Cutter head lifting structure and hay mower with same

A lifting structure and cutter head technology, which is applied to harvesters, agricultural machinery and tools, cutters, etc., can solve the problems of loose locking and increased costs, and achieve the effect of compact structure, convenient adjustment, and quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

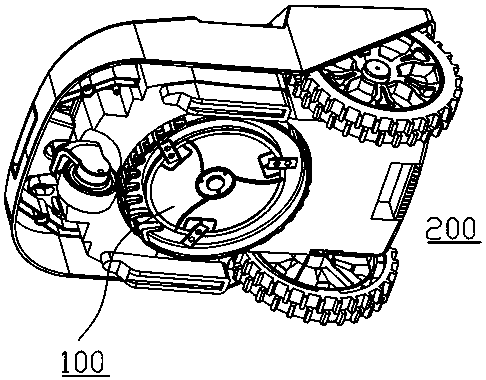

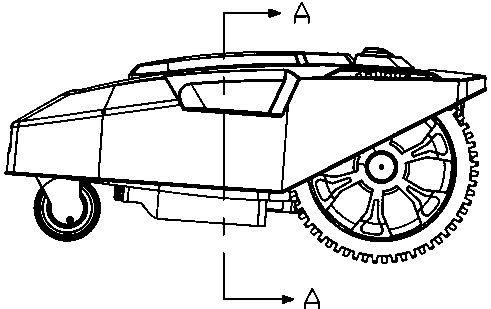

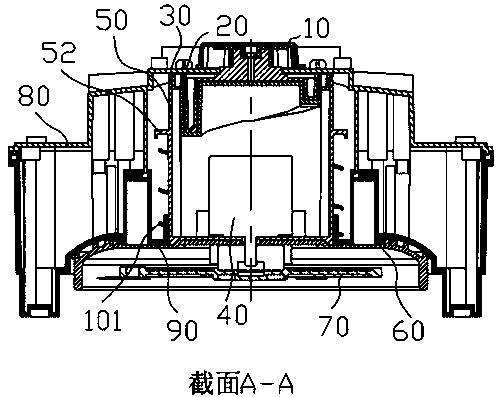

[0027] see Figure 1-7 , in an embodiment of the present invention, a cutter head lifting structure includes a cutting machine body 200; the cutting machine body 200 includes a base 90 and an upper shell 80 that are fixedly connected to each other, and the shell composed of the base 90 and the upper shell 80 is nested There is a cutterhead lifting assembly 100, and the cutterhead lifting assembly 100 includes a vertical moving part 1000 and a lifting spring 101; the vertical moving part 1000 includes a cutterhead 70, and the cutterhead 70 is connected to the output shaft of the cutterhead motor 40, and the cutterhead 70 outside cover is provided with cutter head cover 60, and cutter head cover 60 is protected to cutter head 70; Described cutter head cover 6 is fixedly connected with motor cover 50 by bolt, and motor cover 50 is set on the outside of cutter head motor 40, and cutter head The motor 40 is fixedly connected with the motor cover 50; the cutter head cover 60 is nest...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that a lifting knob 10 is provided above the rotating block 20, and a block 23 is fixedly connected to the upper end surface of the rotating block 20, and the block 23 is clamped and fixed with the lifting knob 10. Realize the rotation of the rotating block 20, and then realize the lifting of the cutter head 70, and the adjustment is convenient and efficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com