Gear hanging wheel mechanism of internal-meshing forced movement chain roller mill

A technology of forced movement and internal meshing, applied in the direction of belts/chains/gears, gear teeth, driving devices, etc., can solve problems such as inability to improve accuracy, and achieve high processing accuracy and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

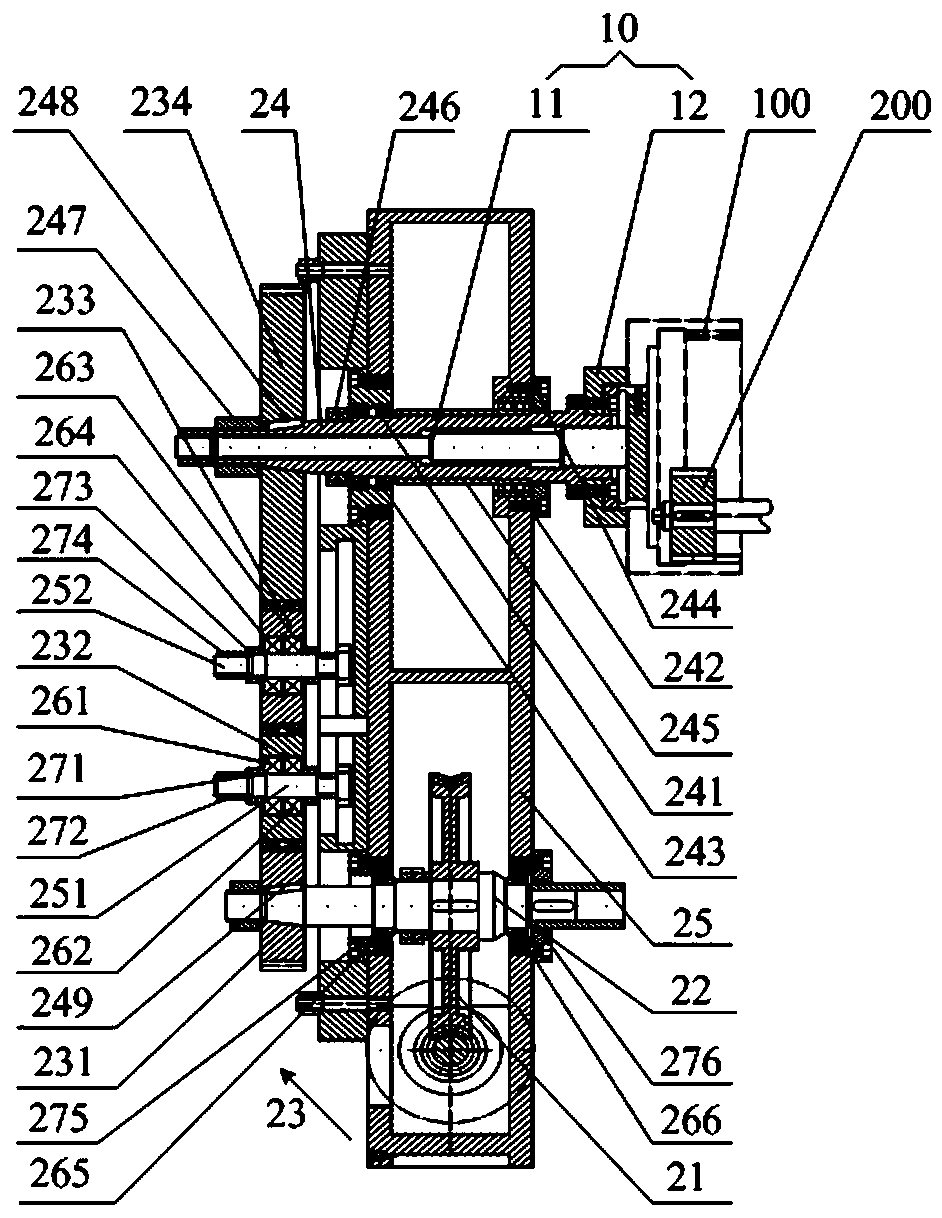

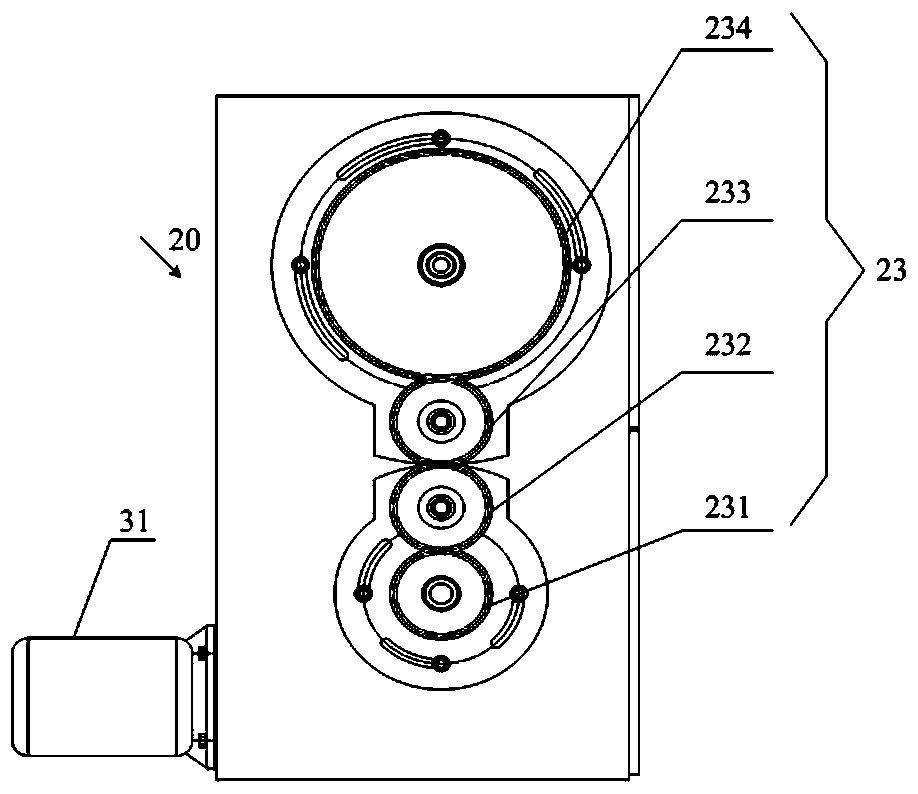

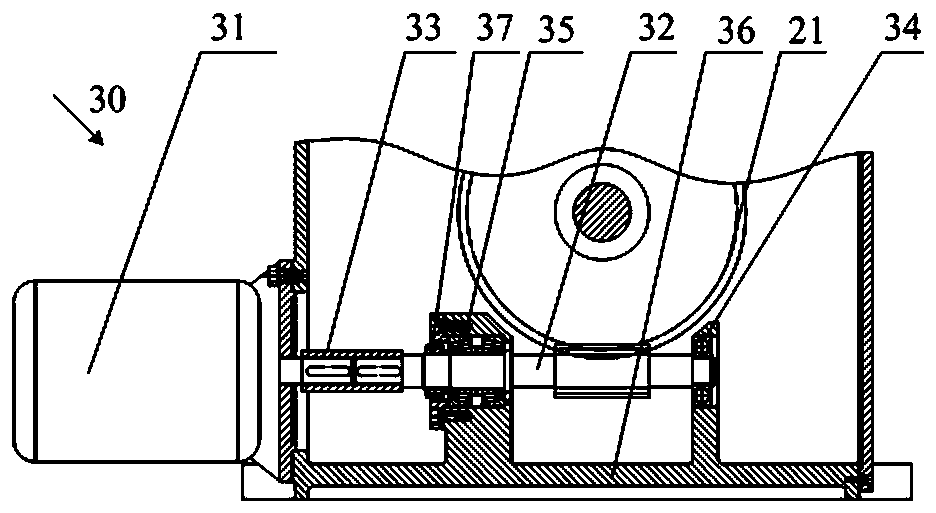

[0024] Such as Figure 1 to Figure 3 As shown, the first embodiment of the present invention proposes an internal meshing forced kinematic chain roller mill deceleration hanging wheel mechanism, which is used to install the processed inner ring gear 100 and uses a forced kinematic chain to synchronously drive the installed processed inner ring gear 100 and rollers. Grinding wheels 200 tumble each other, and the inner meshing forced kinematic chain tumbler mill deceleration hanging wheel mechanism includes a workpiece fixture 10 for installing the processed inner ring gear 100 , connected with the workpiece fixture 10 for installing the processed inner gear for the workpiece fixture 10 The transmission device 20 that transmits torque through the ring 100, and the power output device 30 connected with the transmission d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap