Device used for testing explosive grain shear force

A shear force, grain column technology, applied in the direction of using a stable shear force to test the strength of materials, measuring devices, instruments, etc., can solve the problem of the lack of effective detection methods for small shear forces, and limited data analysis and calculation capabilities. , the detection process and the complexity of the detection device, etc., to achieve the effect of protection and safety, easy operation of the device, and reduction of interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

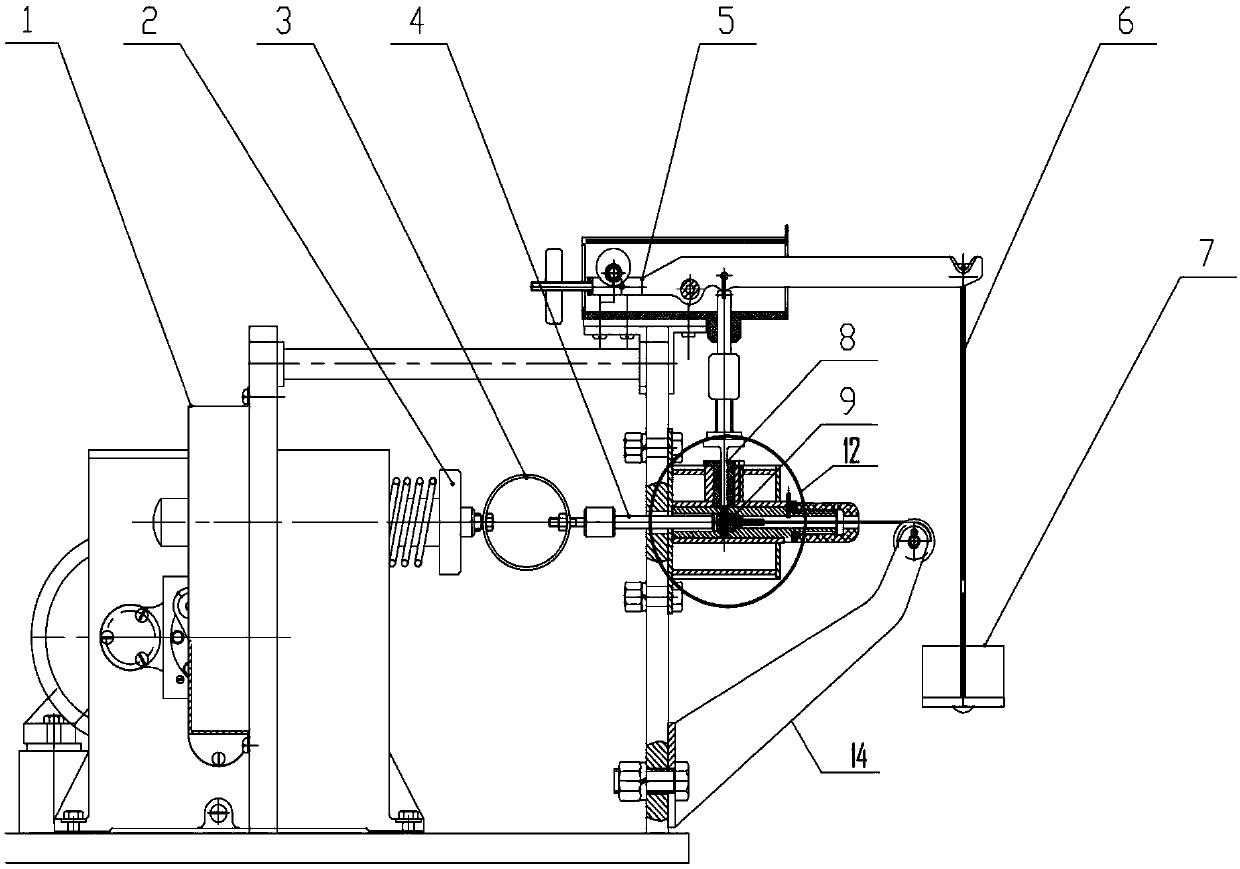

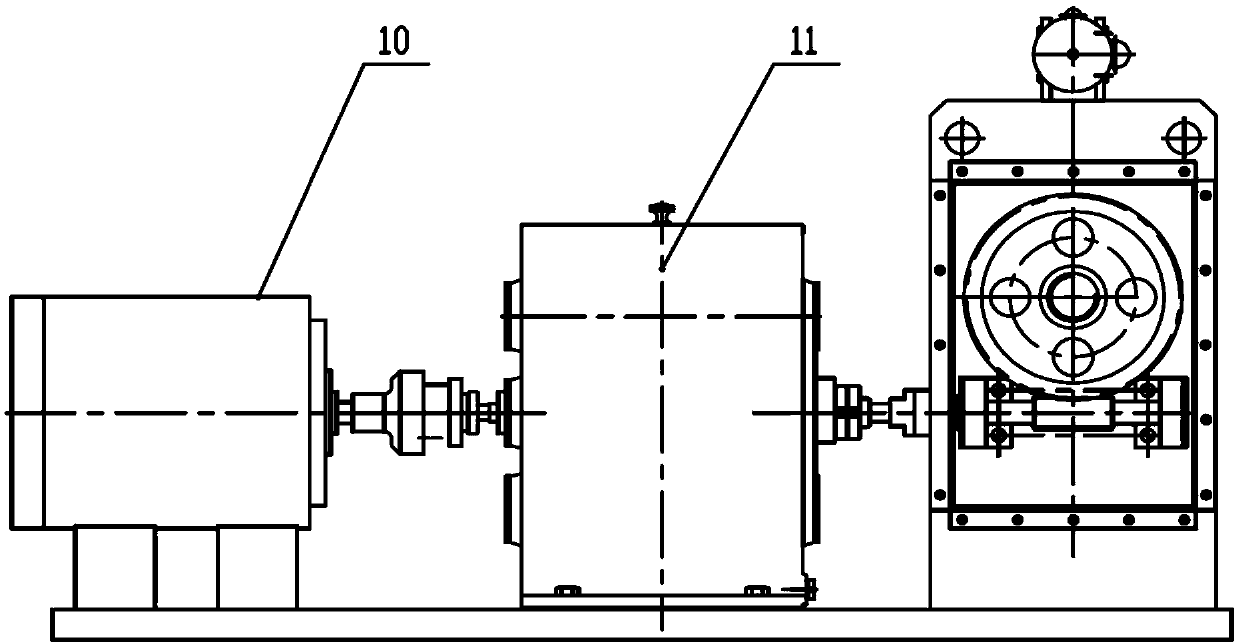

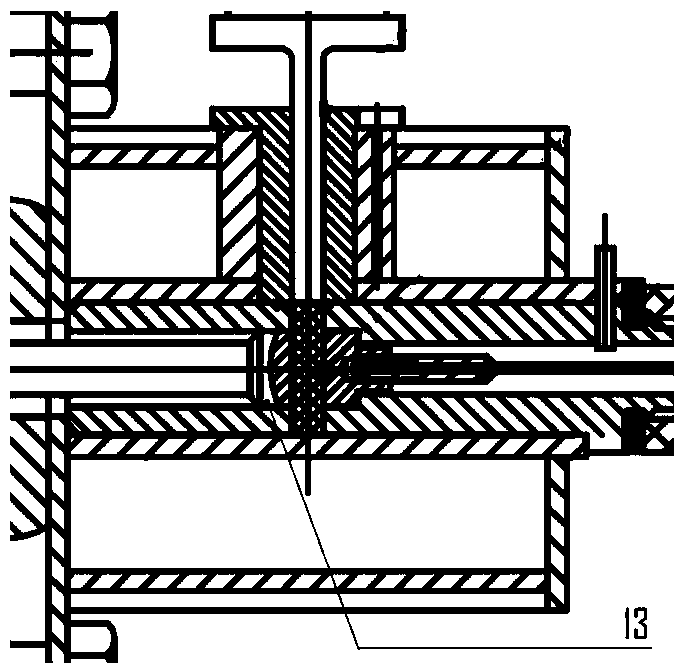

[0029] A device for testing the shear force of an explosive grain, comprising: a frame 1, a first pull rod 2, a shear force sensor 3, a second pull rod 4, a pre-pressure mechanism 5, a steel wire rope 6, a weight 7, and a pressure rod 8. Powder column 9, motor 10, gearbox 11, jacket 12, slider 13 and support frame 14;

[0030] The motor is used to provide pulling force to the device; the force generated by the motor is transmitted to the gearbox through the bearing, and the gearbox is used to adjust the pulling force; the gearbox is connected to the bearing of the frame, and the bearing meshes with the relevant gear to drive the first pull rod in the tension Left and right movement is realized under pulling; the shear force sensor is movably connected with the ends of the first pull rod and the second pull rod; Powder column;

[0031] The pre-pressure mechanism is composed of a connecting rod, a wire rope and a weight; one end of the connecting rod is installed movably, and t...

Embodiment 2

