Patents

Literature

36results about How to "Reduce auxiliary work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

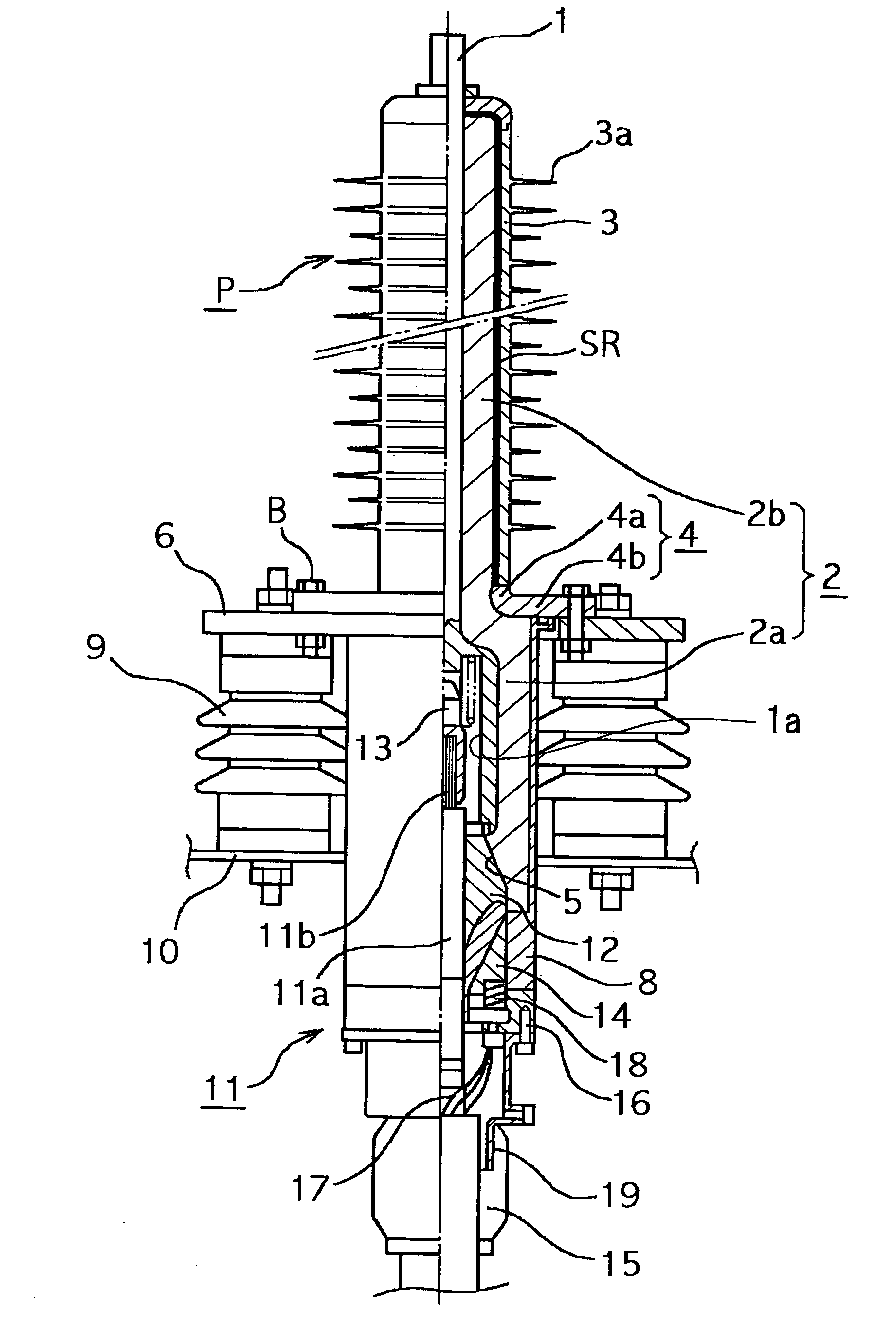

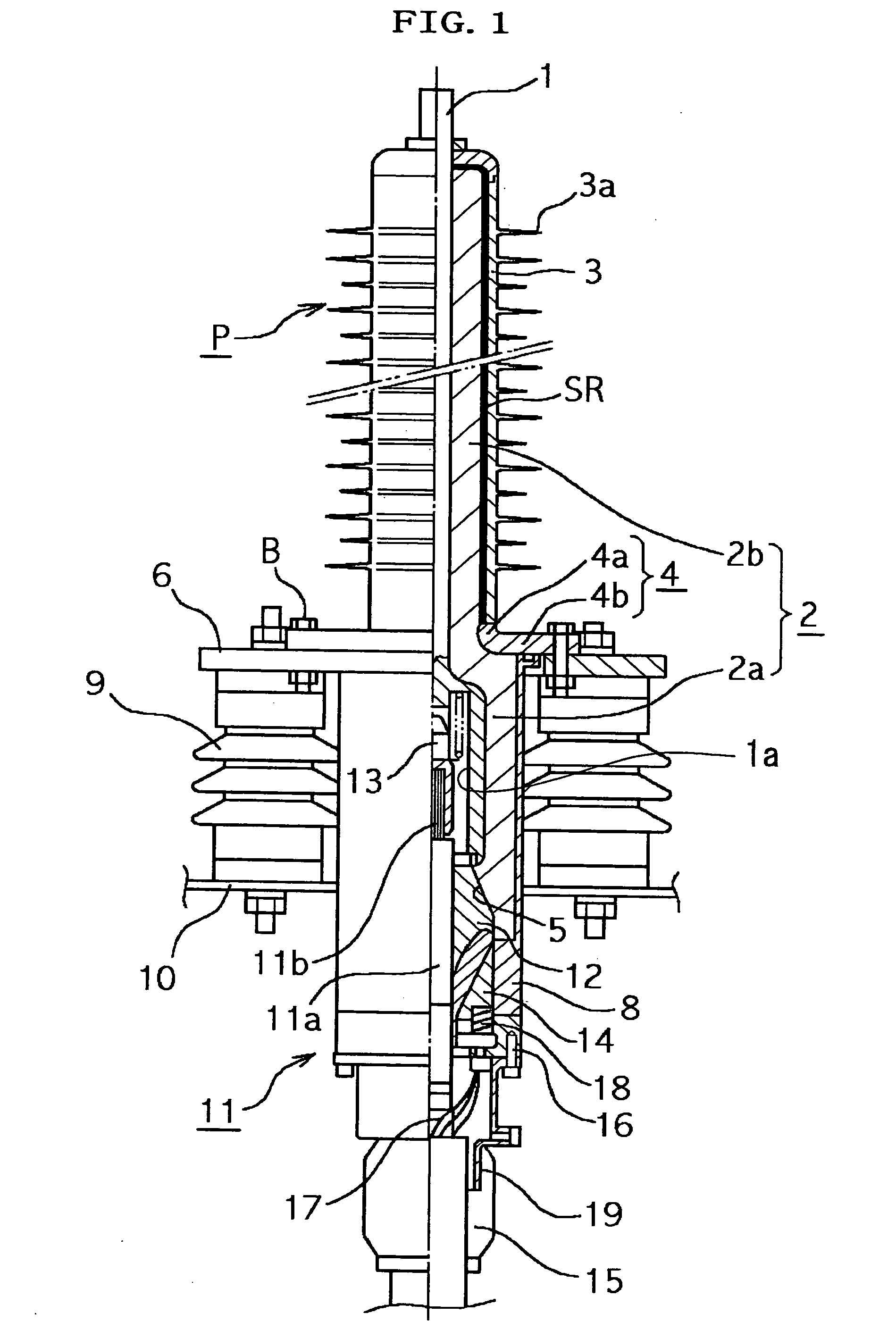

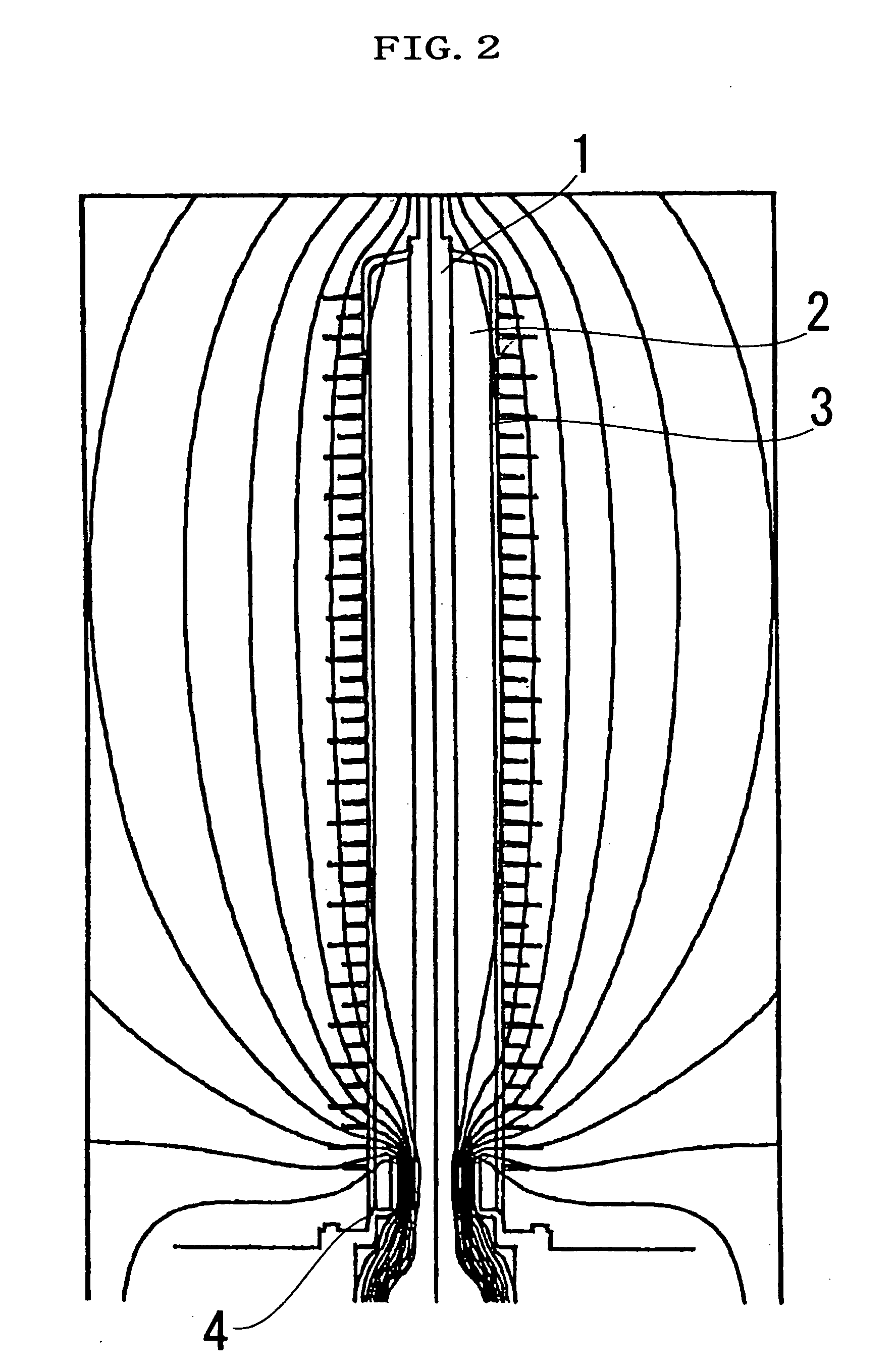

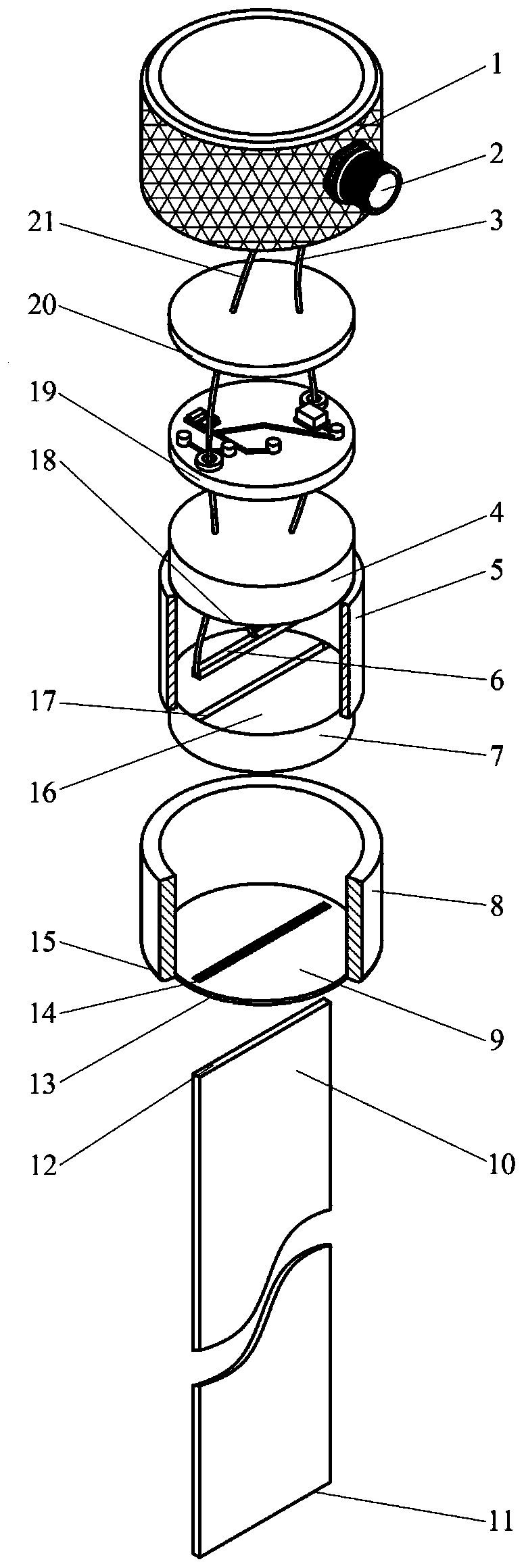

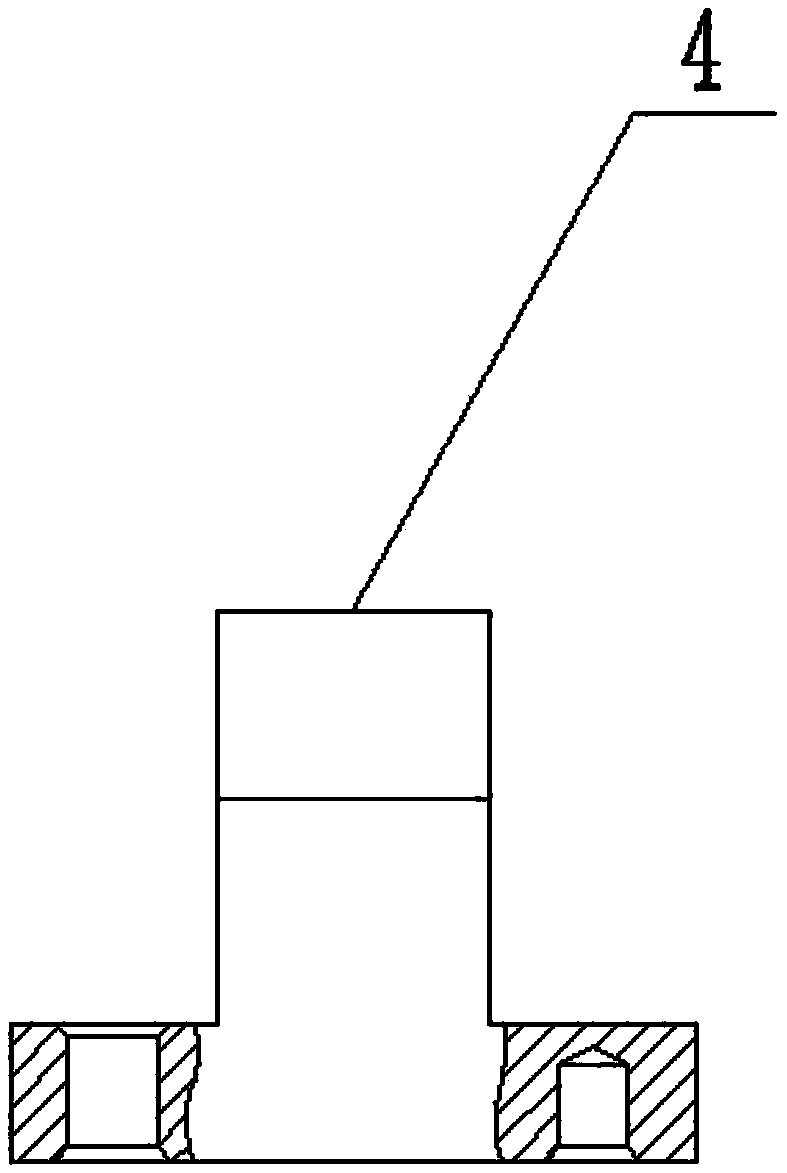

Polymer bushing and cable terminal end connector using the same

InactiveUS20070000680A1Light weightThin structureCable fittingsApparatus for joining/termination cablesControl layerElectrical conductor

