Non-woven fabric needling machine

A technology for acupuncture machines and non-woven fabrics, which is applied in the directions of acupuncture machines, non-woven fabrics, textiles and paper making, etc., can solve the problems of inconvenient operation, complex structure, large space occupation, etc., and achieves convenient operation and good movement stability. , the effect of taking up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the text of the description.

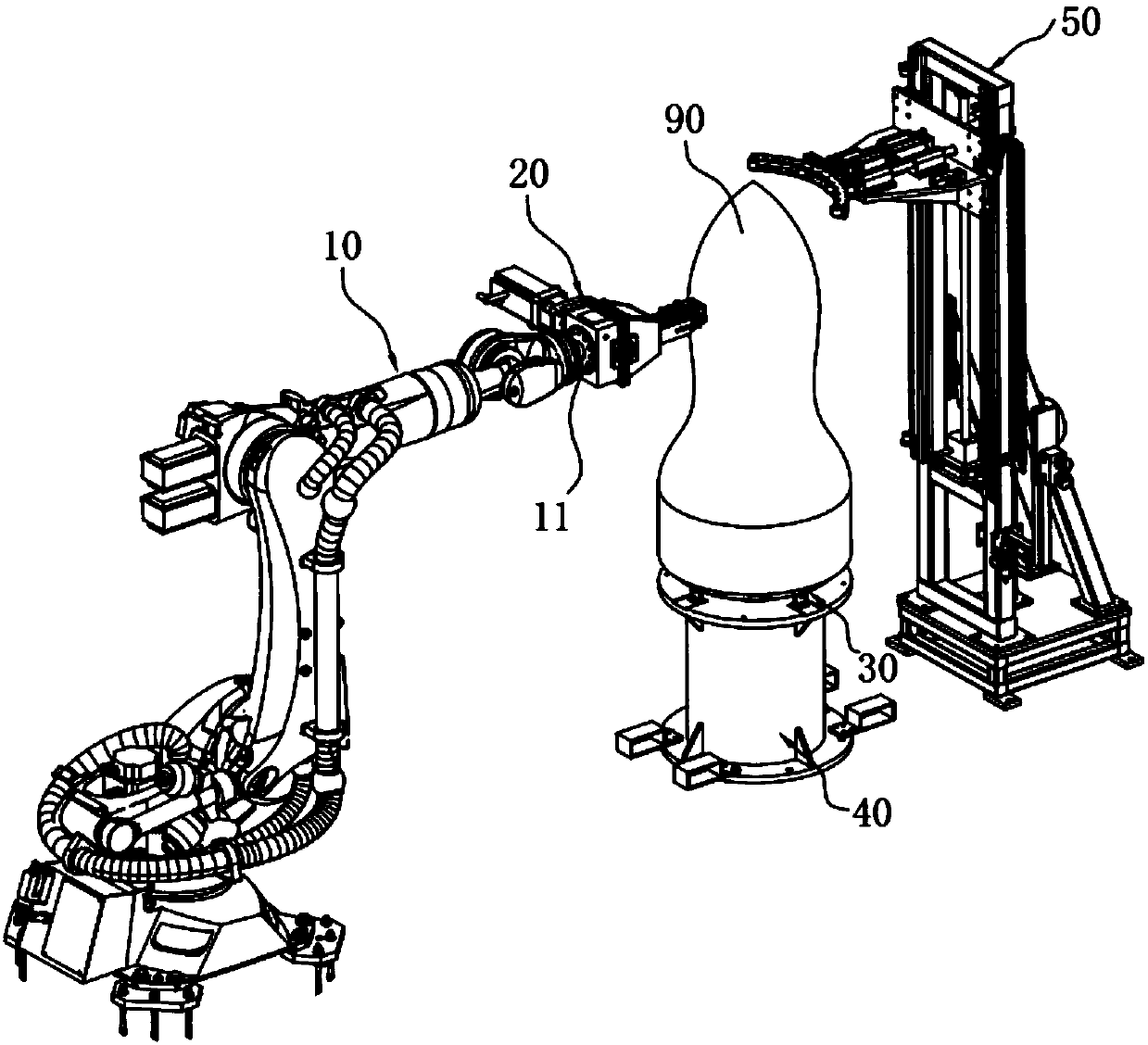

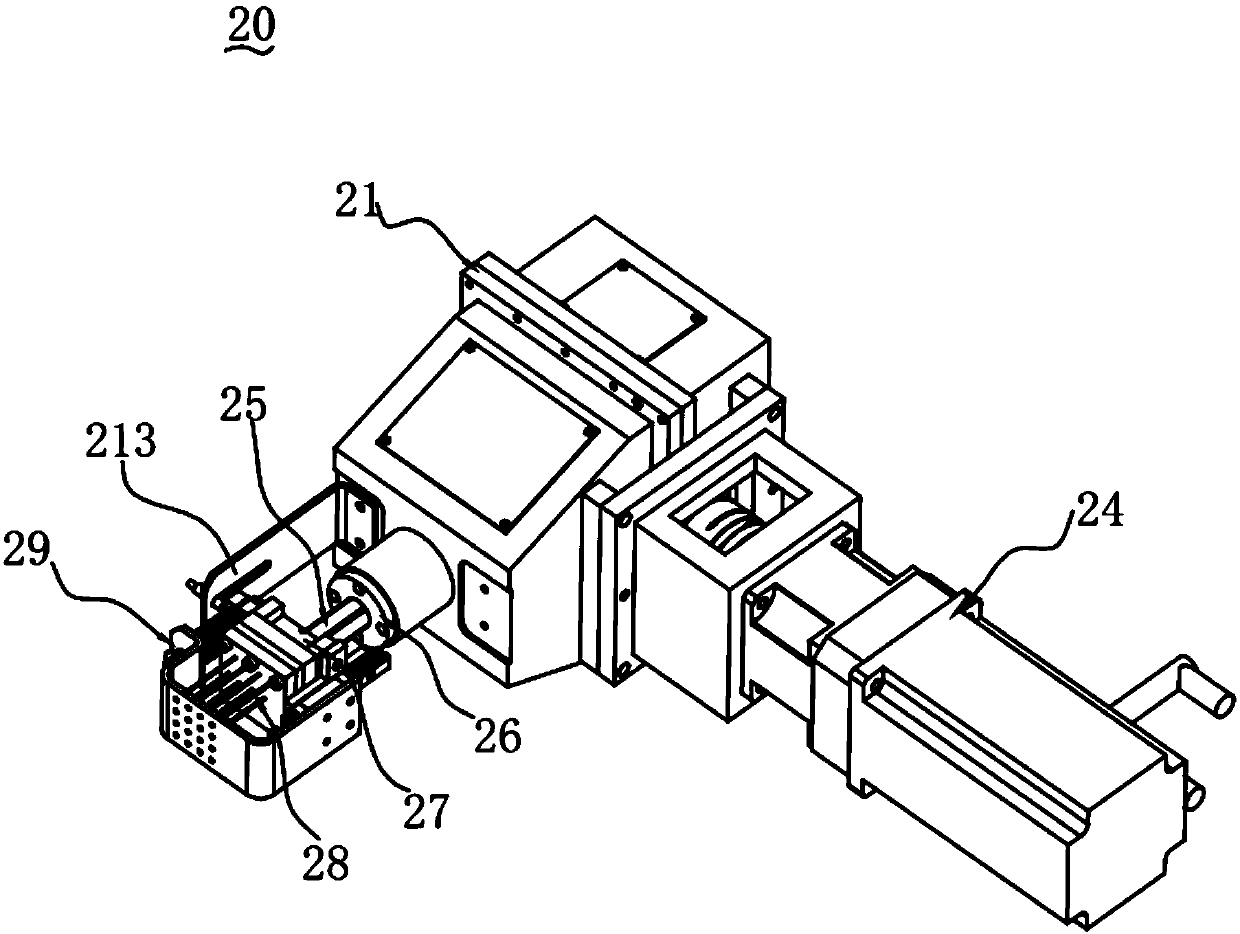

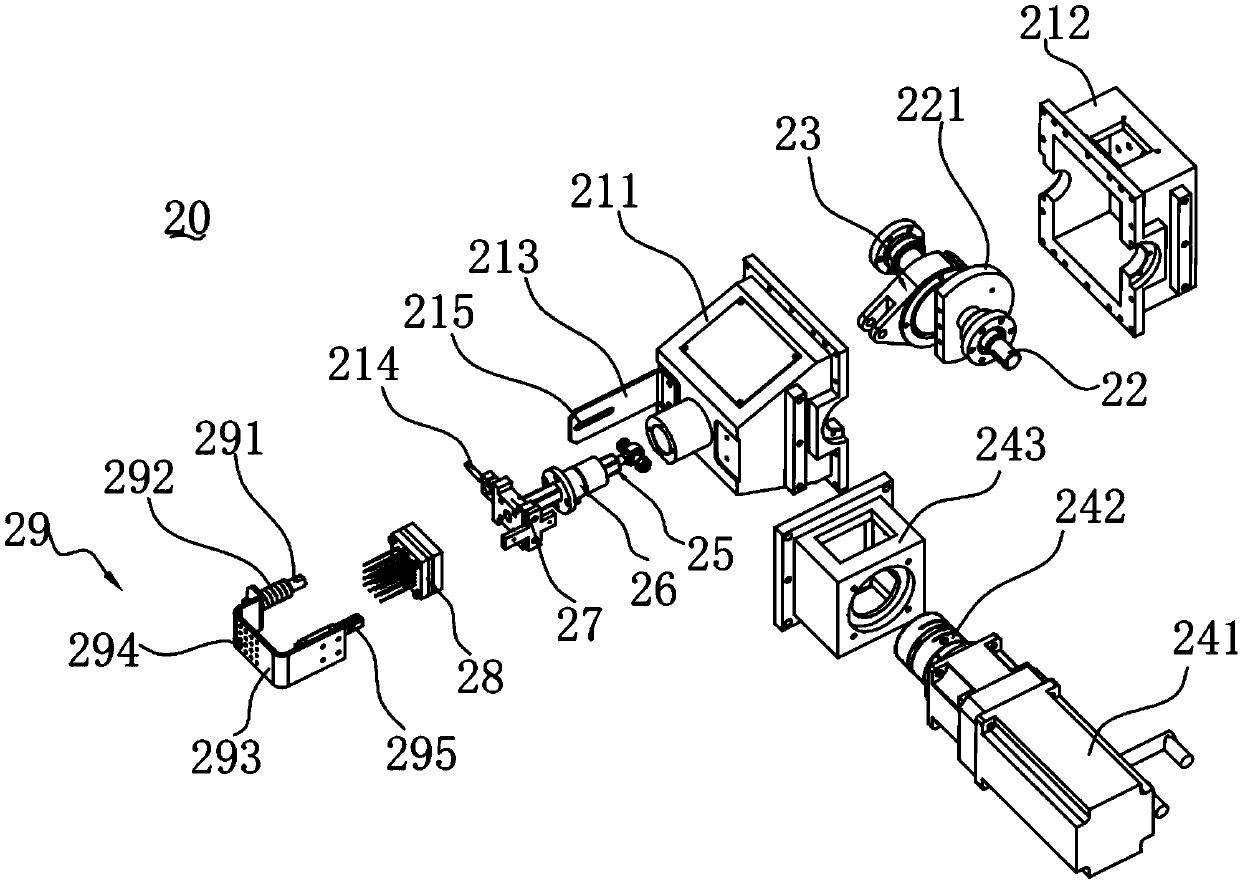

[0031] Such as Figure 1 to Figure 14 As shown, the present invention provides a non-woven fabric needling machine, including: a turntable 40 with a turntable motor built-in; a clamp 30 for fastening the mold 90, the clamp 30 is connected to the output shaft of the turntable motor and With the rotation of the output shaft of the turntable motor, the mold 90 is located directly above the clamp 30, and the mold 90 is wound with carbon fibers to be acupuncture; the manipulator 10 located on one side of the mold 90; The needling assembly 20 on the manipulator 10 for needling the carbon fibers on the mold 90; and the anti-tip assembly 50 on the other side of the mold 90 for supporting the mold 90 laterally; wherein The anti-tip assembly 50 and the manipulator 10 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com