Improved hydraulic cylinder

A technology of hydraulic cylinders and cylinders, applied in the direction of fluid pressure actuation devices, can solve the problems of poor torsional resistance, damage and cracking of oil seals, and achieve the effects of improving torsional resistance, prolonging service life, and good sealing contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The standard parts used in the present invention can all be purchased from the market, the special-shaped parts can be customized according to the description in the manual and the drawings, and the specific connection methods of each part adopt the mature bolts, rivets and welding in the prior art. Conventional methods such as, pasting, etc. will not be described in detail here.

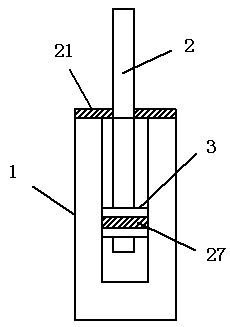

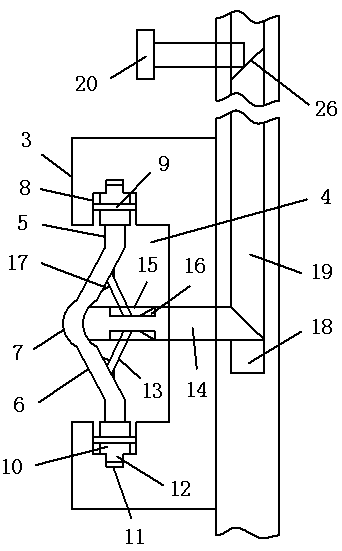

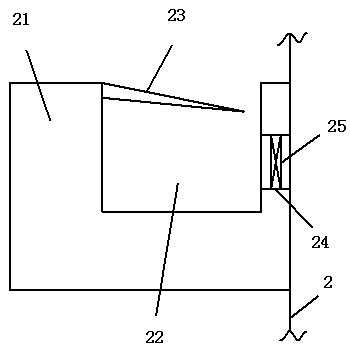

[0017] Reference Figure 1-3 A specific embodiment of the present invention includes a cylinder 1 and a piston rod 2. The end of the piston rod 2 is fixed with a piston 3, the side wall of the piston 3 is provided with a groove 4, and a first sealing ring 27 is installed in the groove 4 The first sealing ring 27 includes a bayonet portion 5 at both ends, a first rubber portion 6 is fixedly connected to the inner side of the bayonet portion 5, a second rubber portion 7 is fixedly connected between the two first rubber portions 6, and the first rubber portion 6 is a plane shape, the second rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com