Return air filtering device for air hundling unit and air conditioner box

A return air filtration and air conditioning box technology, applied in the field of air purification and air conditioning in workshops, can solve the problems of excessive oil pollution and blockage of the filter screen, and achieve the effect of ensuring normal operation, wide industrial value, and preventing oil pollution from clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

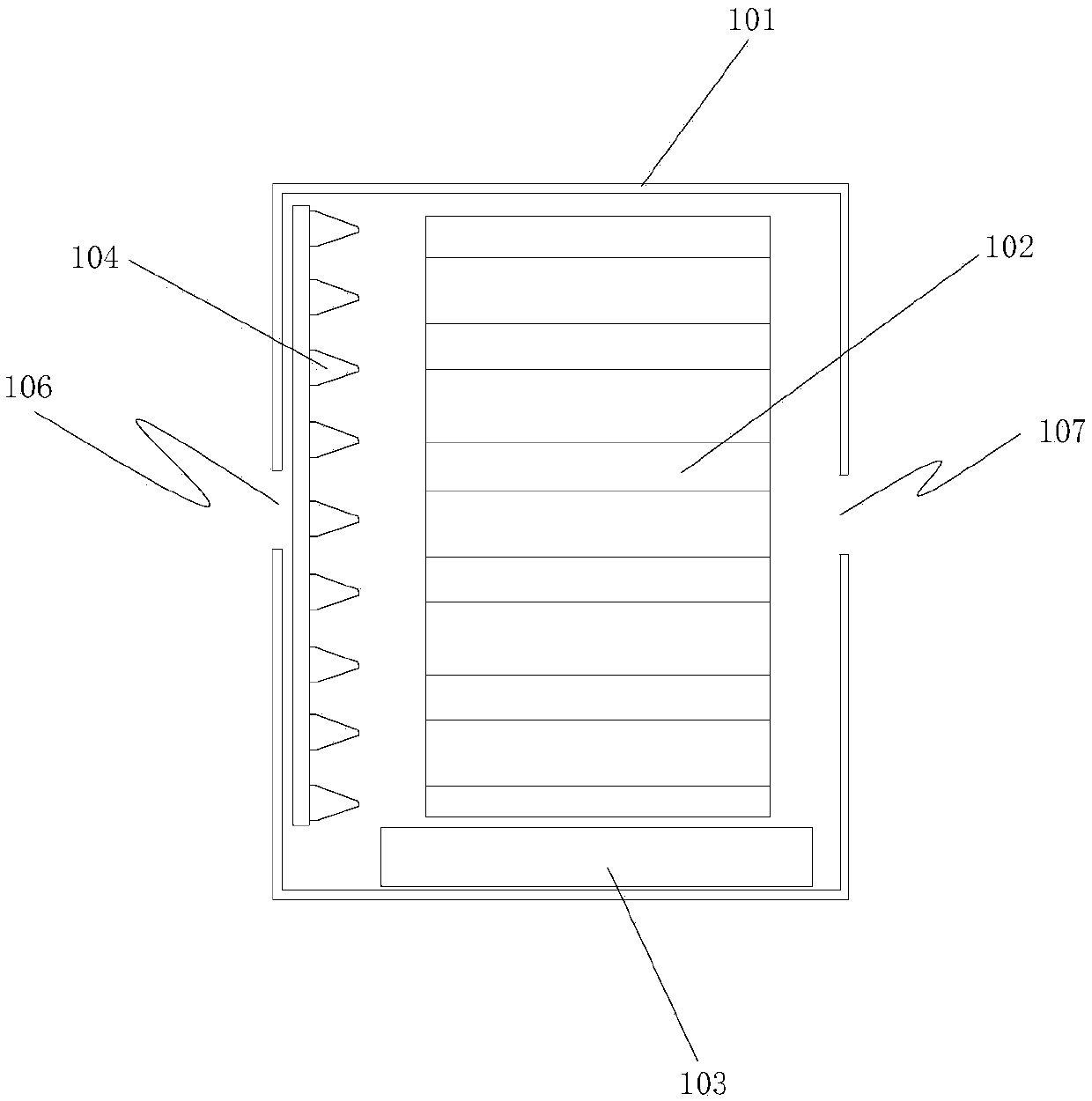

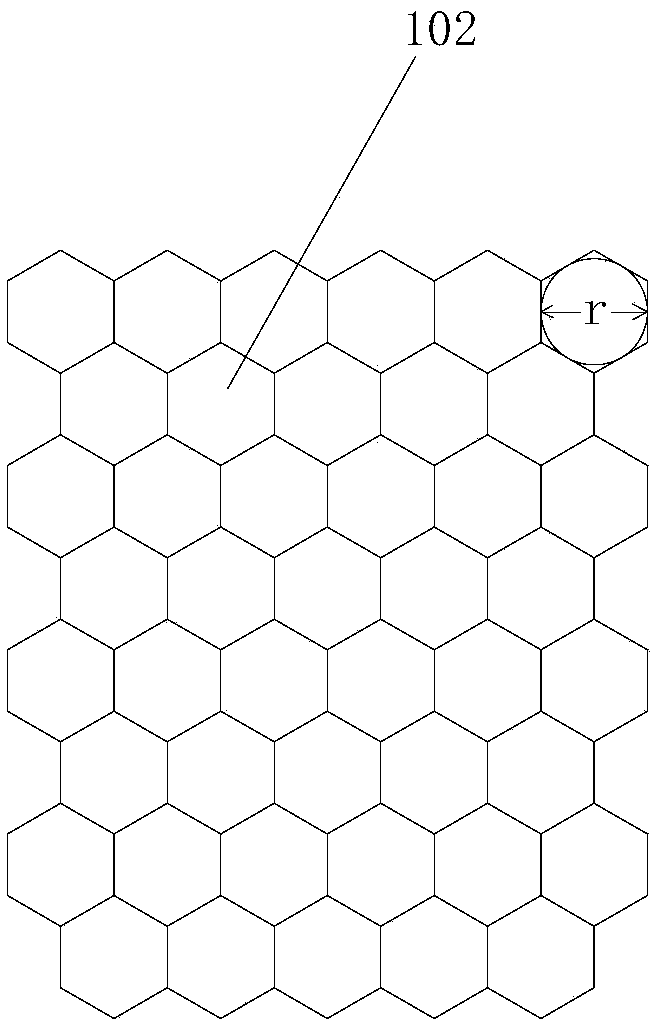

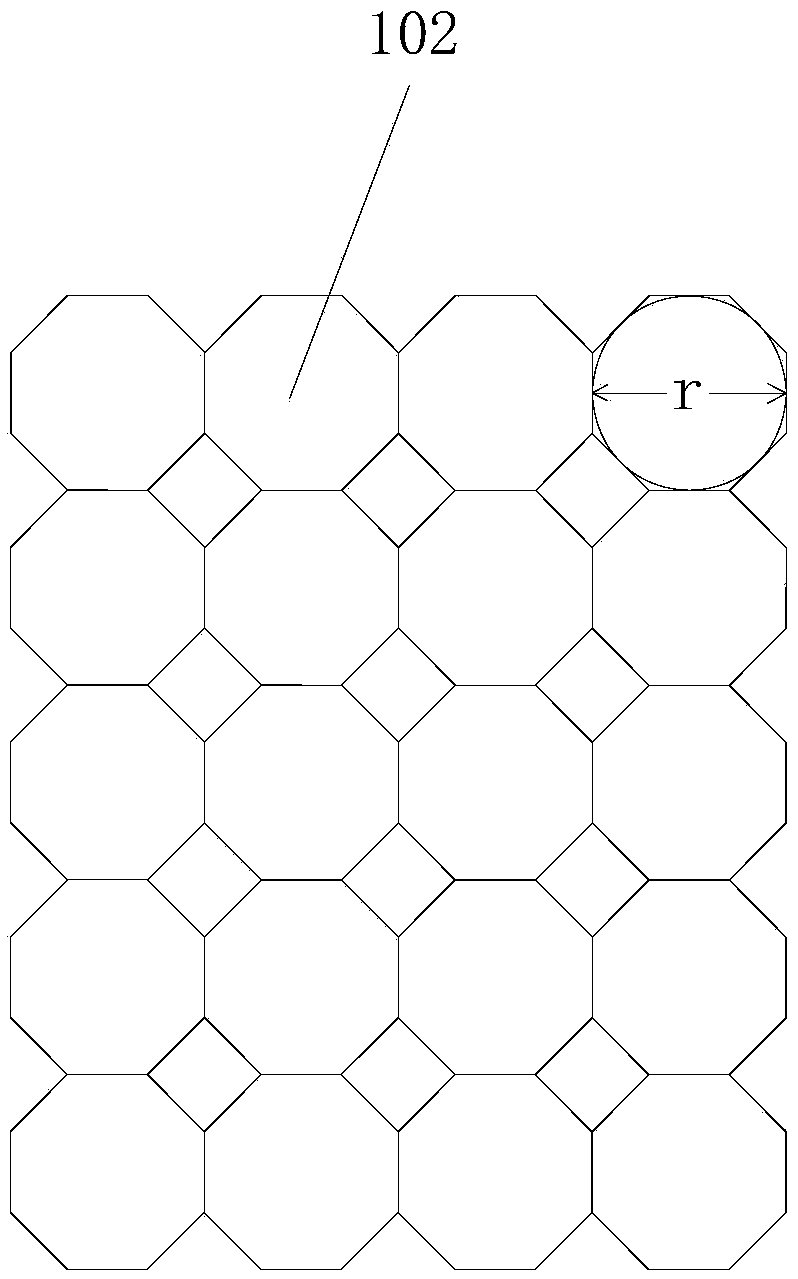

[0031] see Figure 1 to Figure 3 As shown, the present embodiment provides a return air filter device for an air-conditioning box, including a box body 101, the box body 101 has an air inlet 106 and an air outlet 107 arranged oppositely, and the inside of the box body 101 is provided with a spray device, The oil mist filter 102 and the oil collector 103, the injection device is located between the air inlet 106 and the oil mist filter 102, and is used to spray cleaning agent to the oil mist filter 102; the