A performance test method and device for a downhole packer

A test method and packer technology, applied in measuring devices, testing of machine/structural components, instruments, etc., can solve problems such as the gap between packers and achieve the effect of strengthening the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

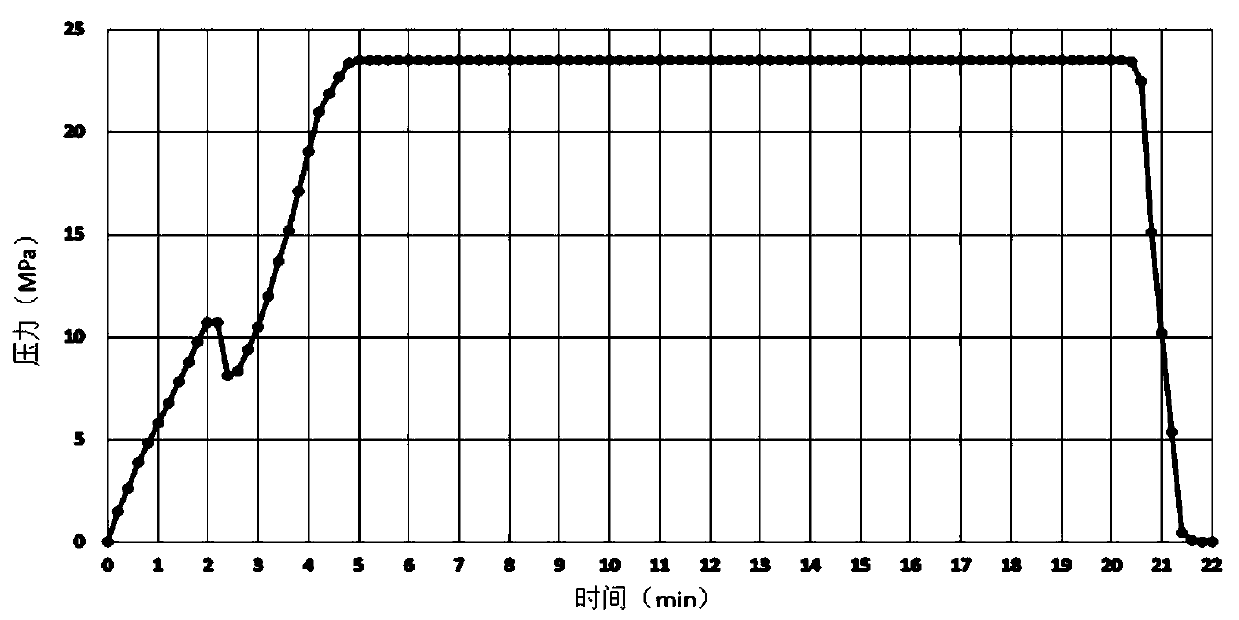

[0041] A downhole packer performance test method, the steps are:

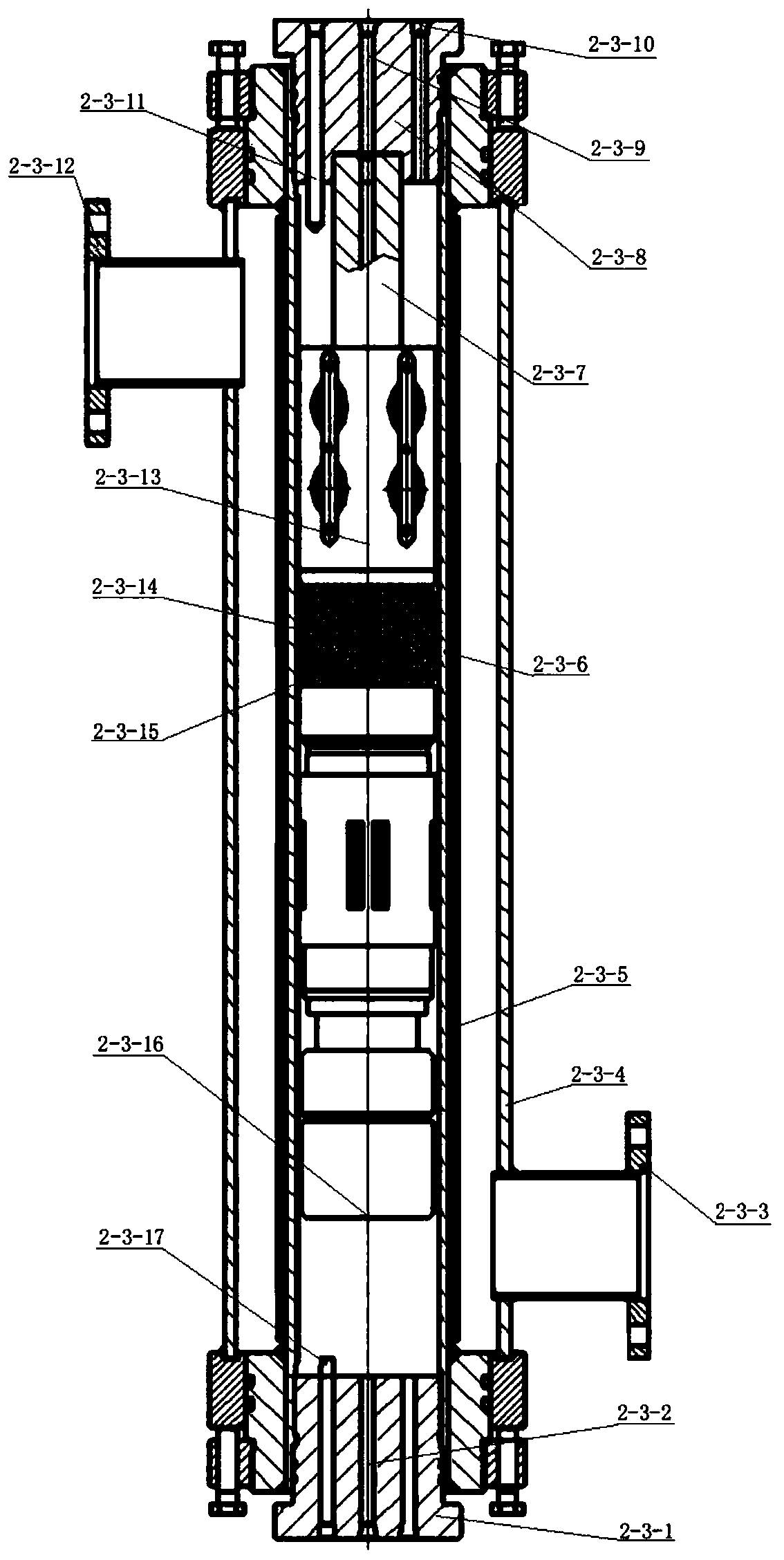

[0042] 1. Install the rubber cylinder stress detection device at the position of the packer rubber cylinder; the packer is connected to the packer plug, the upper part is connected to the central pipe joint, and then lowered into the experimental container; the upper and lower parts of the experimental container are respectively connected to the upper joint of the container and the container The lower joint; the pressure hole of the central tube of the container is connected to the brine mixture and CO 2 The interface line of the packer center pipe in the pressurization system; the pressure hole in the lower part of the vessel is connected to the brine mixture and 2 The lower annulus interface pipeline in the pressurized system; the pressure hole in the upper annulus of the container is connected to the brine mixture and CO 2 The upper annular space interface pipeline in the pressurized system; connect the cir...

