Sleeve grouting defect ultrasonic detection device and method based on wavelet packet energy

A technology of sleeve grouting and ultrasonic testing, which is applied to the analysis of solids, materials, and instruments using sound waves/ultrasonic waves/infrasonic waves. It can solve problems such as complex structures, increased concealment of grouting defects, and damage to the integrity of precast concrete components. Low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

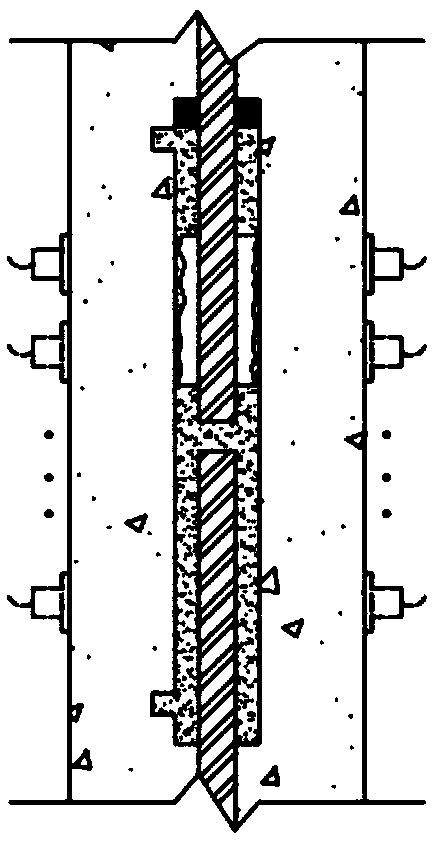

[0068] Embodiment 1 The relevant principle and device explanation of the test method of the present invention

[0069] In this embodiment, the principle of the ultrasonic detection method for steel sleeve grouting connection defects based on wavelet packet energy is as follows.

[0070] According to the characteristics of the ultrasonic detection signal, the wavelet packet analysis decomposes the high-frequency part and low-frequency part of the signal at the same time, adaptively selects the corresponding frequency band to match the signal spectrum, and improves the time-frequency resolution.

[0071] The wavelet packet analysis solves the problem that the frequency resolution is too low when the time resolution of the wavelet analysis is relatively high, and the wavelet packet analysis has more extensive application value.

[0072] Compared with the ultrasonic transmission detection signal of the sleeve grouting dense part, the energy received by the ultrasonic transmission ...

Embodiment 2

[0097] Example 2 The device and method of the present invention based on wavelet packet energy for the ultrasonic detection of sleeve grouting defects are used for the testing of steel sleeve grouting connection defects

[0098] In order to verify the effectiveness of the method of the present invention in detecting the grouting connection defect of the steel bar sleeve, the following test for detecting the grouting defect of the steel bar sleeve test piece was done.

[0099] This test designed 3 types of test specimens and 4 groups of 20 pieces in total: plain concrete + centering sleeve (SJ1 and SJ2), longitudinal reinforcement on both sides + centering sleeve (SJ3) and longitudinal reinforcement on one side + offset sleeve (SJ4 ), and according to the possible existence of steel sleeve grouting connection defects in actual engineering, the sleeve grouting defects are simplified and set as circumferential defects along the connecting steel bars. The size and defect settings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com