Photoelectric hybrid separation off connector

An optoelectronic hybrid and connector technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device. , to achieve the effect of improving stability, eliminating influence and reducing fiber loss value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A high-life, low-loss photoelectric mixed separation and drop-off connector includes a separation plug and a separation socket.

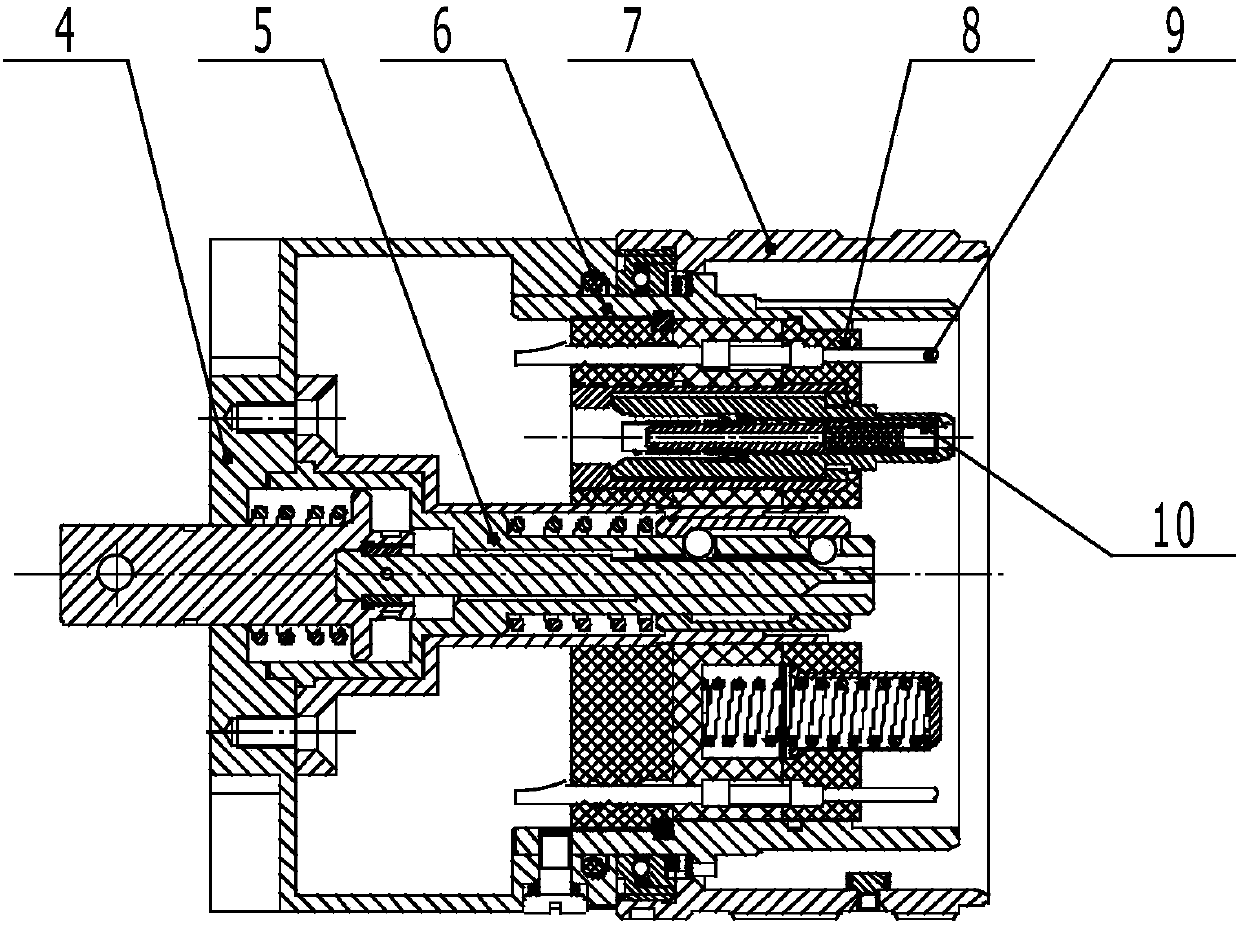

[0023] Such as figure 2 As shown, the split plug is composed of a tail sleeve 4 , a locking assembly 5 , a plug housing 6 , a cap part 7 , an insulator 8 , an electrical contact 9 and a floating fiber jack module 10 . The electrical contact 9 and the floating optical fiber jack module 10 are installed inside the plug insulator 8 to form an insulator part; the insulator part is installed inside the plug housing 6 to form a plug housing part; the plug housing part and the locking assembly 5 are installed to the tail by screws On the sleeve 4; the cap part 7 is installed between the tail sleeve 4 and the plug housing part.

