Interference fit-type flange

An interference fit and flange technology, applied in flange connection, passing components, pipes/pipe joints/fittings, etc., can solve the problems of difficult flange assembly process, mismatch of flange and pipe diameter, affecting project quality, etc. , to achieve the effect of reducing gaps, improving sealing, and connecting firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The embodiments of the present invention have been presented for purposes of illustration and description, but are not intended to be exhaustive or to limit the invention to the form disclosed. Many modifications and changes will be apparent to those of ordinary skill in the art. The embodiment was chosen and described in order to better explain the principles of the invention and the practical application, and to enable others of ordinary skill in the art to understand the invention and design various embodiments with various modifications as are suited to the particular use.

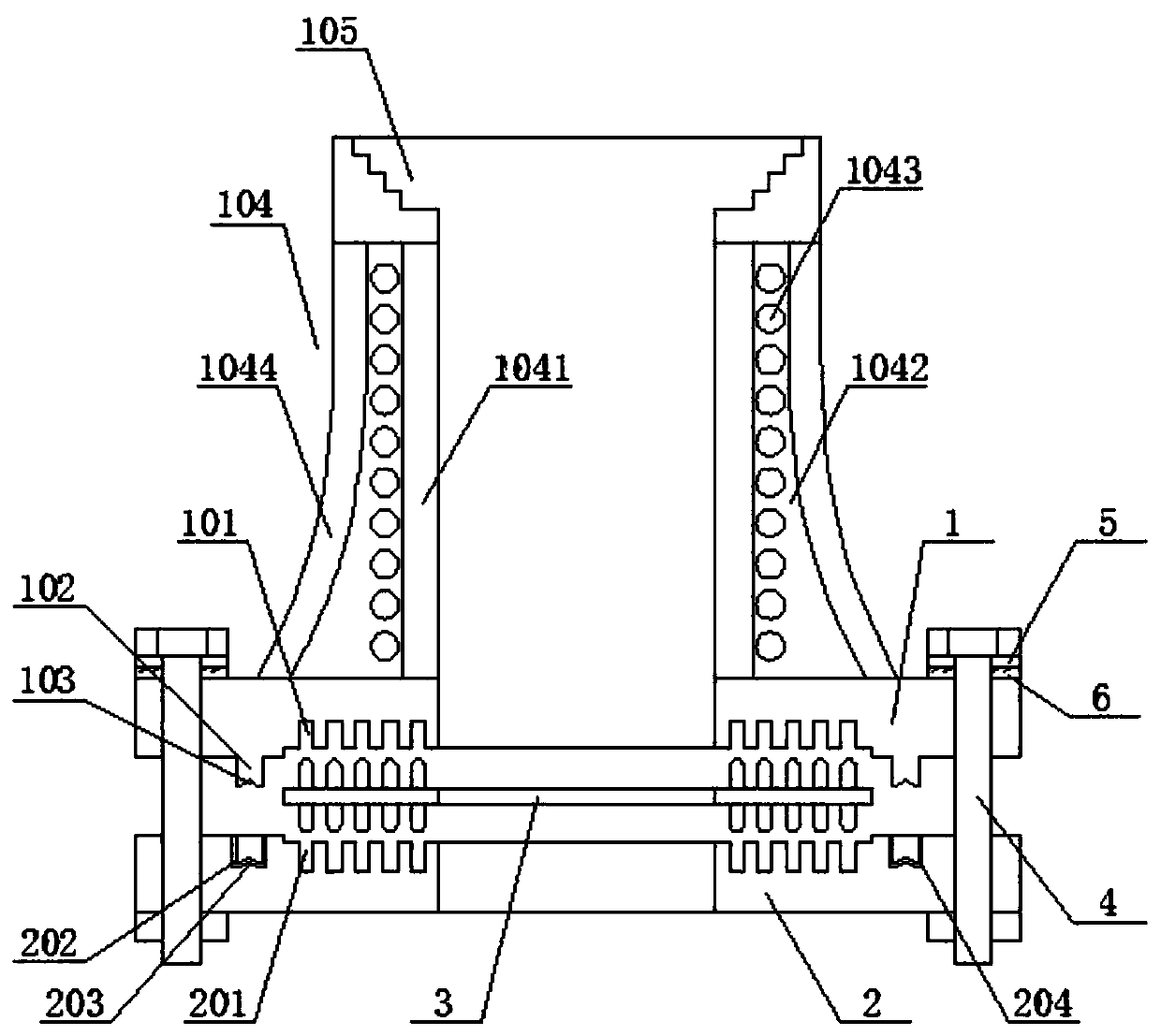

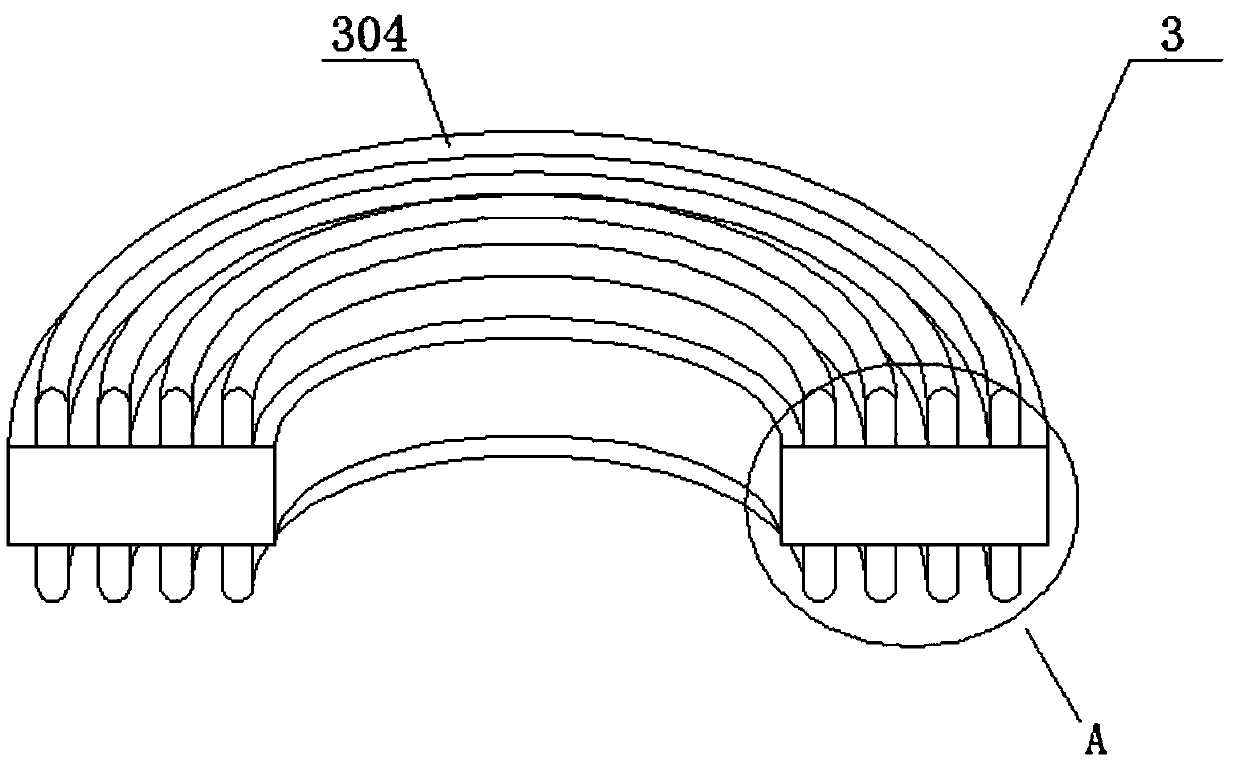

[0017] An interference fit flange such as figure 1 As shown, it includes a first flange 1 and a second flange 2 fixed by bolts 4 , and a self-adjusting gasket 3 is provided between the first flange 1 and the second flange 2 .

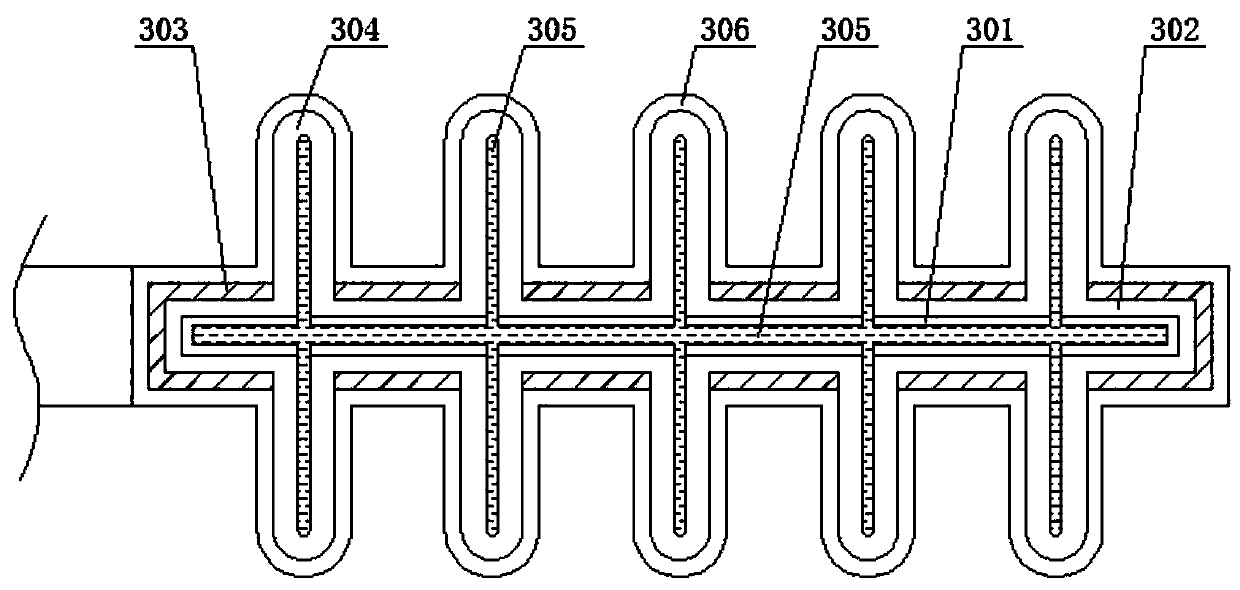

[0018] The self-adjusting gasket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com