Engine rotational inertia measuring device

A technology of measuring device and moment of inertia, applied in the direction of measuring device, machine/structural component test, static/dynamic balance test, etc., can solve problems such as poor stability, low measurement accuracy, poor adaptability, etc., and achieve good elasticity and guarantee The effect of transmission quality and precision, easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In describing the present invention, it should be understood that the terms "upper", "lower", "inner", "outer", "top", "bottom", "end", "front view", "side view", " The orientations or positional relationships indicated by "overlooking", "symmetrical", etc. are based on the orientations or positional relationships shown in the drawings, and are only for the convenience of describing the present invention and simplifying the description, and should not be construed as limiting the present invention.

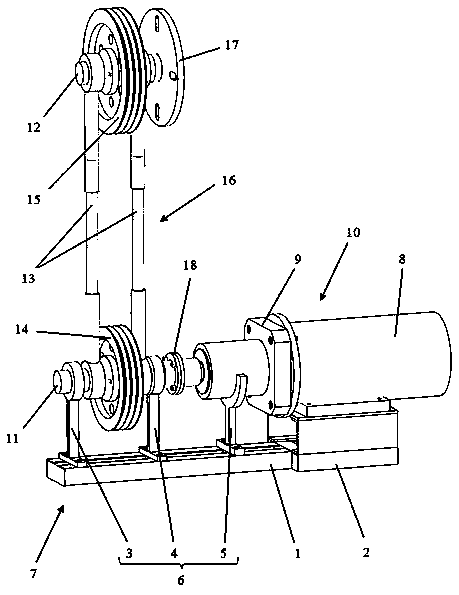

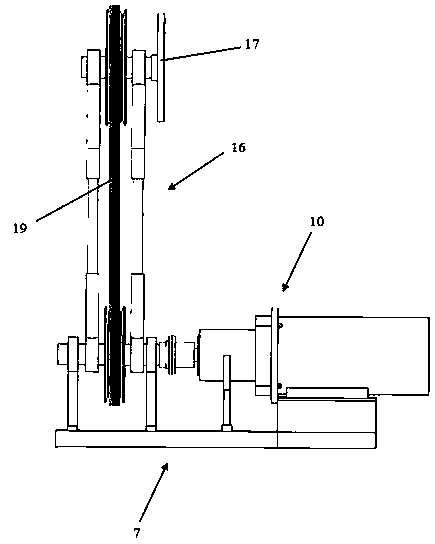

[0042] As a preferred embodiment of the present invention, it discloses a measuring device for moment of inertia of an engine, which is characterized in that it includes a body 7, a drive mechanism 10, a belt drive assembly 16 and a connecting flange 17; the body 7 includes a base and The support member 6 installed on the upper end of the base; the drive mechanism 10 includes a motor 8 and a reducer 9, and the drive mechanism 10 is placed on the base; the belt drive assembly...

Embodiment 2

[0044] As the best embodiment of the present invention, such as Figure 1 to Figure 6 As shown, the engine moment of inertia measuring device of the present invention includes a body 7, a drive mechanism 10, a belt drive assembly 16 and a connecting flange 17;

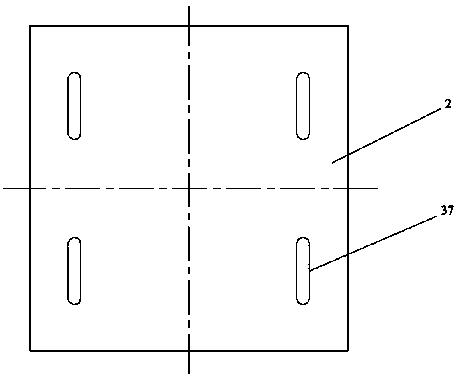

[0045] The body 7 includes a base A1, a base B2 and a support member 6. The base A1 and the base B2 are arranged adjacent to each other, and the connection and detachment of the two bases can be realized by bolts. The upper end of the base B2 is provided with four Fixed waist-shaped hole 37, the support member 6 includes support seat one 3, support seat two 4 and support seat three 5, all installed on the base A1;

[0046] The drive mechanism 10 includes a motor 8 and a reducer 9, the output end of the motor 8 is connected in transmission with the reducer 9, and the base of the motor 8 and the base B2 are adjustable connected through the waist-shaped hole 37, which can be adjusted according to the actual situation. Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com