Antifreeze equipment for garden soil

A soil and garden technology, applied in the fields of botanical equipment and methods, horticulture, direct liquid fertilizer delivery systems, etc., can solve problems such as lack of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

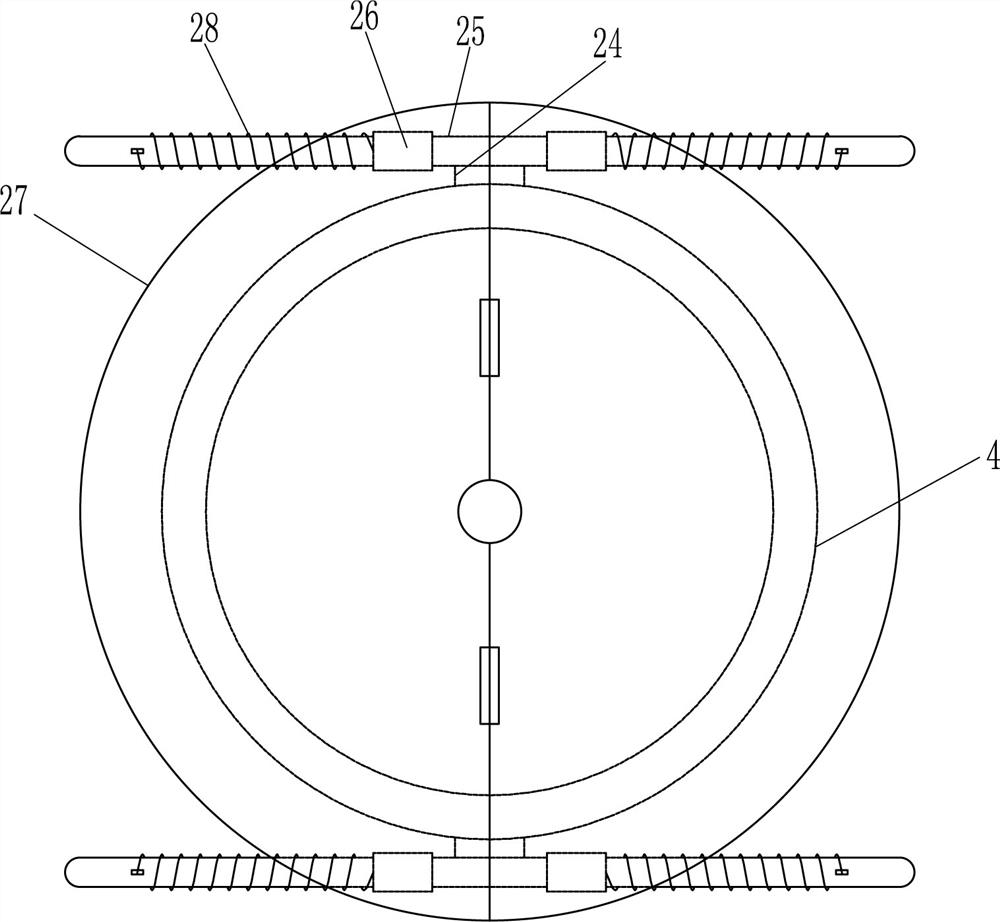

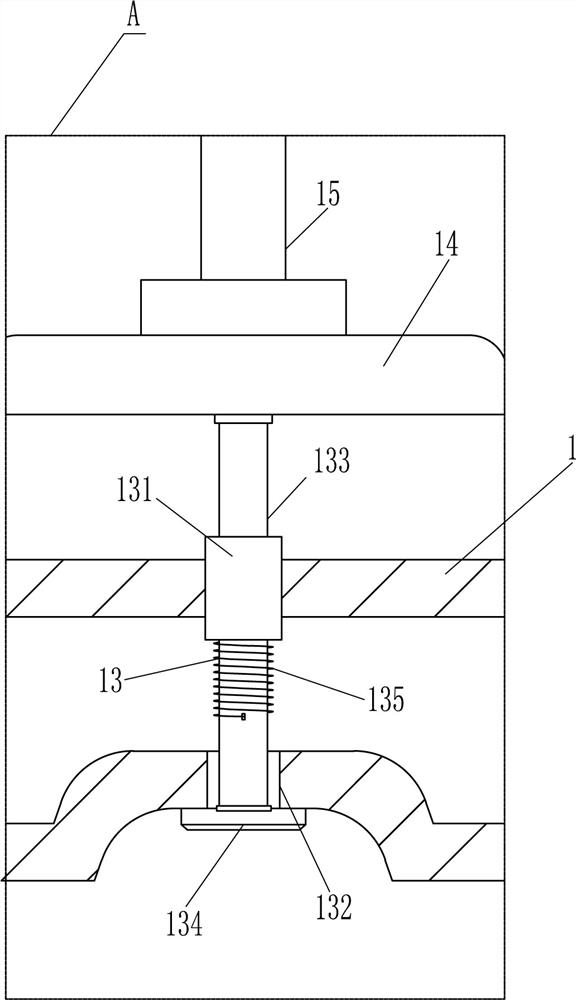

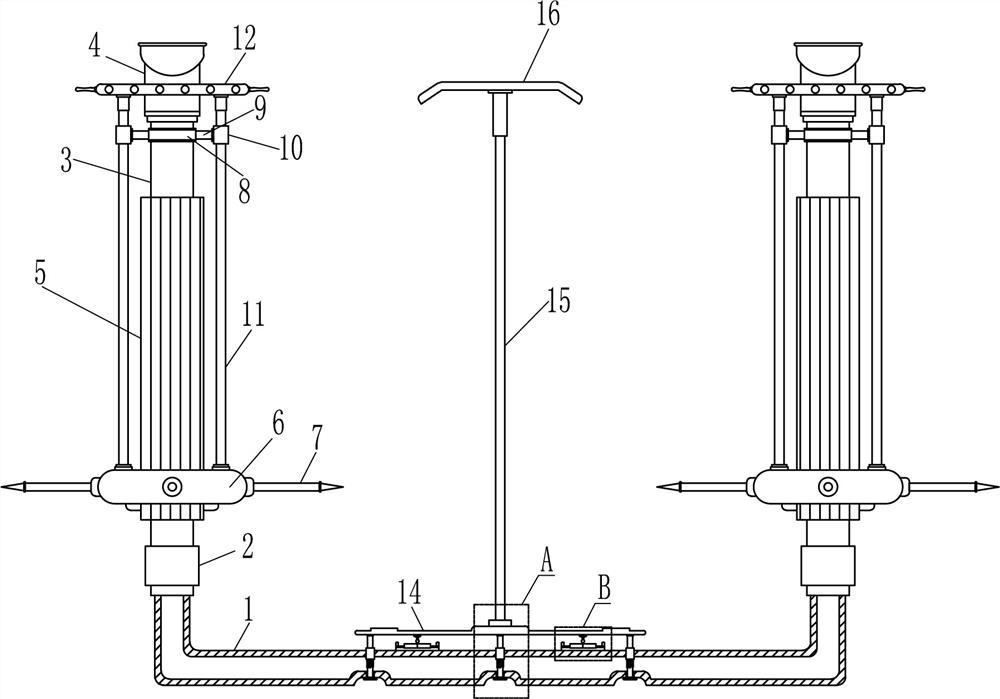

[0018] A garden soil antifreeze device, such as Figure 1-2 As shown, it includes a first connecting pipe 1, a connecting sleeve 2, a second connecting pipe 3, a water injection sleeve 4, a rolling spline shaft 5, a sliding sleeve 6, a stirring rod 7, a rolling bearing seat 8, a first connecting rod 9, a first connecting rod A guide sleeve 10, a first guide rod 11, a rotating sleeve 12, a water outlet device 13, a connecting plate 14, a pull rod 15 and a handle 16, the top left and right sides of the first connecting pipe 1 are provided with connecting sleeves 2, and the first connecting pipe 1 passes through The welding connection is connected with the connecting sleeve 2, the connecting sleeve 2 is provided with a second connecting pipe 3, the top of the second connecting pipe 3 is provided with a water injection jacket 4, the water injection jacket 4 is communicated with the second connecting pipe 3, and the second connecting pipe 3. The upper rotating type is provided with...

Embodiment 2

[0020] A garden soil antifreeze device, such as Figure 1-2 As shown, it includes a first connecting pipe 1, a connecting sleeve 2, a second connecting pipe 3, a water injection sleeve 4, a rolling spline shaft 5, a sliding sleeve 6, a stirring rod 7, a rolling bearing seat 8, a first connecting rod 9, a first connecting