Method for decomposing residual iron of blast furnace

A residual iron and blast furnace technology, which is applied in the field of residual iron decomposition, can solve the problems of complicated operation of the wire saw cutting method, low efficiency of the crushing method, broken rope and stuck rope, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

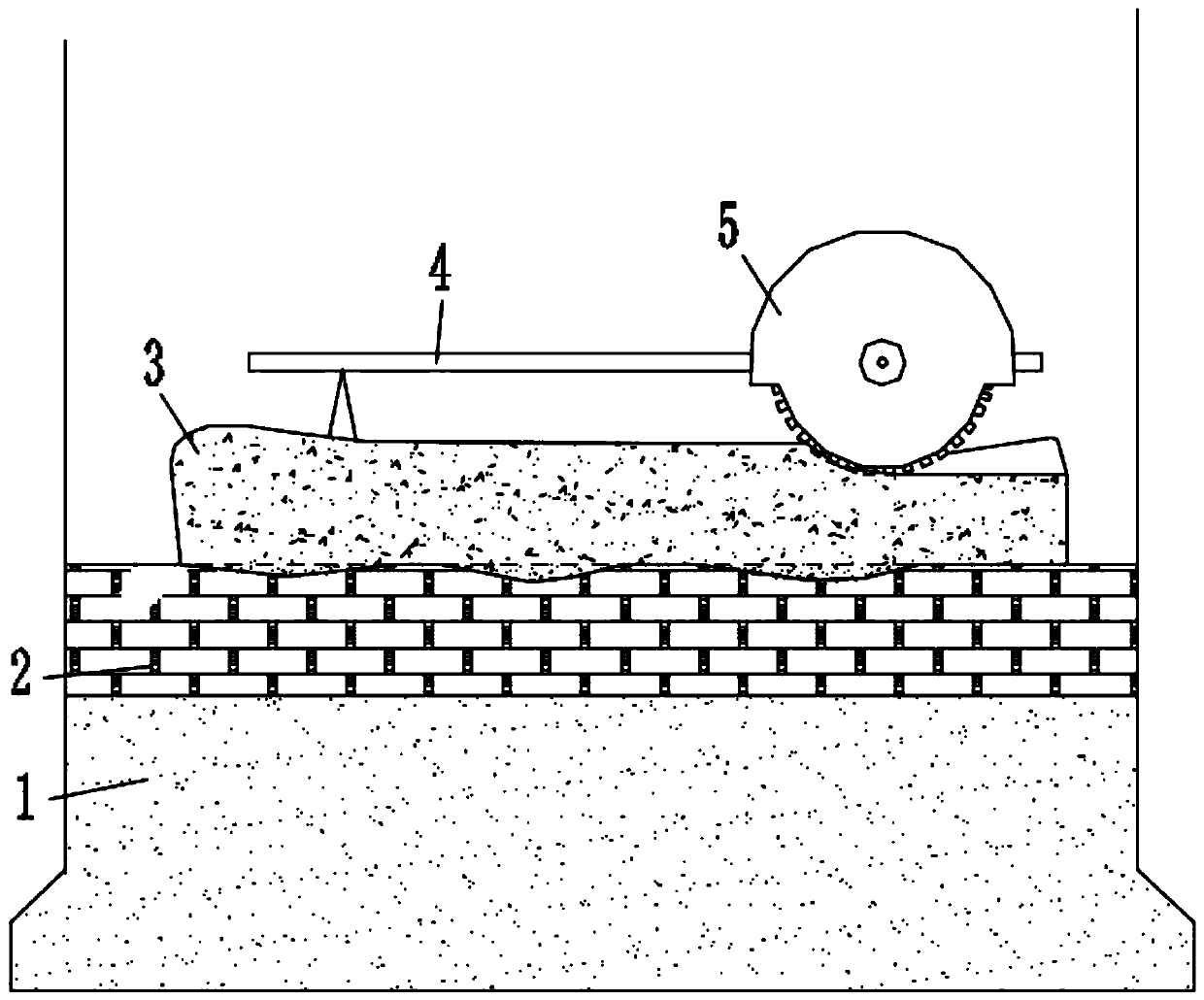

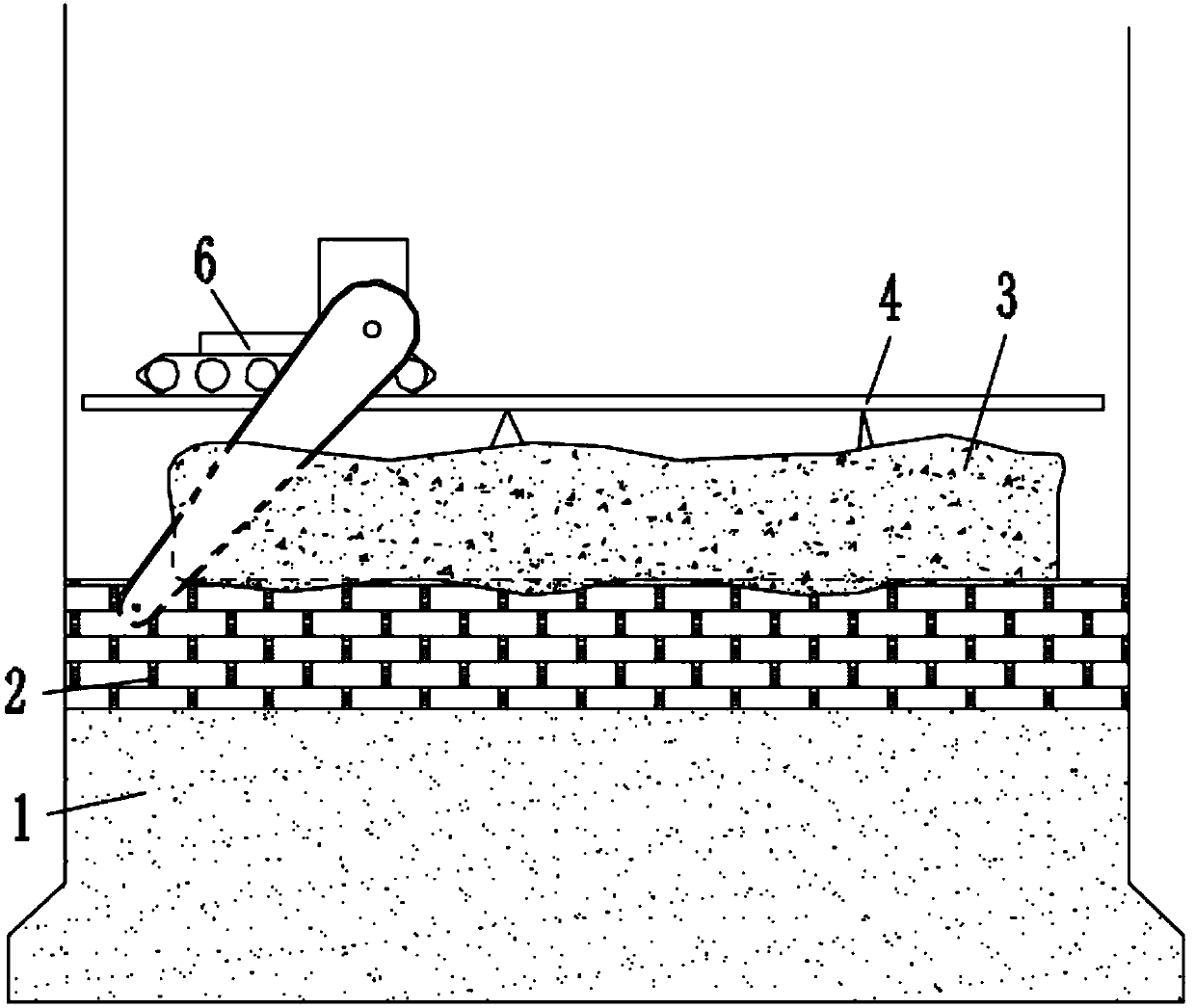

