Automatically-overturning clamping device for wind power blades

An automatic flipping and clamping device technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of easy damage to the electric cylinder, large design size, difficult handling, etc., and achieve perfect blade fitting and clamping mechanism, Good universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

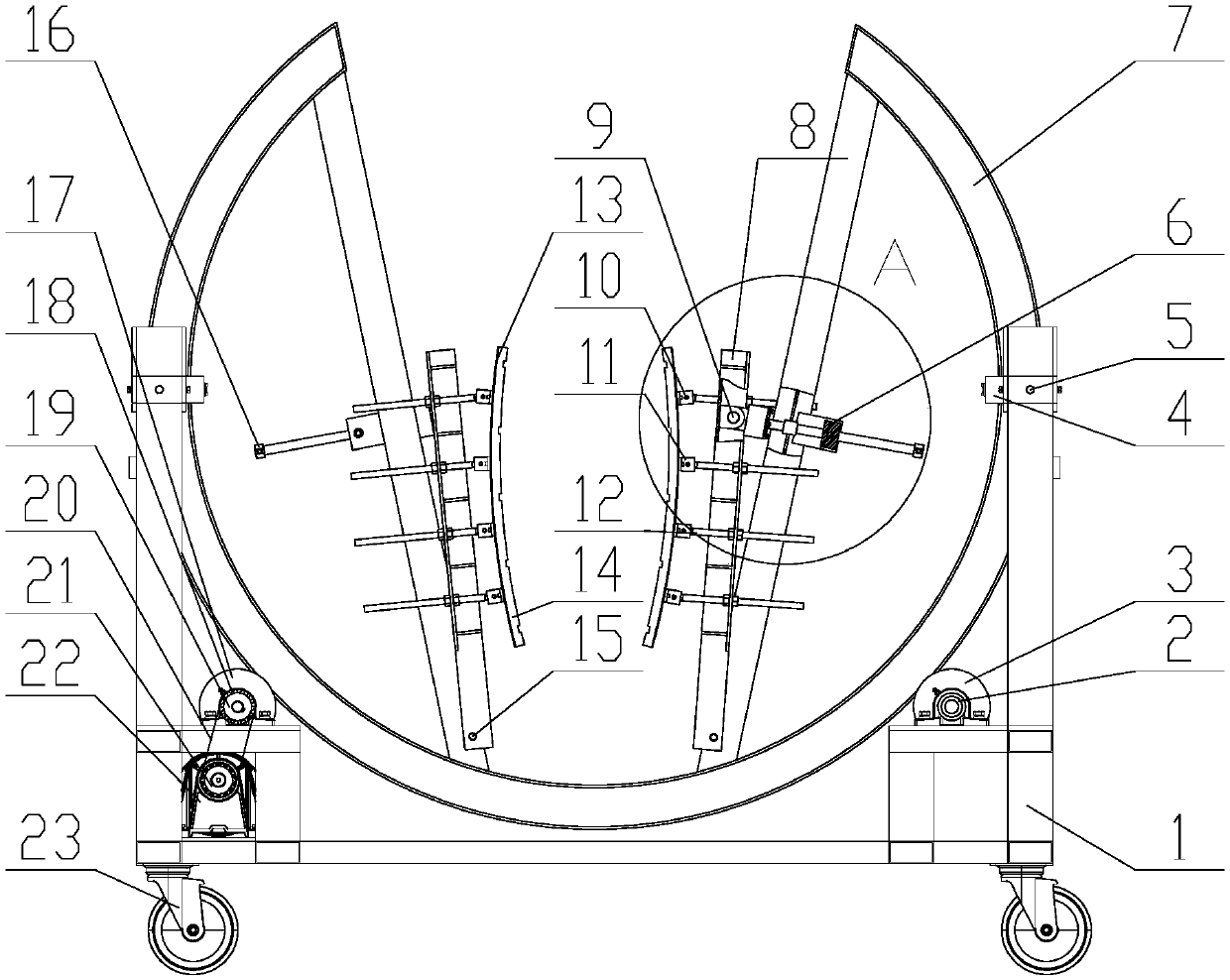

