Bundling machine for mechanically picking straw rods

A technology of baler and straw, which is applied in the field of baler for mechanized picking up straw, which can solve the problems of straw easy to fall, reduce the efficiency of picking up straw, and pick up unclean, so as to avoid the falling of straw, Improved stability and pickup efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

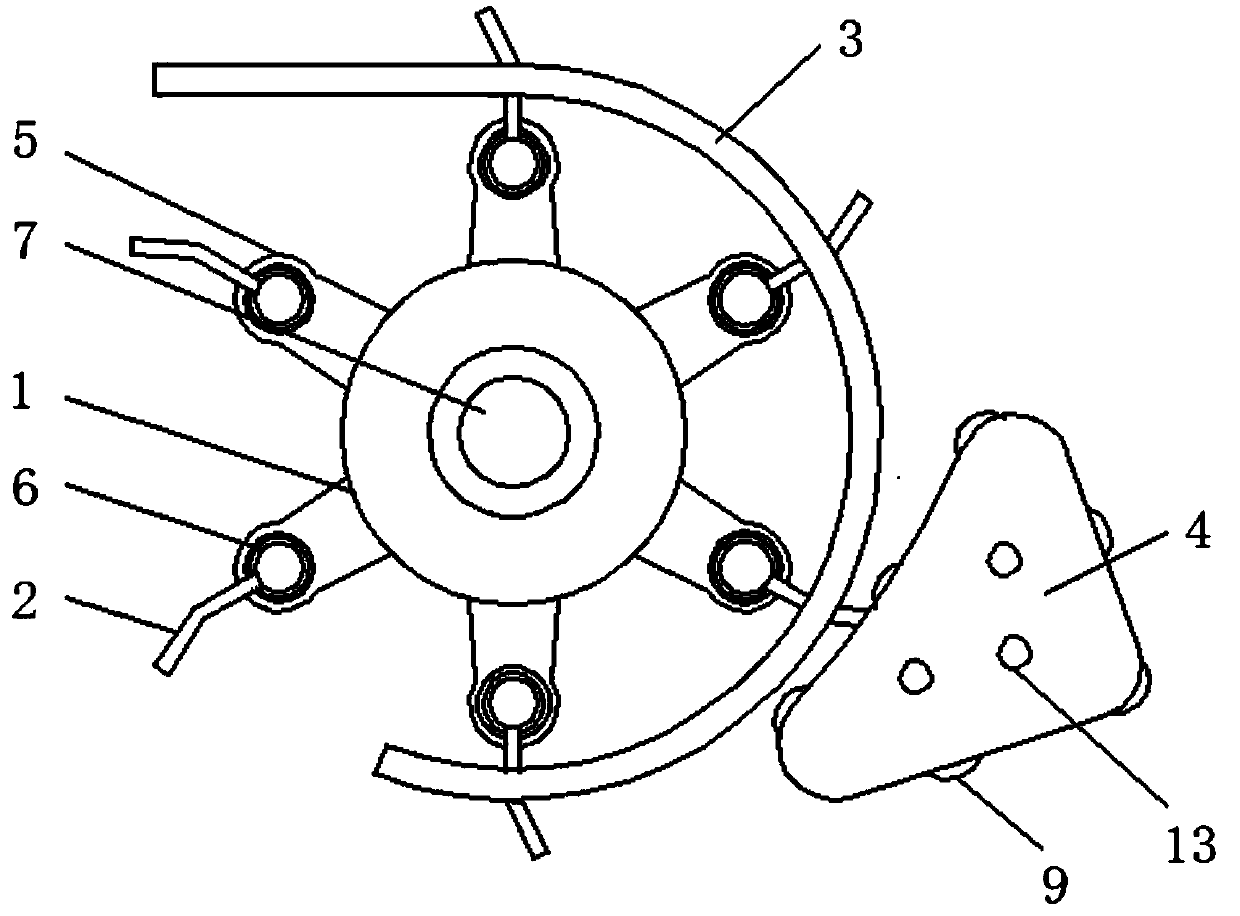

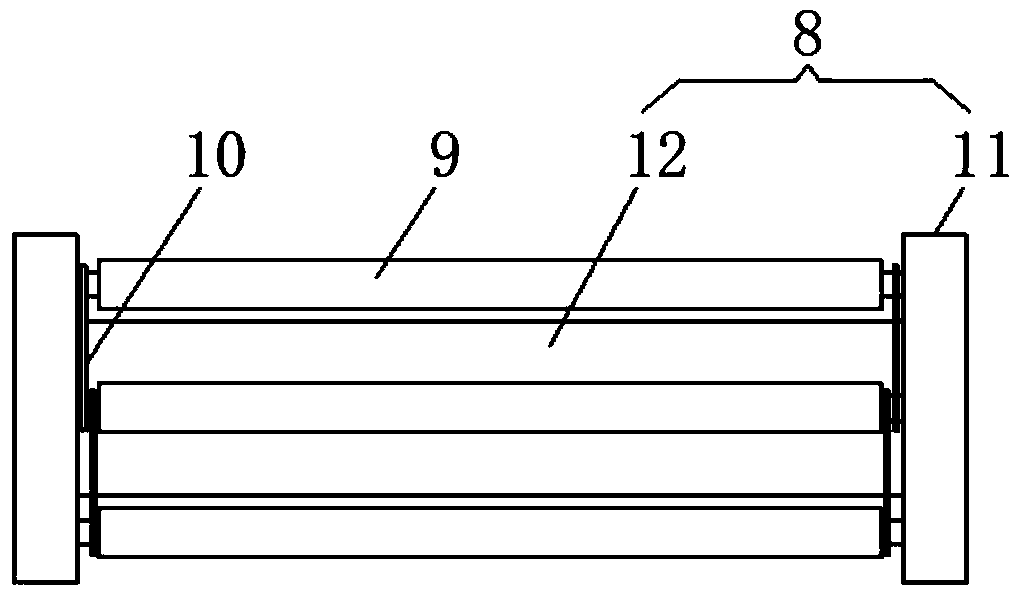

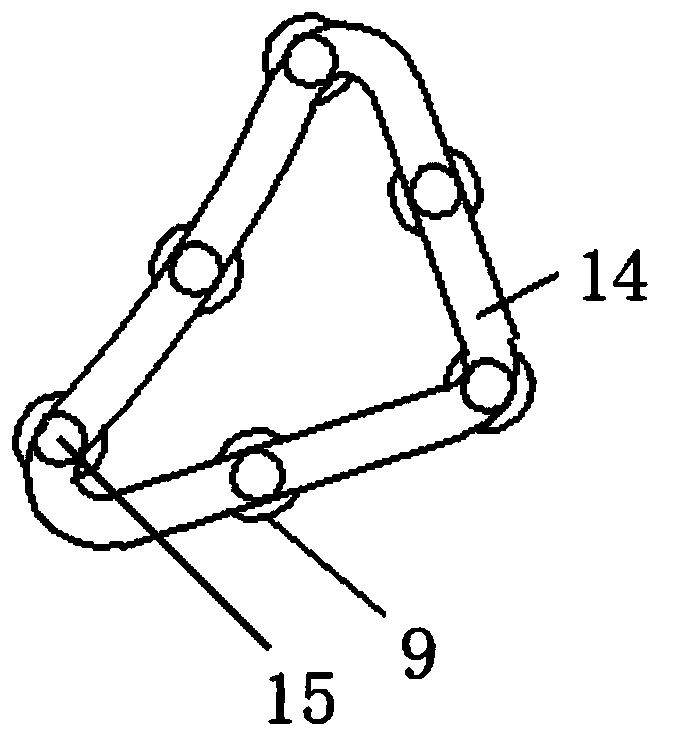

[0017] see Figure 1-3 The present invention provides a technical solution: a baler for mechanized picking up grass stalks, comprising a weed wheel 1, a weed bar 2, a weed retaining frame 3 and an auxiliary grass pressing mechanism 4, the surface of the weed wheel 1 is set There are installation heads 5 evenly distributed in a ring shape, the surface of the installation head 5 is provided with a movably connected weed lever 2, and a torsion spring 6 is provided at the connection between the weed lever 2 and the installation head 5, and the torsion spring One end of 6 is fixedly connected with weeding bar 2 and the other end is fixedly connected with installation head 5, and the center of described weeding wheel 1 is provided with rotating shaft 7, and described weed retaining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com