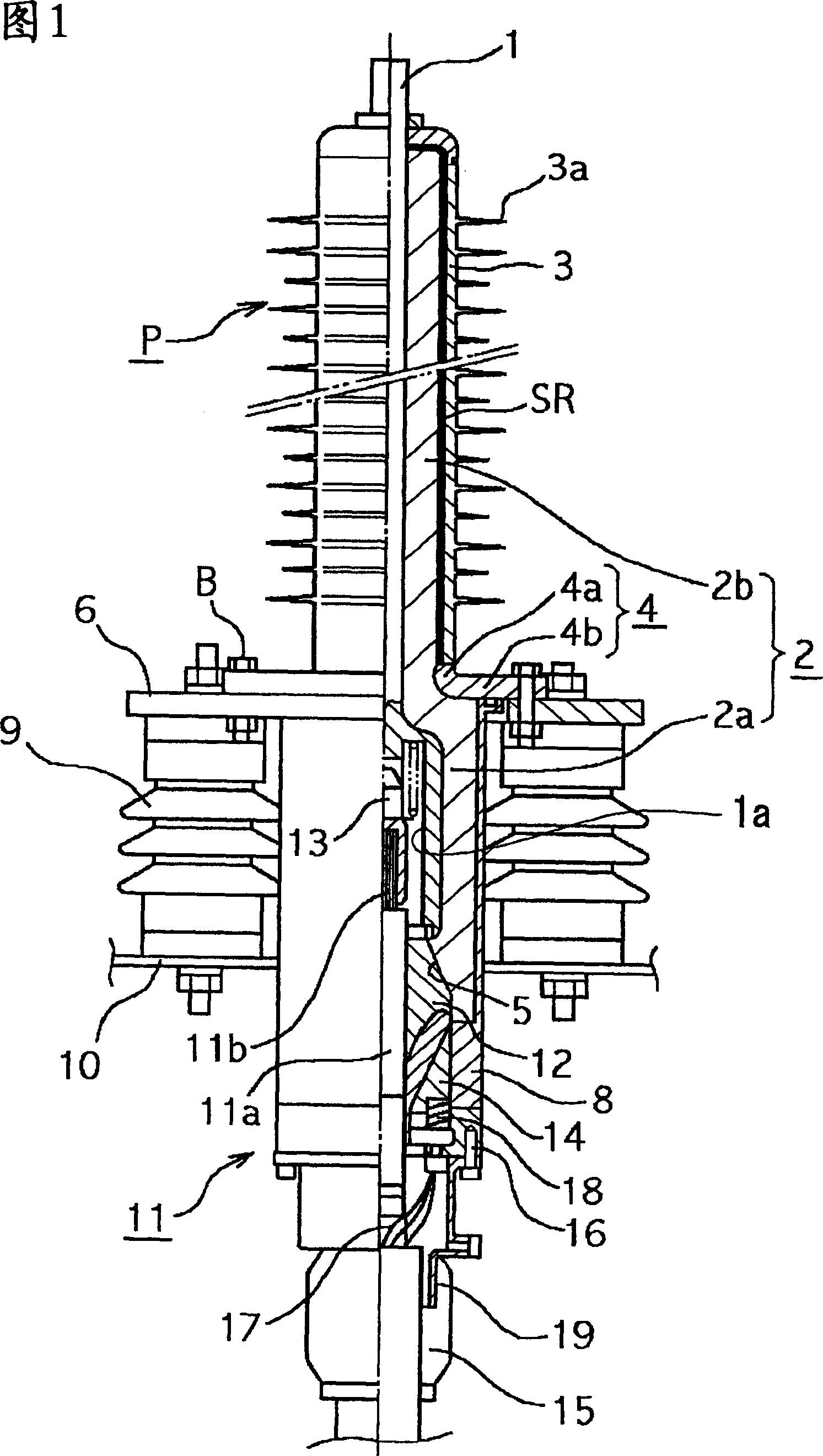

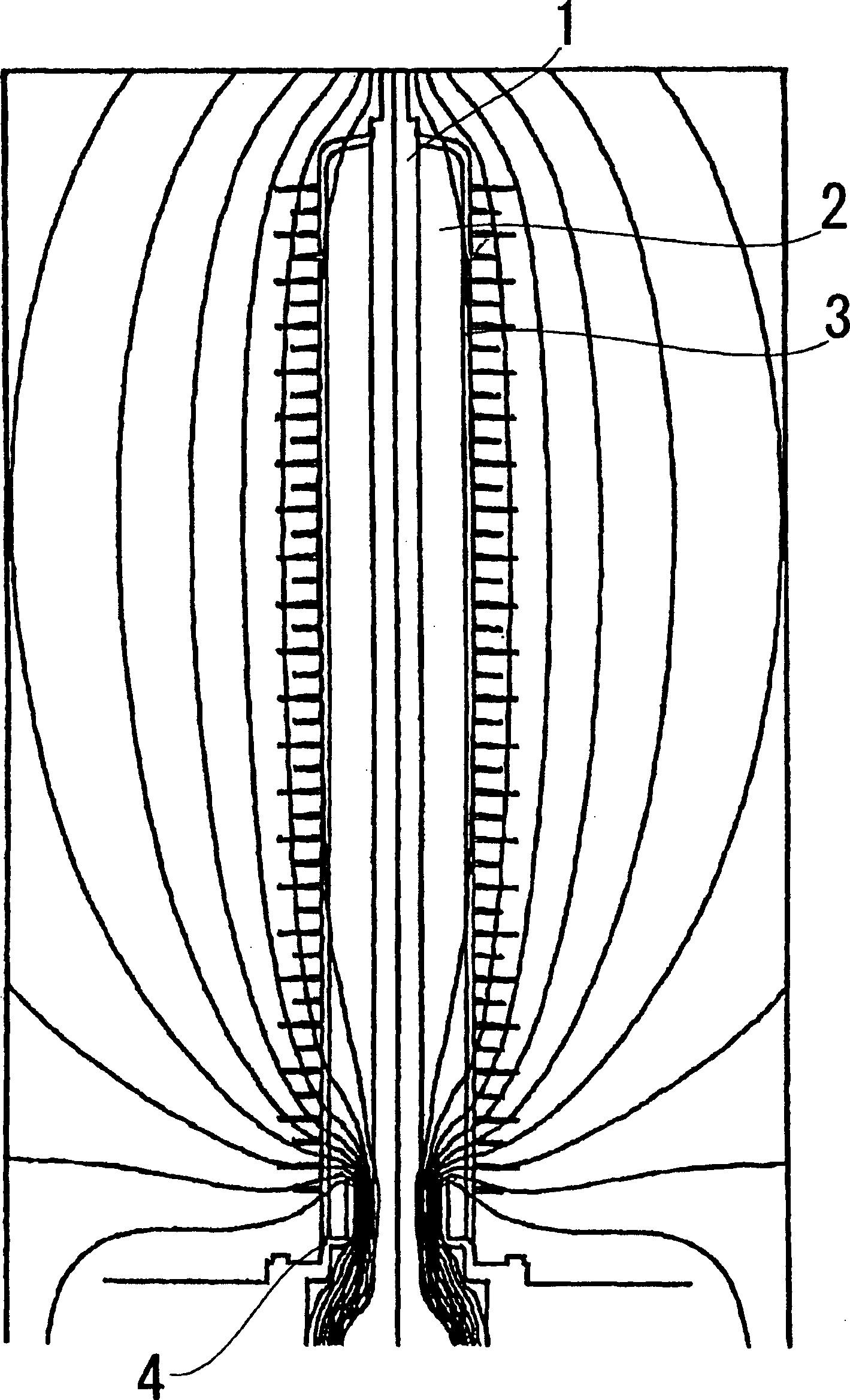

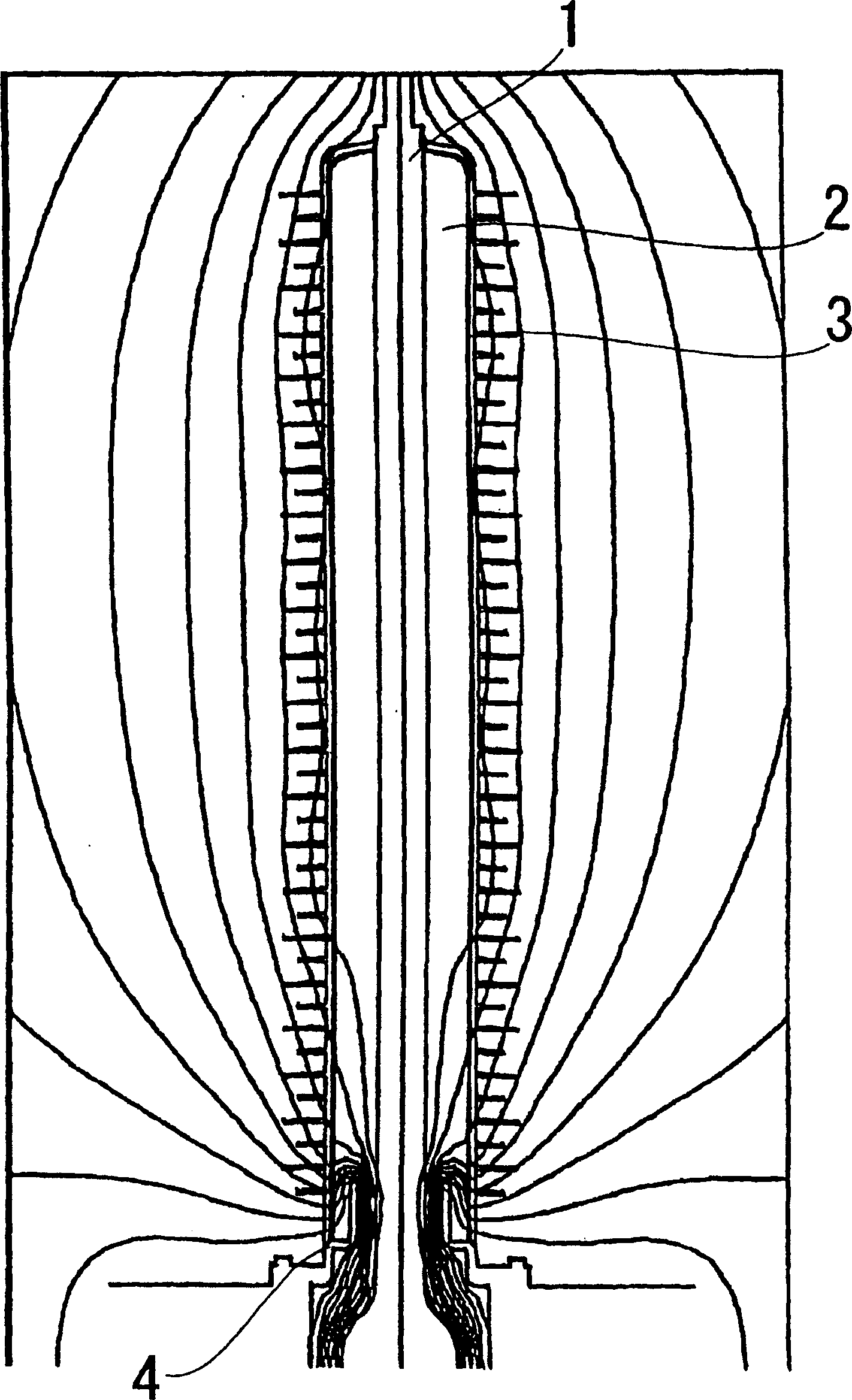

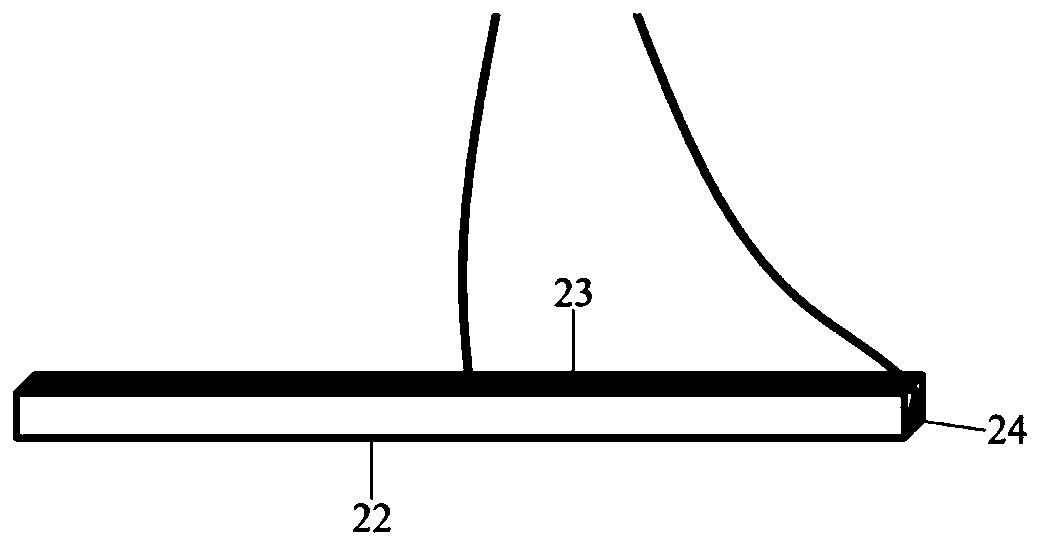

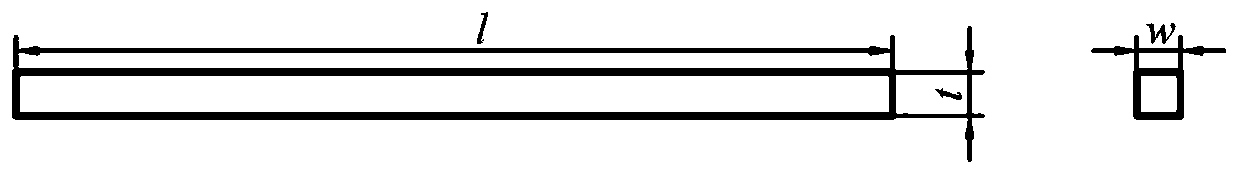

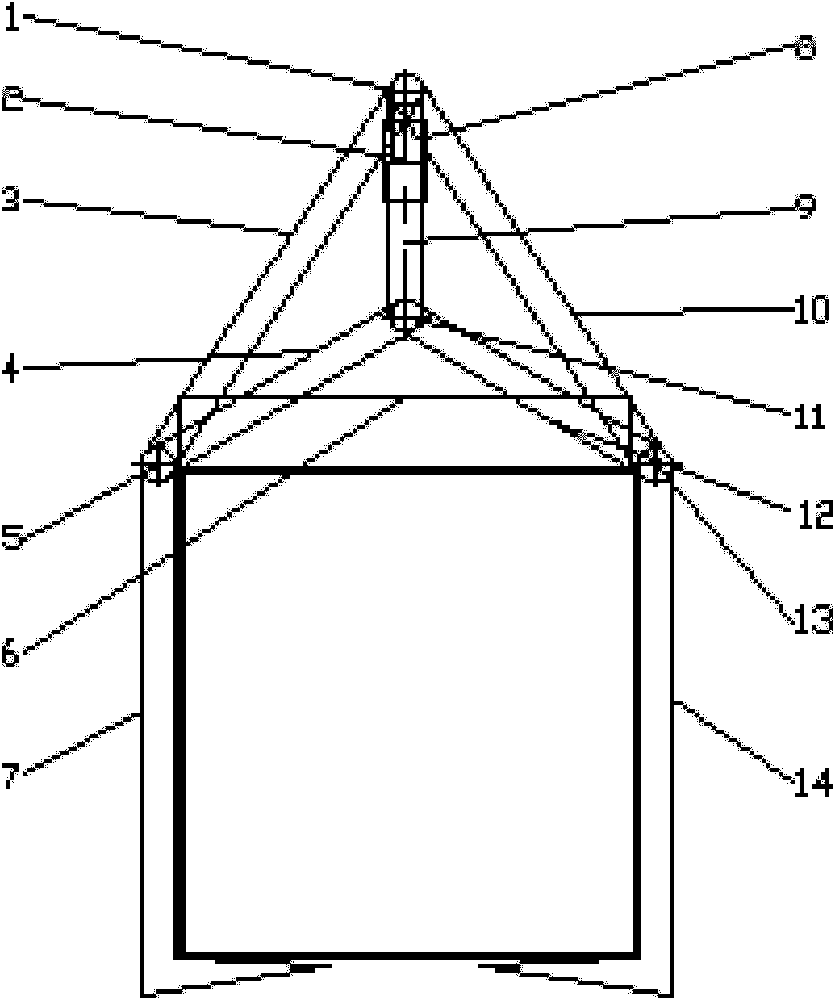

It is intended to achieve the weight reduction, sliming, and downsizing of bushings, compatibility of types of bushings, and simplification of operating steps. A polymer bushing comprises a conductor draw-out bar (1) having a conductor insertion hole (1a) in the lower end, a hard insulation sleeve (2) installed around the outer periphery of the conductor draw-out bar (1), a polymer clad body (3) installed around the outer periphery of the insulation sleeve (2), and an electric field stress-control layer installed on the interface between the insulation sleeve (2) and the polymer clad body (3). The insulation sleeve (2) comprises a large-diameter insulation sleeve (2a) installed around the outer periphery of the lower region of the conductor draw-out bar (1), and a small-diameter insulation sleeve (2b) installed around the outer periphery of a portion of the conductor draw-out bar (1) excluding the front end. An embedment metal part (4) for electric field mitigation purposes is embedded in a portion of connection between the large-and small-diameter insulation sleeves (2a, 2b). Further, installed at the lower end of the large-diameter insulation sleeve (2a) is a cone-shaped receiving port (5) for receiving the stress cone (13) of a cable terminal (11), the receiving port (5) communicating with the conductor insertion hole (1a) in the conductor draw-out bar (1).

