Deep sea buoy hydraulic system

A hydraulic system and buoy technology, which is applied in the direction of buoys, fluid pressure converters, fluid pressure actuators, etc., can solve the problems of insufficient self-priming force of plunger pumps, prolong underwater working time, and occupy a large space Lower working time, light weight, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to clearly illustrate the technical characteristics of this solution, the present invention will be described in detail below through specific implementation methods and in conjunction with the accompanying drawings.

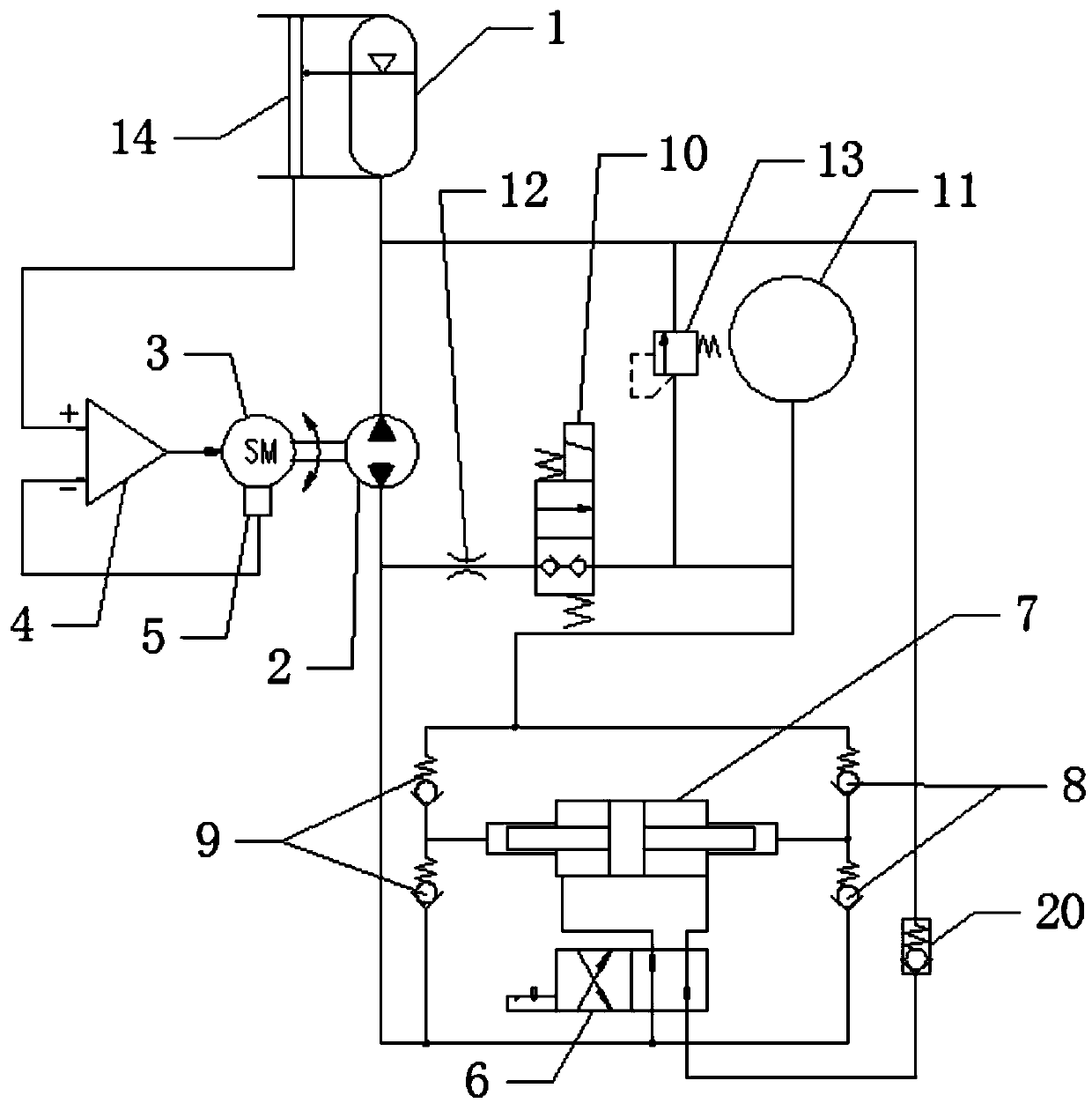

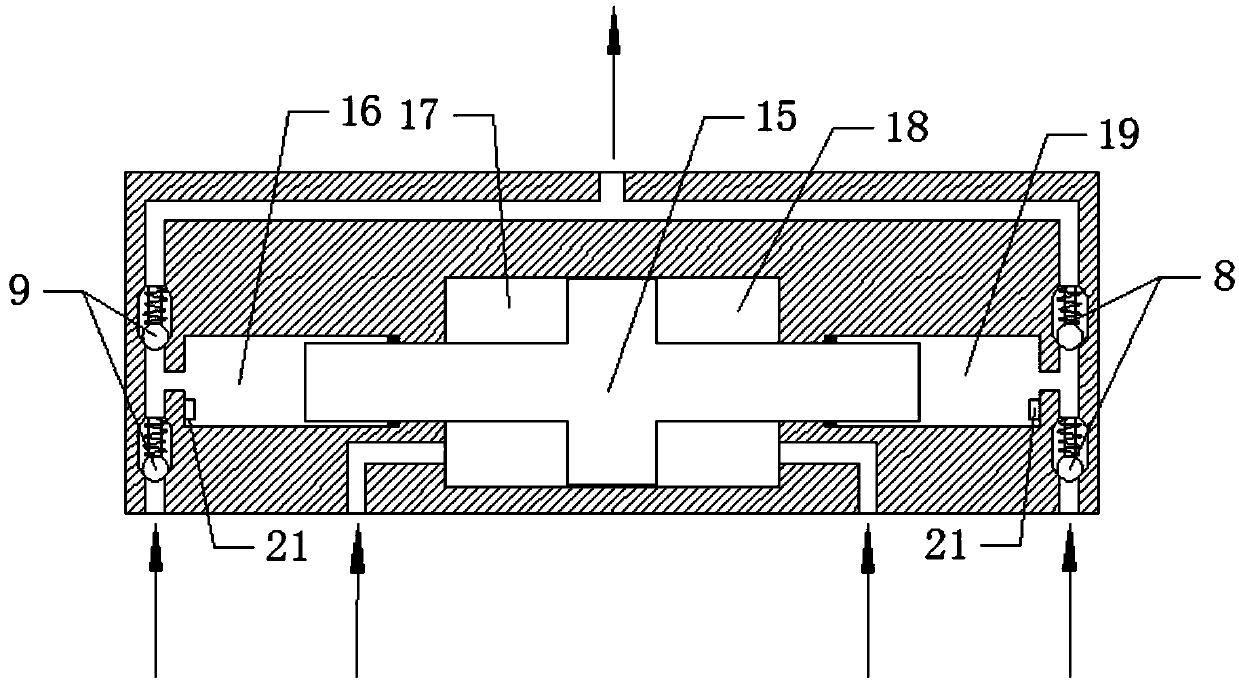

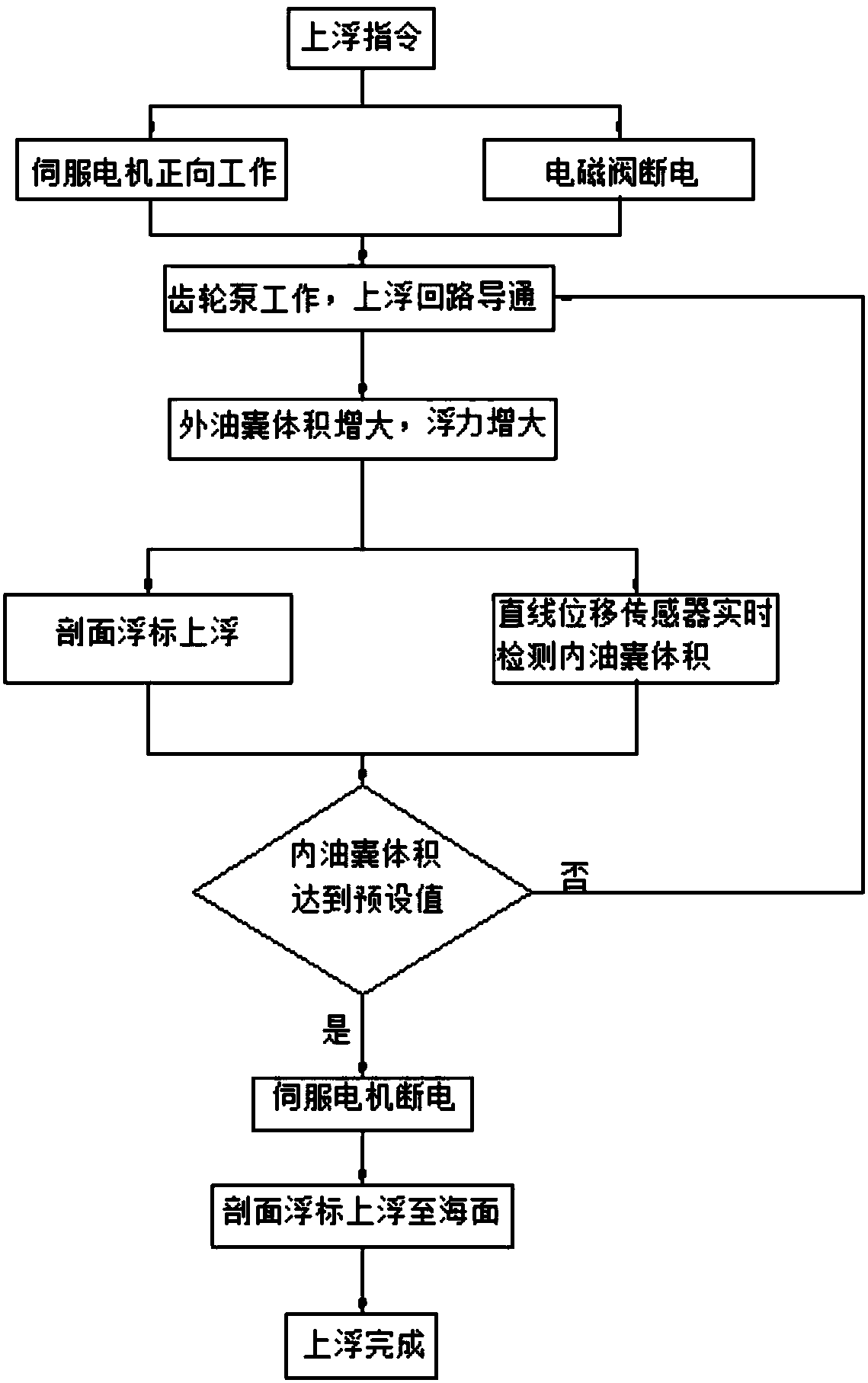

[0026] Such as Figure 1-4 As shown, a deep-sea buoy hydraulic system includes: an inner oil bag 1, the oil outlet of the inner oil bag 1 is connected with a two-way gear pump 2, and in this embodiment, the working pressure is 7-15MPa, and the displacement is 0.75ml / r low-pressure two-way gear pump 2, plunger pump is generally more expensive than two-way gear pump 2, under the same working pressure, to complete the same working oil volume, the energy consumption of low-pressure two-way gear pump 2 is higher than that of high-pressure plunger pump 1 / 5 of that, greatly reducing energy consumption, and using the bidirectional gear pump 2 can shorten the working time and improve the working efficiency of the system. The two-way gear pump 2 is driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com