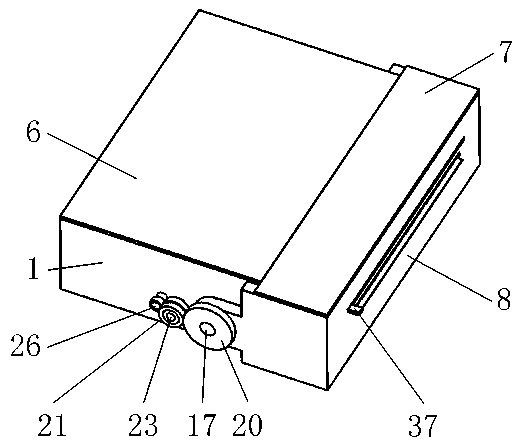

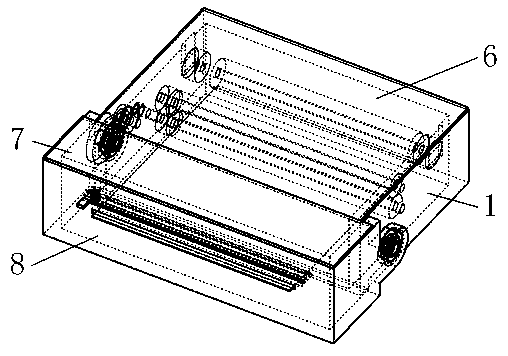

Household fresh-keeping film packaging machine

A technology of plastic wrap and packaging machine, applied in the directions of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of failing to meet the hygienic requirements of packaged food, contamination of plastic wrap, complicated operation, etc., to avoid injury and ensure hygiene requirements. , the effect of avoiding dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

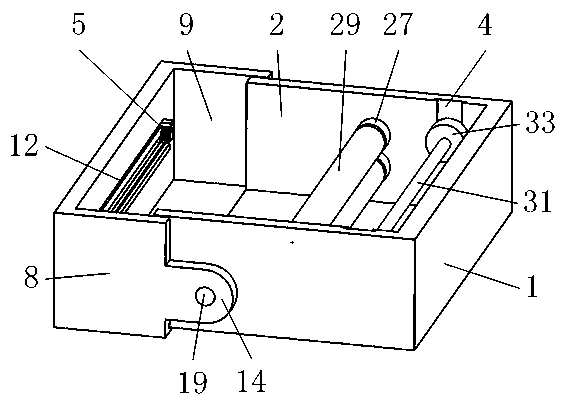

specific Embodiment approach

[0039]Specific implementation method: when extracting and cutting the fresh-keeping film, the hand acts on the movable casing 8, so that the movable casing 8 swings around the first pin shaft 19 and the second pin shaft 17; the two scroll springs 18 deform and store energy at the same time; The moving casing 8 drives the first gear 20 to rotate around the second pin shaft 17; the first gear 20 drives the second gear 21 to rotate; the second gear 21 drives the third gear 24 to rotate through the one-way clutch 22; the third gear 24 passes through the fourth Gear 25 and two fifth gears 27 drive two drums 29 to rotate; two drums 29 sandwich and drive the plastic wrap to be pumped outward; The amount of deformation of the coil spring 18 reaches the maximum, and the plastic wrap between the two cylinders 29 and the cutting pallet 34 tends to be slack. Fiddle with the fingers to fiddle with an end where the plastic wrap adheres to the cutting pallet 34, so that the plastic wrap and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com