[0043] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

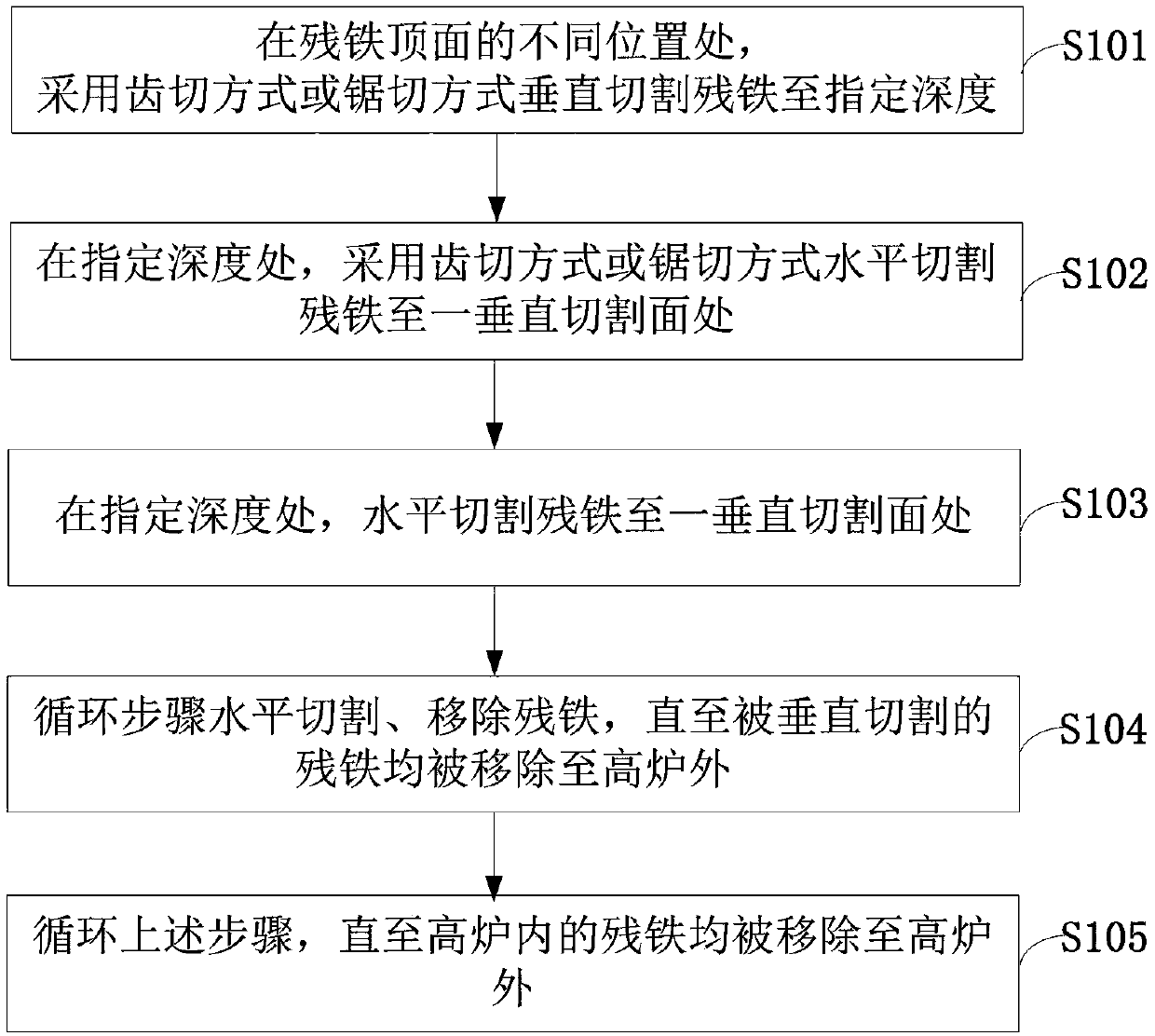

[0044] see Figure 1 to Figure 3 , the invention provides a method for decomposing residual iron in a blast furnace, comprising:

[0045] Vertical cutting: step S101 vertically cuts the residual iron 3 to a specified depth at different positions on the top surface of the residual iron 3 by tooth cutting or sawing;

[0046] Horizontal cutting: step S102, at a specified depth, horizontally cut the residual iron 3 to a vertical cutting surface by means of tooth cutting or sawing;

[0047] Removing residual iron: Step S103 removes the separated residual iron to the outside of blast furnace 1;

[0048] Step S104 is a cycle of horizontally cutting and removing residual iron until the vertically cut residual iron is removed to the outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com