Intelligently-controlled injection molding machine production machine group

An intelligent control and injection molding machine technology, applied in the field of injection molding machine production clusters, can solve problems such as low efficiency and low degree of automation, and achieve the effects of improving production efficiency, improving replacement efficiency, and shortening replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

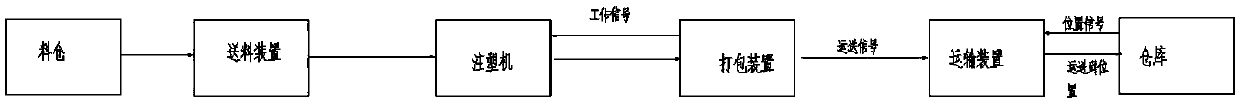

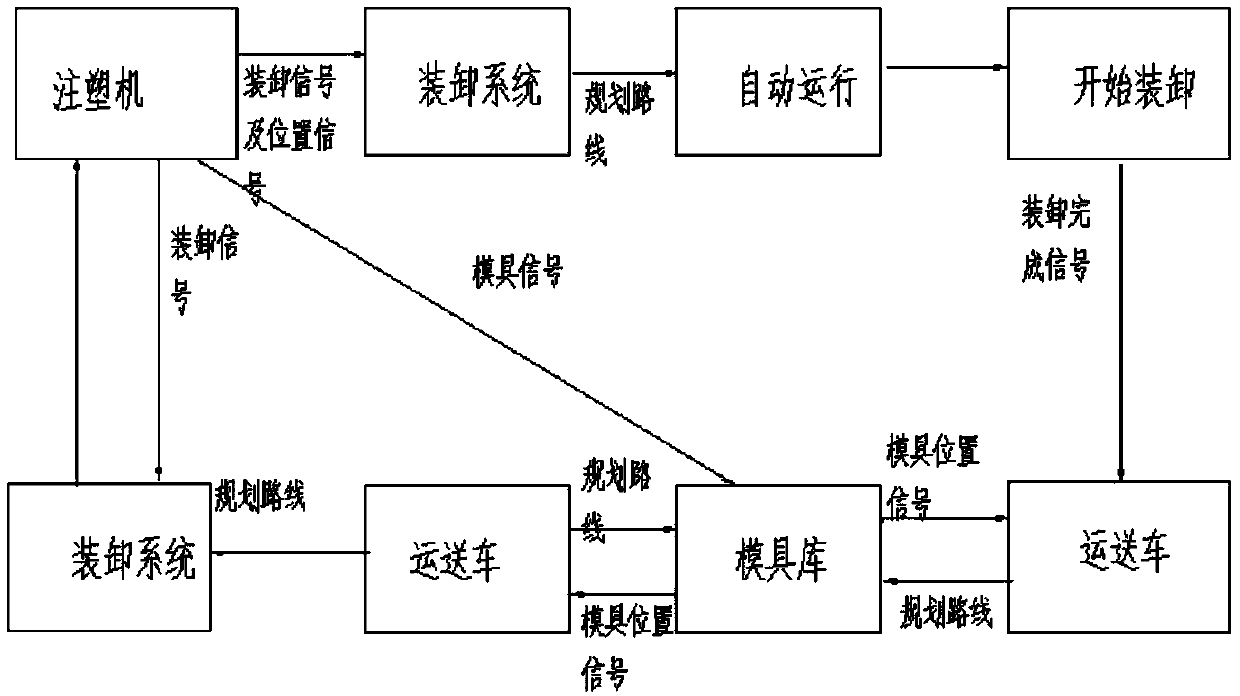

[0020] The invention proposes an intelligently controlled injection molding machine production fleet, equipped with packaging devices, transport devices, warehouses, etc., when the injection molding machine is producing products, the counting system counts the products it produces, and when the number of packages is reached, the packaging machine starts to pack , when the packaging is finished, the delivery signal will be sent to the delivery device, and the packaged products will be delivered to the designated location of the warehouse through the delivery device, so as to improve the degree of automation and production efficiency, and realize automatic production.

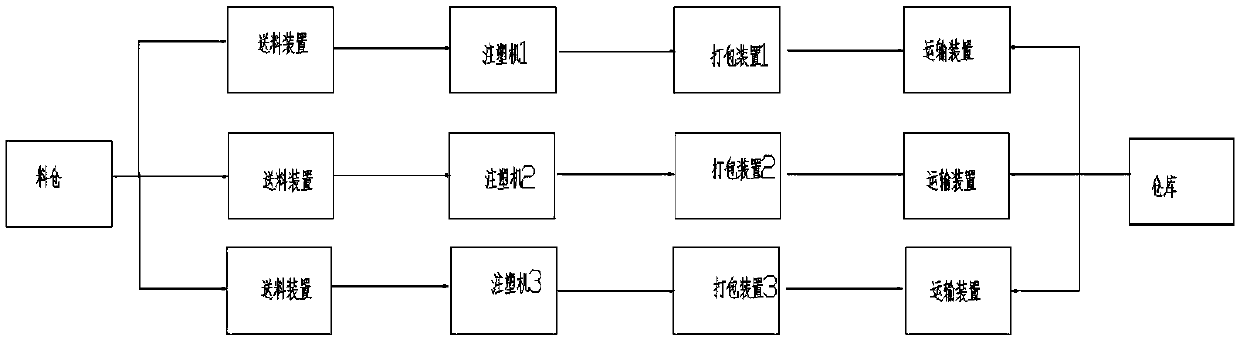

[0021] In order to realize the above-mentioned technical solution, in order to realize the above-mentioned technical solution, the intelligently controlled injection molding machine production cluster of the present invention is mainly composed of a silo, a feeding device, an injection molding machine, a packaging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com