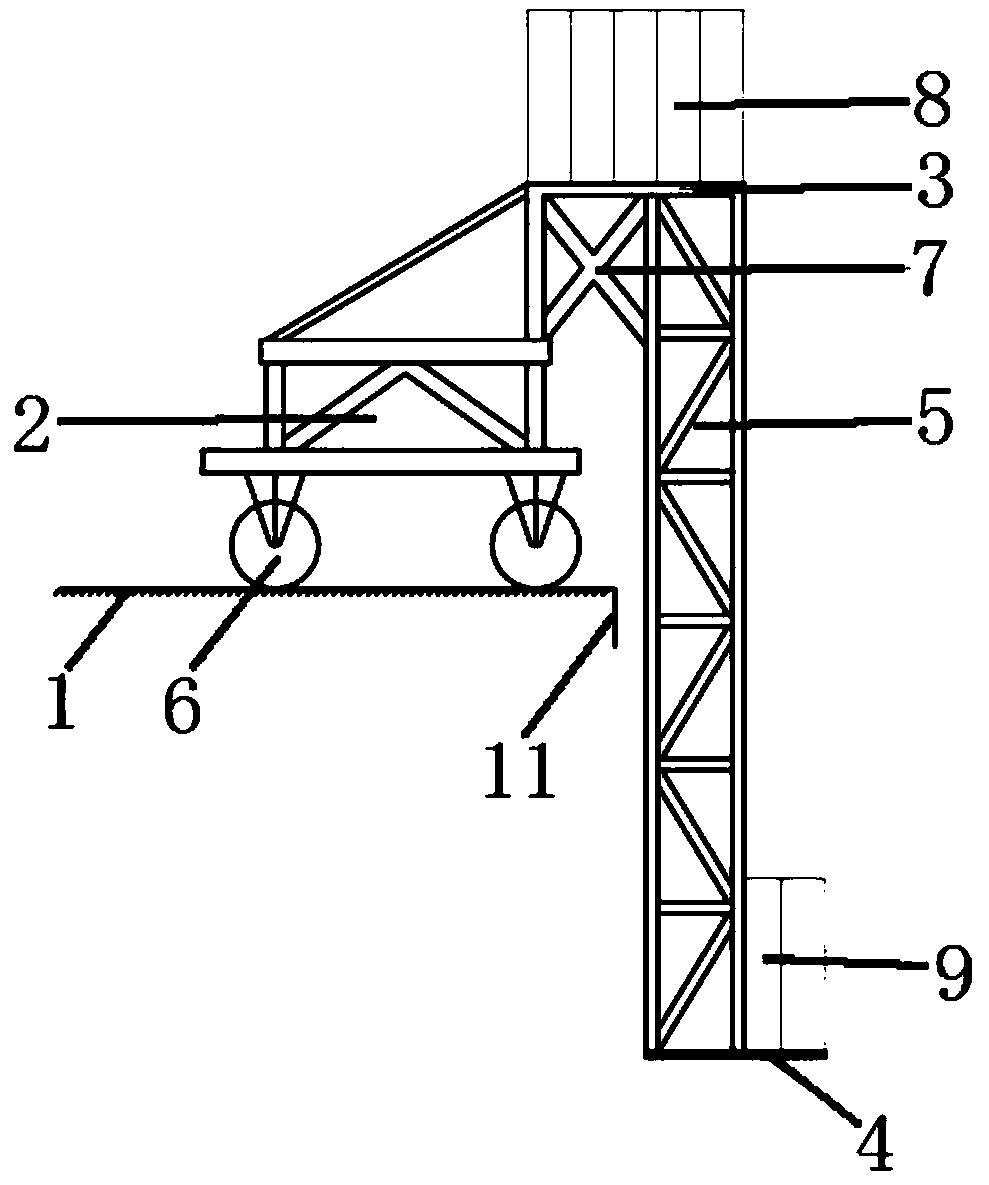

[0024] Such as figure 1 , figure 2 , image 3 A kind of bridge transverse prestressed tension stand shown, comprises the counterweight frame 2 that is placed on the bridge deck 1, the safety platform 3 that is stretched out from the upper end of the counterweight frame 2, and is fixed on the safety platform 3 bottom and uses Rollers 6 are arranged between the contact surface of the counterweight frame 2 and the bridge deck 1 on the working platform 4 where the workers construct. The stability of the platform is ensured by the counterweight frame 2 and the counterweights placed on the counterweight frame 2, and the movement of the platform on the bridge deck 1 is realized by the rollers 6. One person pushes and pulls on the bridge deck 1, and the other person works on the working platform 4 On the construction, cooperate with each other, improve efficiency, and effectively protect the safety of operators.

