Running gear structure and gear vehicle wheel set

A gear structure and gear technology, applied in the field of rail transit vehicles, can solve the problems of shortened wheel life, high life cycle cost, cumbersome disassembly process, etc., to achieve good replaceability, save maintenance time and cost, and improve Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

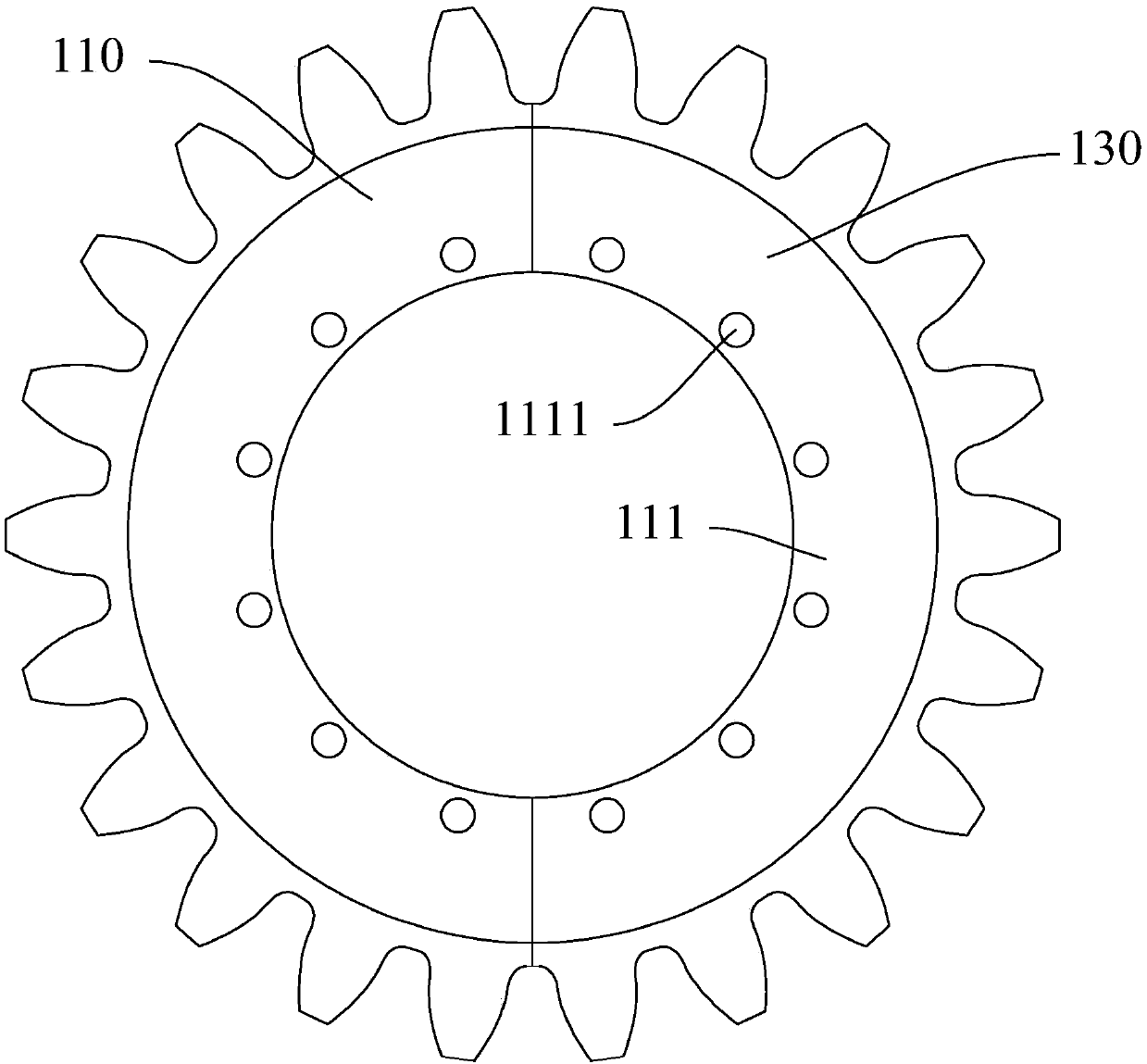

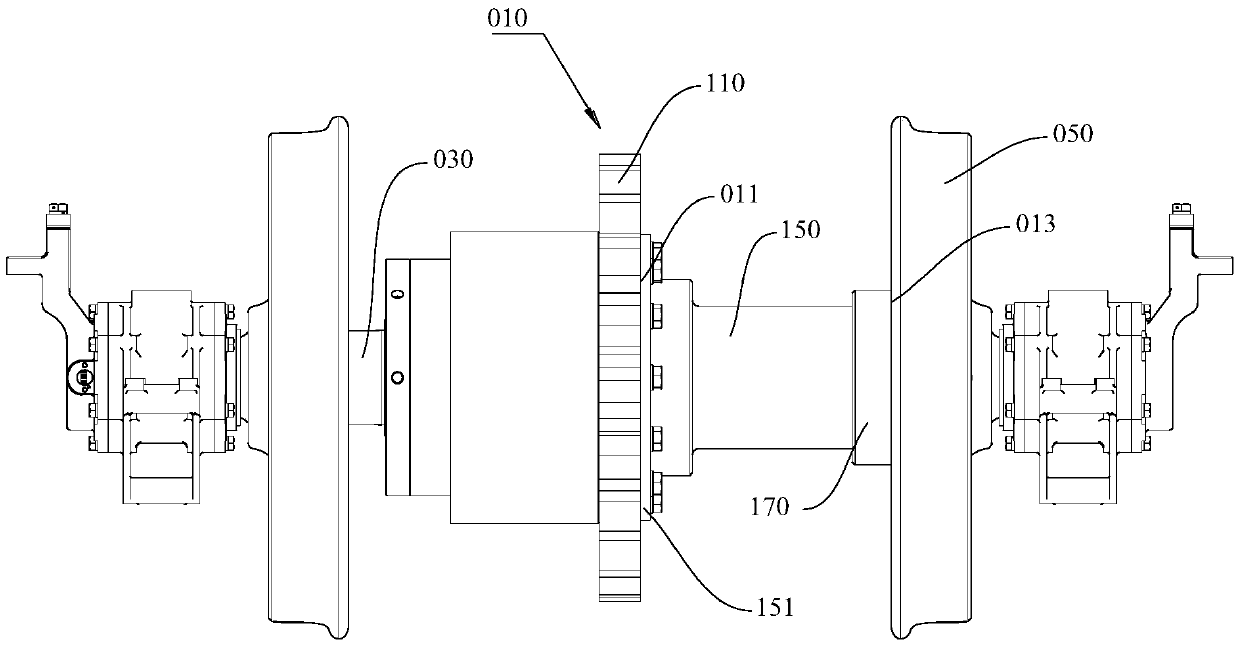

[0033] This embodiment provides a traveling gear structure 010, please refer to figure 1 with figure 2 , this traveling gear structure 010 includes a first half ring gear 110, a second half ring gear 130 and a gear hub 150;

[0034] The gear hub 150 includes an axial first end 011 and a second end 013;

[0035] see Figure 5 , the first end 011 of the gear hub 150 is provided with a first mounting part, and the second half ring gear 130 and the first half ring gear 110 are provided with a second mounting part; through the first mounting part and the second mounting part Cooperate so that the first half ring gear 110 and the second half ring gear 130 are installed on the first end 011 of the gear hub 150, and the first half ring gear 110 and the second half ring gear 130 are fixed on the gear hub 150 to form a circle Shaped integral gear.