Embodiment 2

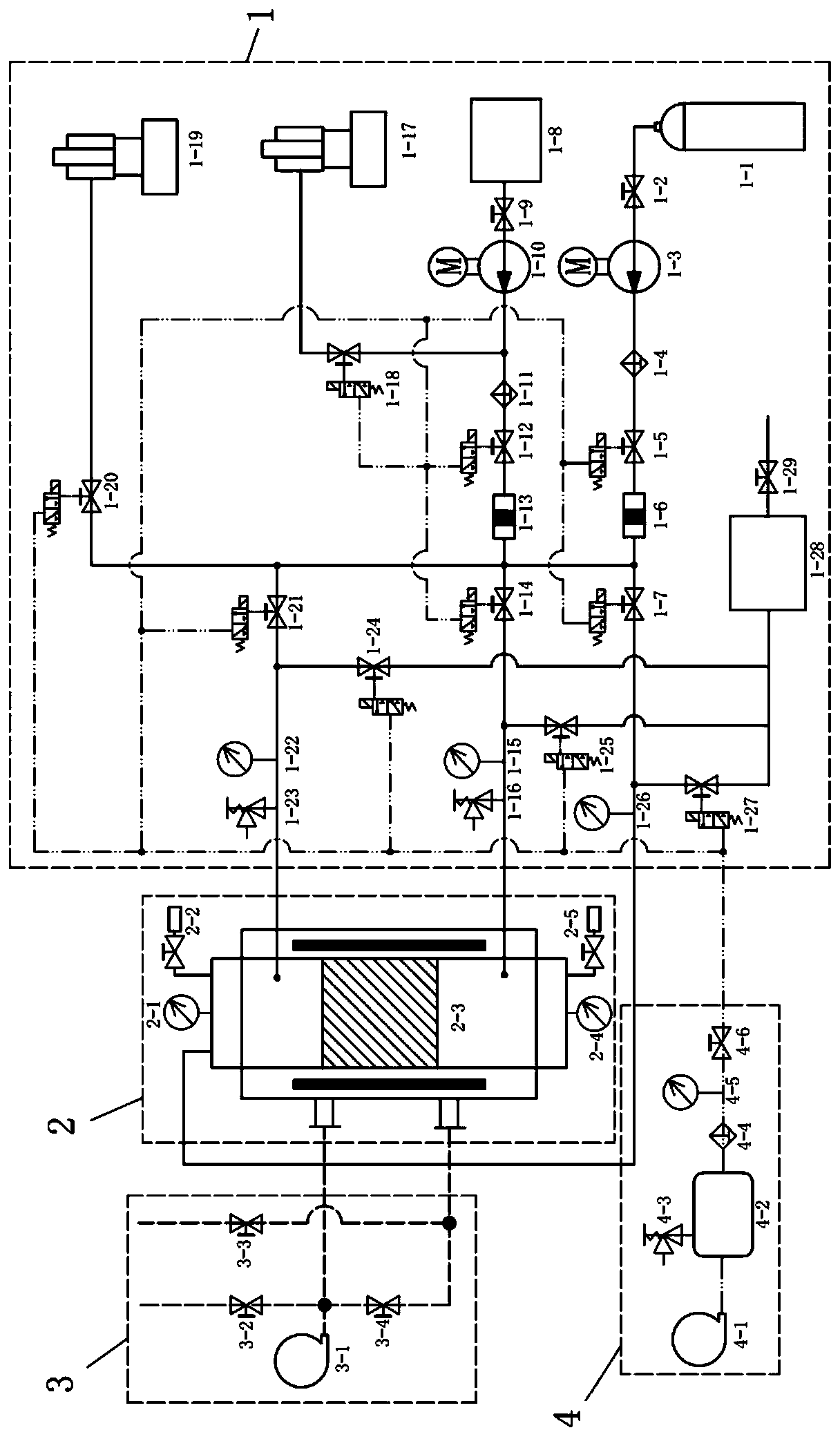

[0054] A downhole equipment performance test device is composed of a brine mixed liquid and CO2 pressurization system 1, an experimental container system 2, a circulation heating system 3, a low-pressure driving air system 4, a computer automatic control system, and 5 an experiment process monitoring system. The connection relationship is: in the brine mixture and CO2 pressurization system 1, the packer central tube pressurization pneumatic control valve 1-7, the lower annular space pressurization pneumatic control valve 1-14 are respectively connected with the experimental container system 2 The experimental container 2-3 is connected, the packer central pipe pressure relief pneumatic control valve 1-27 in the brine mixed liquid and CO2 pressurization system 1 is connected with the ball valve 4-6 in the low-pressure driving air system 4, and the experimental container system 2 The experimental container 2-3 in the circulatory heating system 3 is respectively connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com