Treatment technology of low-content radioactive pollutants in rare-earth smelting wastewater

A pollutant treatment and low-content technology is applied to the treatment process of uranium radioactive pollutant wastewater, the treatment process of low-content radioactive pollutants in rare earth smelting wastewater, and the field of thorium, and achieves improved treatment effect, low cost, and process flow. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In the radioactive wastewater discharged by a rare earth enterprise, the concentrations of uranium and thorium were 1.53mg / L and 1.85mg / L respectively, and the pH value was 9.4.

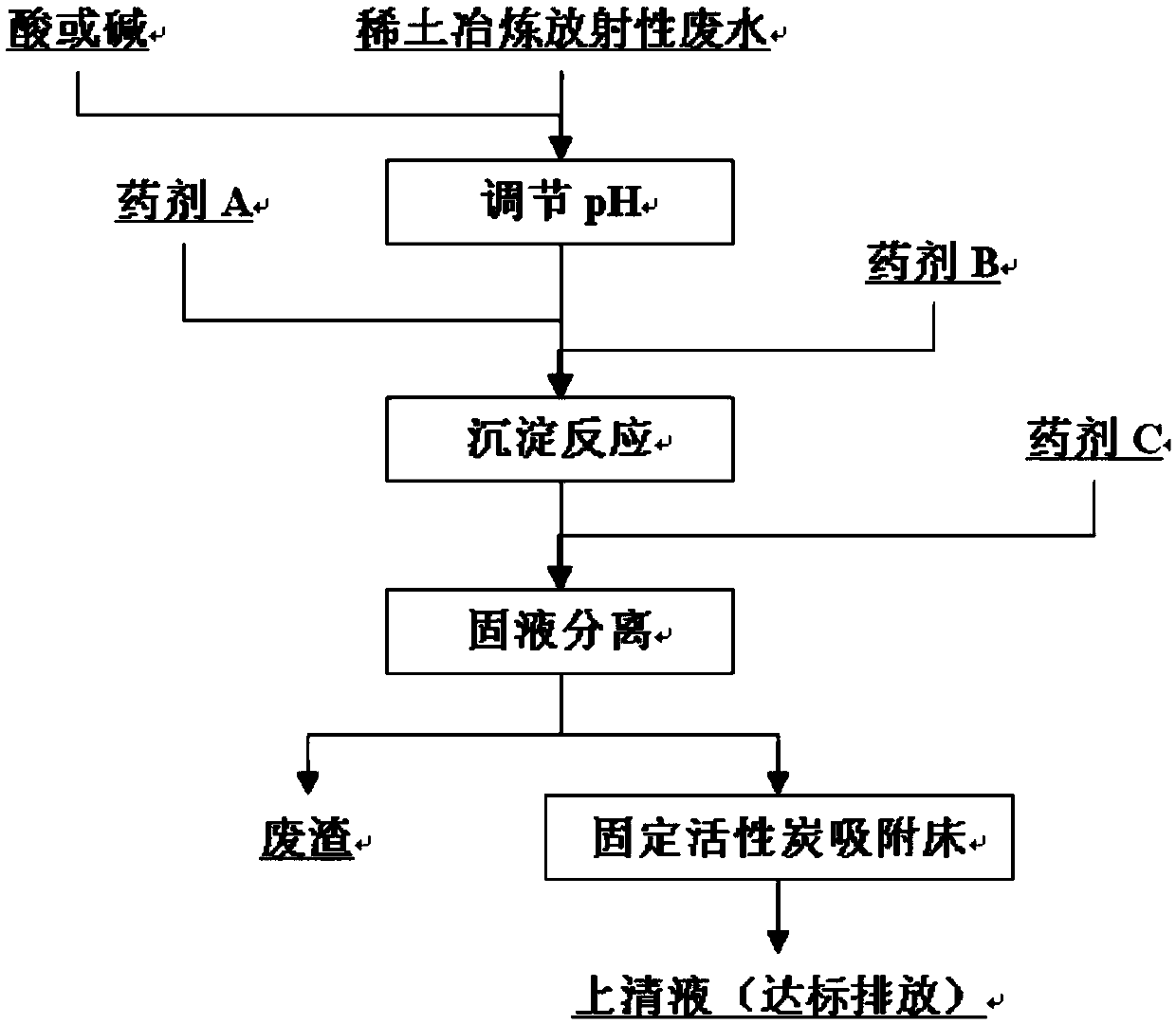

[0036] A process for treating low-level radioactive pollutants in rare earth smelting wastewater, comprising the following steps:

[0037] 1) Adjust the rare earth smelting wastewater to neutral or slightly alkaline; use 1mol / L dilute sulfuric acid to adjust the pH of the rare earth smelting wastewater to 7-9;

[0038] 2) In the solution obtained in step 1), add 40g of medicament A (BaCl 2 2H 2 O), after stirring and reacting with 0.3L of agent B (concentrated sulfuric acid), add 5g of agent C (polyacrylamide flocculant) and stir and mix evenly. After precipitation occurs, solid-liquid separation is carried out to obtain waste residue and supernatant. 1h;

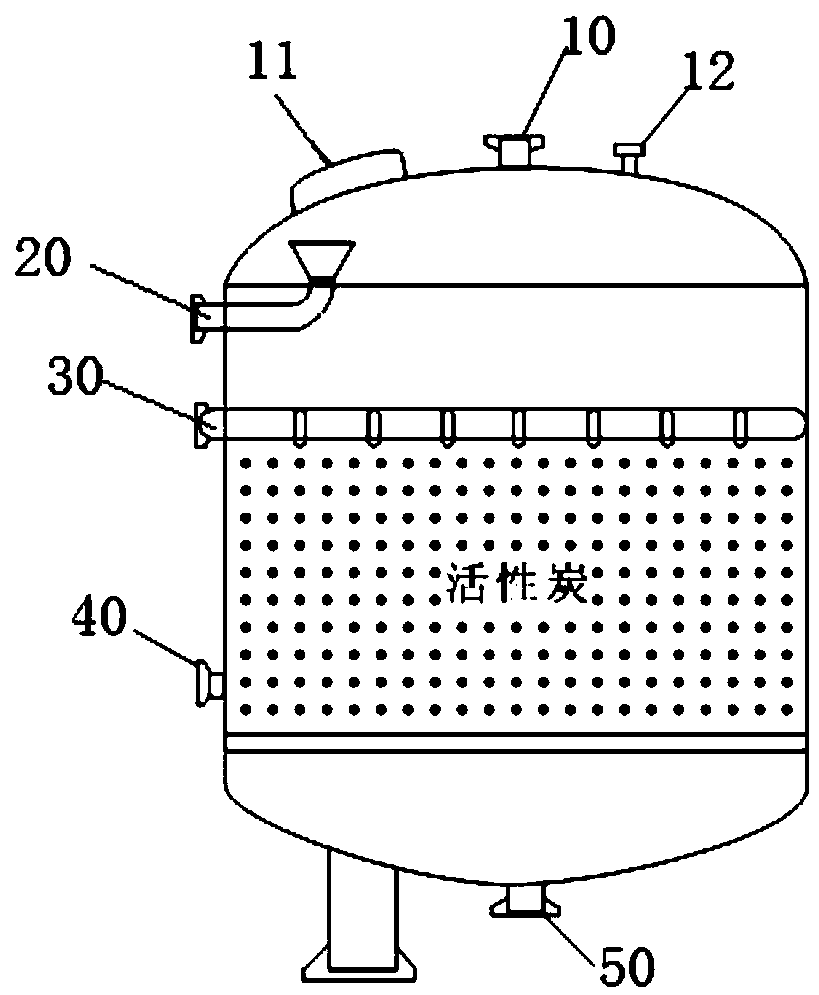

[0039] 3) The supernatant liquid obtained from the solid-liquid separation in step 2) flows through the fixed activated carbon adsorpti...

Embodiment 2

[0042] In the radioactive wastewater discharged by a rare earth enterprise, the concentrations of uranium and thorium were 1.66mg / L and 6.59mg / L respectively, and the pH value was 3.6.

[0043] A process for treating low-level radioactive pollutants in rare earth smelting wastewater, comprising the following steps:

[0044] 1) First, adjust the rare earth smelting wastewater to pH 7-9 with liquid caustic soda;

[0045] 2) In the solution obtained in step 1), add 60g of medicament A (BaCl 2 2H 2 0), after stirring and reacting 0.6L of medicament B (concentrated sulfuric acid), add 10g of medicament C (polyacrylamide flocculant) and mix evenly. After fixing the activated carbon adsorption bed, the final effluent is obtained after activated carbon adsorption, and the reaction time is 0.5~1h;

[0046]3) The supernatant liquid obtained from the solid-liquid separation in step 2) flows through the fixed activated carbon adsorption bed, and after the activated carbon adsorption, t...

Embodiment 3

[0049] In the radioactive wastewater discharged by a rare earth enterprise, the concentrations of uranium and thorium were 1.72mg / L and 4.38mg / L respectively, and the pH value was 5.3.

[0050] A process for treating low-level radioactive pollutants in rare earth smelting wastewater, comprising the following steps:

[0051] 1) First, adjust the rare earth smelting wastewater to pH 7-9 with liquid caustic soda;

[0052] 2) In the solution obtained in step 1), add 50g of medicament A (BaCl 2 2H 2 0), after stirring and reacting 0.5L of medicament B (concentrated sulfuric acid), add 8g of medicament C (polyacrylamide flocculant) and mix evenly. After precipitation occurs, solid-liquid separation is carried out to obtain waste residue and supernatant. After fixing the activated carbon adsorption bed, the final effluent is obtained after activated carbon adsorption, and the reaction time is 0.5~1h;

[0053] 3) The supernatant liquid obtained from the solid-liquid separation in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com