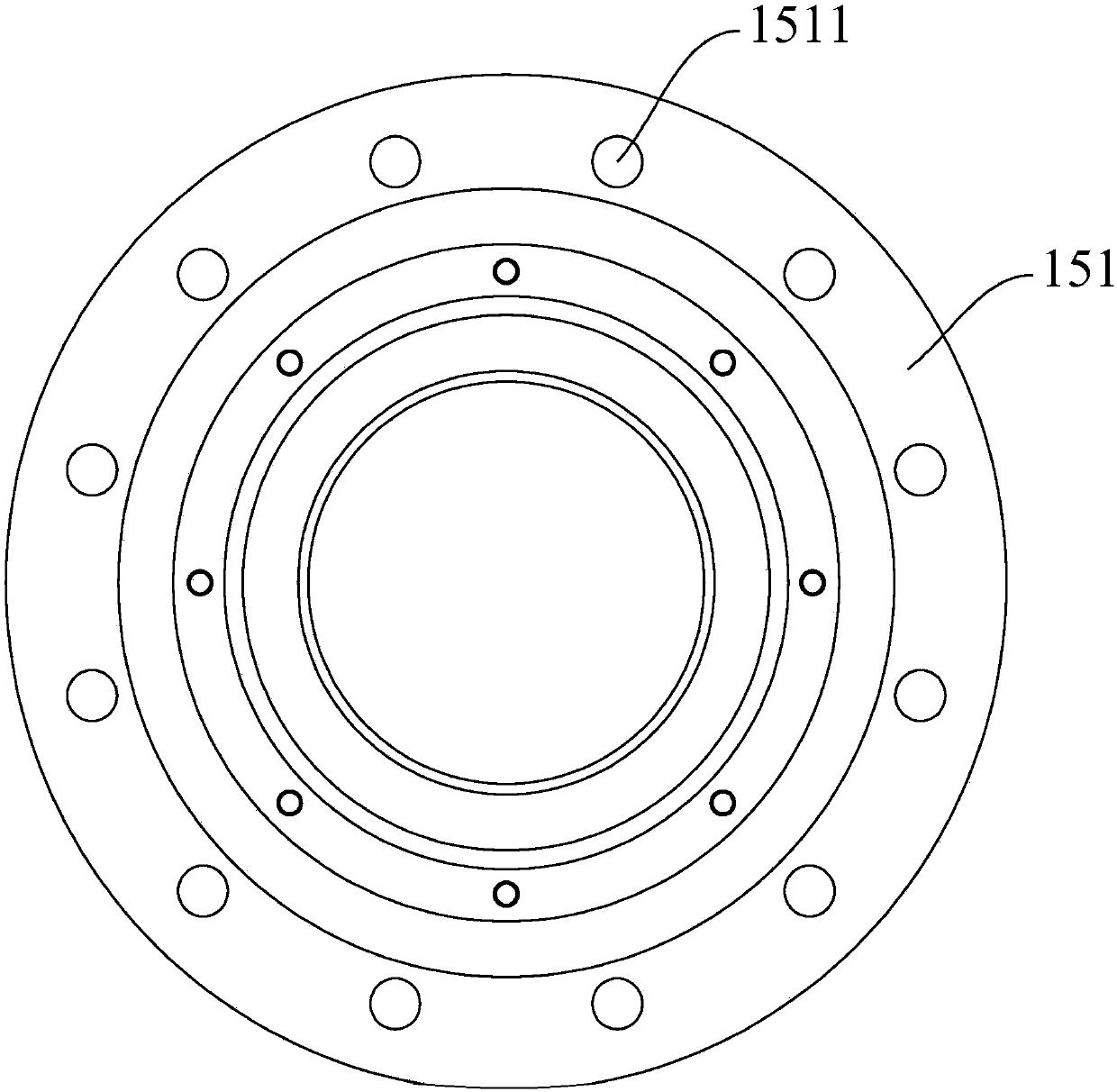

[0036] see image 3 with Figure 4 , in this embodiment, the first mounting part is the first mounting plate 151 protruding radially...

Embodiment 2

[0044] This embodiment provides a wheel set for a geared vehicle, please refer to figure 1 with figure 2 , this traveling gear structure 010 includes an axle 030, a wheel 050 and the traveling gear structure 010 in the first embodiment;

[0045] The axle 030 passes through the installation through hole 015, and the axle 030 and the gear hub 150 are in interference connection, and the wheels 050 are fixedly arranged at both ends of the axle 030.

[0046] In order to further fix the gear hub 150 and the axle shaft 030, a third mounting part (not shown) is also arranged on the axle shaft 030, the third mounting part is a third mounting plate, and a third fixing channel is provided on the third mounting plate hole, the gear hub 150 is provided with a fourth mounting piece, the fourth mounting piece is a fourth mounting plate, and the fourth mounting plate is provided with a fourth fixing through hole corresponding to the third fixing through hole, through which the bolt passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com