Owner:SWCC SHOWA CABLE SYST CO LTD

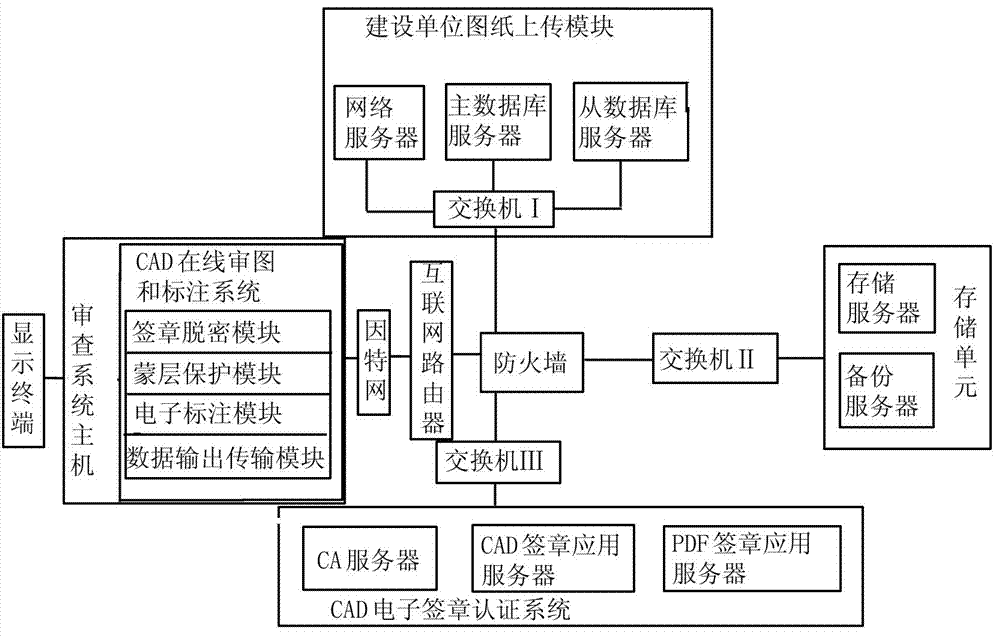

Big data O2O drawing reviewing cloud platform management system used for construction project construction drawing reviewing

PendingCN107451737AAchieve separationImprove access speedResourcesTransmissionNetwork servicePaperless office

The invention discloses a big data O2O drawing reviewing cloud platform management system used for construction project construction drawing reviewing. A construction organization drawing paper upload module comprises a network server and a database server assembly. A construction unit data terminal is connected with the input end of the network server. The data output end of the network server is connected with the database server assembly. A firewall is connected on the port of the database server assembly through a switch I. The firewall is divided into three paths to be connected with a reviewing organization drawing reviewing management terminal, a storage unit and a CAD electronic signature authentication system. The whole course of paperless drawing reviewing of construction drawing reviewing can be realized, the drawing reviewing efficiency and the installation performance can be enhanced, and the cost can be greatly saved and the project period can be shortened.

Owner:泰州市抗震办公室 +1

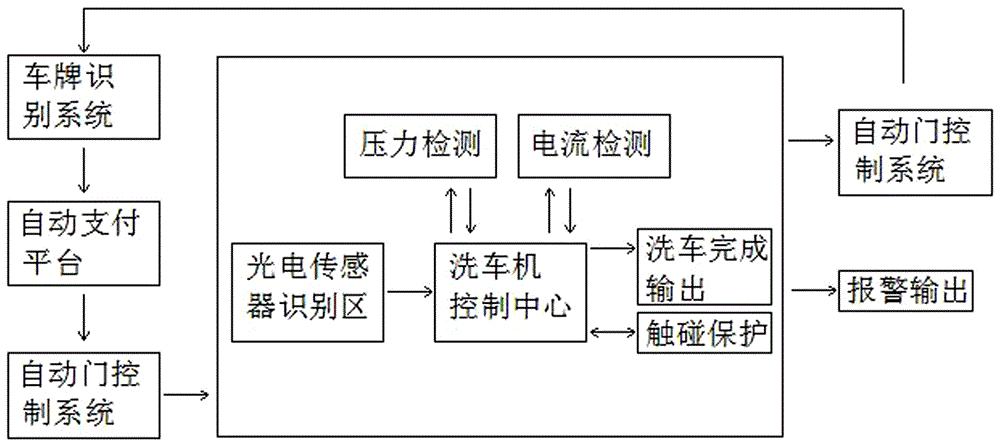

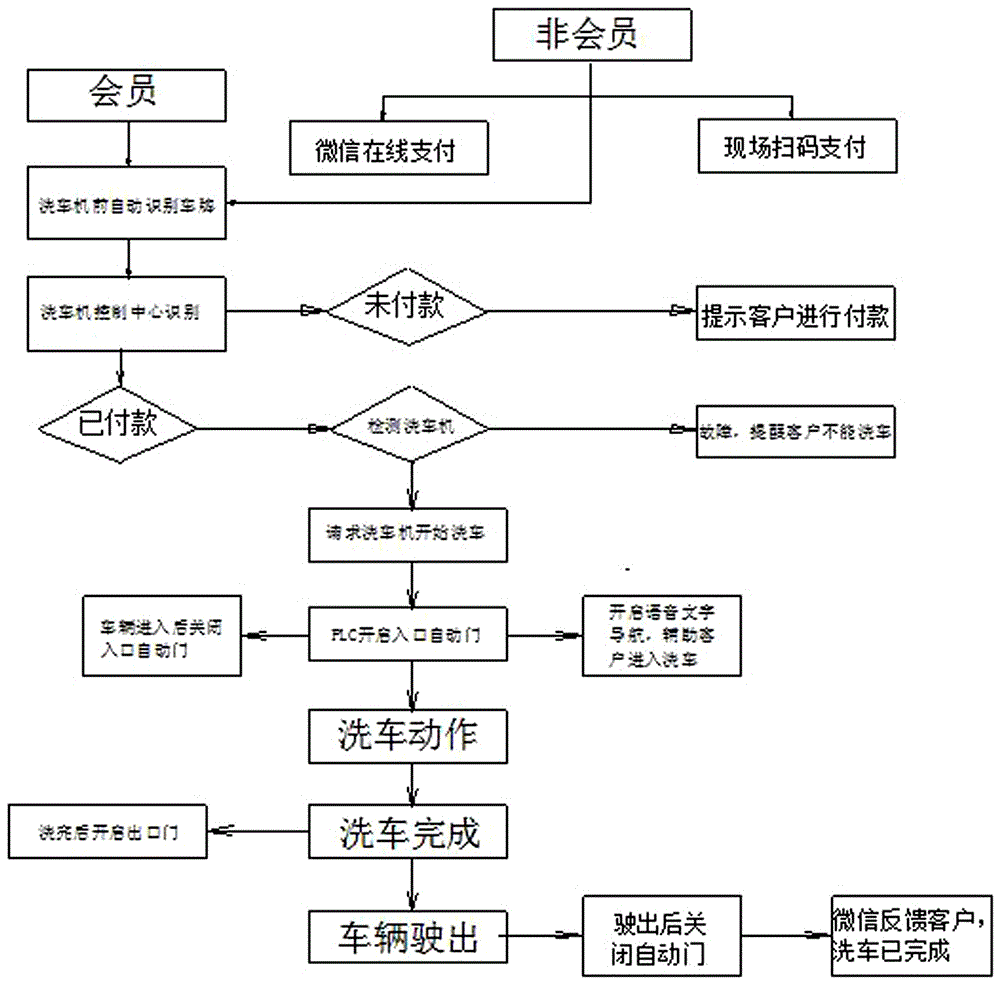

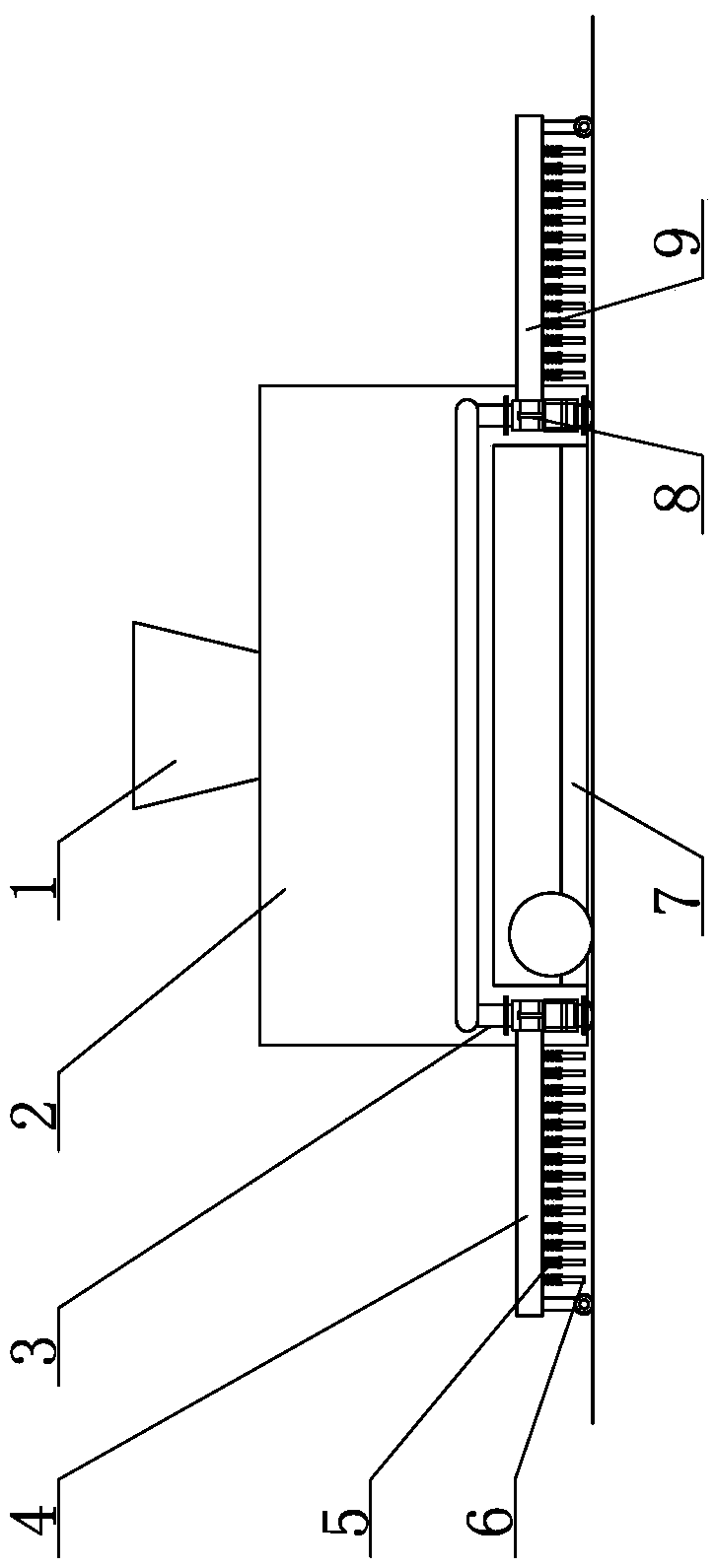

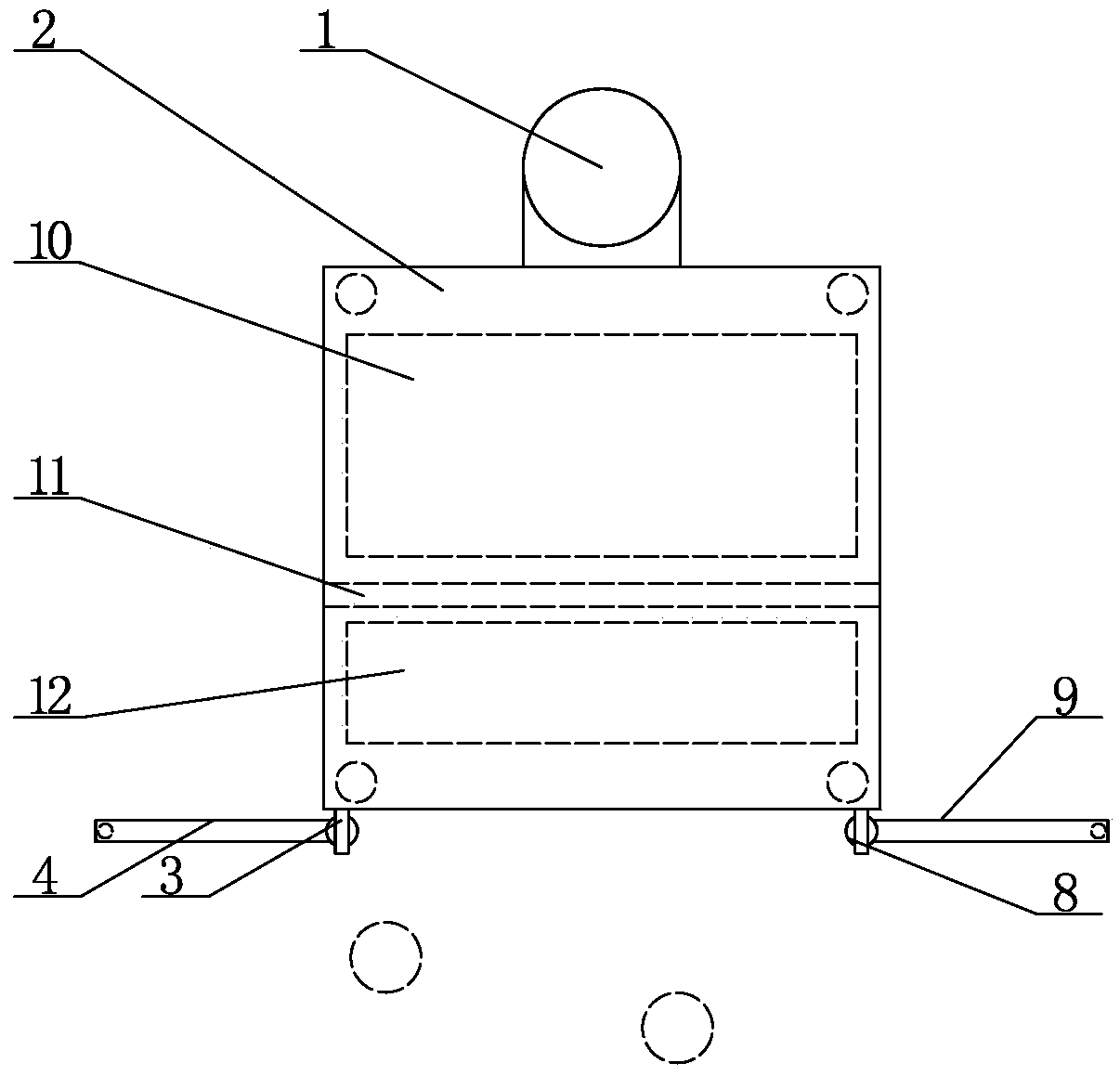

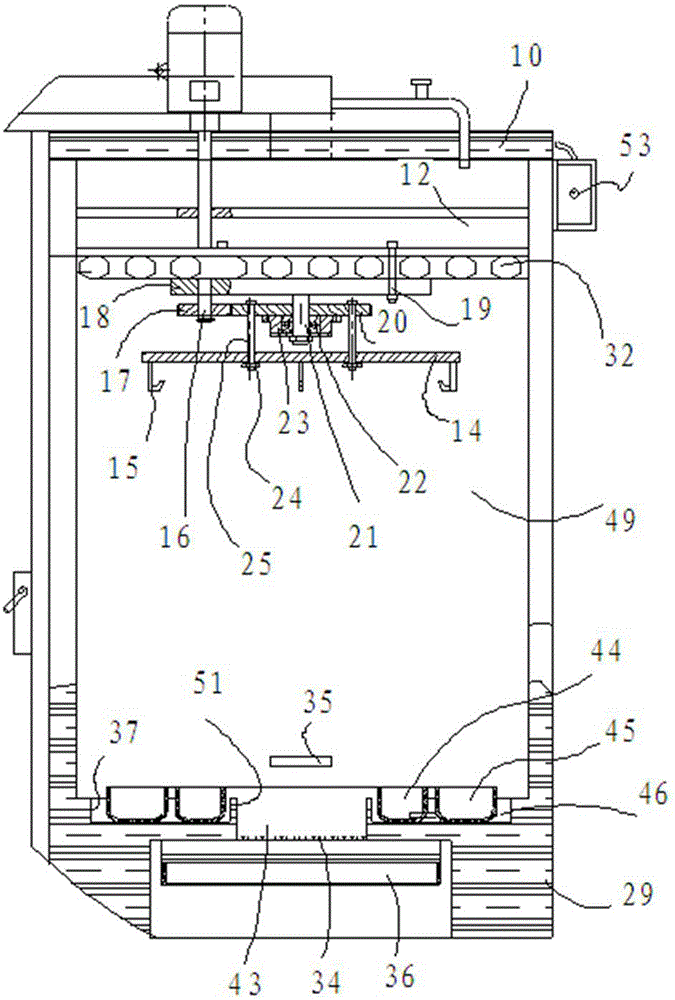

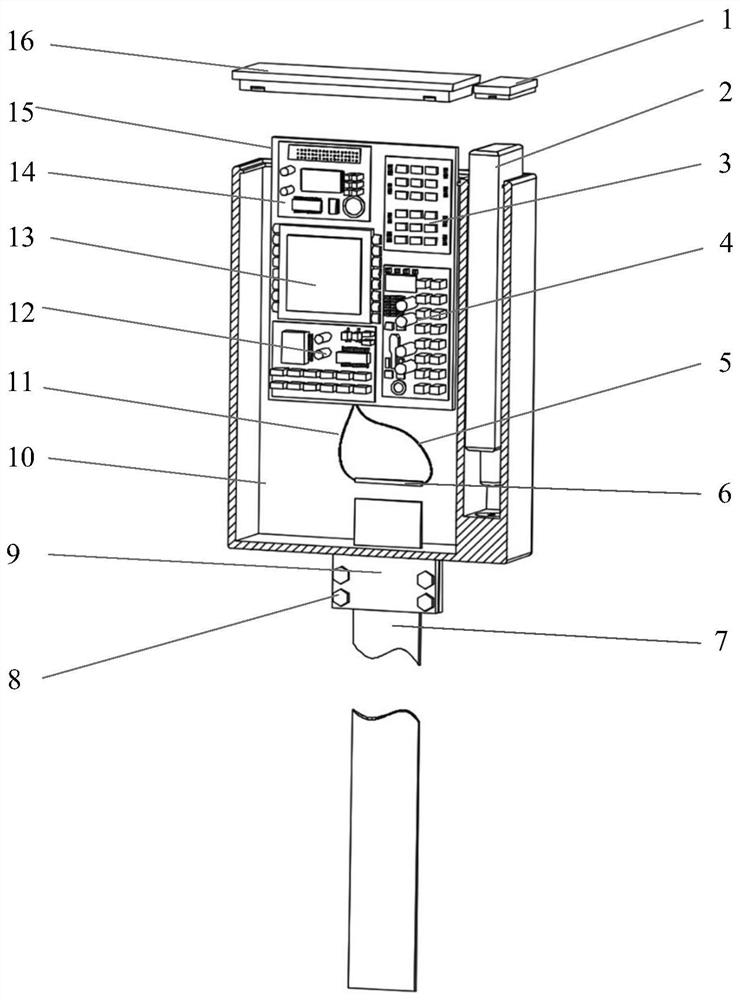

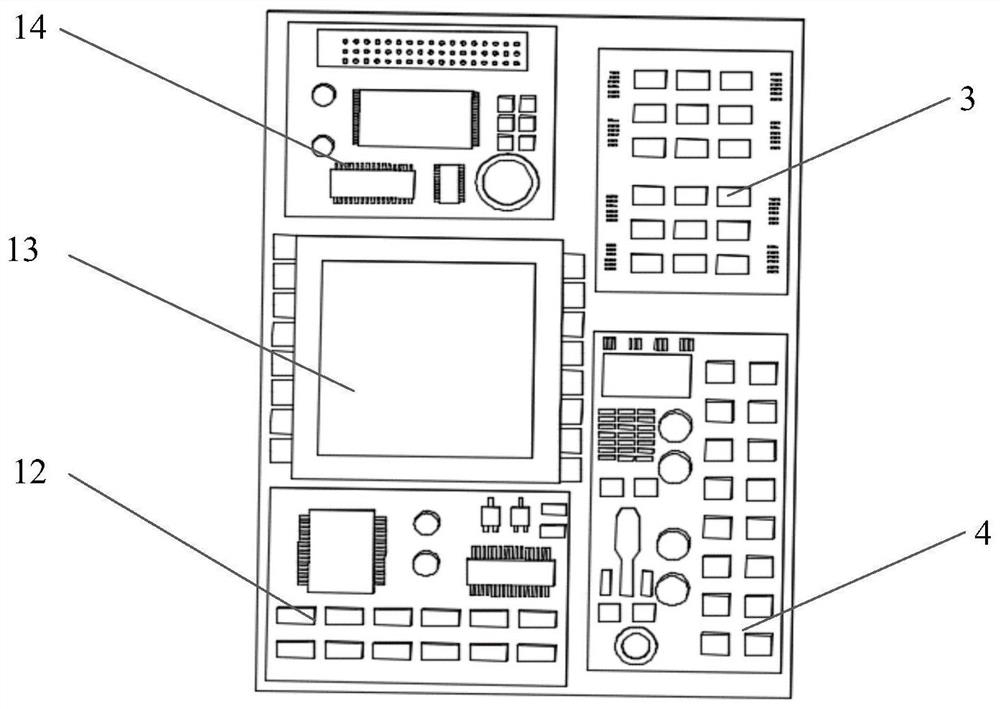

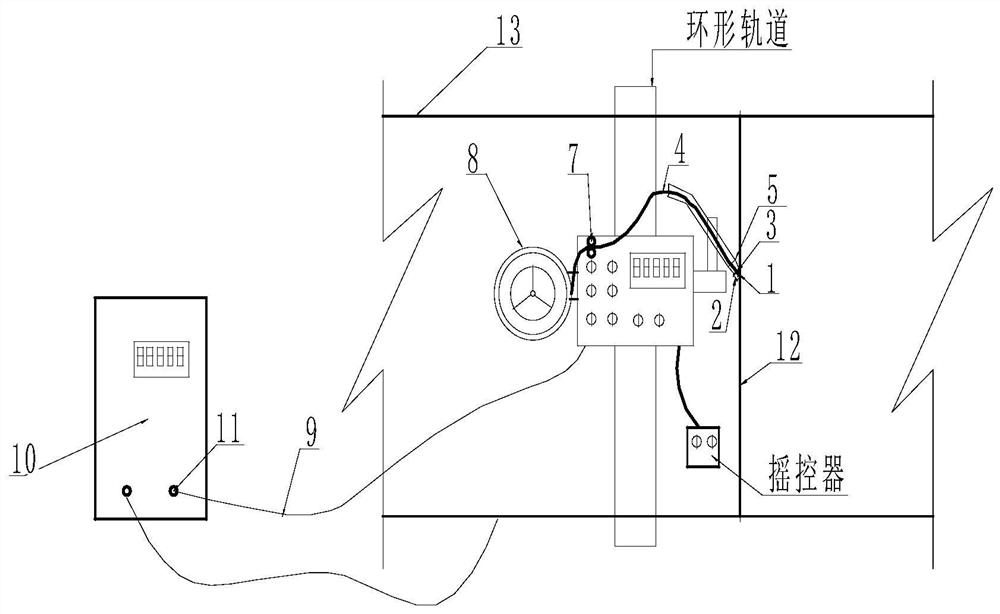

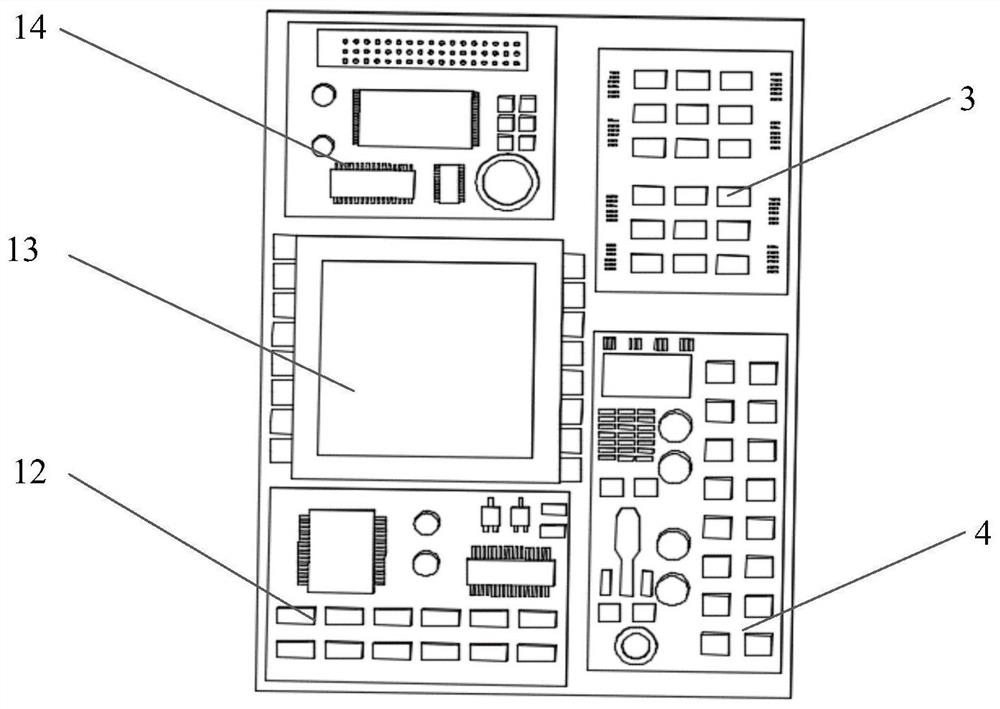

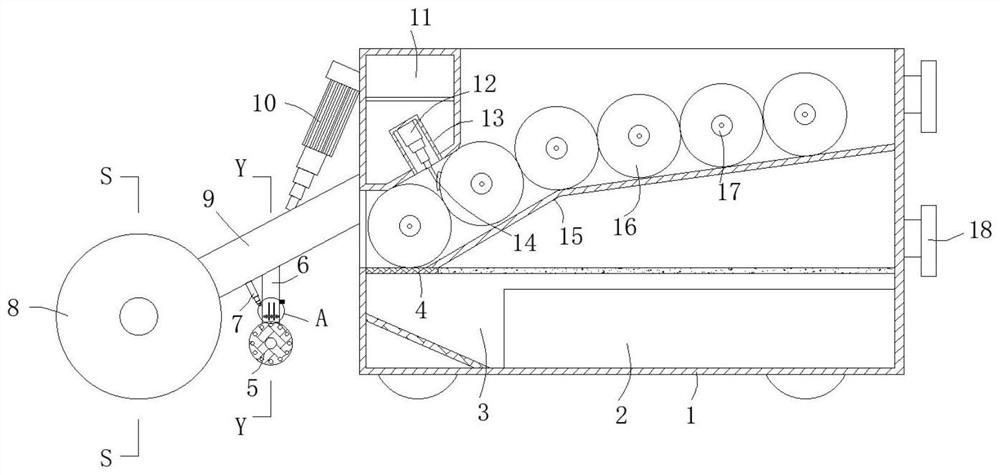

Intelligent control center and intelligent control method for full-automatic car washer

InactiveCN106541931AReduce auxiliary workCleaning apparatus for vehicle exteriorsAutomatic controlAutomotive engineering

The invention relates to the technical field of washing of motor vehicles, in particular to an intelligent control center and an intelligent control method for a full-automatic car washer. According to the technical scheme, the intelligent control center for the car washer comprises a central control module, wherein the central control module is respectively connected with a pressure detecting module, a current detecting module, a photoelectric identifying module and a touch protection switch; the pressure detecting module is connected with a pressure sensor of an air pressure system on the car washer; the current detecting module is connected with current sensors of various power sources on the car washer; the photoelectric identifying module is connected with various photoelectric sensors on the car washer; and the touch protection switch is connected with various travel switches on the car washer. Because car washing actions are controlled automatically in a whole process, cars are washed by a machine or a computer completely, the cars can be washed in a pipelined manner, manual auxiliary operation is omitted, the amount of cleaning water and the amount of cleaning fluid are controlled, and therefore, the intelligent control center and the intelligent control method for the full-automatic car washer is environment-friendly and energy-saving.

Owner:DONGGUAN SAIL AUTOMATION TECH CO LTD

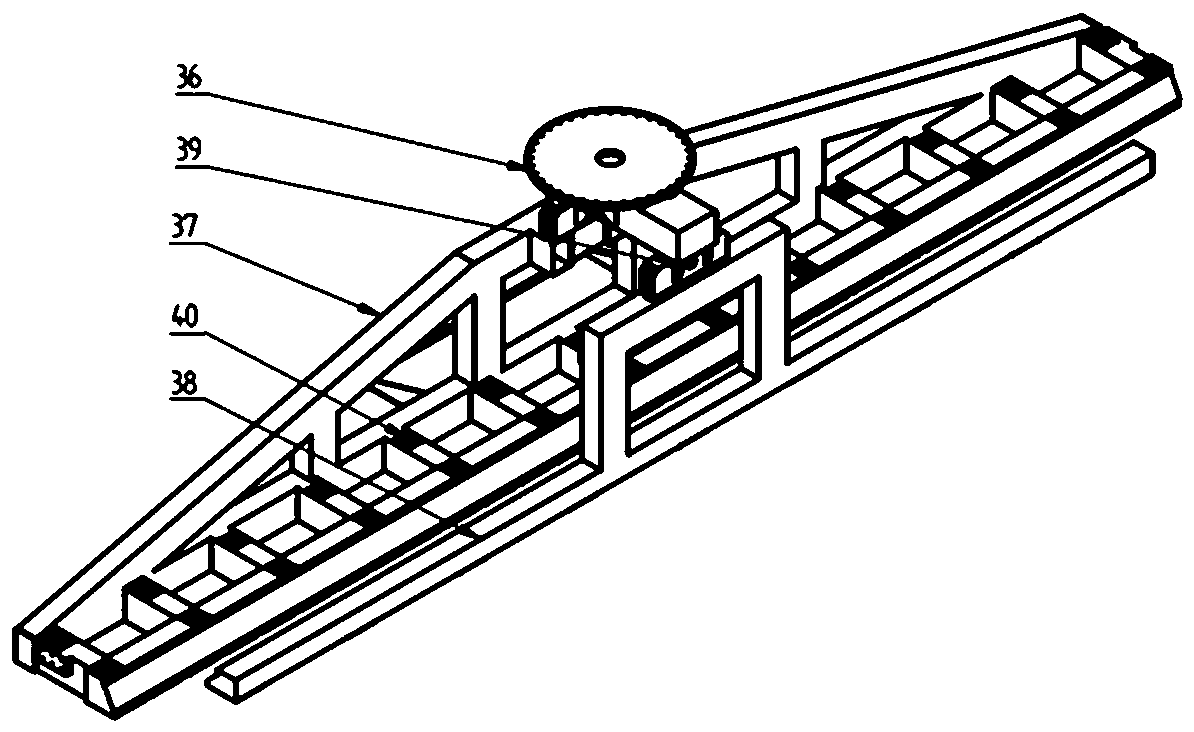

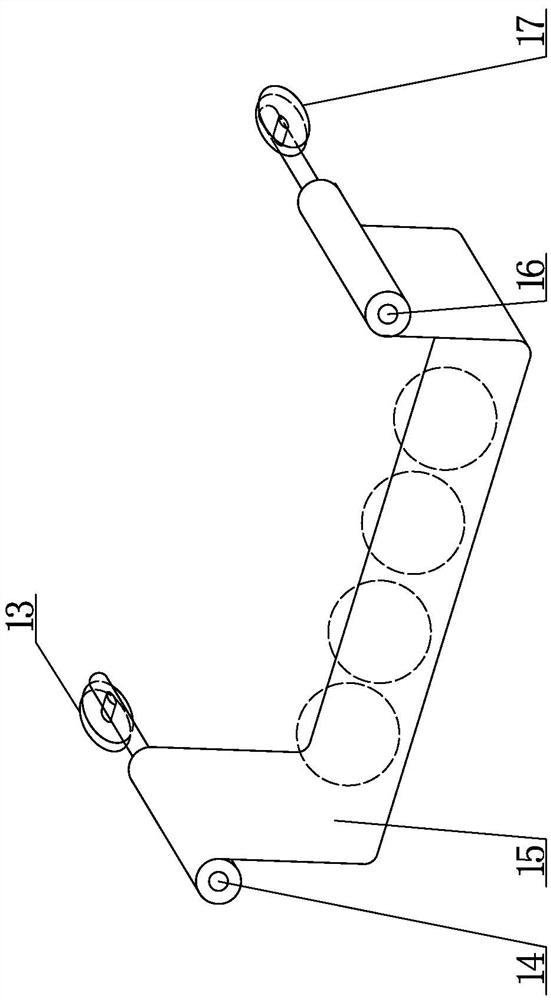

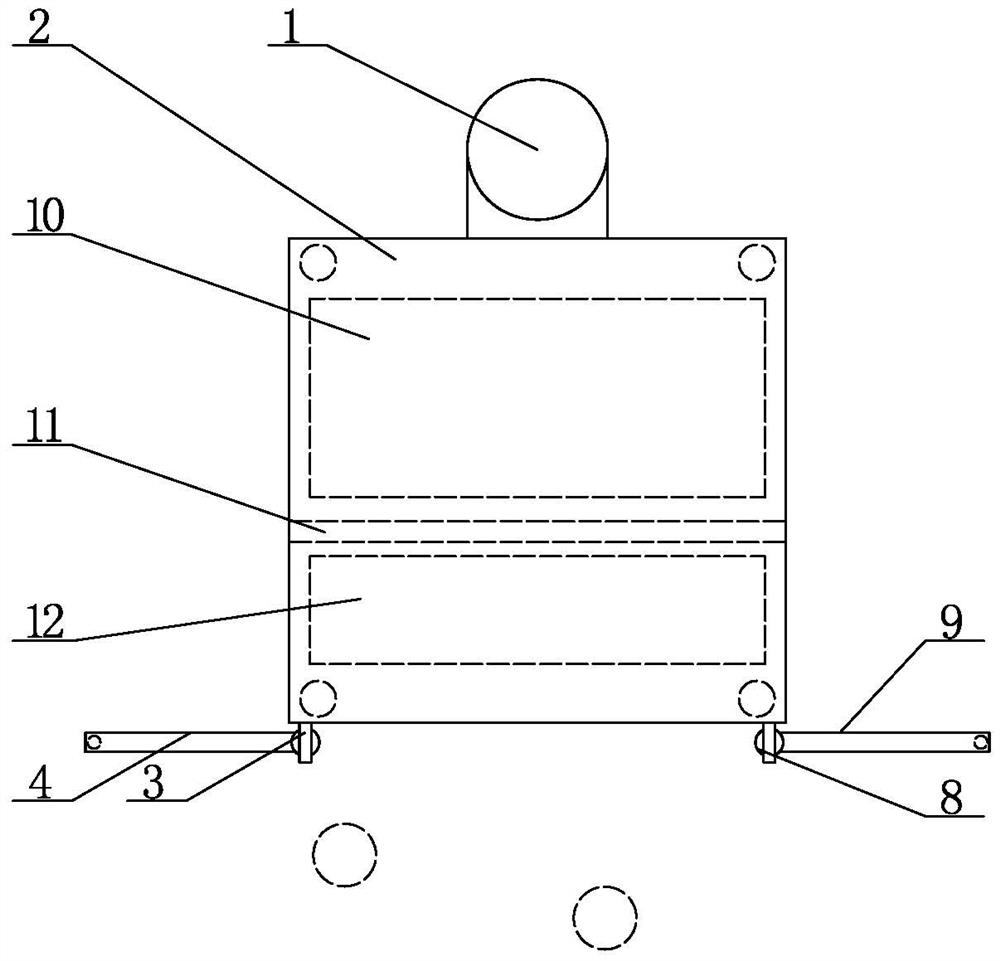

Indoor intelligent basketball collecting and training device

InactiveCN109045637AReduce auxiliary workImprove the efficiency of individual trainingBall sportsMechanical engineeringPhysical exercise

