Buried gas conveying pipeline leakage cross positioning method based on beam forming

A technology for cross positioning and gas transmission pipelines, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc. It can solve the problems of accurate leakage positioning, inability to meet buried pipelines, and inability to achieve accurate three-dimensional positioning. Precise positioning, solving the effect of insufficient precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

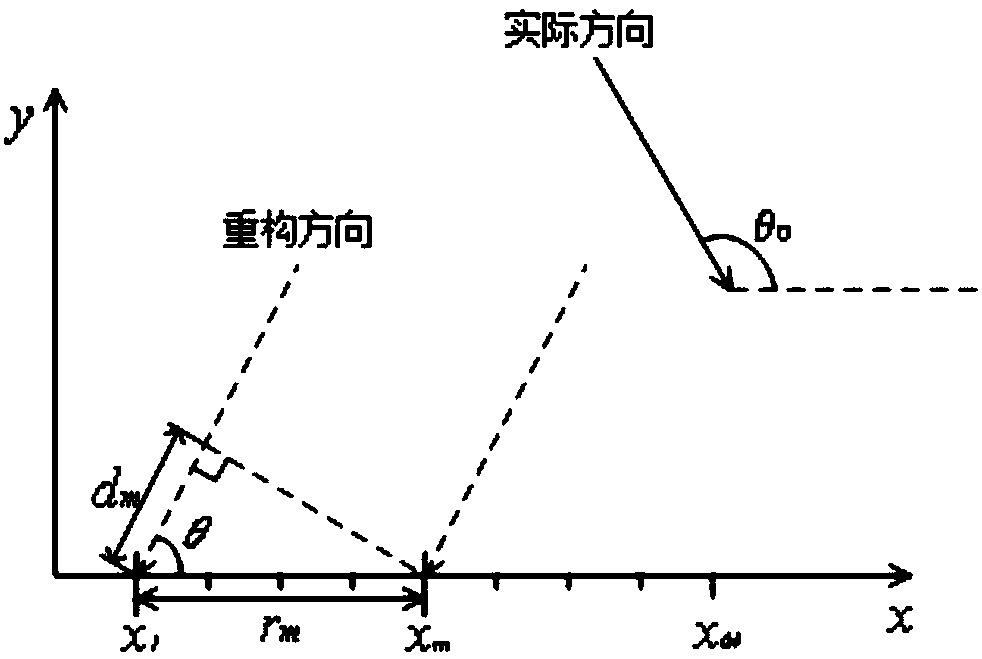

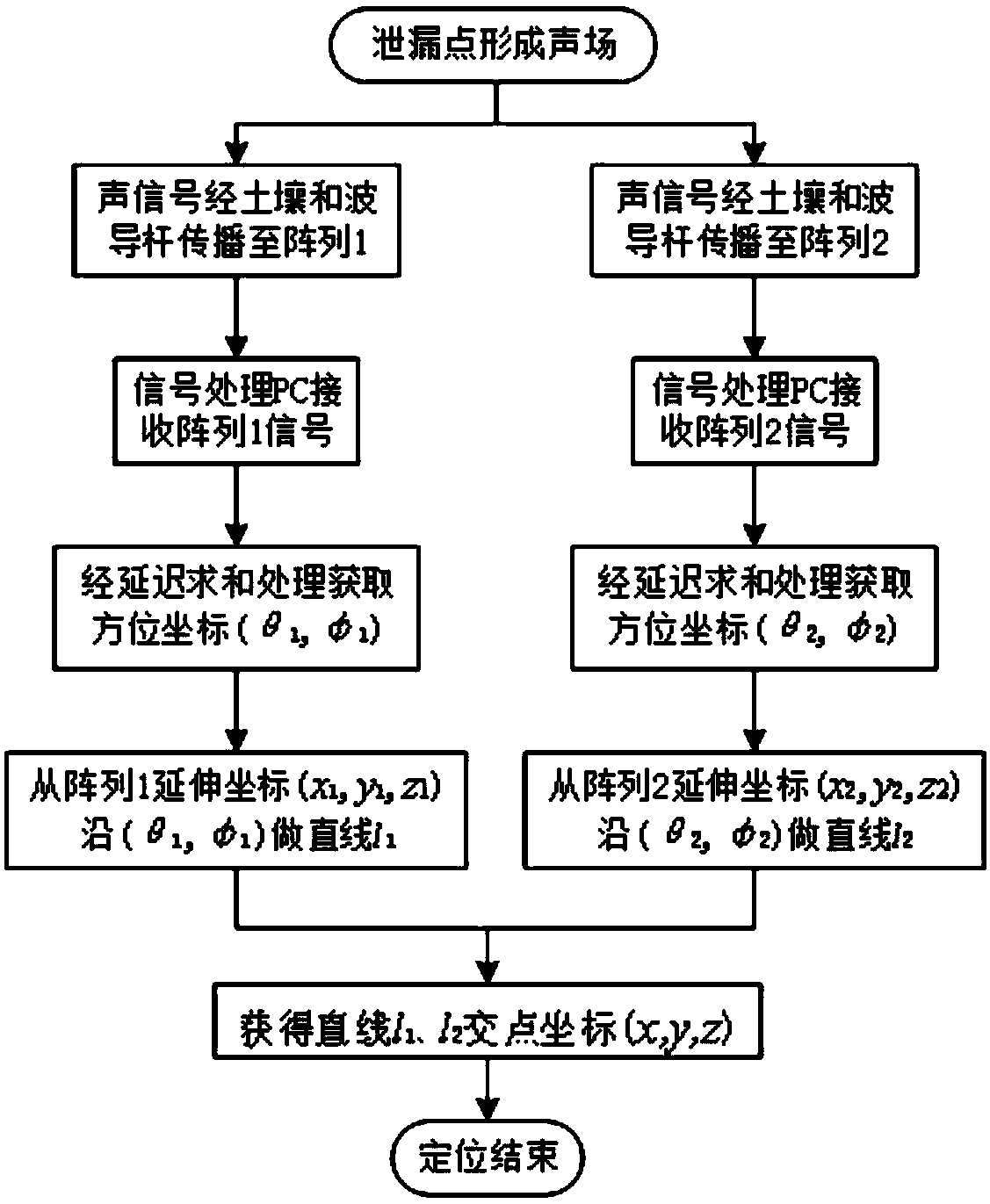

[0067] Based on the above existing technologies and design ideas and principles: see Figure 1-5 : A beamforming-based buried gas pipeline leakage cross-locating method in this embodiment, the method is based on the beamforming method, combined with the principle of cross-location to realize the spatial location of the sound source generated by the buried gas pipeline leakage positioning, thereby completing the positioning of the leakage point, wherein the cross positioning method comprises the following steps:

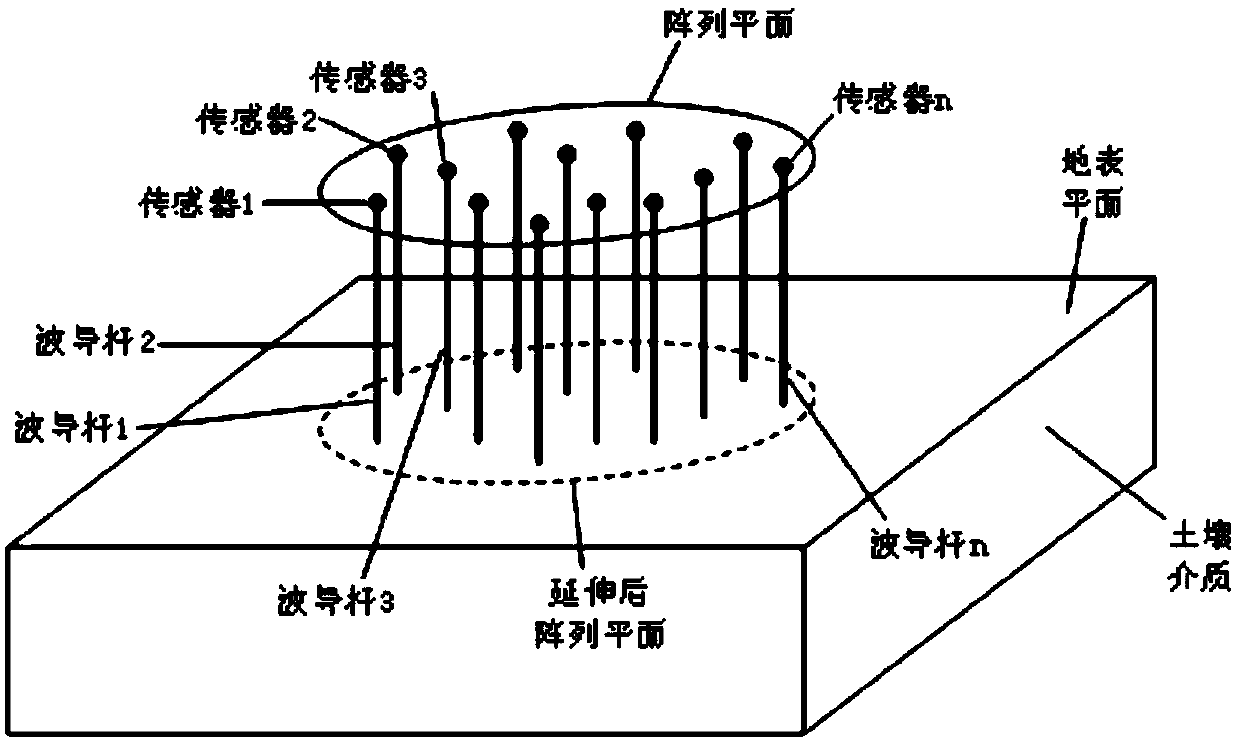

[0068] (1) First place two sensor arrays on the ground above the leaking pipeline and extend into the soil through the waveguide rod; the step (1) is specifically: the two sensor arrays are connected to one end of the waveguide The other ends of the two sets of waveguide rods of the sensor array are inserted into two different positions on the surface above the pipeline, so that the sensor array is still in the air medium, and the waveguide rods can transmit the sound...

Embodiment 2

[0085] The following is a further description of this embodiment with more specific data: a beamforming-based buried gas pipeline leakage cross-locating method in this embodiment uses a beamforming-based double-array cross-locating method for the sound source For the precise location of the leak, after obtaining the area where the sound source of the leak is located, the two sensor arrays, waveguide rods, and signal processing PC required for cross-location are set up in the area.

[0086] Among them, the two sensor arrays are arranged in a cross shape, and each sensor array is composed of 9 acoustic wave sensors, one of which is located at the intersection of the cross shape, and the remaining 8 sensors are evenly arranged on the two intersection lines of the cross shape, and the distance between the sensors is 0.2 m. Each sensor is connected to one end of a waveguide, a total of 18 waveguide rods with the same length. The other end of the waveguide rod is in close contact wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com