Straw pullout machine

A rod pulling machine and straw technology, applied in collectors, agricultural machinery and implements, solid separation, etc., can solve the problem of not being able to clean the soil at the bottom of the straw stubble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

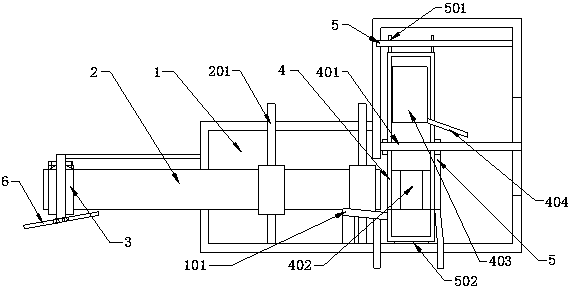

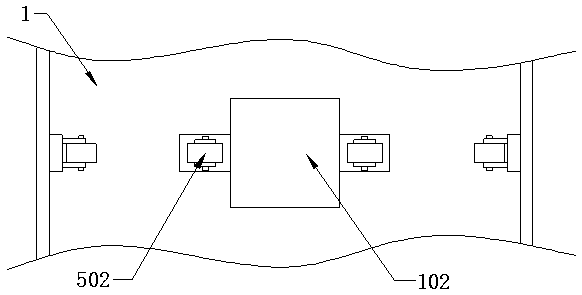

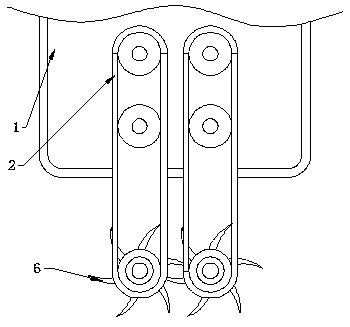

[0026] as attached figure 1 to attach Figure 8 Shown:

[0027] The invention provides a straw pulling machine, comprising: a harvesting box 1, a receiving board 101, a mud outlet 102, a material conveying belt 2, a fixed roller and a fixed rod 201, a fixed roller 3, a cleaning screen 4, and a cleaning screen Net fixing rod 401, guide plate 402, non-return plate 403, deflector plate 404, broken soil protrusion 405, grass-pointing claw 406, driving rod 5, driving tooth 501, supporting tooth 502, soil breaking claw 6 and baffle plate 7, harvesting The inner bottom surface of casing 1 is fixedly provided with collecting plate 101, and the bottom surface of harvesting casing 1 is provided with mud outlet 102, and the inside of harvesting casing 1 is fixedly provided with fixed roller fixed rod 201, and the outer periphery of fixed roller fixed rod 201 is fixed. A fixed roller 3 is provided, and the outer periphery of the fixed roller 3 is wound with a conveying belt 2. The side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com