Owner:XIAN TECH UNIV

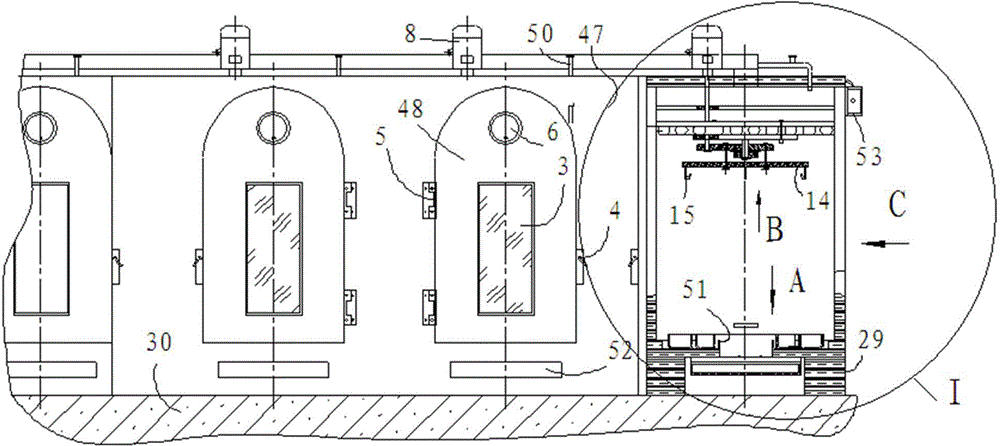

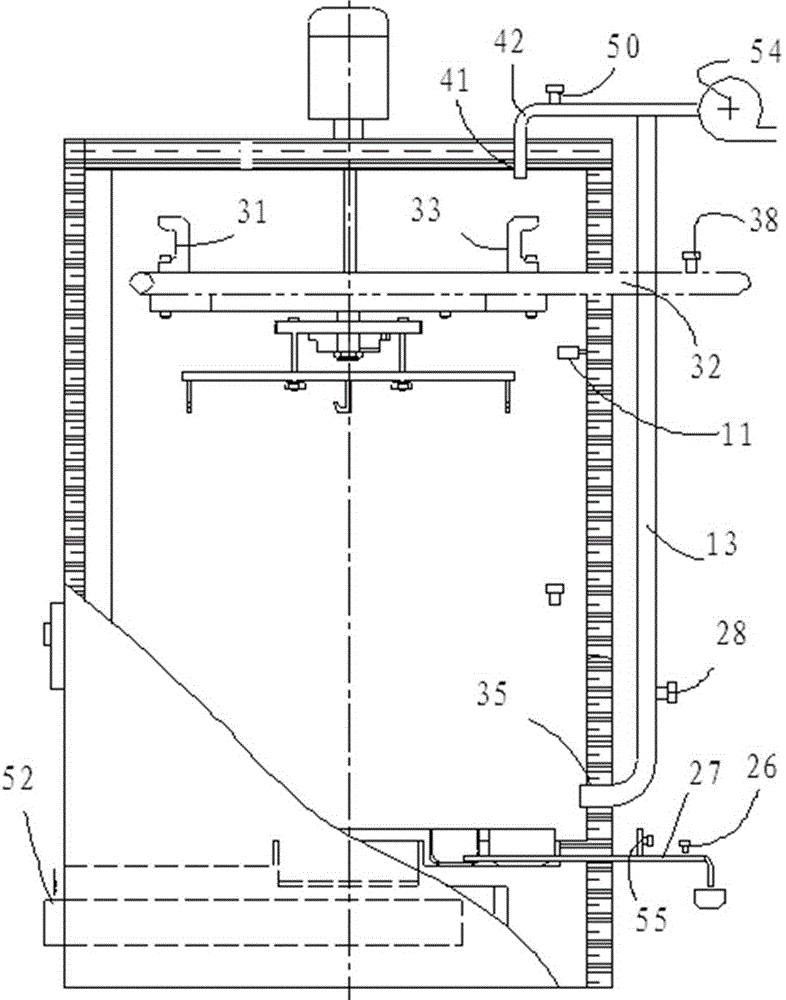

Goat roasting oven

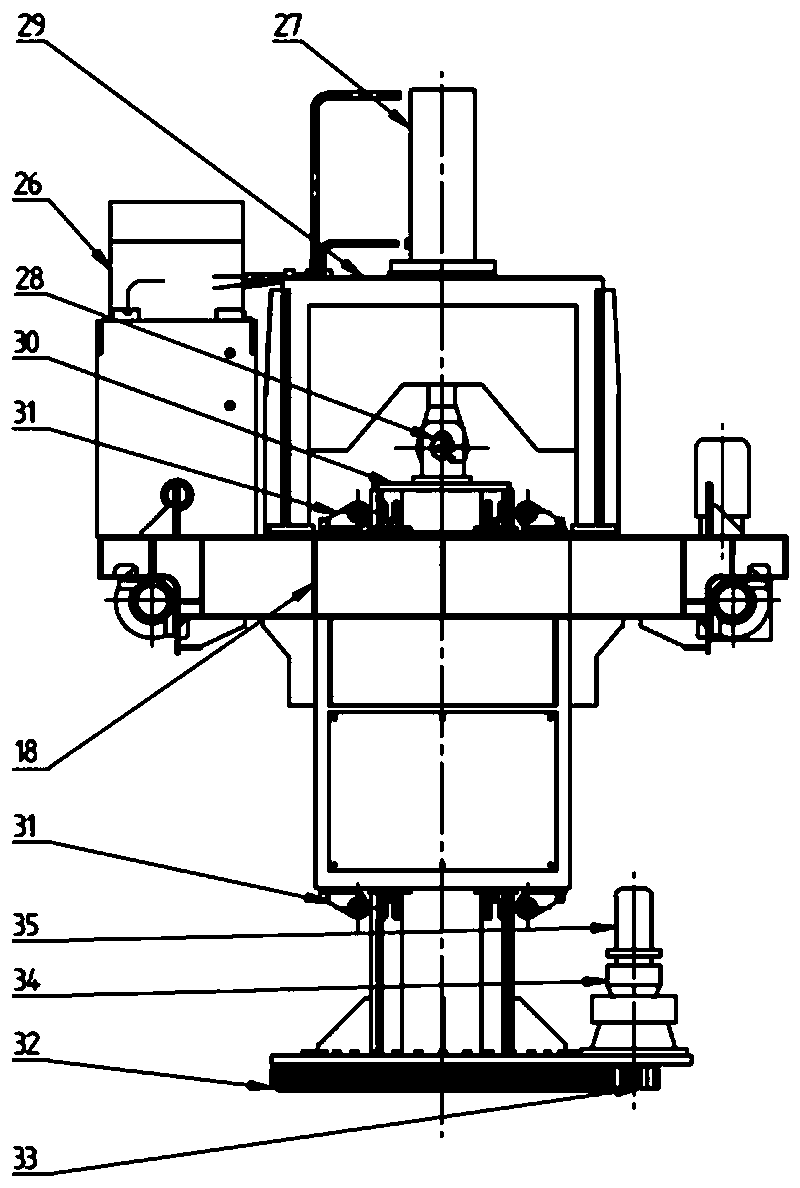

ActiveCN104304355ASmooth rotationGuaranteed qualityOven air-treatment devicesOven doors/gatesEngineeringExhaust pipe

The invention discloses a goat roasting oven. The goat roasting oven comprises a stove body, wherein a heat-preserving oven door is arranged at the front part of the oven body, a door opening handle is arranged on the oven door, a rotating structure is arranged at the upper part of the inner chamber of the oven body, the rotating structure is connected with a motor at the upper part of the outer side of the oven body, an upper smoke exhaust port is formed in the rear side of the top part of the oven body, the upper smoke exhaust port is connected with an upper smoke exhaust pipe, a switching valve is arranged on the upper smoke exhaust pipe, the upper smoke exhaust pipe is connected with a dust catcher through an induced draft fan, and the external part of the dust catcher is connected with a dust and oil stain collector; a hollow fire pan is arranged at the lower part of the oven body, a fire grate is arranged at the lower part of the fire pan, an ash tank is arranged at the lower part of the fire grate, the ash tank is matched with a surrounding wall surface, an air inlet with air inlet amount which can be adjusted is formed in the ash tank, an upper groove is formed in the upper part of the fire pan, an annular water storage groove is formed in the plane of the upper groove, an annular oil receiving groove is formed in the outer side of the water storage groove, and the outer side of the upper groove and the surrounding part of the oven body are of an integral structure. The goat roasting oven has the advantages that since a closed space is formed, the roasting efficiency is high, the occupied space is smaller and the goat roasting oven is particularly suitable for places with numerous people who have meals.

Owner:济南龙乡食品有限公司

Polymer bushing and cable terminal end connector using the same

ActiveCN1864309AShorten the lengthReduce weightCable fittingsApparatus for joining/termination cablesElectrical conductorEmbedment

It is intended to achieve the weight reduction, sliming, and downsizing of bushings, commonality of types of bushings, and simplification of operating steps. A polymer bushing comprises a conductor draw-out bar (1) having a conductor insertion hole (1a) in the lower end, a hard insulation sleeve (2) installed around the outer periphery of the conductor draw-out bar (1), a polymer clad body (3) installed around the outer periphery of the insulation sleeve (2), and an electric field mitigation layer installed on the interface between the insulation sleeve (2) and the polymer clad body (3). The insulation sleeve (2) comprises a large-diameter insulation sleeve (2a) installed around the outer periphery of the lower region of the conductor draw-out bar (1), and a small-diameter insulation sleeve (2b) installed around the outer periphery of a portion of the conductor draw-out bar (1) excluding the front end. An embedment metal part (4) for electric field mitigation purposes is embedded in a portion of connection between the large- and small-diameter insulation sleeves (2a, 2b). Further, installed at the lower end of the large-diameter insulation sleeve (2a) is a cone-shaped receiving port (5) for receiving the stress cone (13) of a cable terminal (11), the receiving port (5) communicating with the conductor insertion hole (1a) in the conductor draw-out bar (1).

Owner:SWCC SHOWA CABLE SYST CO LTD

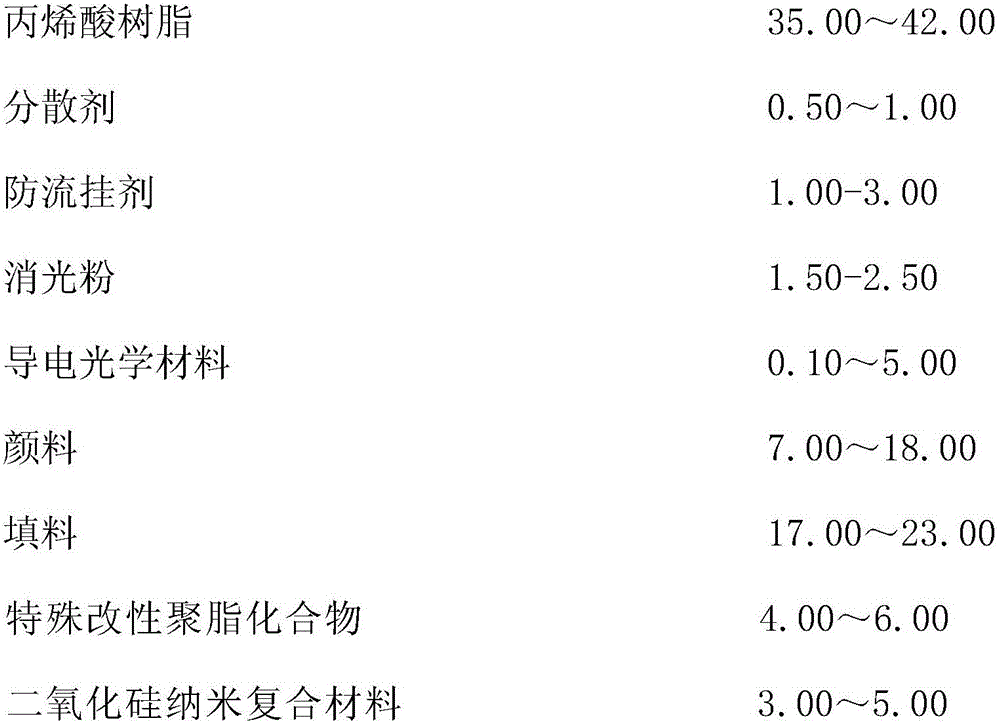

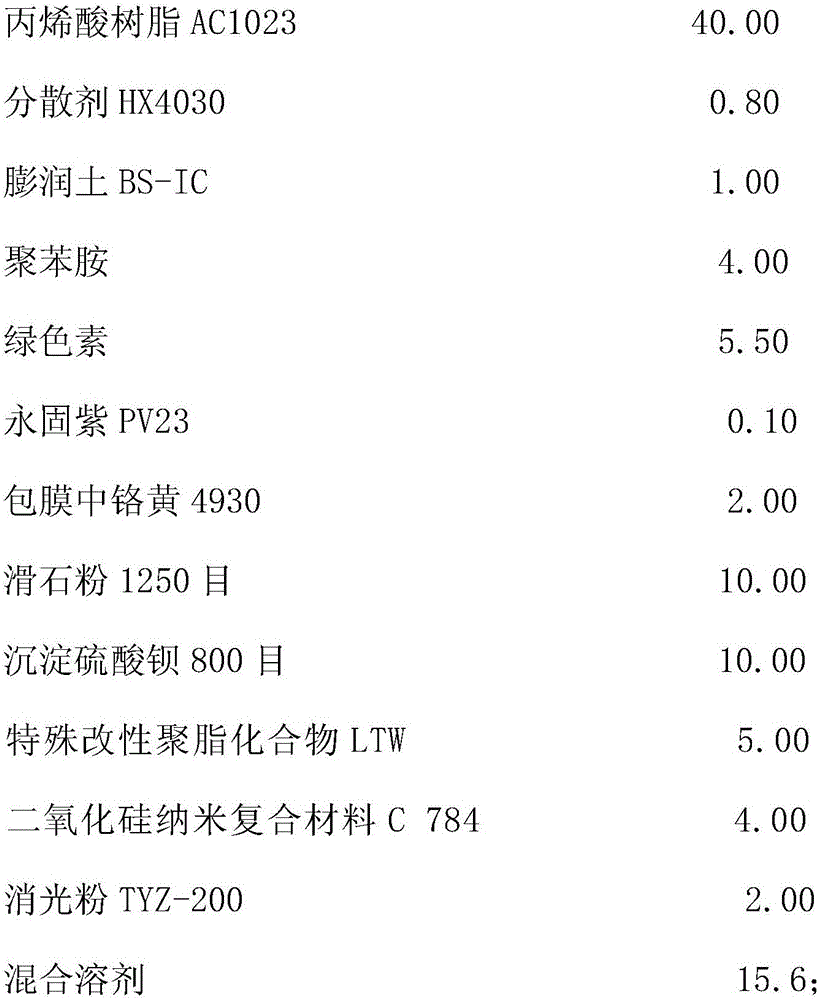

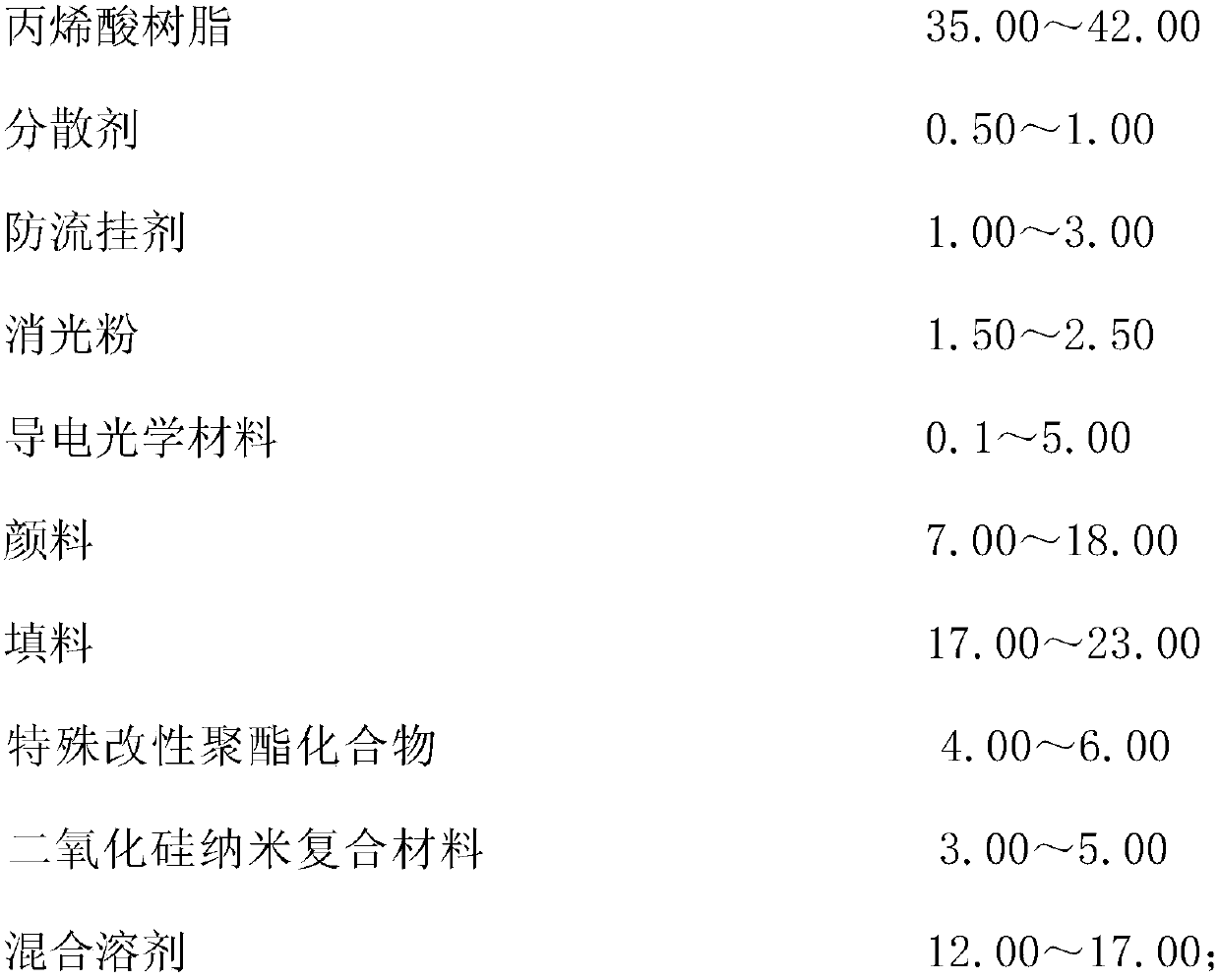

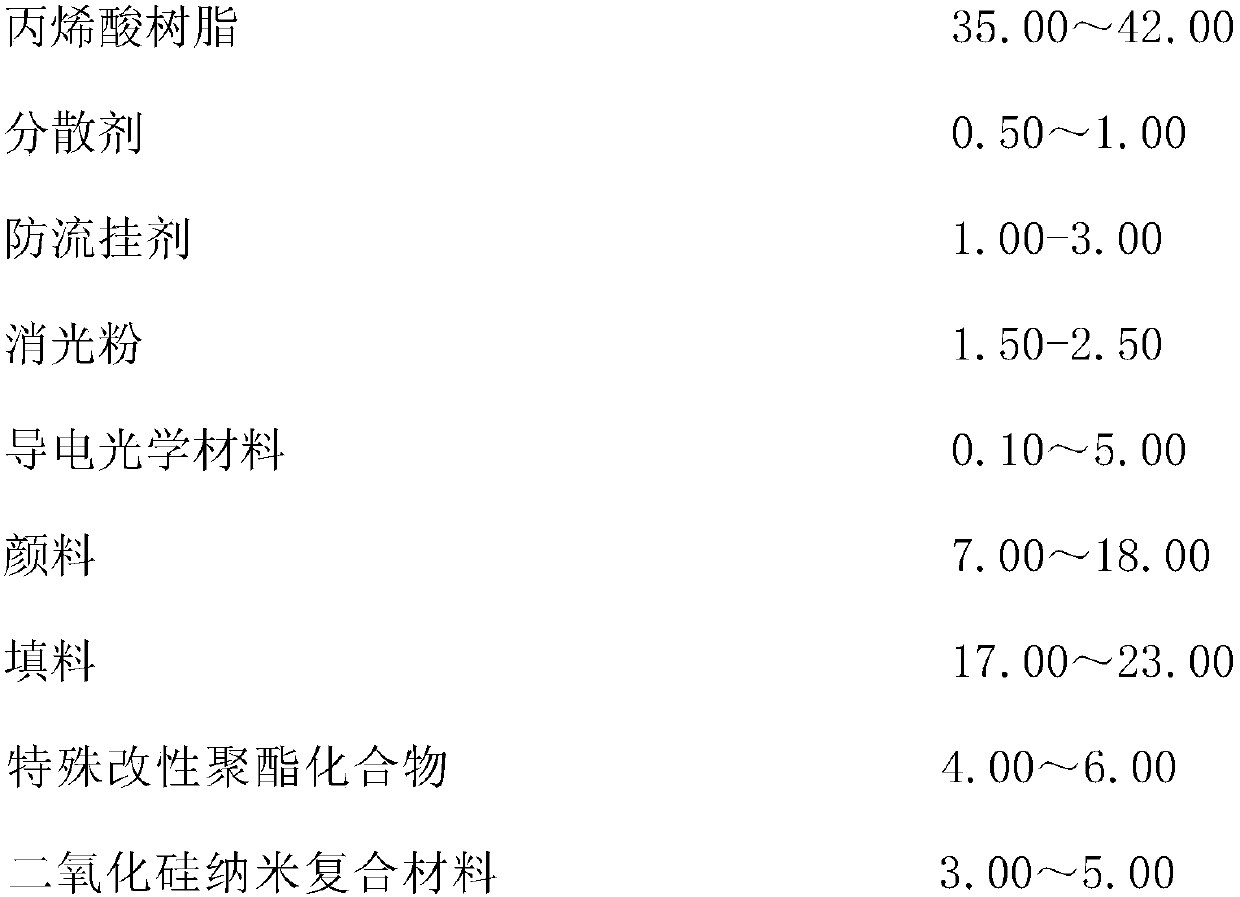

Automatic spraying camouflage coating for manipulators and method for preparing automatic spraying camouflage coating

The invention discloses automatic spraying camouflage coating for manipulators and a method for preparing the automatic spraying camouflage coating. The method includes (1), adding 35.00-42.00 parts of acrylic resin, 0.50-1.00 part of dispersing agents, 1.00-3.00 parts of anti-sagging agents, 1.50-2.50 parts of extinction powder, 0.10-5.00 parts of electrically conductive optical materials, 7.00-18.00 parts of pigment, 17.00-23.00 parts of fillers and 6.00-8.50 parts of mixed solvents into an accessory tank and uniformly stirring the acrylic resin, the dispersing agents, the anti-sagging agents, the extinction powder, the electrically conductive optical materials, the pigment, the fillers and the mixed solvents to obtain first mixtures; (2), grinding the first mixtures by the aid of a sand mill until the fineness of the first mixtures reaches 18-22 micrometers; (3), adding 4.00-6.00 parts of special modified polyester compounds, 3.00-5.00 parts of silicon dioxide nanometer composite materials and 6.00-8.50 parts of mixed solvents into paste and uniformly stirring the special modified polyester compounds, the silicon dioxide nanometer composite materials, the mixed solvents and the paste to obtain second mixtures; (4), regulating the viscosity of the second mixtures until the viscosity of the second mixtures reaches coating-4 cup 65-80 S; (5), filtering and packaging the automatic spraying camouflage coating. The automatic spraying camouflage coating and the method have the advantages that the automatic spraying camouflage coating is reasonable in design and has tone which is consistent with natural backgrounds, anti-infrared camouflage effects of spectral reflection curves can be realized by the automatic spraying camouflage coating, and problems in the aspects of sagging, drying speeds, surface smoothness and the like in automatic paint spraying procedures can be solved.

Owner:CHANGZHOU JIAERKE SIMULATION EQUIP CO LTD

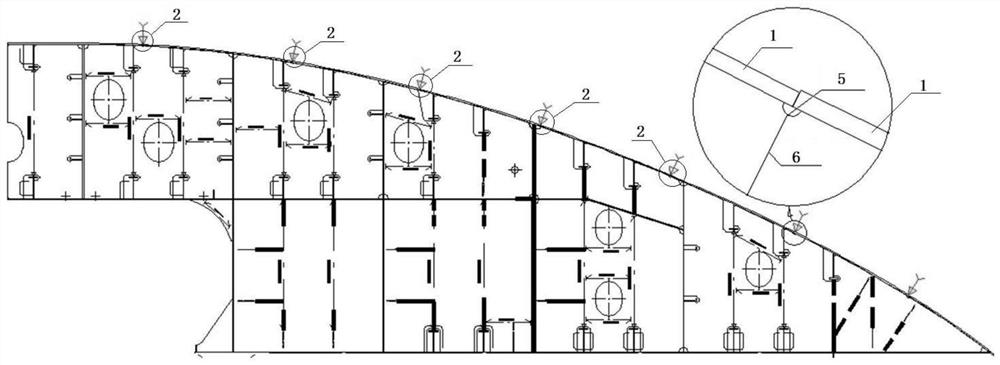

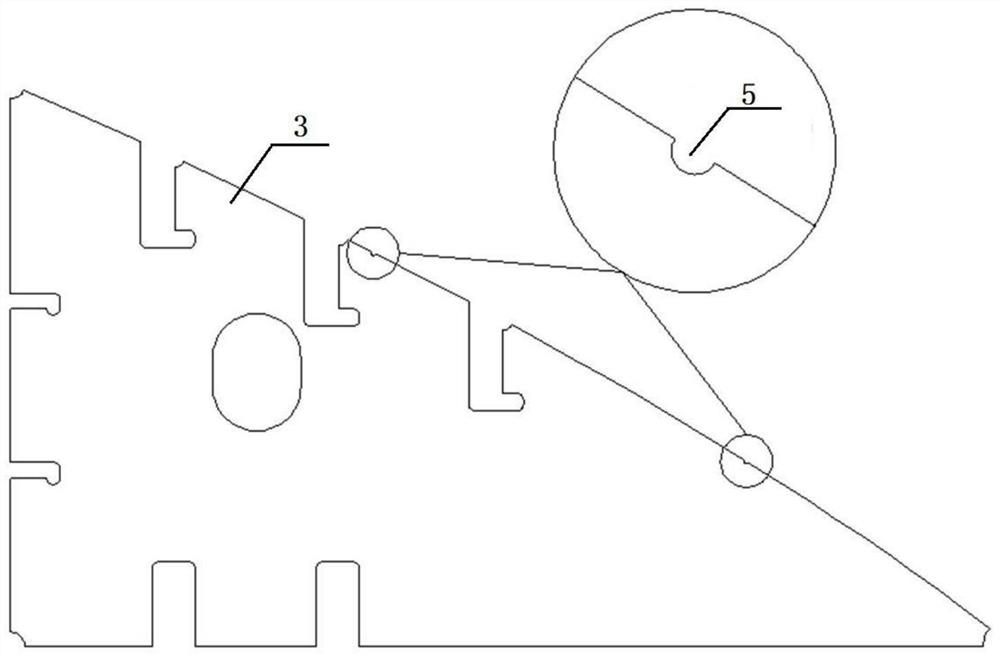

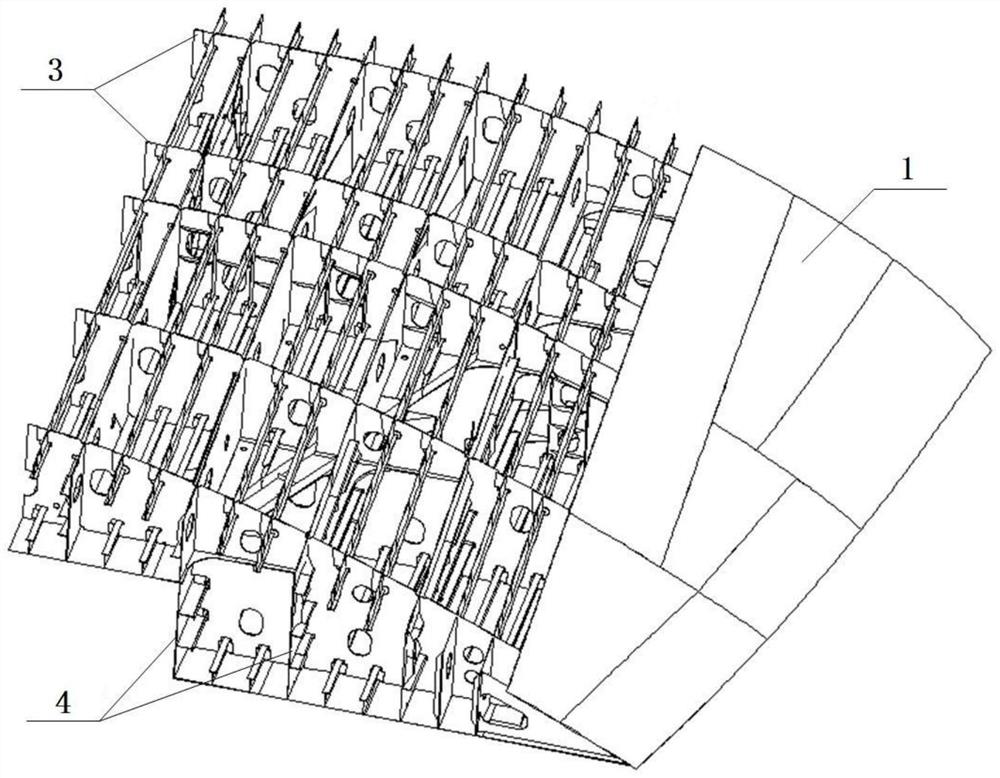

Positioning method for bulk outer plate

PendingCN114228940AAvoid gap over toleranceAvoid the situationVessel designingNumerical controlMarking out

