Pipe bending machine

A pipe bender and straight pipe technology, which is applied in the field of pipe bending, can solve the problem that the pipe bender cannot meet the bending requirements of pipe fittings with space angles, and achieve the effects of easy implementation, simplified structure, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

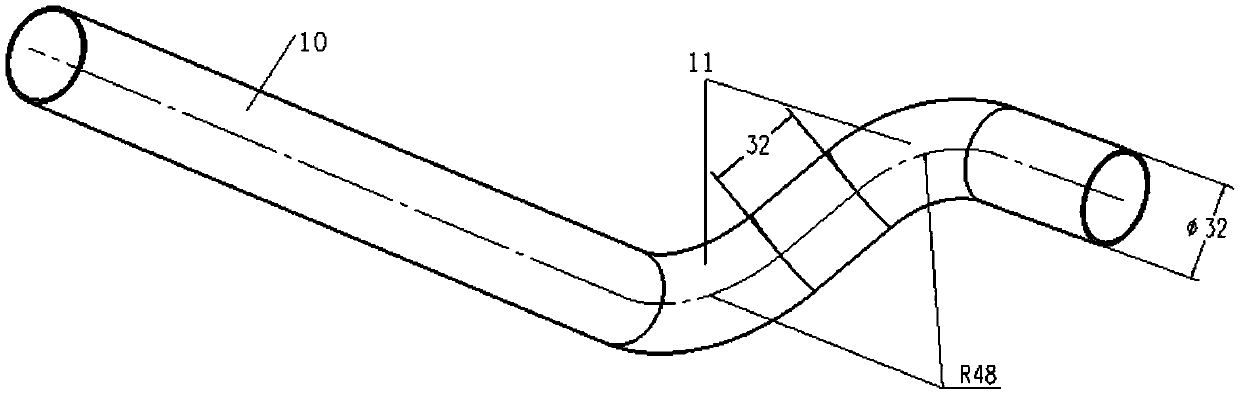

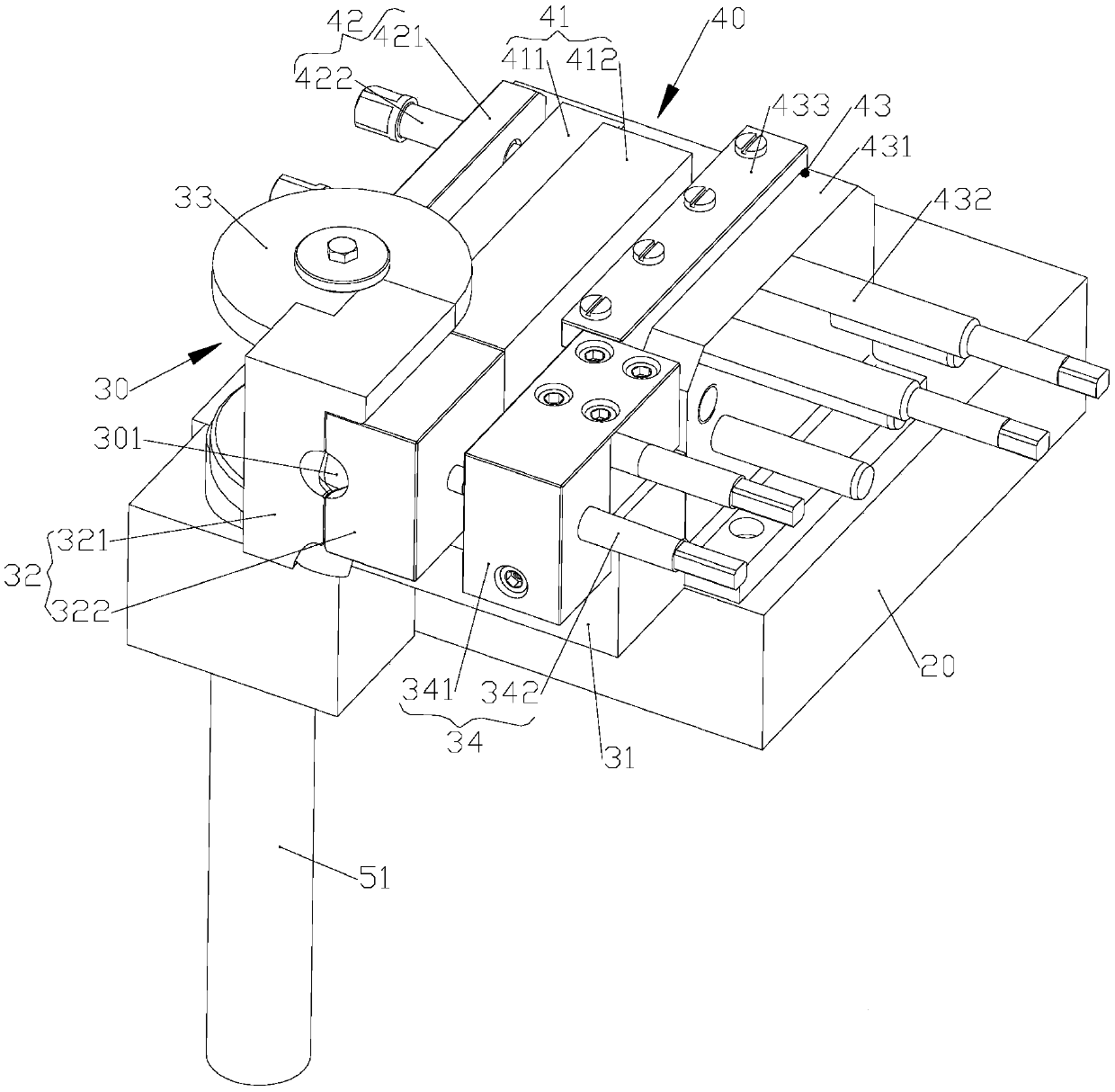

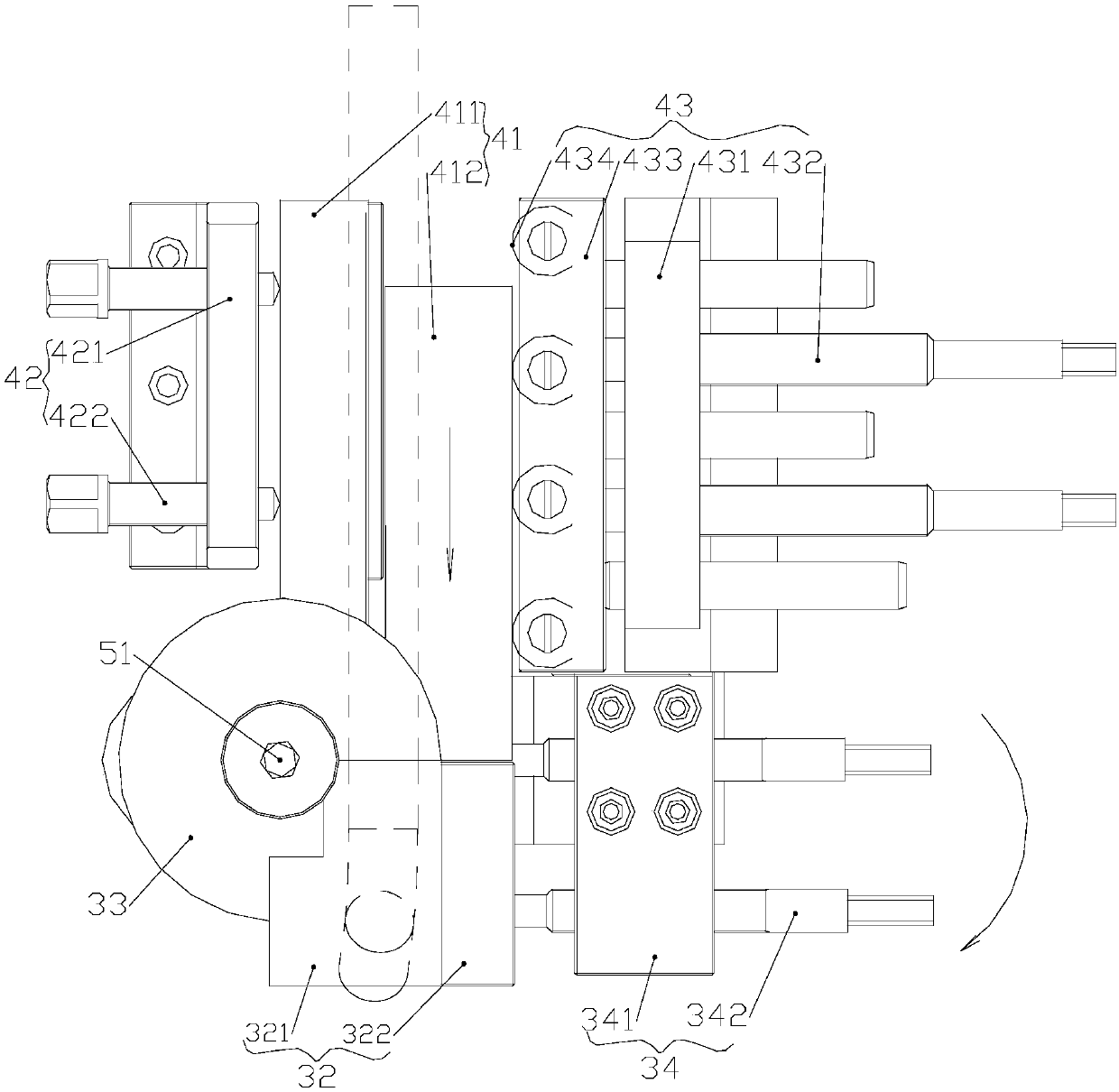

[0032] refer to Figure 2-3 , the preferred embodiment of the present invention provides a pipe bending machine for bending a linear straight pipe into a pipe bend 10 with two arcs 11, and the bending radii of the two arcs 11 are the same but the bending direction With a spatial angle, the pipe bending machine includes: a machine body 20, which is provided with a clamping seat assembly 30 that rotates around a fixed axis relative to the machine body 20 and a mounting seat assembly 40 connected to the machine body 20, clamping The seat assembly 30 is connected with a driving member to drive its rotation, and the clamping seat assembly 30 is provided with a through clamping channel 301, and the clamping channel 301 is used for clamping and locking the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap