Cable laying equipment with automatic pay-off and ground-breaking functions for underground cable

An automatic and functional technology, applied in ground cable installation, cable installation, etc., can solve the problems of low automation, inability to carry out at the same time, reduce embedding efficiency, etc., achieve high automation, compact structure, and reduce workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

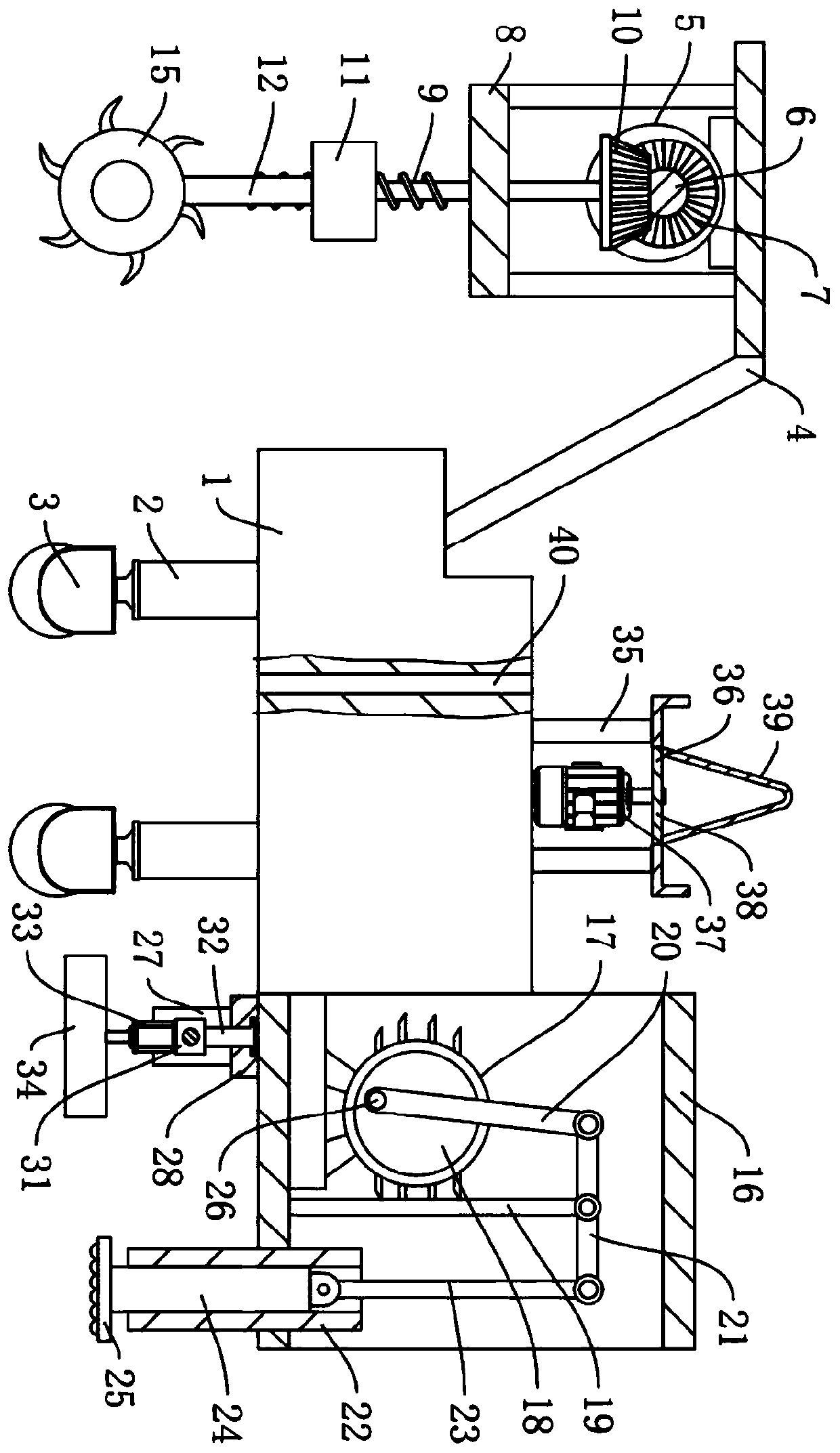

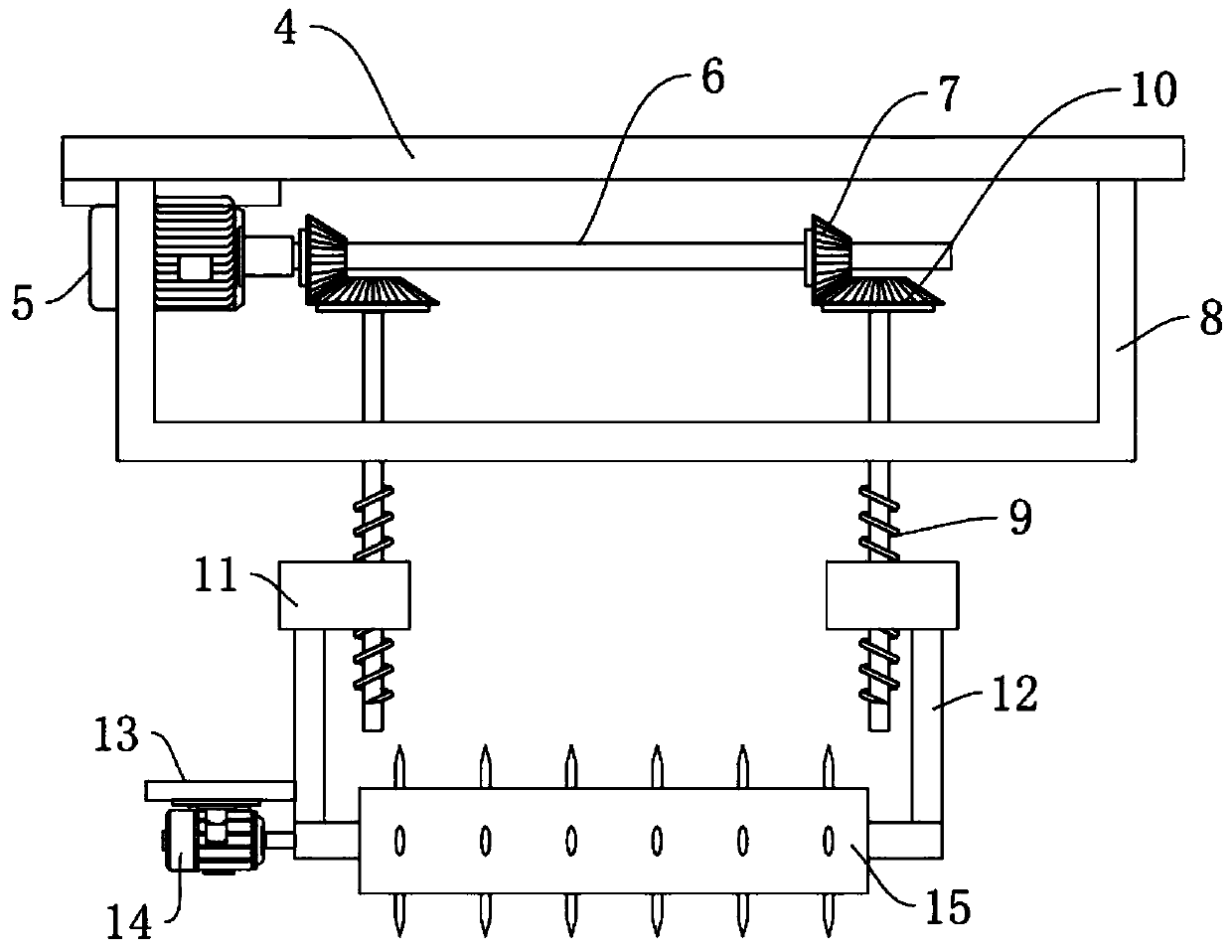

[0057] Example: When in use, turn on the power, according to figure 1 as well as figure 2It can be seen that the first servo motor 5 is placed under the beam of the bracket 4, the rotating rod 6 is placed on the driving end of the first servo motor 5, a pair of active bevel gears 7 is placed on the rotating rod 6, and the mounting frame 8 is placed under the beam of the bracket 4 wall, and located below the first servo motor 5, a pair of threaded screw rods 9 are inserted in the mounting frame 8, and a pair of driven bevel gears 10 are arranged on one side end of a pair of threaded screw rods 9, and are connected with the active umbrella The gears 7 are meshed, a pair of moving seats 11 are placed on the other end of a pair of threaded screw rods 9, the first servo motor 5 receives the signal from the motor driver, and the driving end rotates clockwise, synchronously driving the rotating rod 6 Rotate, at this time the active bevel gear 7 sleeved on the rotating rod 6 rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com