Detection equipment, method and system of virtual reality (VR) glasses and cleaning equipment of VR glasses

A technology of VR glasses and testing equipment, which is applied to the cleaning methods, chemical instruments and methods, cleaning methods and utensils using gas flow, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in further detail below in conjunction with the accompanying drawings.

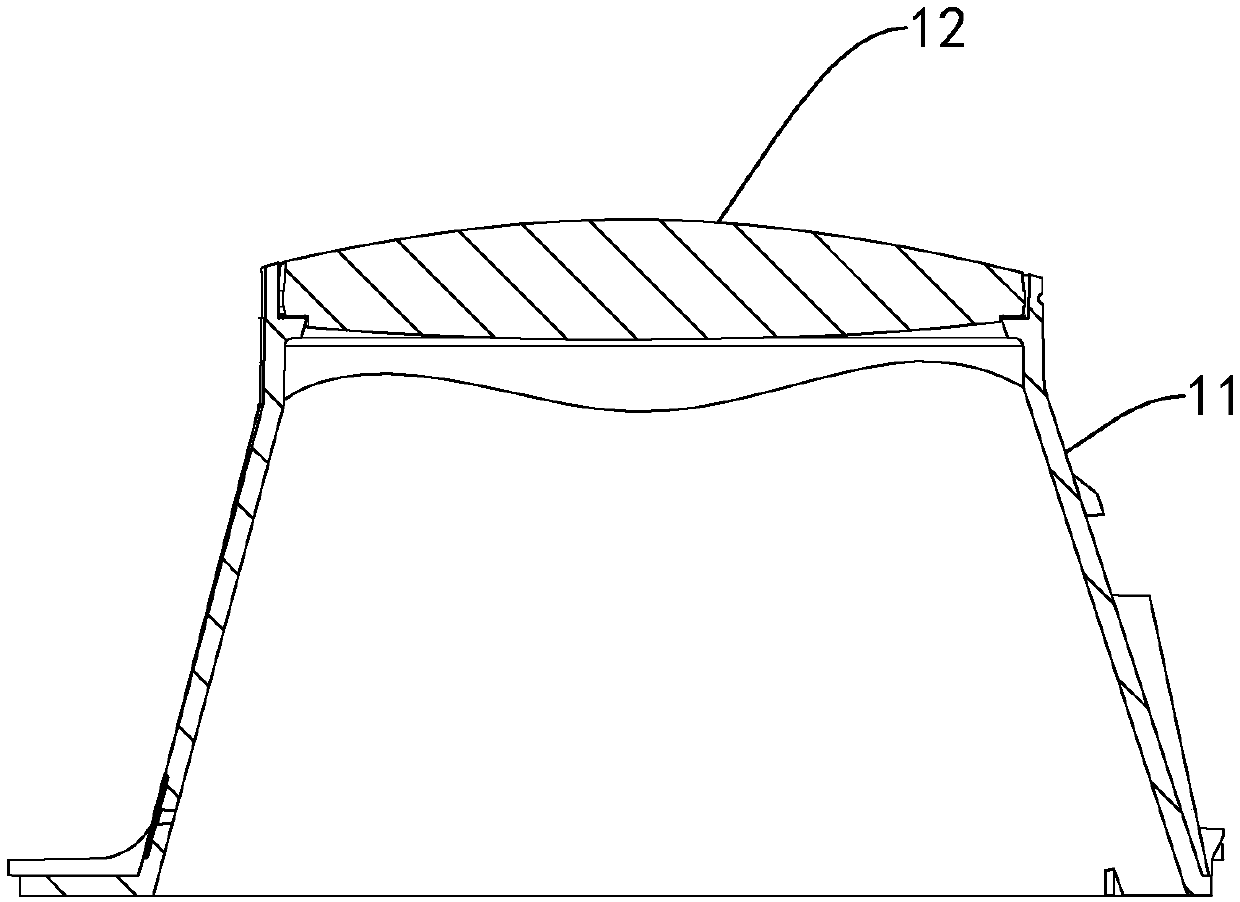

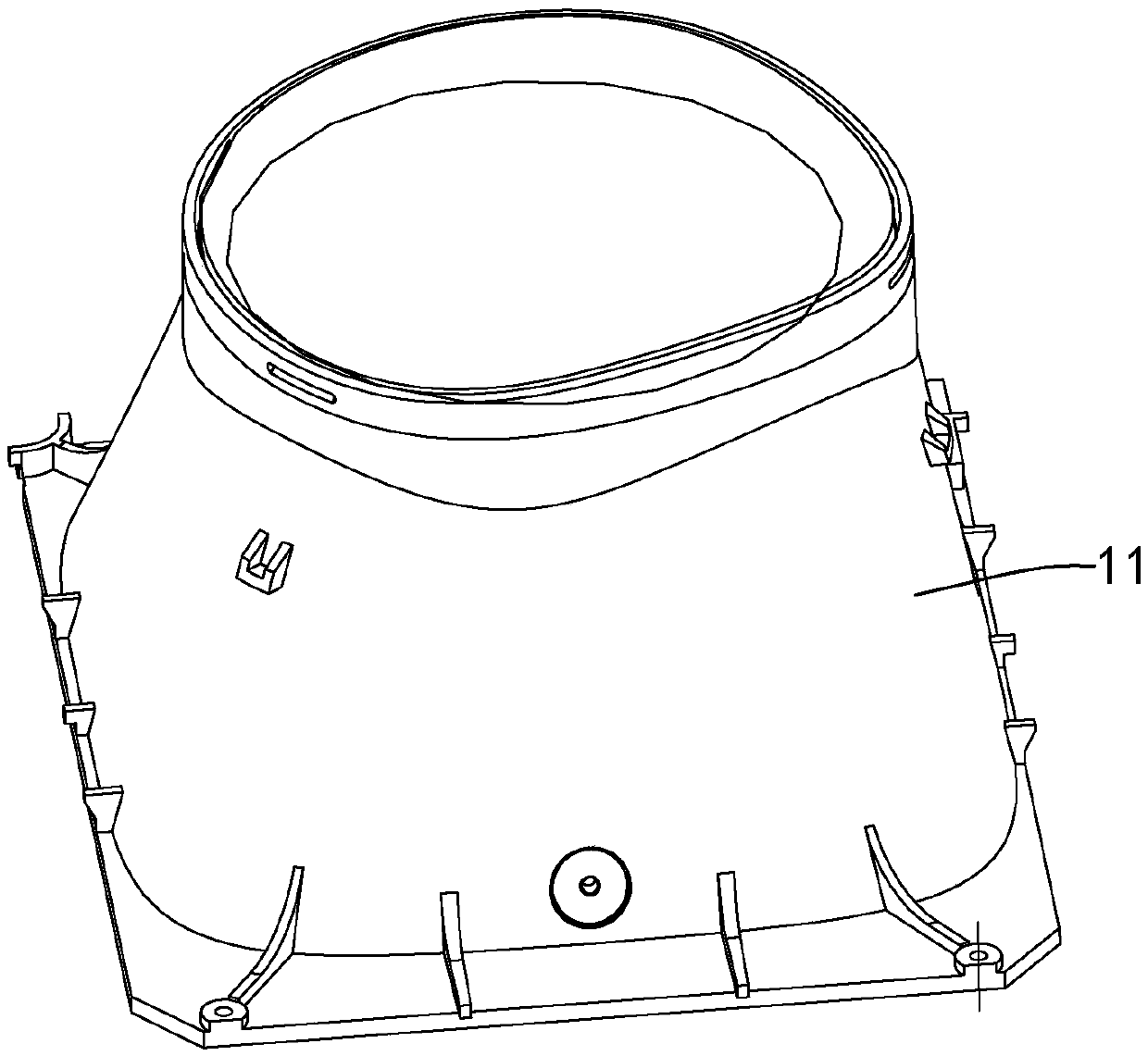