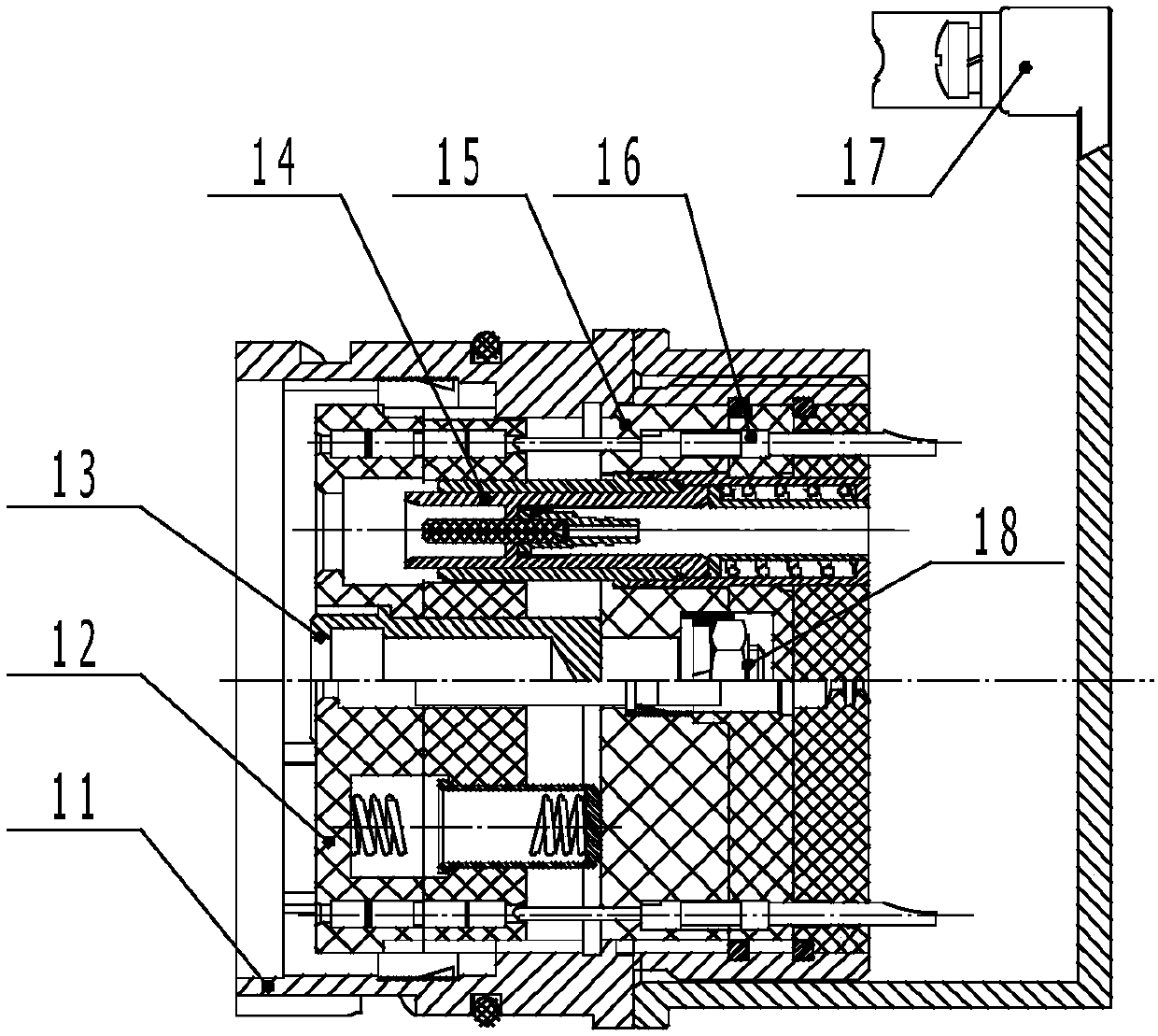

[0024] Such as image 3 As shown, the separated socket is composed of a socket housing 11 , a front insulator 12 , a locking sleeve 13 , a floating fiber optic ferrule module 14 , a rear insulator 15 , an electrical conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com