Liquid unloading method of LNG prying-mounting station

A liquid unloading and liquid phase technology, which is applied in the container filling method, the container discharging method, and the equipment loaded into the pressure vessel, etc. Improve work efficiency and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

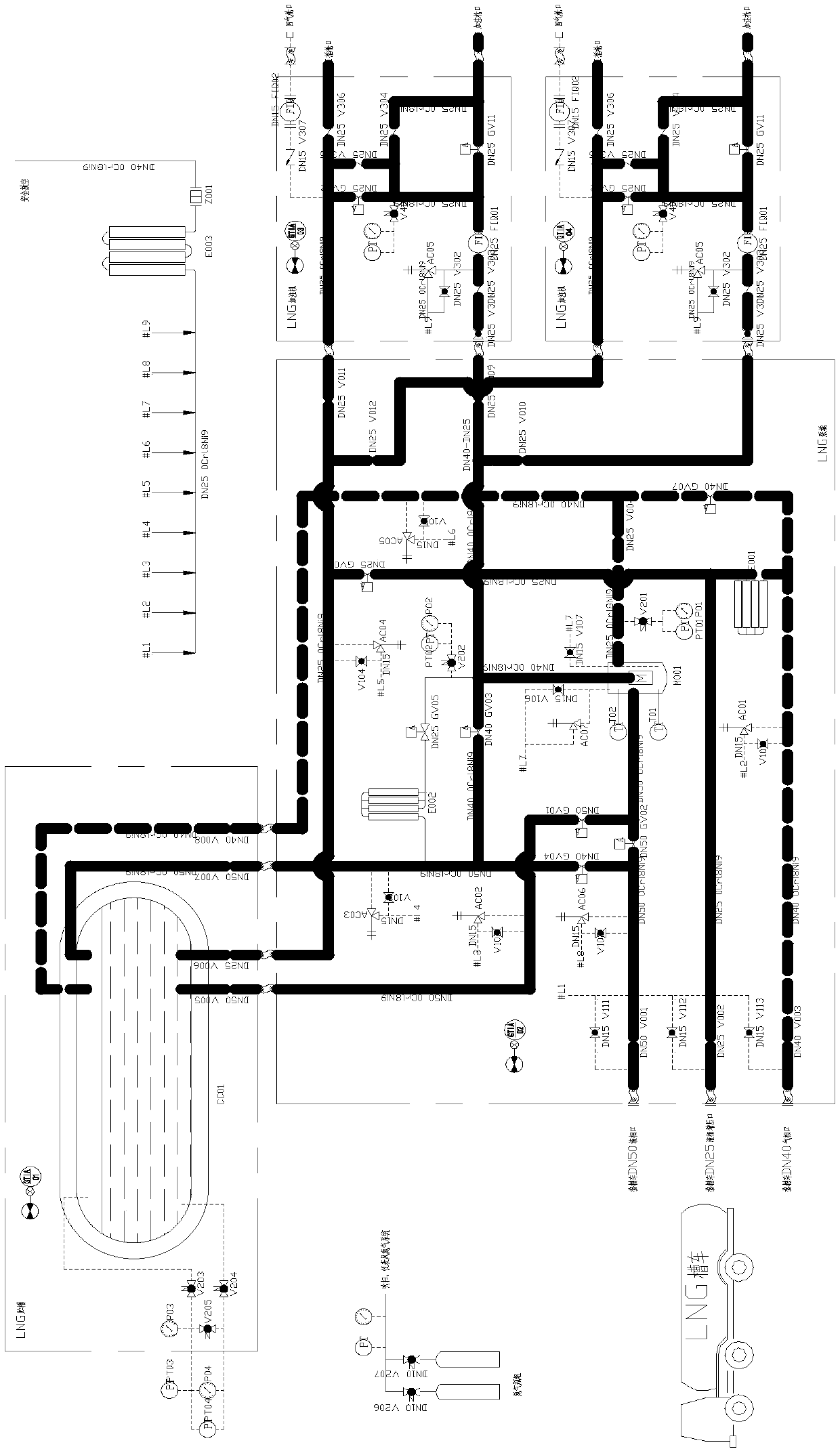

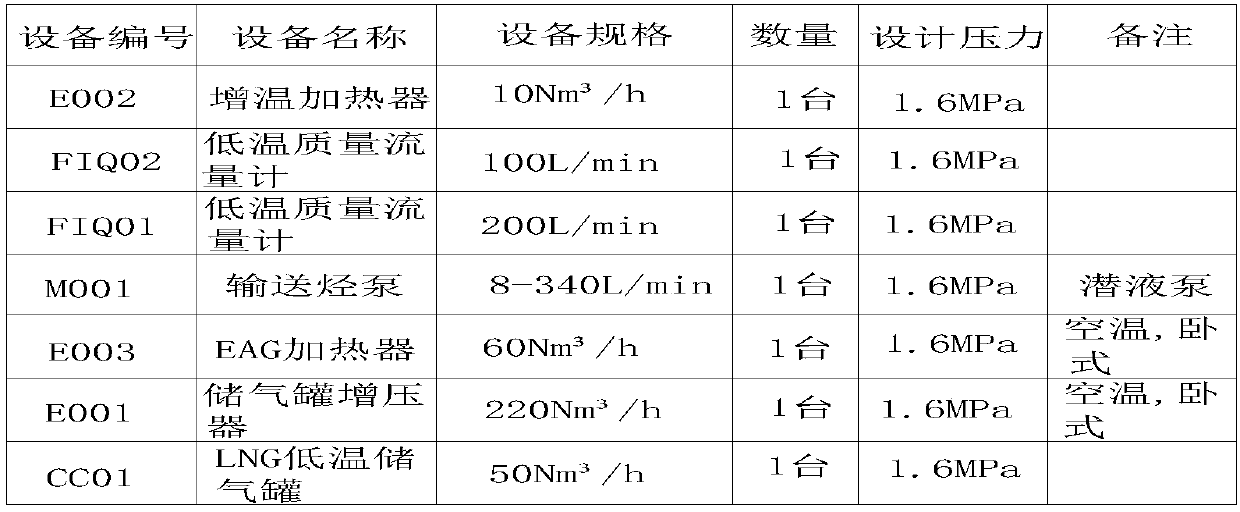

[0015] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

[0016] The invention provides a liquid unloading method for an LNG skid loading station, which has a wonderful concept, smooth operation, and is practical and convenient. Using a first-generation LNG skid loading station can also carry out liquid filling while unloading, which can effectively improve work efficiency. The present invention comprises the following steps:

[0017] Step 1. After the tank car arrives at the station, connect its unloading liquid phase pipe, gas phase pipe and booster pipe with the corresponding pipes of the gas storage tank respectively.

[0018] Step 2. Balance the pressure between the gas storage tank and the tanker, and stop the pressure balance when the pressure of the gas storage tank reaches the set value. The set value of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com