Defect displaying method in back light detection

A defect display and backlight technology, which is applied in the direction of optical defect/defect test, material analysis through optical means, measurement device, etc., can solve the problem of low efficiency of BLU defect detection, relieve human eye fatigue, improve efficiency and accuracy , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

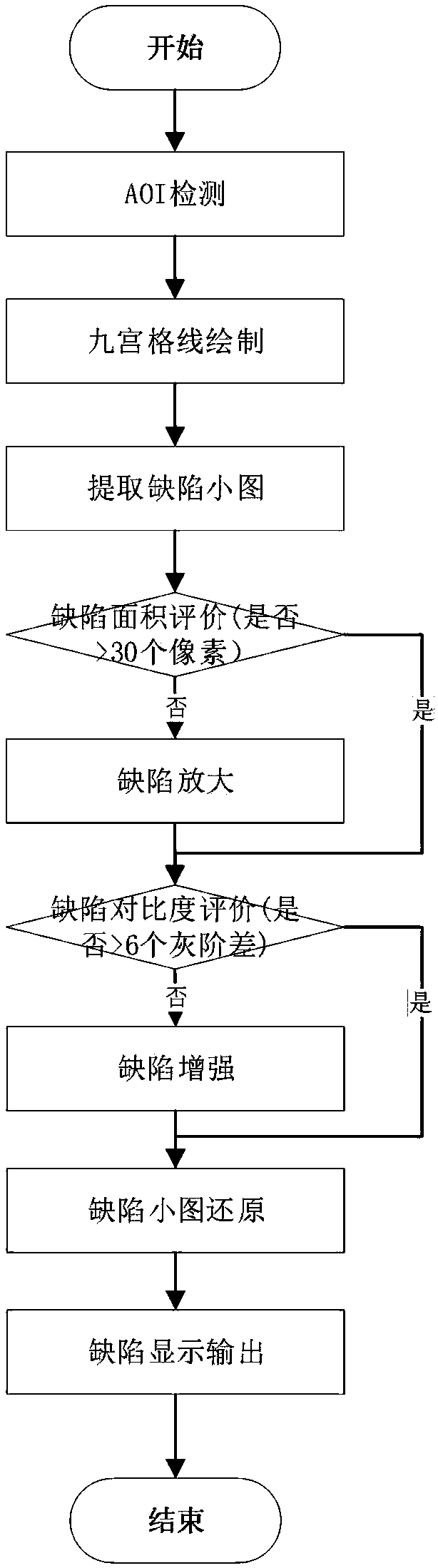

[0031] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0032] The design process of the existing BLU defect AOI detection system is generally divided into five processes: personnel loading, AOI image detection, personnel re-judgment of defects, defect marking, and personnel unloading. In these five processes, the time for personnel loading and unloading, AOI imaging detection and defect marking is basically fixed and will not change much, but the process of personnel re-judgment is subject to the type, size and area of defects. AOI detection Only the coordinates on the map are given, and the actual characteristics of the defect have to be observed repeatedly by human eyes. Due to the small size and low contrast of the backlight defect, it will be very time-consuming to observe the defect with human ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com