Automatic exhaust gas removing device for attracting paint particles through static electricity to prevent clogging

An anti-clogging and automatic technology, applied in the fields of combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of strengthening the labor intensity of staff, difficult to clean the filter screen, reducing the efficiency of exhaust gas filtration and purification, etc., to promote the collection of deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0028] like Figure 1-6 As shown in the figure, the present invention provides a technical solution for an automatic degassing device that uses electrostatic suction paint particles to prevent clogging:

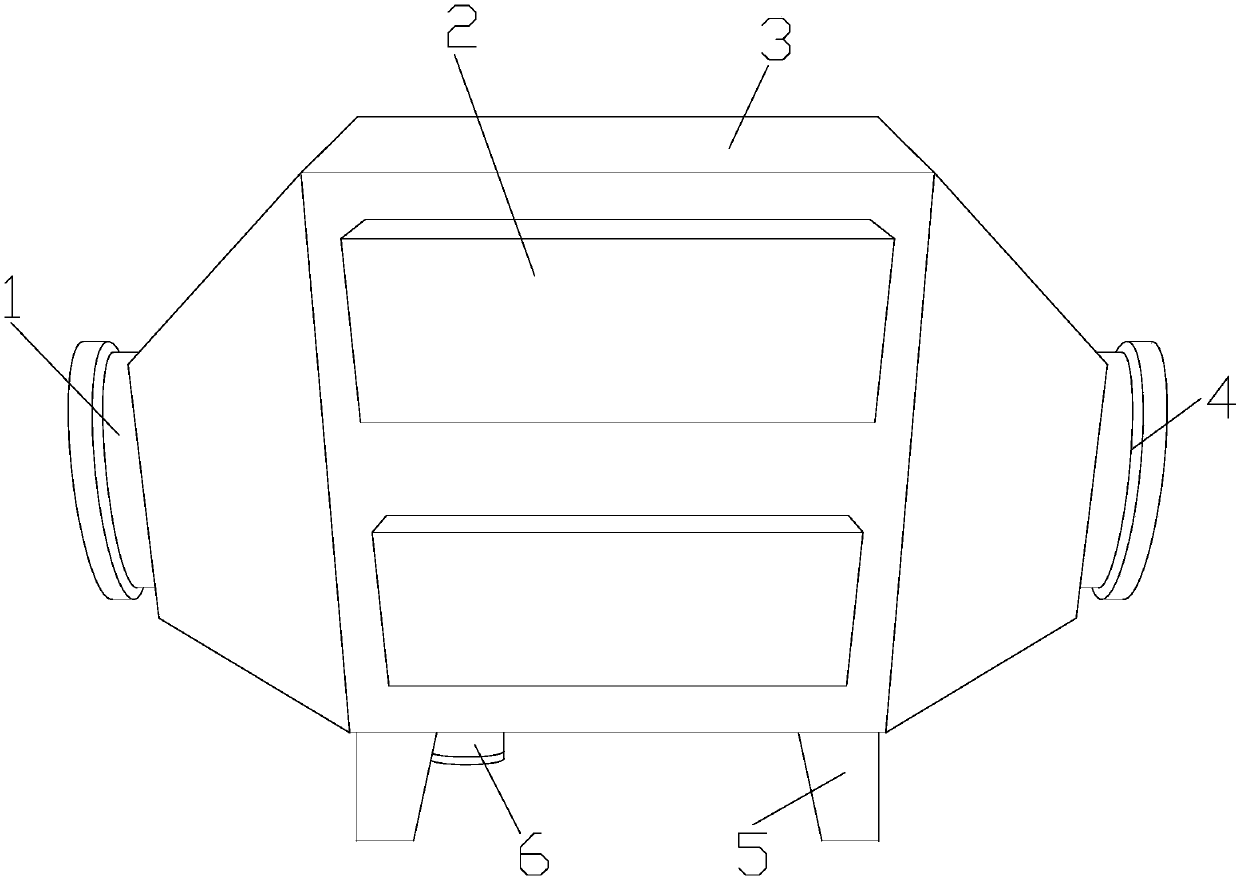

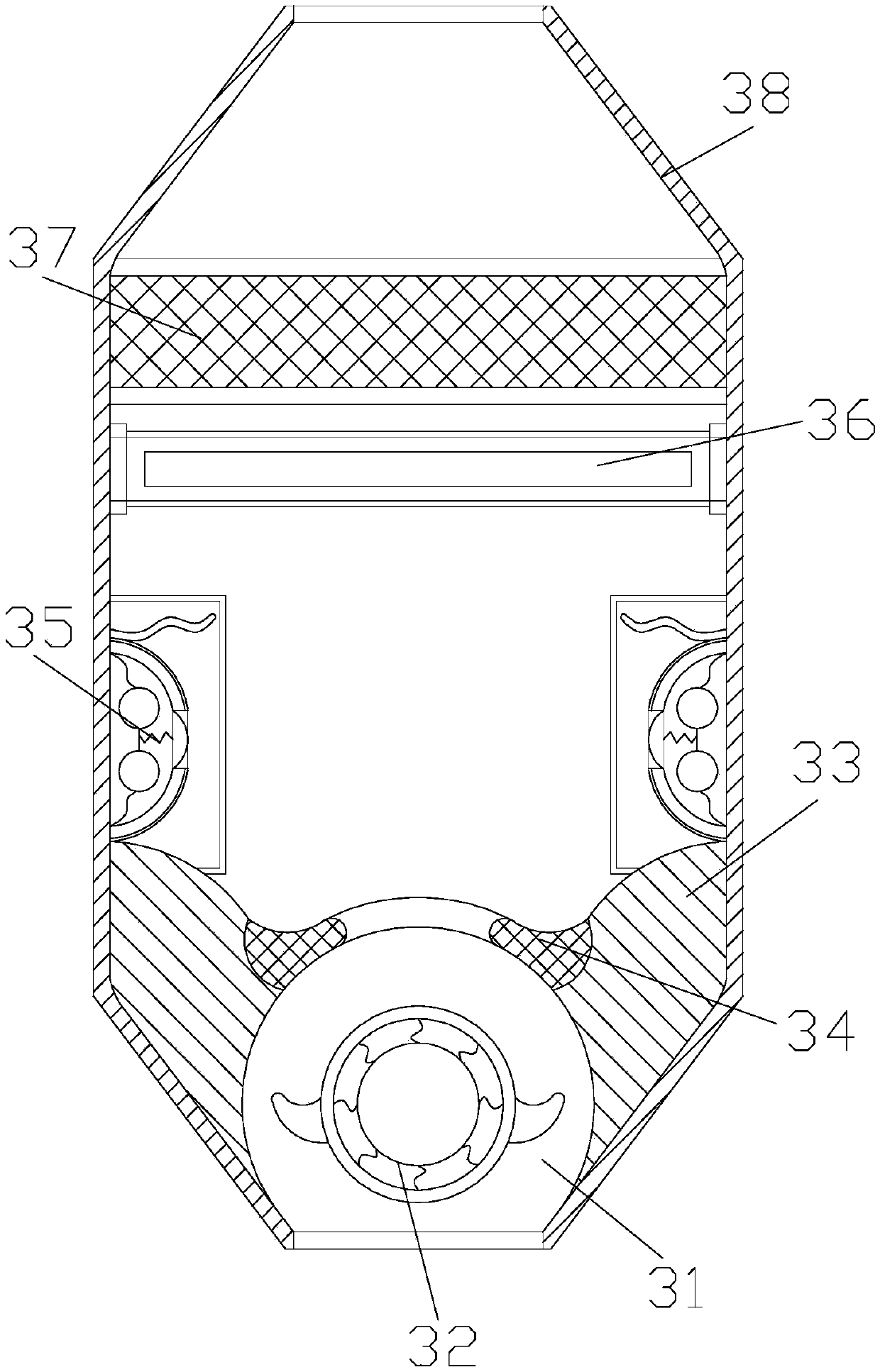

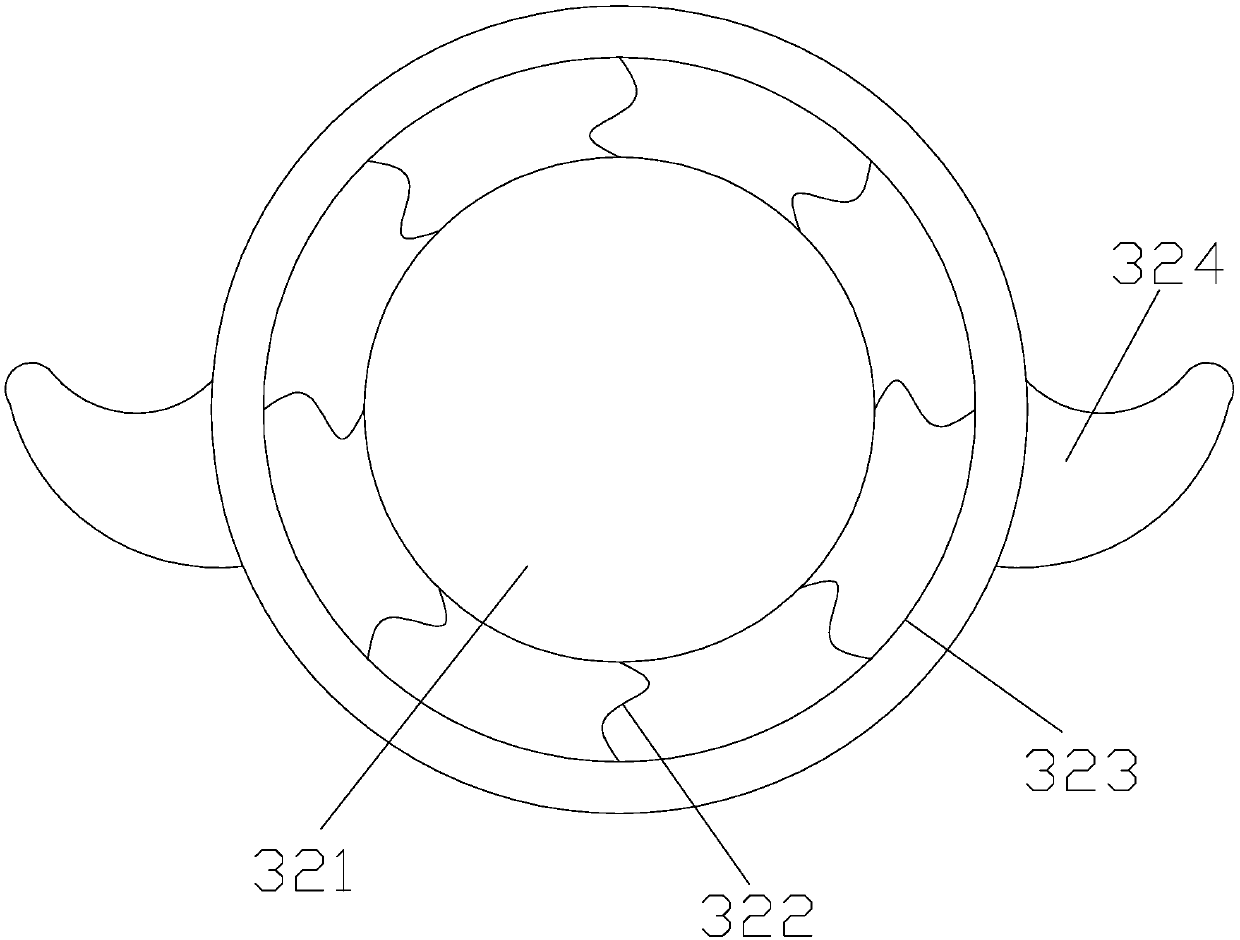

[0029] like Figure 1-2 As shown, an automatic degassing device that uses electrostatic paint particles to prevent clogging, its structure includes an air intake pipe 1, an inspection cabinet 2, an anti-clogging device 3, an air outlet pipe 4, support feet 5, and a sewage outlet 6. The gas pipeline 1 is embedded and installed on the left end face of the anti-clogging device 3. The front surface of the anti-clogging device 3 is equipped with an inspection cabinet 2 and is connected by hinges. The air outlet pipe 4 is embedded and installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com