Numerical control system

A technology of numerical control and evaluation value, which is applied in the field of numerical control system, can solve problems such as difficult to realize, and achieve the effect of efficient machine learning and improvement of anomaly detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

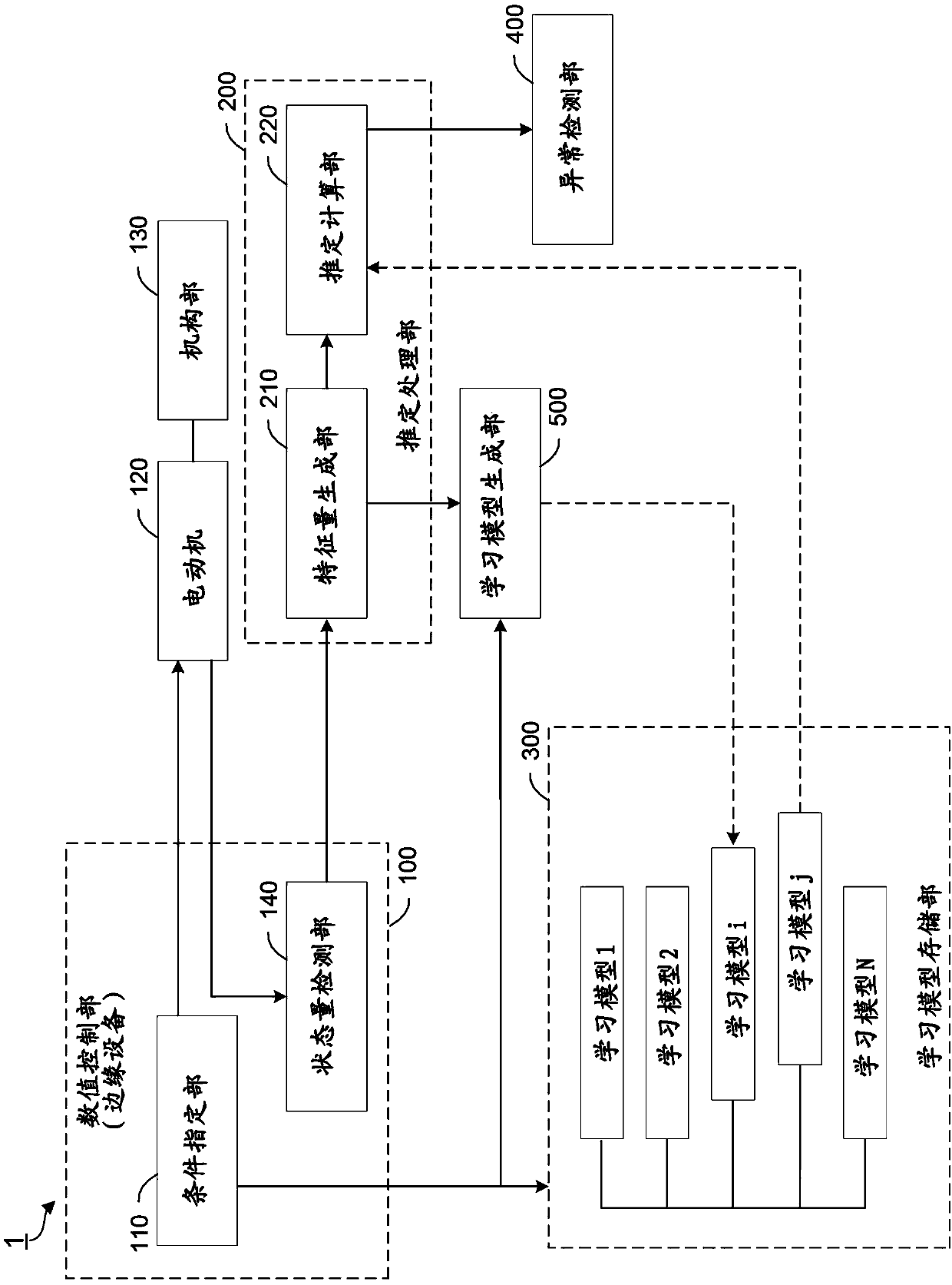

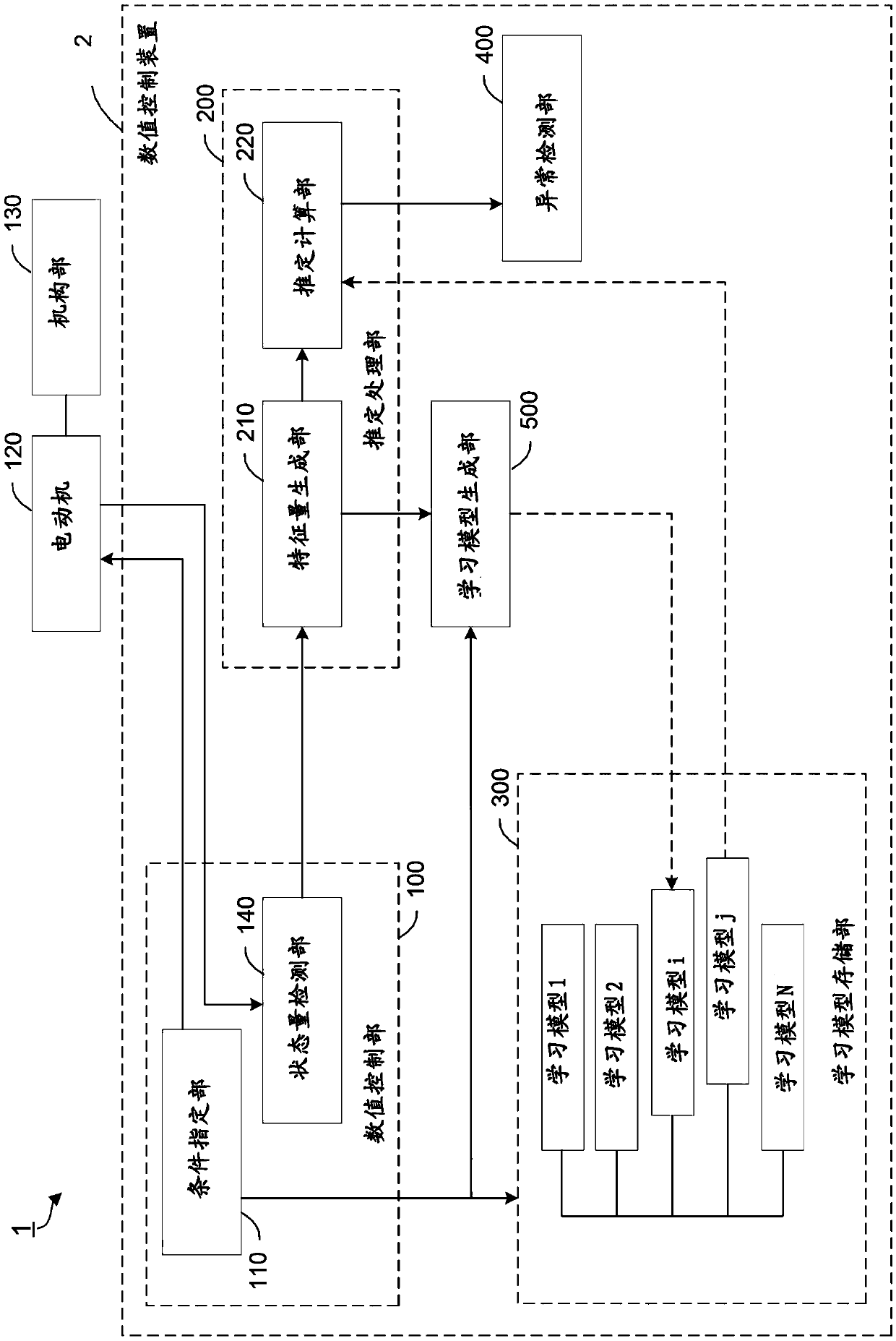

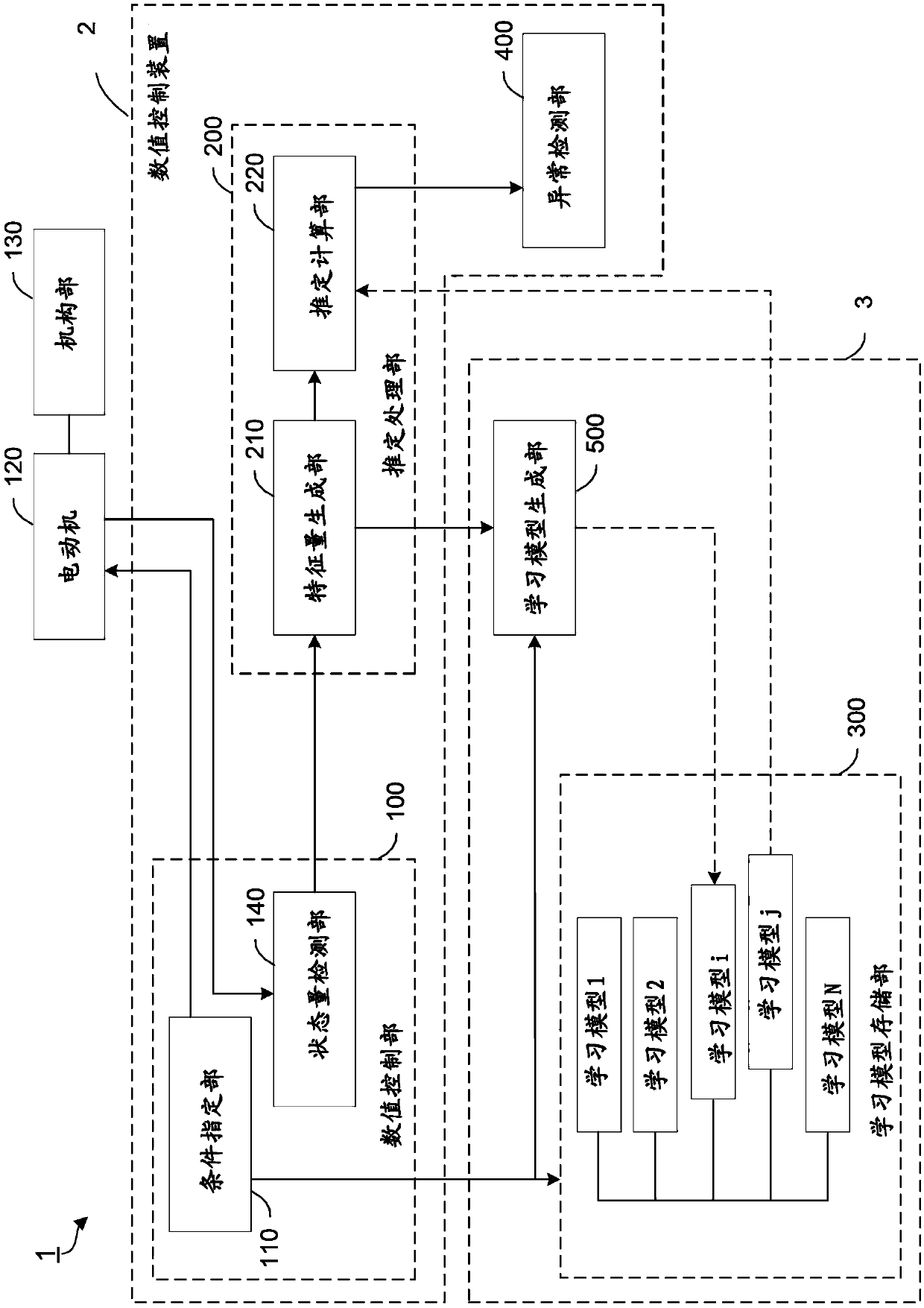

[0030] figure 1 is a schematic functional block diagram of the numerical control system 1 provided in the first embodiment.

[0031] figure 1 Each of the shown functional blocks is realized by controlling the operation of each part of the device according to the respective system programs by processors such as CPU and GPU included in the numerical control device, unit computer, host computer, cloud server and other computers constituting the numerical control system 1 .

[0032] The numerical control system 1 of the present embodiment includes at least a numerical control unit 100 of an edge device as an object of state observation / estimation, an estimation processing unit 200 for estimating the state of the edge device, and a learning model storage unit 300 for storing and managing a plurality of learning models. . This numerical control system 1 further includes an abnormality detection unit 400 that detects a tool abnormality based on the state estimation result of the ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com