A Low Noise Chain Outer Link Press Fitting System

An outer chain link, low noise technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of eardrum effect noise, workers' health effects, etc., to achieve the effect of reducing noise, avoiding noise pollution, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

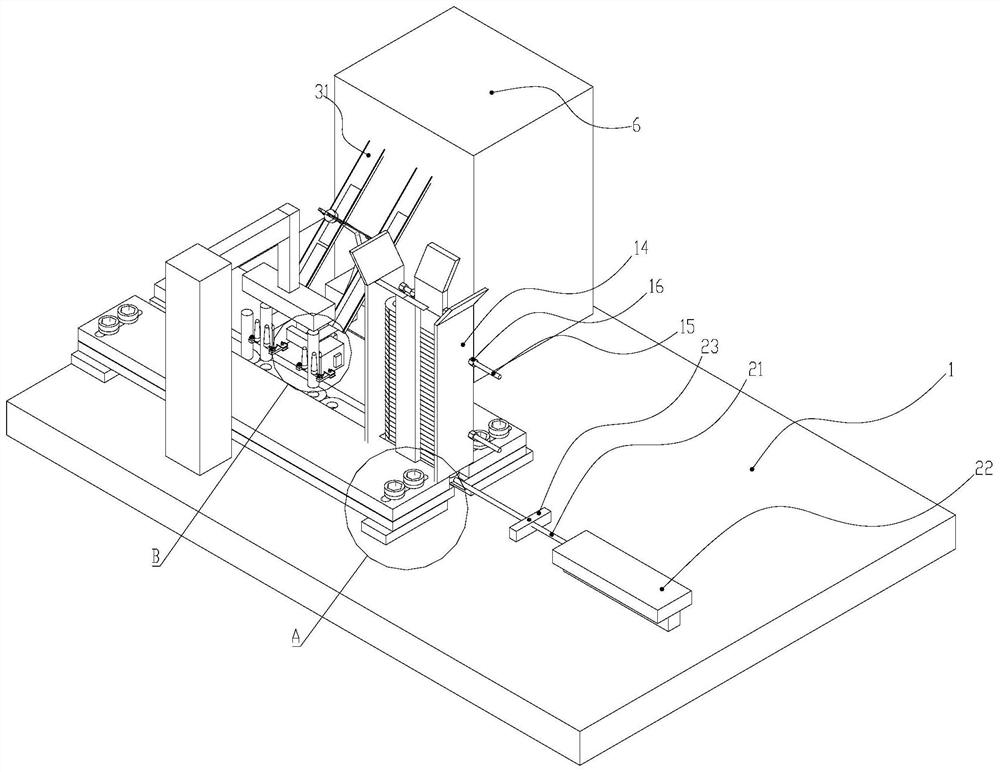

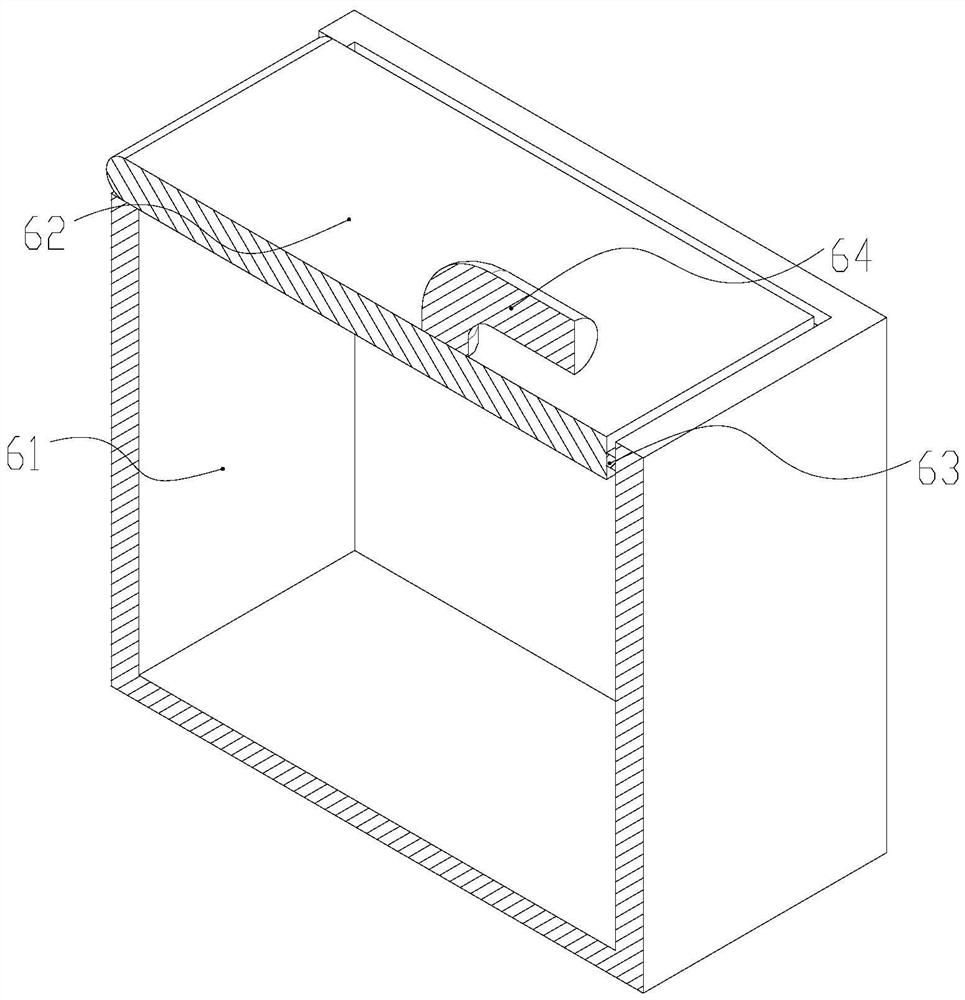

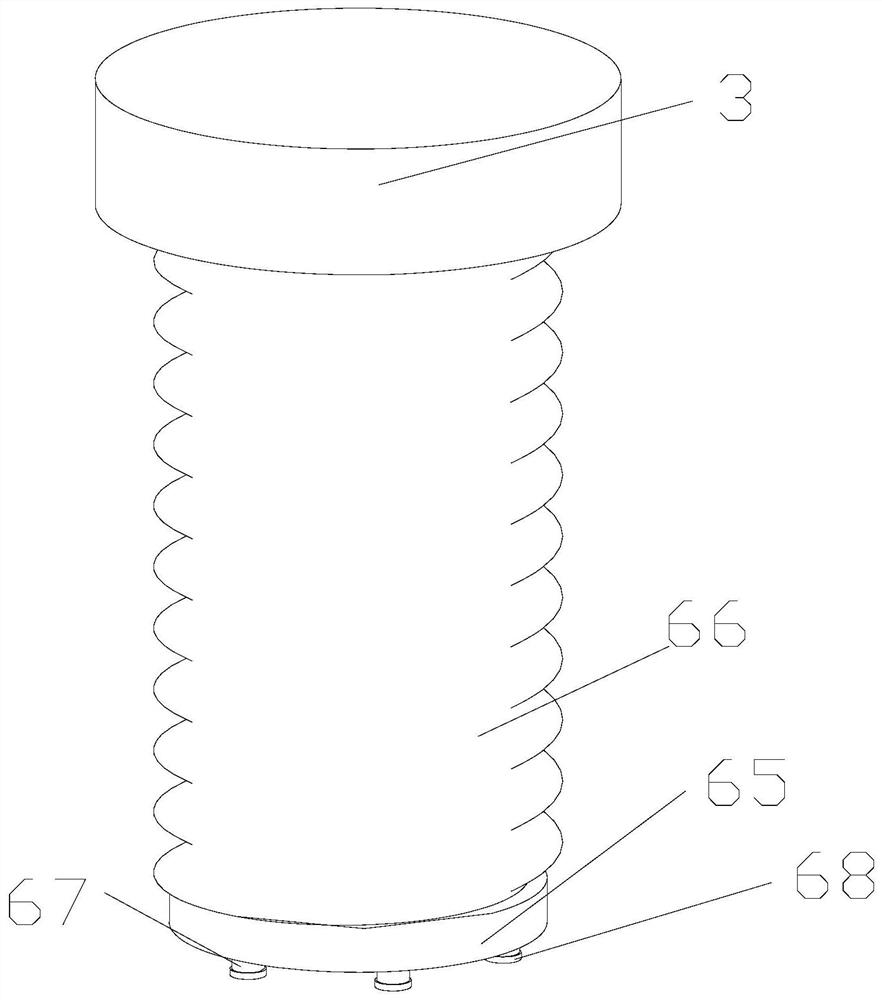

[0022] Such as Figure 1-8 As shown, a low-noise chain outer chain link press-fitting system includes a workbench 1, a placement device, a conveying device, a blanking device, a positioning device, and a stamping device. The placement device includes a backing plate 11 and a limit plate 12 , the first fixed plate 13, the second fixed plate 14, the first screw rod 15 and the nut 16, the backing plate 11 is symmetrically fixed on the workbench 1, the limiting plate 12 is symmetrically arranged on the backing plate 11, through The adjustment groove 17 and the screw 18 provided on the limit plate 12 are fixed on the backing plate 11, and the screw 18 is selected from a convention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com