A High Precision Rogowski Coil

A Rogowski coil, high-precision technology, used in coils, electrical components, voltage/current isolation, etc., can solve problems such as inconvenient operation and long adjustment process, and achieve high practicability, improved position error and accuracy, and improved measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

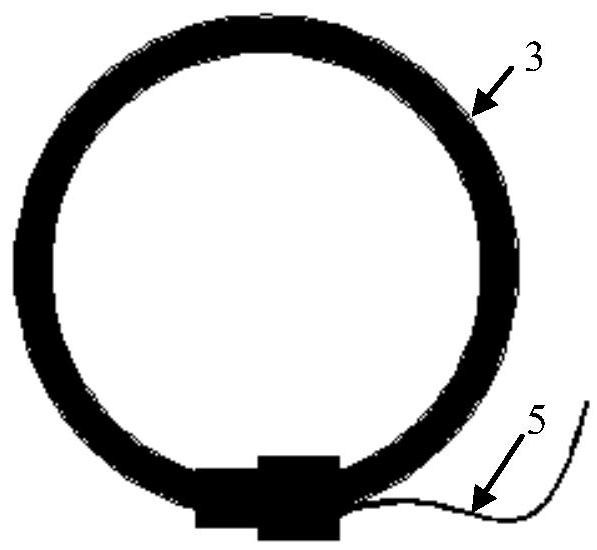

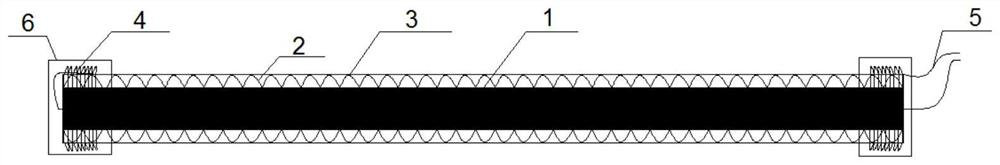

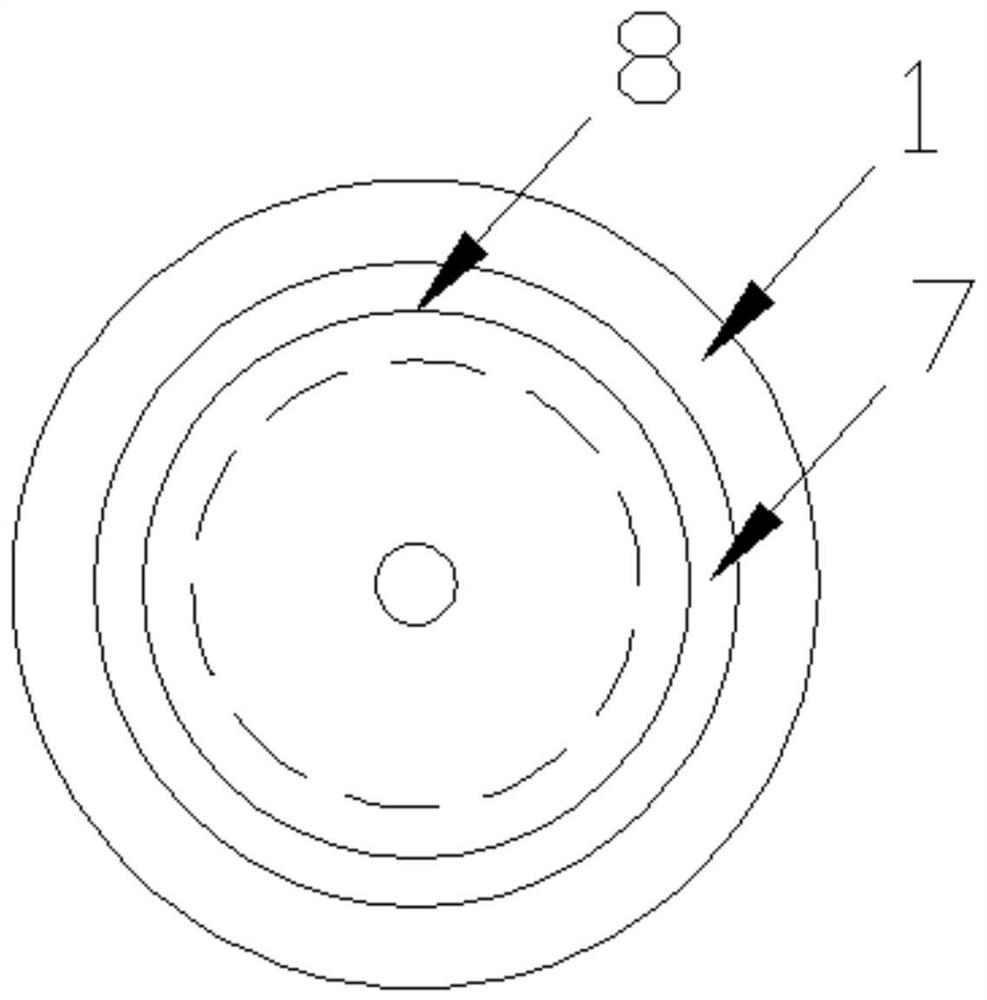

[0029] Such as Figure 1 to Figure 4 shown (for ease of illustration, figure 2 The flexible skeleton is not shown), the present invention is a high-precision Rogowski coil, comprising an annular body composed of an ignition wire 1, an enameled wire 2 and a silicone tube 3 arranged sequentially from the inside to the outside, and the enameled wire 2 is wound on the ignition wire 1 , the two ends of the ignition wire 1, the enameled wire 2 and the silicone tube 3 are connected through the joint 6, and the compensation coil 4 and the lead wire 5 are arranged in the joint 6, and one end of the compensation coil 4 is connected with the enameled wire 2, and the other end is connected with the lead wire 5; A flexible skeleton 7 is arranged on the inner side of the ring of the live wire 1, and a wire centering mechanism is fixedly arranged on the flexible skeleton 7. The wire centering mechanism includes a conical housing 8 fixed on the flexible framework 7, the large end of the con...

Embodiment 2

[0031] The difference from Embodiment 1 is that, as Figure 5 , Figure 6 As shown, the wire centering mechanism includes two pairs of clamping rods 9 fixed on the flexible skeleton 7, and the dimensions and specifications of all the clamping rods 9 are the same; one end of all the clamping rods 9 is fixed on the inner ring of the flexible skeleton 7, and all the clamping rods 9 The other ends of the coils are fixedly connected to each other and the connection point is located on the central axis of the annular Rogowski coil.

Embodiment 3

[0033] The difference from Embodiment 1 is that, as Figure 7 As shown, the wire centering mechanism includes two sections of elastic sliver 10 fixed on the inner side of the ring of the flexible skeleton 7, and the elastic sliver 10 is in a semi-circular shape; four pressure sensors are arranged in the elastic sliver 10 in a central circular array of Rogowski coils. 11. The pressure sensor 11 is fixed on the ring wall of the inner ring of the flexible skeleton 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com