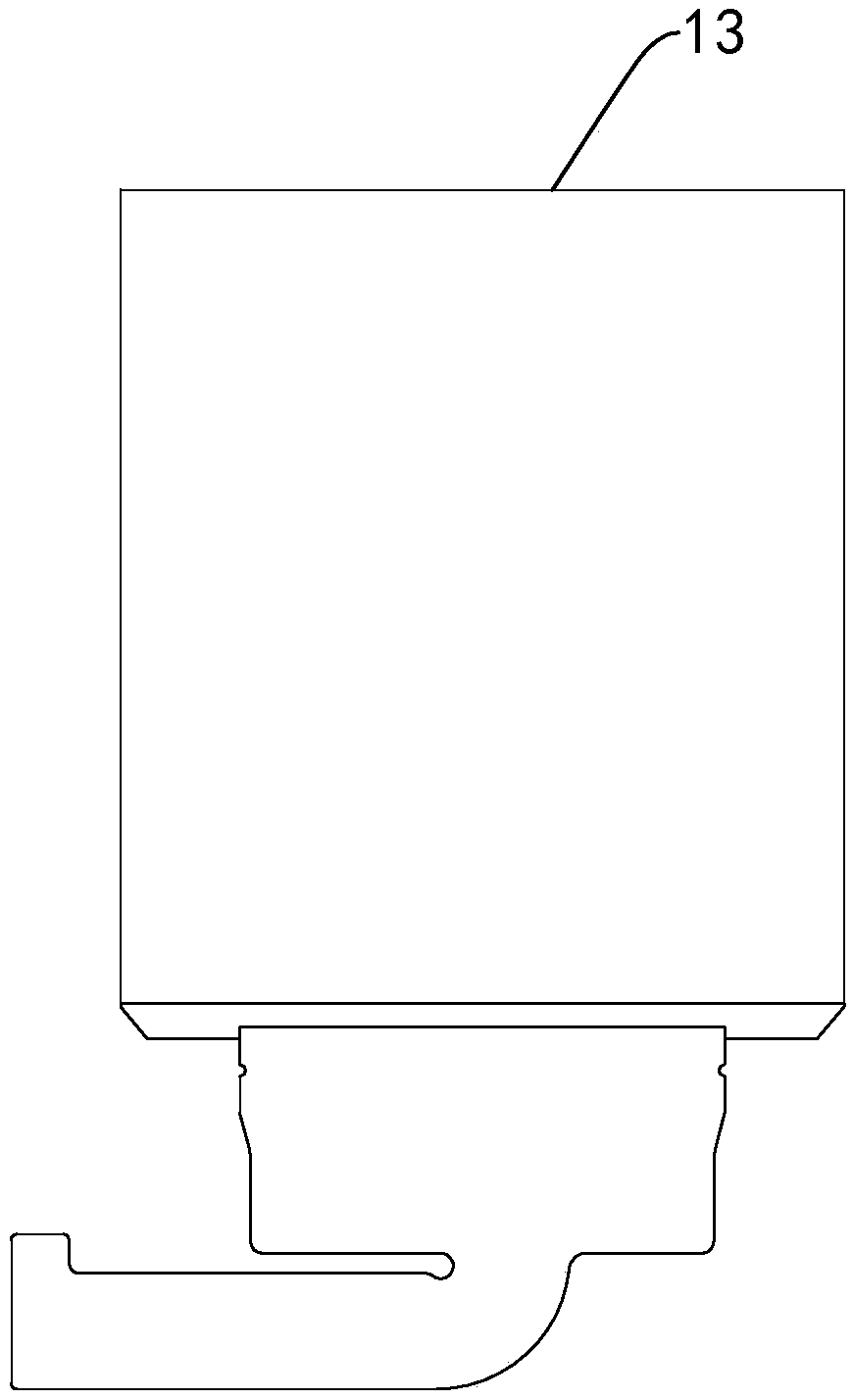

[0057] refer to Figure 4 with Figure 5 , which is a detection device and a cleaning device for VR glasses disclosed in the present invention, including a workbench 2, on which a carrier device 3, a blower device 4 and a detection device 5 are arranged, and the carrier device 3 is used to place a CUP11, The blowing device 4 is used to blow and dust the inner wall of the placed CUP 11 , and the detection device 5 is used to detect the cleanliness of the inner wall of the CUP.

[0058] refer to Figure 5 with Image 6 , the carrier device 3 includes a carrier platform 31, the carrier platform 31 is provided with a pressing driver 33, the pressing driver 33 can be an air cylinder, the pressing driver 33 is connected to the pressing plate 32, and the pressing plate 32 presses down the CUP11. Compression, the bottom side of the pressure plate 32 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com