A metal ore overlying rock three-dimensional space stress calculation method under artificial pillar support

A technology of artificial mine pillar and calculation method, applied in calculation, design optimization/simulation, special data processing application, etc., can solve problems such as less tectonic stress and actual engineering deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

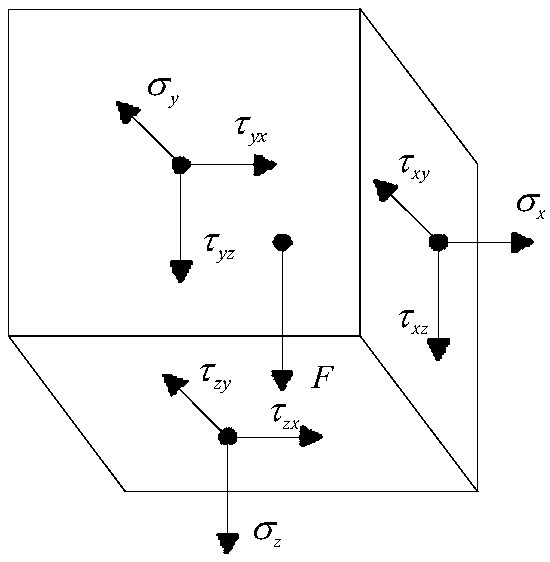

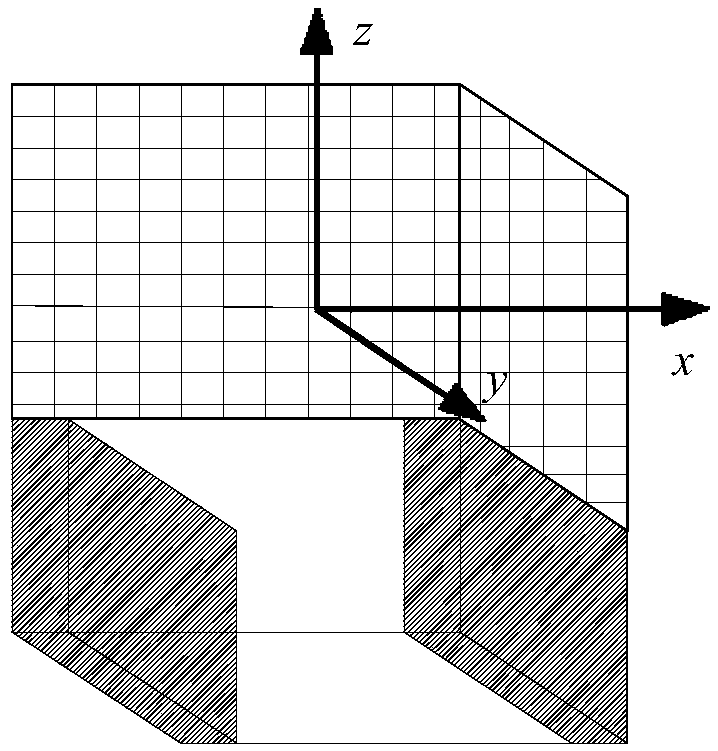

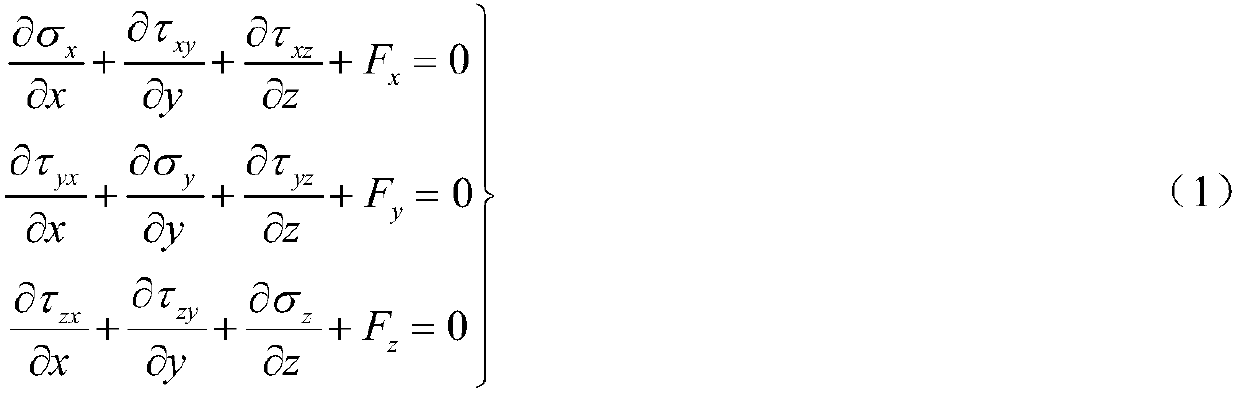

[0092] A method for calculating the three-dimensional space stress of the overlying rock of a metal mine under the support of artificial pillars. When the three-dimensional stress model of the overlying rock of the goaf is constructed, the roof of the goaf of the metal mine is regarded as the "surrounding support plate", according to In the actual geological conditions of metal mines, the overlying rock under the support of artificial pillars is regarded as a "slab", and the potential energy is obtained from the stress distribution, and then the potential energy of the entire space rock mass is calculated based on the principle of superposition of forces. Proceed as follows:

[0093] The first step: establish the spatial stress model of the overlying strata in the goaf. The spatial stress model of the overlying strata in the goaf is constructed based on the following assumptions:

[0094] ①Assuming that the overlying rock is continuous, that is, assuming that the volume of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com