Floating crane for overwater hoisting and assembling method thereof

A floating body and crane technology, applied in the direction of cranes, etc., can solve the problems of cumbersome assembly and dismantling, occupying the storage of old materials in steel casings, and increasing the recovery cost of transportation, etc., so as to save machinery and labor costs, reduce construction costs, and improve Effective utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

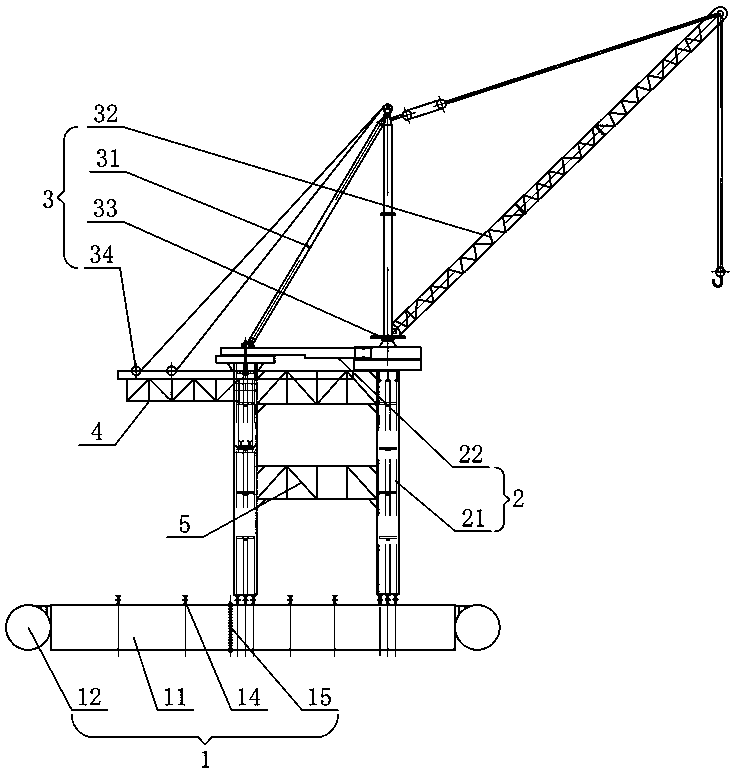

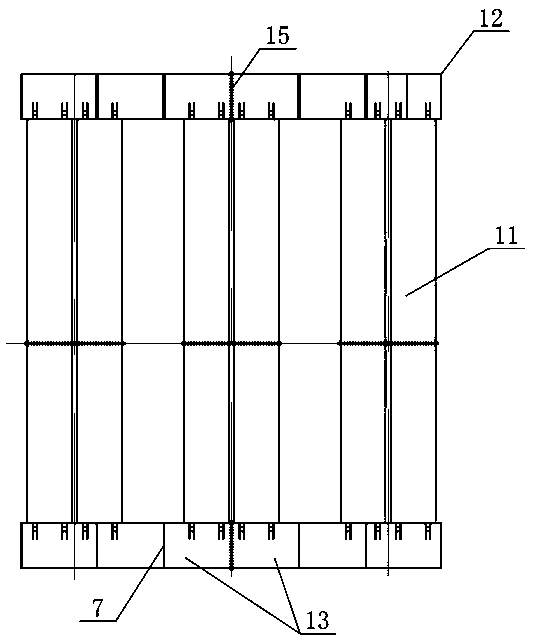

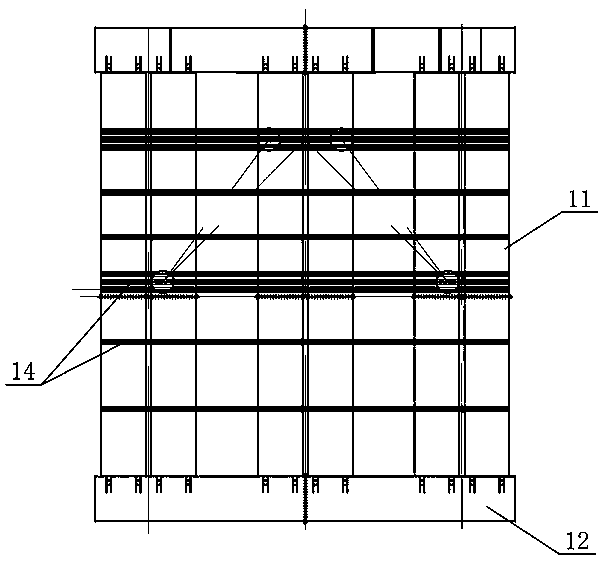

[0031] Such as Figure 1 to Figure 5 As shown, the floating crane for hoisting in water in this embodiment includes a floating chassis 1, a vertical frame 2 and a crane 3. The floating chassis 1 includes at least two groups of longitudinal force-bearing floating bodies 11 arranged side by side in parallel, and each longitudinal force-bearing floating body 11 are connected with horizontally connected buoyant bodies 12 at the same direction ends, and each horizontally connected buoyant body 12 and each longitudinal load-bearing buoyant body 11 are formed by splicing end to end of at least two steel casings 13 with both ends closed, and the vertical frame 2 is arranged on each longitudinal load-bearing buoyant body. The top of the power buoyancy body 11 is placed side by side on the half side of the buoyant body 12 facing any transverse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com