A kind of supercritical extraction kettle capable of continuous feeding and discharging and extraction method

An extraction kettle and supercritical technology, applied in separation methods, solvent extraction, solid solvent extraction and other directions, can solve problems such as opening the lid, pressure relief, etc., and achieve the effects of high extraction efficiency, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

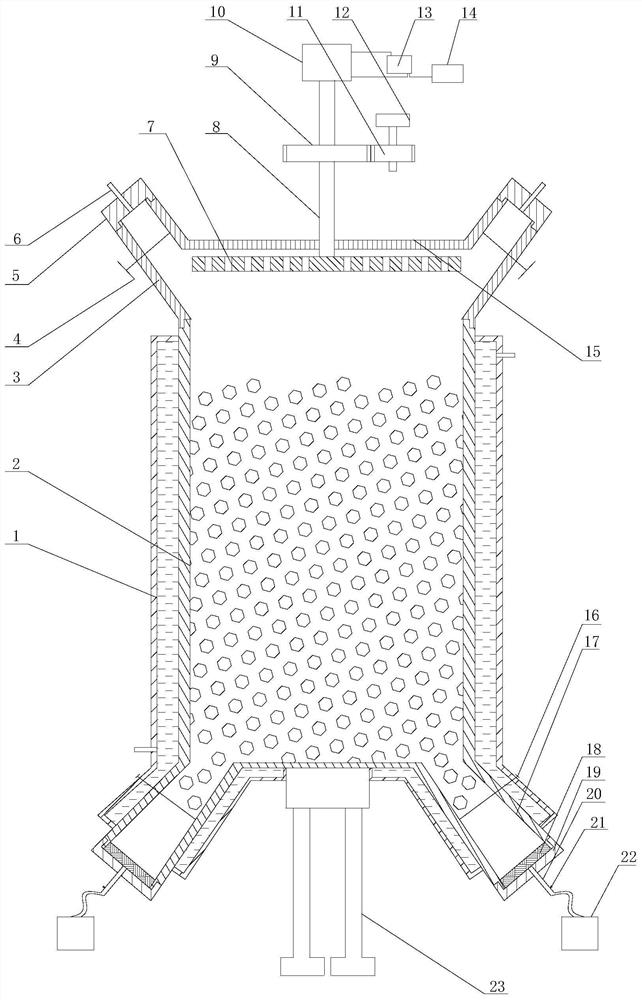

[0029] exist figure 1 Among them, the present invention is a supercritical extraction kettle that can continuously feed in and out materials. An extraction kettle 2 is installed on a bracket 23. A water bath tube 1 is arranged outside the extraction kettle 2. The side wall of the water bath tube 1 is processed into a hollow structure, and the hollow structure is filled with water. The lower end of the side wall of the water bath cylinder 1 is equipped with a water inlet pipe connected to the side wall of the water bath cylinder 1, and the upper end is installed with an outlet pipe connected with the side wall of the water bath cylinder 1. The top of the extraction kettle 2 is fixedly connected and installed with a screw fastening connector. The top cover 15, a sealing device is installed between the top cover 15 and the extraction kettle 2 to prevent the gas in the extraction kettle 2 from leaking out to cause insufficient pressure in the cylinder. The top cover 15 is processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com