[0050]A device for testing the shear force of an explosive grain, comprising: a frame 1, a first pull rod 2, a shear force sensor 3, a second pull rod 4, a pre-pressure mechanism 5, a steel wire rope 6, a weight 7, and a pressure rod 8. Powder column 9, motor 10, gearbox 11, jacket 12, slider 13 and support frame 14;

[0051] The motor is used to provide pulling force to the device; the force generated by the motor is transmitted to the gearbox through the bearing, and the gearbox is used to adjust the pulling force; the gearbox is connected to the bearing of the frame, and the bearing meshes with the relevant gear to drive the first pull rod in the tension Left and right movement is realized under pulling; the shear force sensor is movably connected with the ends of the first pull rod and the second pull rod; Powder column;

[0052] The pre-pressure mechanism is composed of a connecting rod, a wire rope and a weight; one end of the connecting rod is installed movably, and th...

Embodiment 3

[0058] A device for testing the shear force of an explosive grain, comprising: a frame 1, a first pull rod 2, a shear force sensor 3, a second pull rod 4, a pre-pressure mechanism 5, a steel wire rope 6, a weight 7, and a pressure rod 8. Powder column 9, motor 10, gearbox 11, jacket 12, slider 13 and support frame 14;

[0059] The motor is used to provide pulling force to the device; the force generated by the motor is transmitted to the gearbox through the bearing, and the gearbox is used to adjust the pulling force; the gearbox is connected to the bearing of the frame, and the bearing meshes with the relevant gear to drive the first pull rod in the tension Left and right movement is realized under pulling; the shear force sensor is movably connected with the ends of the first pull rod and the second pull rod; Powder column;

[0060] The pre-pressure mechanism is composed of a connecting rod, a wire rope and a weight; one end of the connecting rod is installed movably, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com