[0025] Wherein, the counterweight frame 2 includes 4 vertical rods,...

Embodiment 2

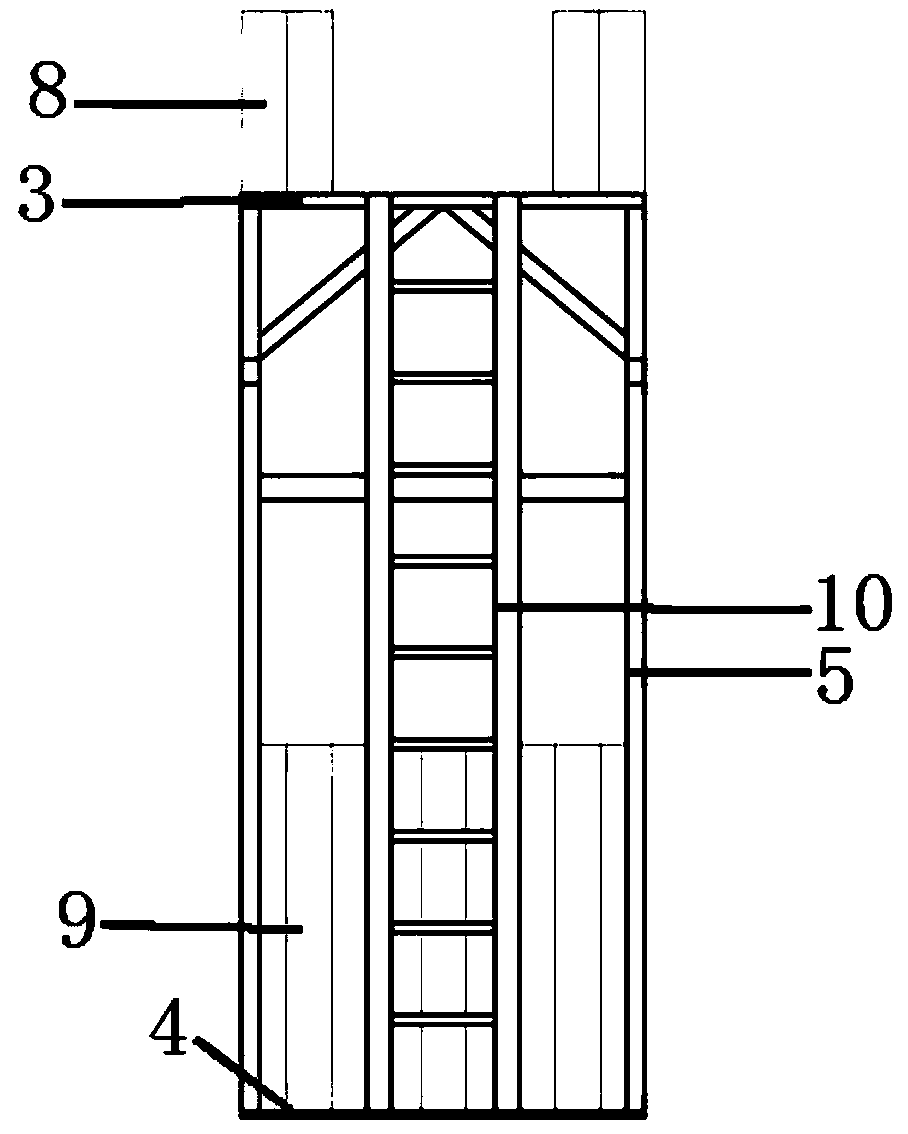

[0031] A bridge transverse prestressed tensioning platform, comprising a counterweight frame 2 arranged on the bridge deck 1, a safety platform 3 arranged on the side of the counterweight frame 2, a working platform 4 arranged below the safety platform 3 and a safety platform arranged on the safety platform 2. The connecting truss 5 between the platform 3 and the working platform 4.

[0032] Wherein, the bottom of the counterweight frame 2 is provided with rollers 6, and is arranged on the bridge deck 1 through the rollers 6 to move. Bridge deck 1 is provided with the moving track that matches with roller 6. The counterweight frame 2 is provided with a counterweight placement plate. A cross-shaped brace 7 is arranged between the counterweight frame 2, the safety platform 3, and the connecting truss 5. The safety platform 3 is provided with a safety platform guardrail 8, and the work platform 4 is provided with a work platform guardrail 9. A hanging ladder 10 is provided bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com