A kind of preparation method of hierarchical pore zeolite molecular sieve

A zeolite molecular sieve, multi-stage pore technology, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolite, etc., to achieve the effects of preventing damage, improving diffusion performance, and preventing excessive desiliconization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

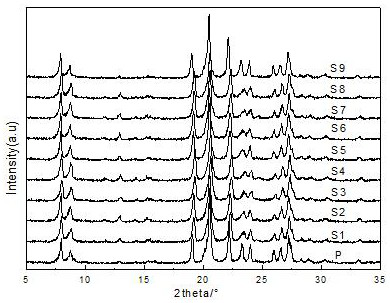

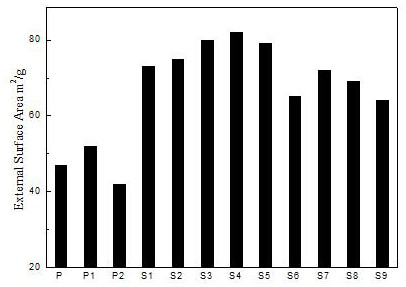

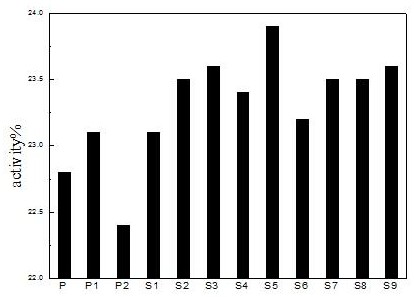

[0029] Take 10g EU-1 (SiO 2 / Al 2 o 3 molar ratio=80:1) Molecular sieve raw powder, according to the 3°C / min temperature rise program to 370°C for 5h, weigh 5g of the sample after the roasting, according to the liquid-solid weight ratio of 20:1 and 1.0mol / L hydrochloric acid solution After mixing and stirring evenly, treat at 150°C for 24h. After the reaction is over, filter and wash until neutral, and dry at 120°C for 12h; mix the dried sample with 0.8mol / L tetramethylammonium hydroxide solution according to the liquid-solid weight ratio of 20 : 1 mix, stir evenly, add 1gCTAB, react at 120°C for 24h, filter and wash to neutral pH, dry at 120°C for 12h, and bake at 550°C for 300 minutes to obtain a hierarchically porous EU-1 molecular sieve product, remember S1.

Embodiment 2

[0031] Take 10g EU-1 (SiO 2 / Al 2 o 3 molar ratio=30:1) Molecular sieve raw powder, roasted at 550 °C for 3 hours according to the temperature rise program of 5 °C / min, weighed 5 g and 0.8 mol / L of the sample after roasting and mixed with hydrochloric acid solution according to the liquid-solid weight ratio of 10:1 , treated at 120°C for 18 hours, the reaction was completed, the pH was filtered and washed to neutral, and dried at 120°C for 12 hours; the dried sample was mixed with 1.0mol / L ammonia solution according to the liquid-solid weight ratio of 30:1, and 3gCTAB was added after stirring evenly. React at 150°C for 30 hours, filter and wash until neutral, dry at 120°C for 12 hours, and calcine at 550°C for 300 minutes to obtain a hierarchically porous EU-1 molecular sieve product, remember sample S2.

Embodiment 3

[0033] Take 10g EU-1 (SiO 2 / Al 2 o 3 molar ratio=40:1) Molecular sieve raw powder, according to the 4°C / min temperature rise program to 450°C for 4.5h, weigh 5g and 0.1mol / L of the sample after the roasting and mix with acetic acid solution according to the liquid-solid weight ratio of 15:1 Mix and treat at 130°C for 16 hours. After the reaction is completed, filter and wash the pH to neutral, and dry at 120°C for 12 hours; mix the dried sample with 0.5mol / L tetraethylammonium hydroxide solution according to the liquid-solid weight ratio of 25:1, After stirring evenly, add 3g of CTAB, react at 140°C for 36h, filter and wash until neutral, dry at 120°C for 12h, and calcined at 550°C for 300 minutes to obtain a hierarchically porous EU-1 molecular sieve product, remember sample S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com