Integrated equipment for on-line production, inspection and identification of fire-resistant and flame-retardant cables

A production testing, fire-proof and flame-retardant technology, applied in the direction of marking conductors/cables, measuring electricity, measuring devices, etc., can solve the problems of unfavorable repair, easy omission of rework, unfavorable search for marking points, etc., and achieve simple structure, simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

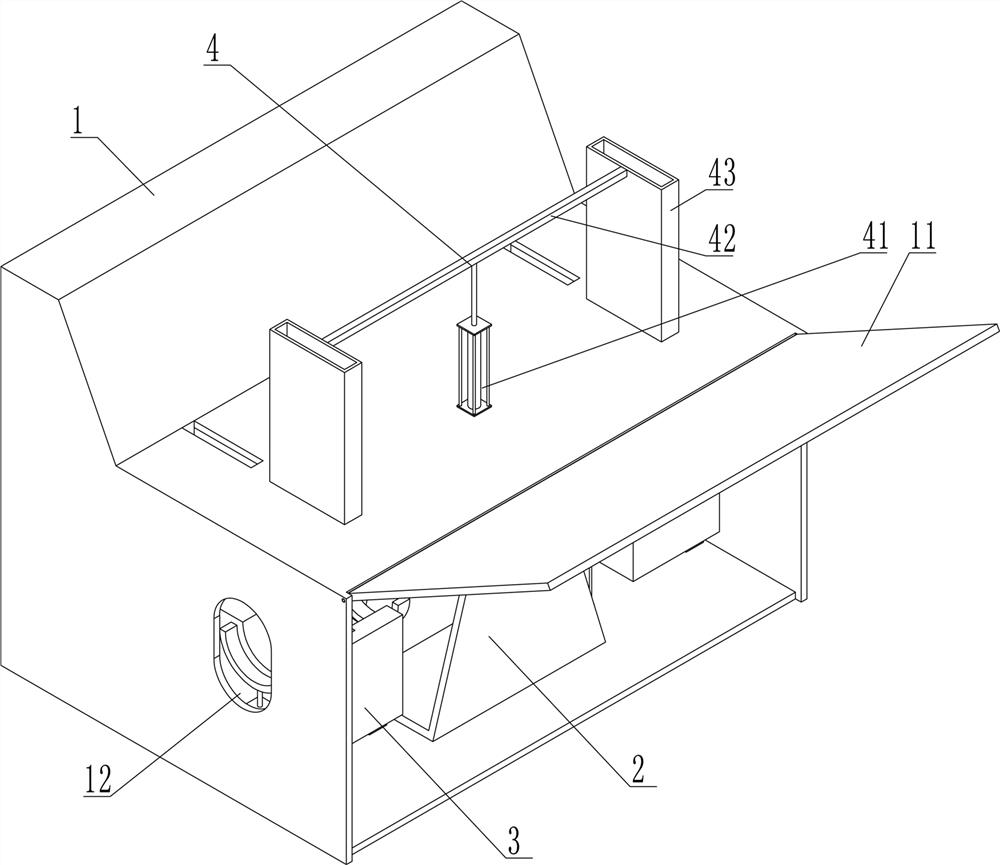

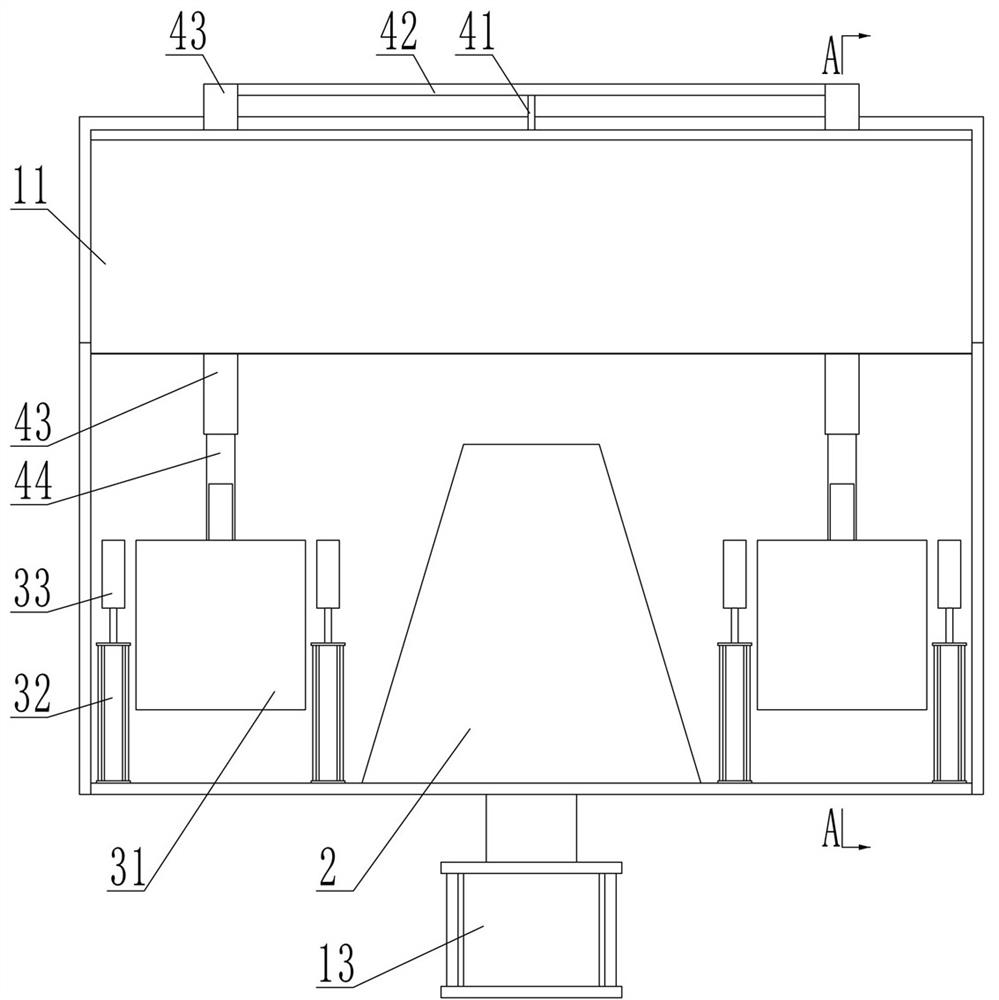

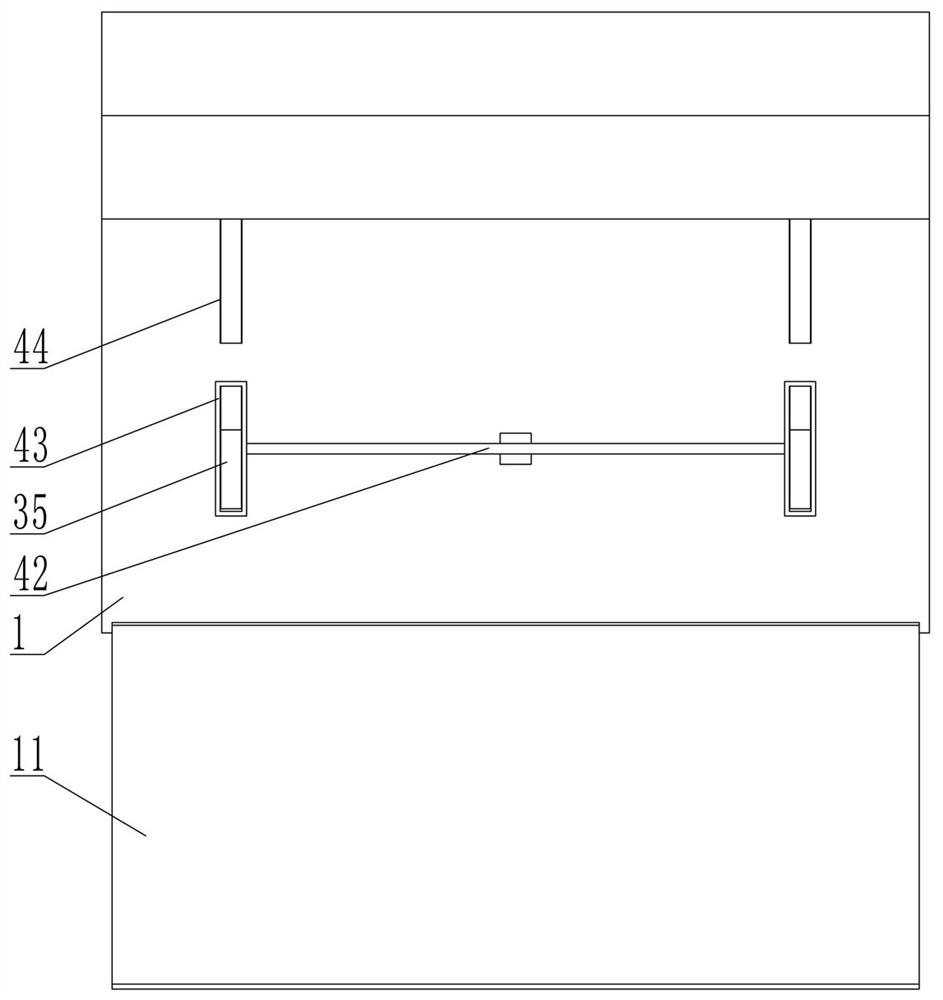

[0059] Such as Figure 1~13 Among them, an integrated equipment for online production, detection and identification of fire-resistant and flame-retardant cables, which includes a detection box 1, a spark machine 2, a marking device 3 and a feeding mechanism 4; the spark machine 2 is located in the detection box 1, and the marking device 3 is located in the detection box On both sides of the spark machine 2 in the box 1, the feeding mechanism 4 is located outside the detection box 1 and connected with the marking device 3. The structure is simple, by setting the spark machine 2 in the closed detection box 1, the marking device 3 is set on both sides of the spark machine 2, the feeding mechanism 4 located outside the detection box 1 is connected with the marking device 3, and the detection is passed through the spark machine 2 The cable defect of box 1 is marked by feeding the passive ring 45 and the movable ring 46 to engage the two ends of the cable defect point through the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com