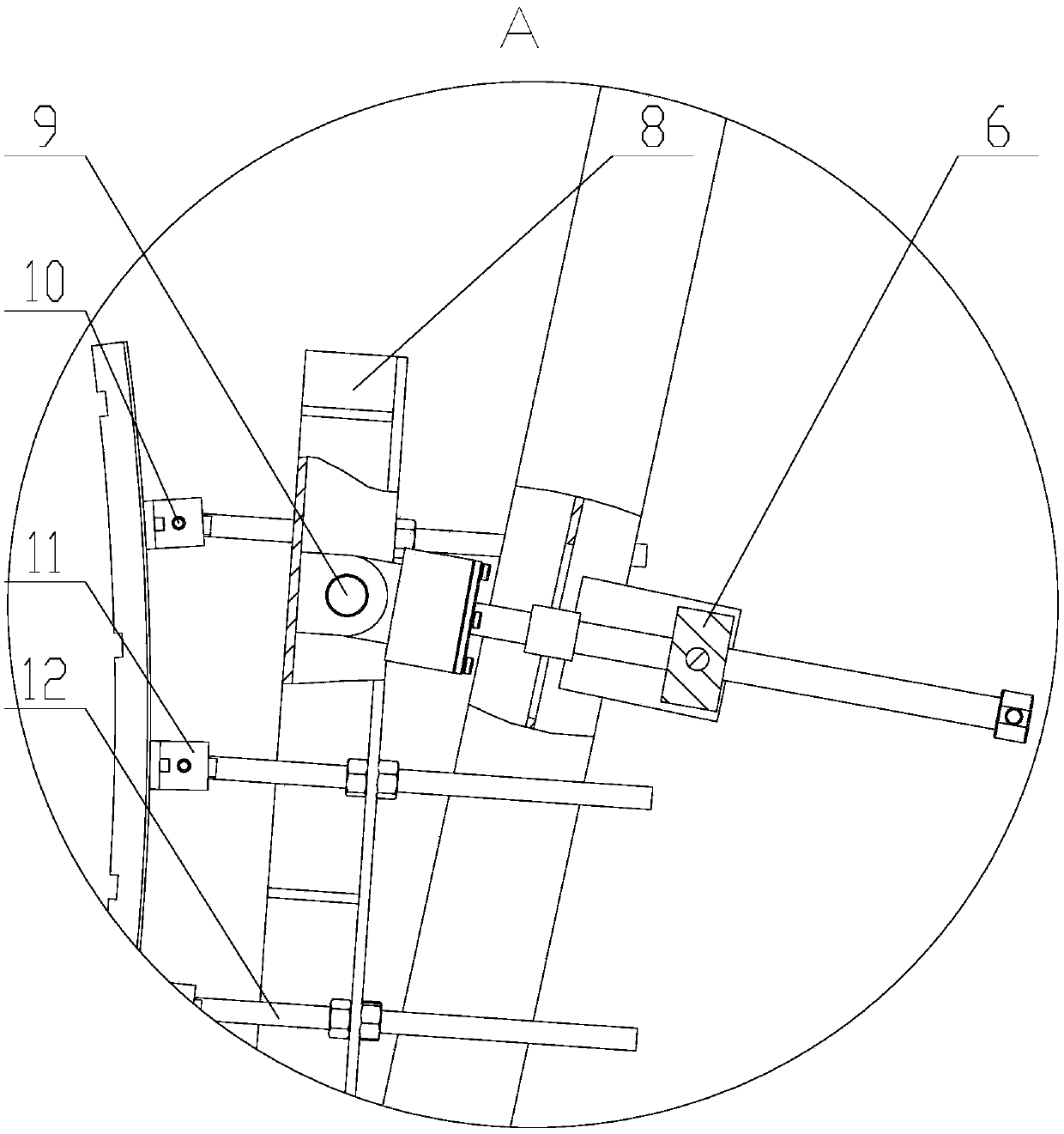

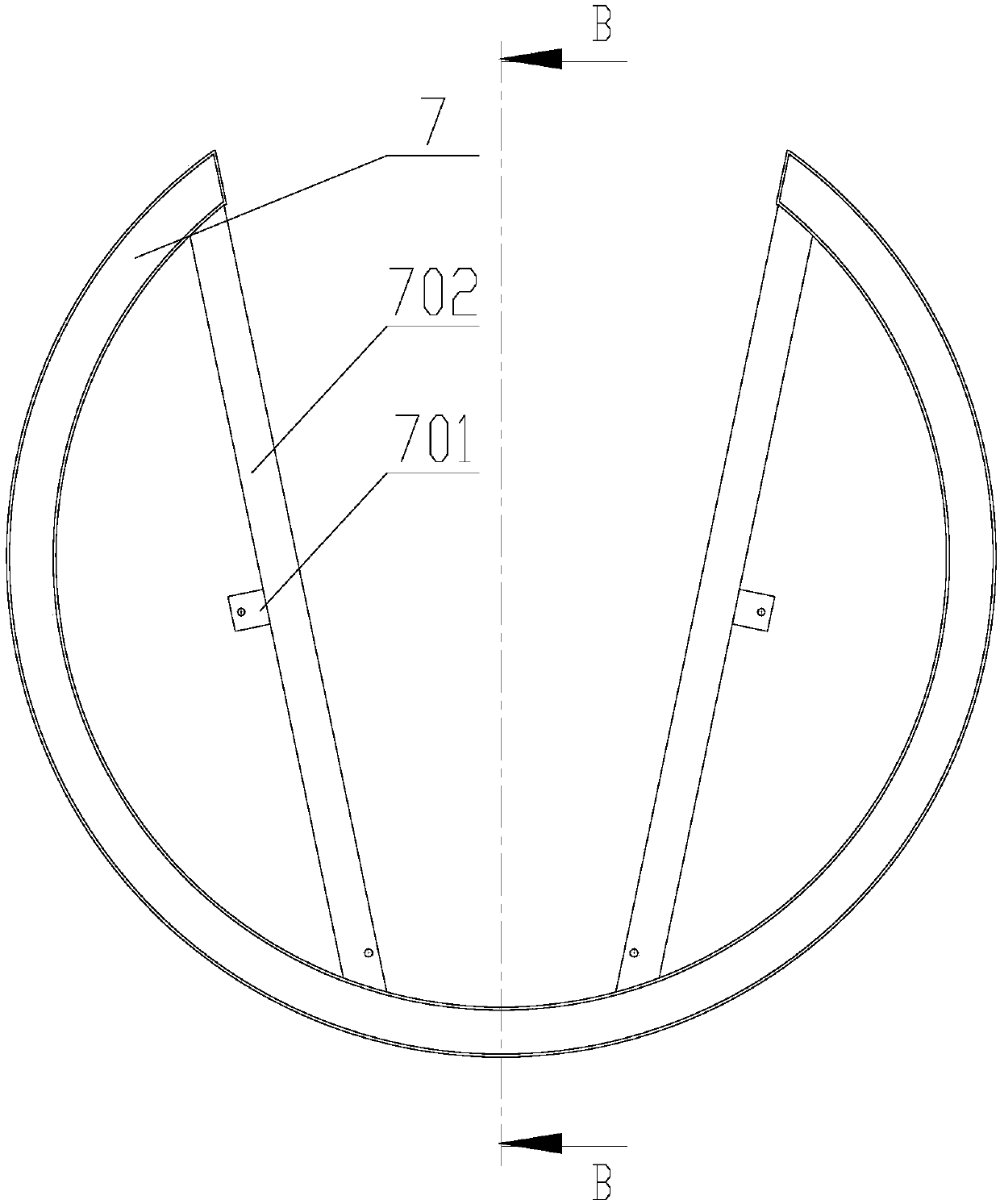

[0035] The invention provides a wind power blade automatic flip clamping device (see Figure 1-11 , hereinafter referred to as the device), the device includes a rotating disk support frame 1, a rotating disk drive mechanism, an annular rotating disk 7, a rotating disk guiding mechanism (including a tensioning structure), a blade fitting clamping mechanism and a control system. The control system controls the action of the rotary disk drive mechanism; the rotary disk drive mechanism is fixed on the rotary disk support frame, the annular rotary disk 7 is in contact with the rotary disk drive mechanism, and is fixed on the rotary disk support frame 1 through the rotary disk guide mechanism, and the blades are attached to each other. The clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com