Carbon dioxide driven technical limit spacing optimization method

A carbon dioxide and optimization method technology, which is applied in earthwork drilling, wellbore/well components, production fluid, etc., can solve problems such as large deviations in calculation results, achieve the effects of improving accuracy, increasing economically recoverable reserves, and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

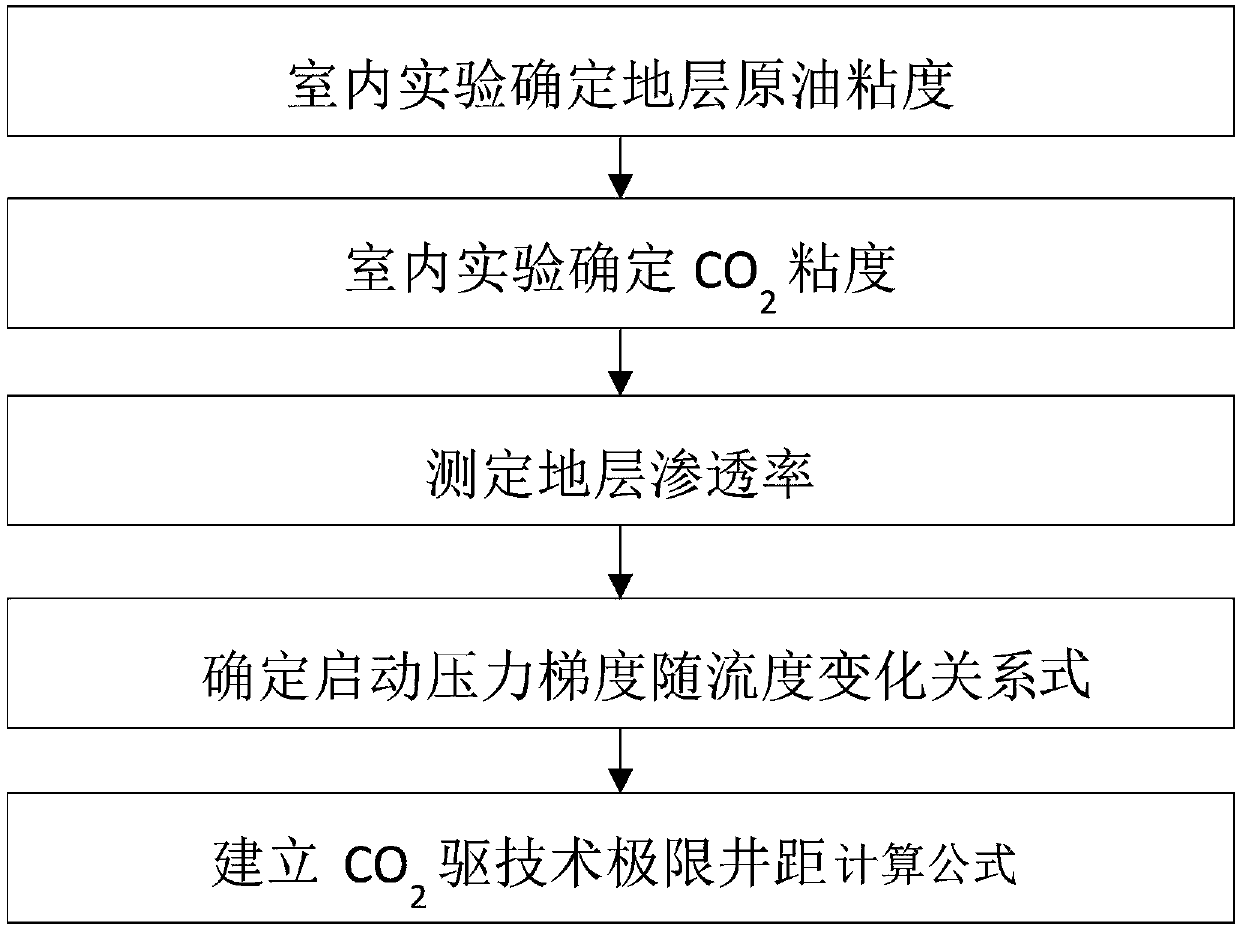

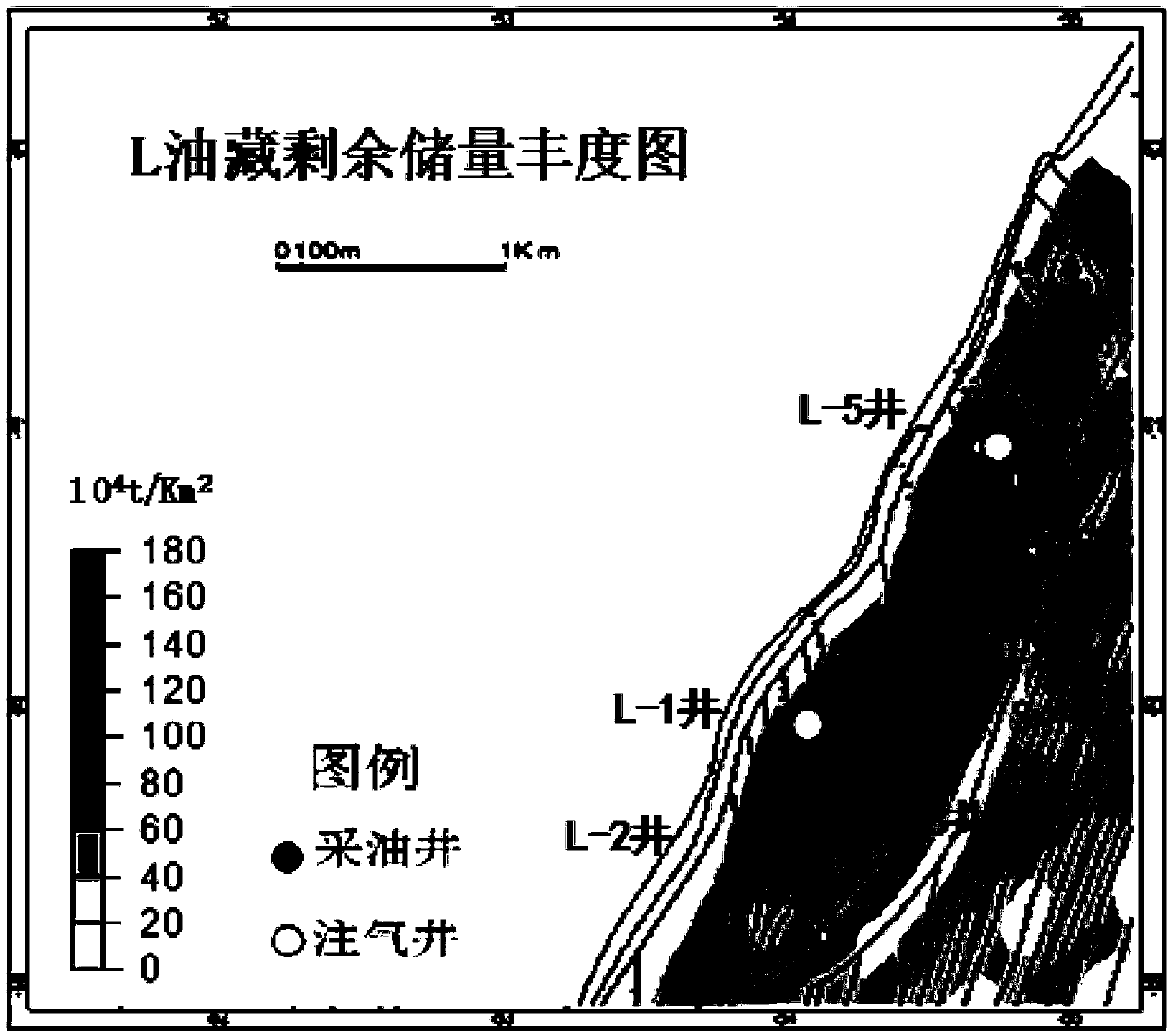

[0030] Embodiment 1, a method for optimizing the limit well spacing of carbon dioxide flooding technology under different production pressure differences, including the following five steps:

[0031] S1. Use the downhole sampler to extract crude oil samples from the L reservoir formation in the wellbore separator of the production well. Using the extracted formation crude oil samples, it is determined through laboratory experiments that the viscosity of the L reservoir formation crude oil is 0.78mPa·s. The specific extraction and determination process can be Obtained by a method for predicting the minimum miscible pressure of CO2 flooding in the patent publication number CN104462753A, which is a prior art and will not be described in detail here;

[0032] S2. Through the formation temperature and pressure test, it is determined that the formation temperature of the L reservoir is 151°C and the formation pressure is 60MPa. The viscosity of CO2 under the formation temperature and...

Embodiment 2

[0043] Embodiment 2. On the basis of Embodiment 1, the step S4 determines that the relationship between the start-up pressure gradient and the flow rate is specifically:

[0044] Through the core displacement experiment, the minimum start-up pressure gradient of CO2 flooding under different permeability cores under bound water, different pressures and different crude oil viscosities was measured, and the change curve of the start-up pressure gradient with the mobility was obtained. The fluidity change relation is:

[0045] G=1 / a·(K / μ) -b

[0046] In the formula: G is the starting pressure gradient, the unit is MPa / m; K is the air permeability, the unit is 10-3μm2; μ is the fluid viscosity, the unit is mPa s; a=3.226, b=0.5992.

Embodiment 3

[0047] Embodiment 3, on the basis of Embodiment 1, the specific steps for establishing the CO2 flooding technology limit well spacing calculation formula in the step S5 are:

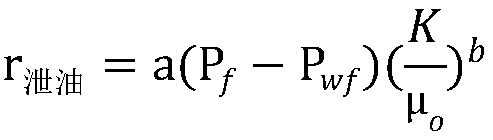

[0048] S51. Using the reservoir engineering method, establish the bottom hole flow pressure of the production well as P wf Time CO 2 Calculation formula of limit oil supply radius of flooding technology;

[0049]

[0050] In the formula: r 泄油 is the oil drainage radius around the production well, in m; P f is formation pressure in MPa; P wf is the bottomhole flow pressure of the production well, in MPa; μ o is the viscosity of formation crude oil, in mPa s;

[0051] S52. Using the reservoir engineering method, establish a formula for calculating the limit displacement radius of the CO2 flooding technology when the bottom hole pressure of the injection well is Pe;

[0052]

[0053] In the formula, r displacement is the displacement radius around the gas injection well, in m; Pf is the formatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com