section of the oil mist filter 102 is honeycomb; The oil collector 103 is located below the oil mist filter 102 , and the oil collector 103 is detachably connected to the box body 101 .

[0032] Based on this structure, the return air filter device for the air conditioning box provided in this embodiment can effectively purify the oil mist in the return air by setting the oil mist filter 102, and prevent the filter screen in the air conditioning box from being blocked by oil...

Embodiment 2

[0054] see Figure 4 As shown, this embodiment also provides a return air filter device for the air conditioner, the return air filter device for the air conditioner in this embodiment is an improvement on the basis of Embodiment 1, in addition The technical solution of Embodiment 1 also belongs to this embodiment, and will not be described again here. The same components use the same reference numerals as in the first embodiment, and reference is made to the description of the first embodiment.

[0055] In some embodiments, the return air filter device for the air conditioner further includes a pressure sensor 105 and a controller, the pressure sensor 105 is connected to the controller, and the controller is connected to the injection device.

[0056] With the continuous accumulation of oil in the oil mist filter 102, the pressure in the oil mist filter 102 will gradually increase. Automatic cleaning saves manpower and improves efficiency.

[0057] It should be noted that ...

Embodiment 3

[0062] This embodiment provides an air conditioning box, including the return air filter device for the air conditioning box provided in Embodiment 1 of the present invention.

[0063] The air conditioning box provided in this embodiment uses the return air filter device for the air conditioning box provided in Embodiment 1 of the present invention, which can realize the organic combination of air conditioning and oil mist purification, and realize the effective purification of liquid oil mist in the workshop. Prevent the filter in the air conditioning box from being clogged by oil, and ensure the normal operation of the air conditioner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com