rod A guide sleeve 10, a first guide rod 11, a rotating sleeve 12, a water outlet device 13, a connecting plate 14, a pull rod 15 and a handle 16, the top ends of the left and right sides of the first connecting pipe 1 are provided with connecting sleeves 2, and the connecting sleeves 2 are provided with The second connecting pipe 3, the top of the second connecting pipe 3 is provided with a water injection jacket 4, the water injection jacket 4 communicates with the second connecting pipe 3, the second connecting pipe 3 is rotatably provided with a rolling spline shaft 5, and the rolling spline shaft The upper sliding type is provided with a sliding sleeve 6,...

Embodiment 3

[0023] A garden soil antifreeze device, such as Figure 1-3 As shown, it includes a first connecting pipe 1, a connecting sleeve 2, a second connecting pipe 3, a water injection sleeve 4, a rolling spline shaft 5, a sliding sleeve 6, a stirring rod 7, a rolling bearing seat 8, a first connecting rod 9, a first connecting rod A guide sleeve 10, a first guide rod 11, a rotating sleeve 12, a water outlet device 13, a connecting plate 14, a pull rod 15 and a handle 16, the top ends of the left and right sides of the first connecting pipe 1 are provided with connecting sleeves 2, and the connecting sleeves 2 are provided with The second connecting pipe 3, the top of the second connecting pipe 3 is provided with a water injection jacket 4, the water injection jacket 4 communicates with the second connecting pipe 3, the second connecting pipe 3 is rotatably provided with a rolling spline shaft 5, and the rolling spline shaft The upper sliding type is provided with a sliding sleeve 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com