The invention discloses a bulk outer plate positioning method, which comprises the following steps of: marking an outer plate positioning mark on a segmented internal component of a segmented three-dimensional model, and then generating a segmented internal component processing drawing by utilizing the segmented three-dimensional model with the outer plate positioning mark; a numerical control machine tool can be directly used for cutting the segmented internal components with the outer plate positioning holes or the outer plate positioning lines, when the segments are built, relevant marks such as ground lines do not need to be surveyed on the ground below the segments, and the bulk outer plates can be accurately positioned by directly using the outer plate positioning holes or the outer plate positioning lines on the segmented internal components. A large amount of auxiliary work is reduced, meanwhile, the installation precision and the installation efficiency of the bulk outer plates are improved, and the situation that gaps of the outer plates are out of tolerance and staggered when the outer plates are assembled and carried is avoided.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

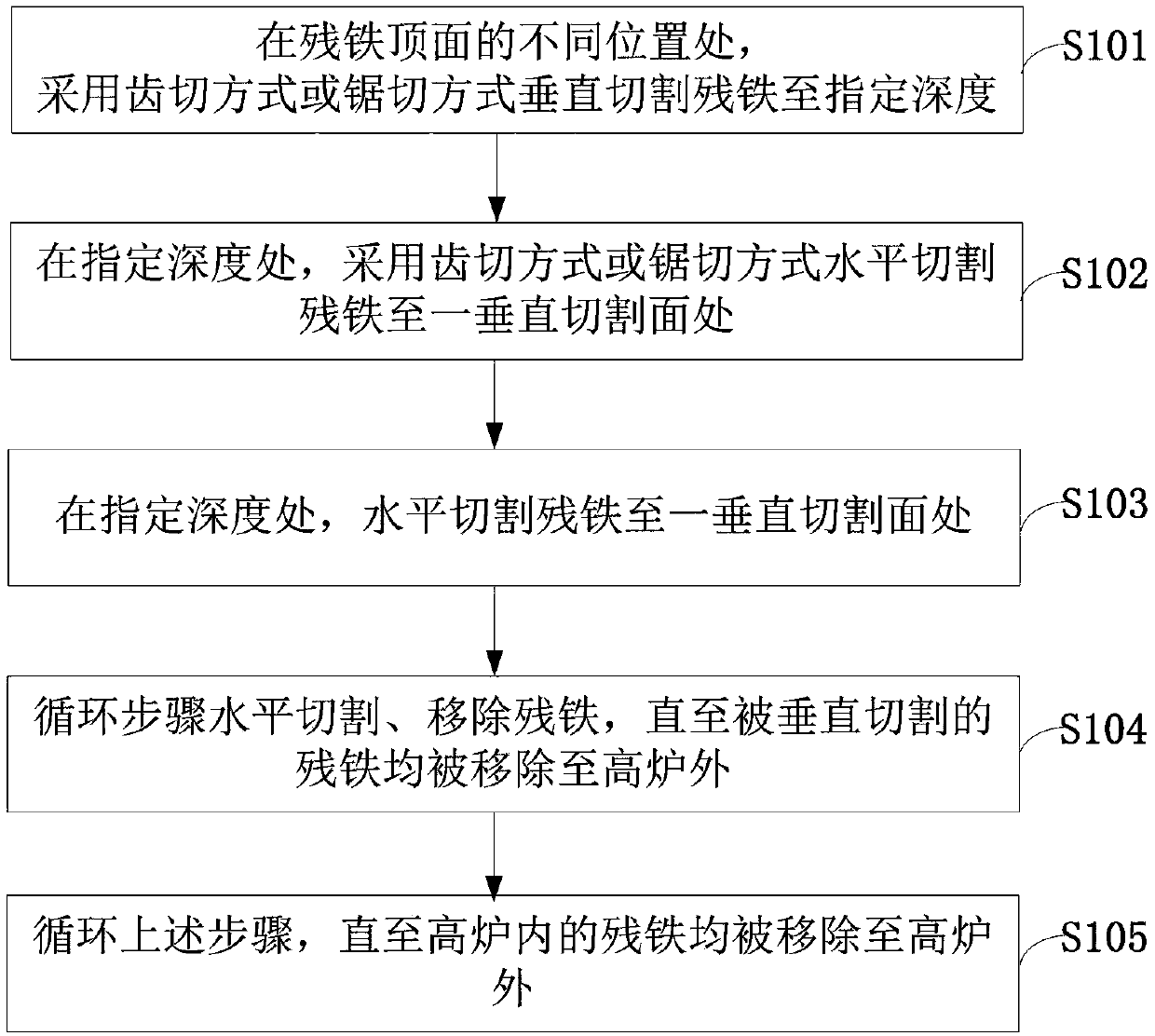

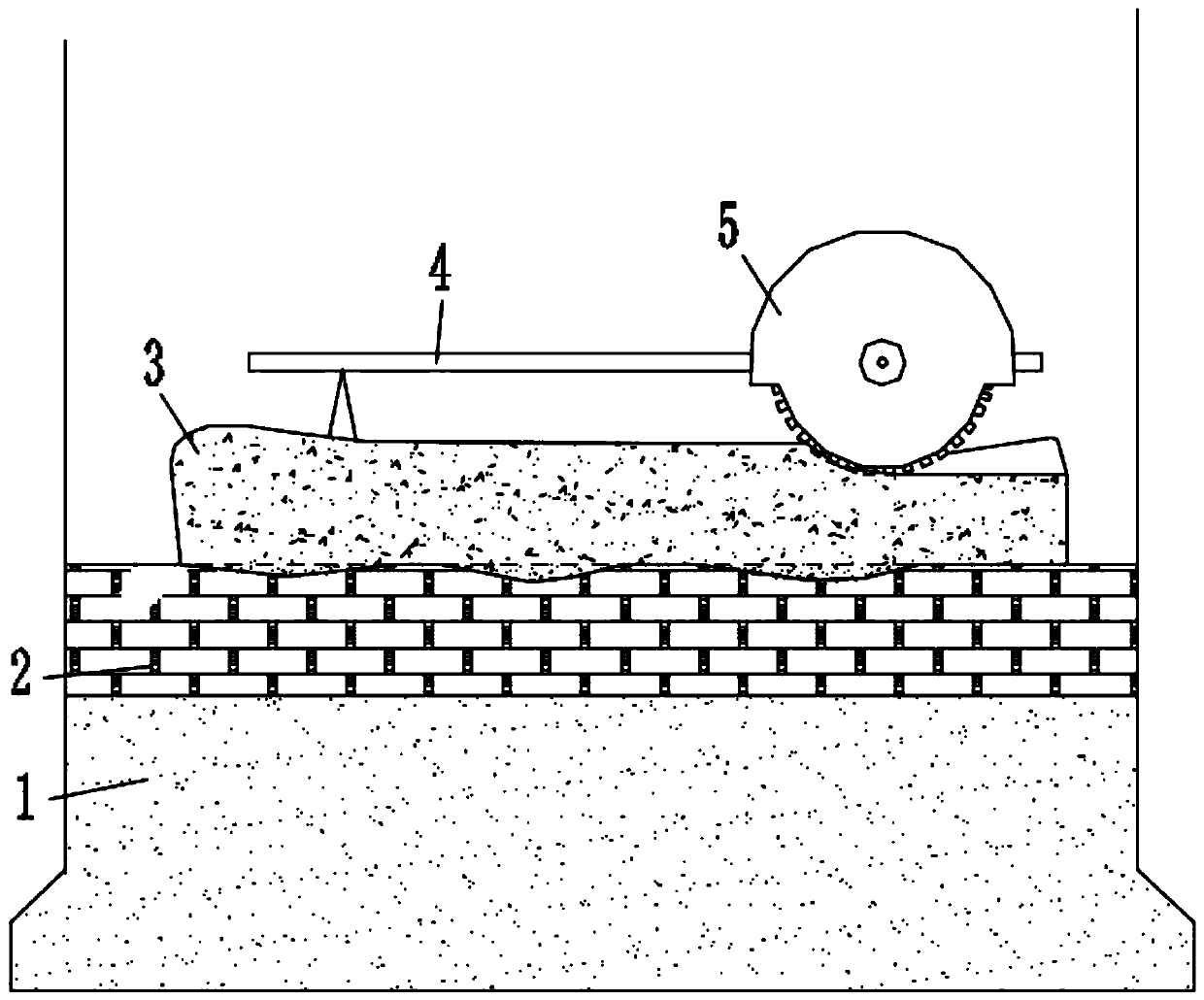

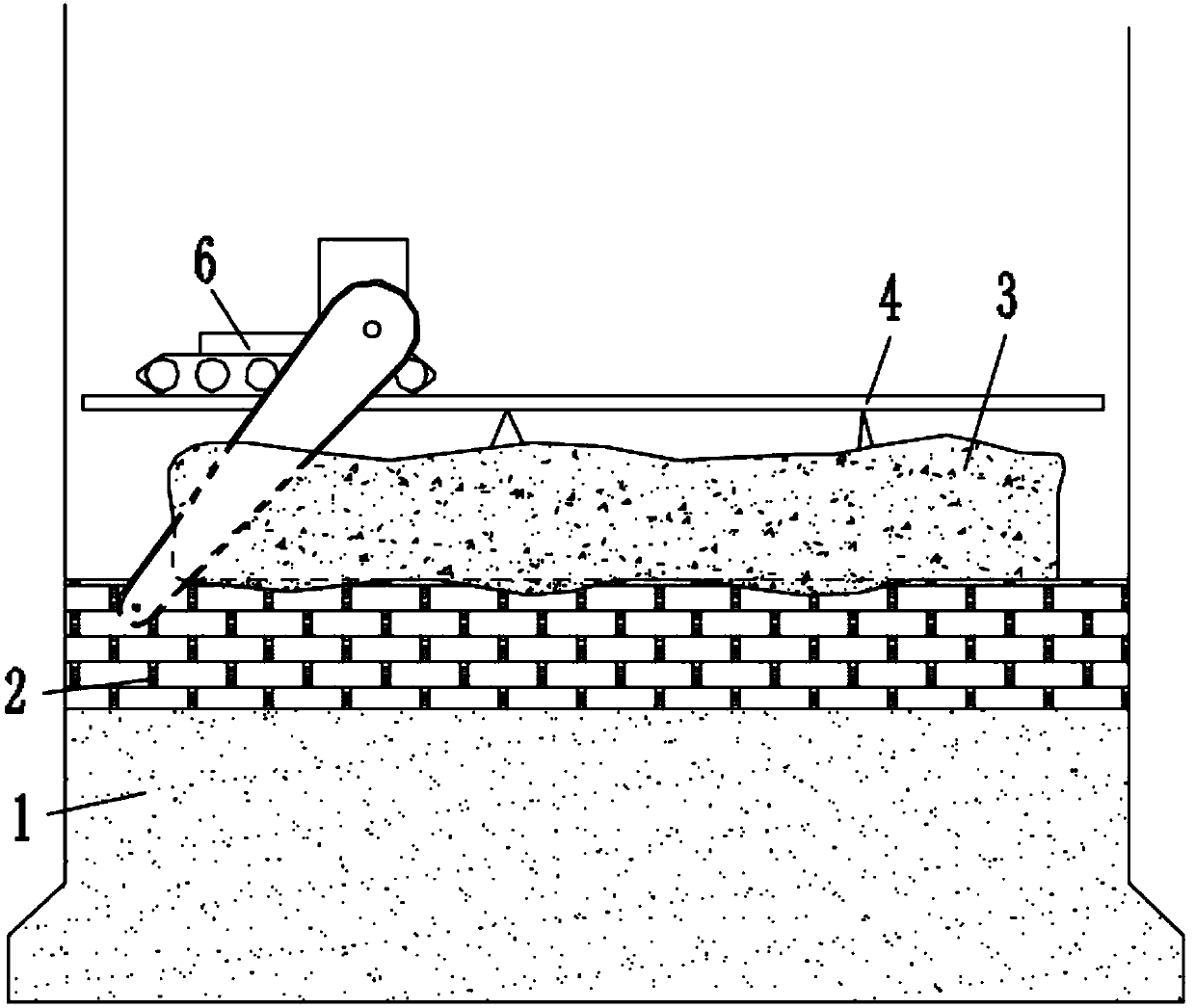

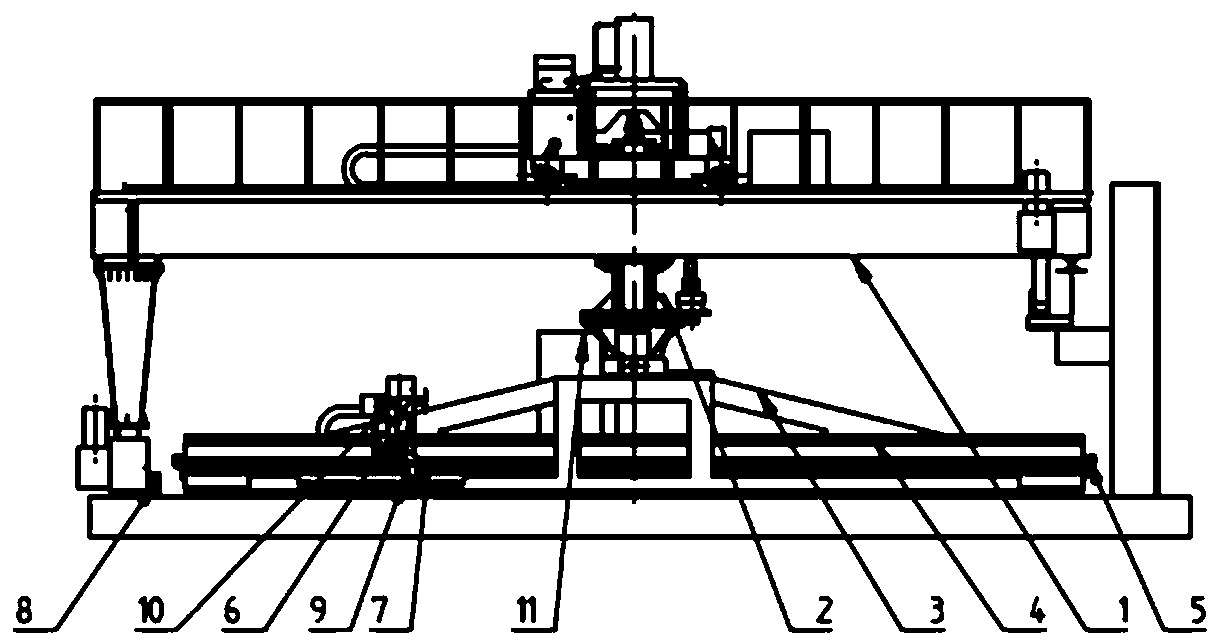

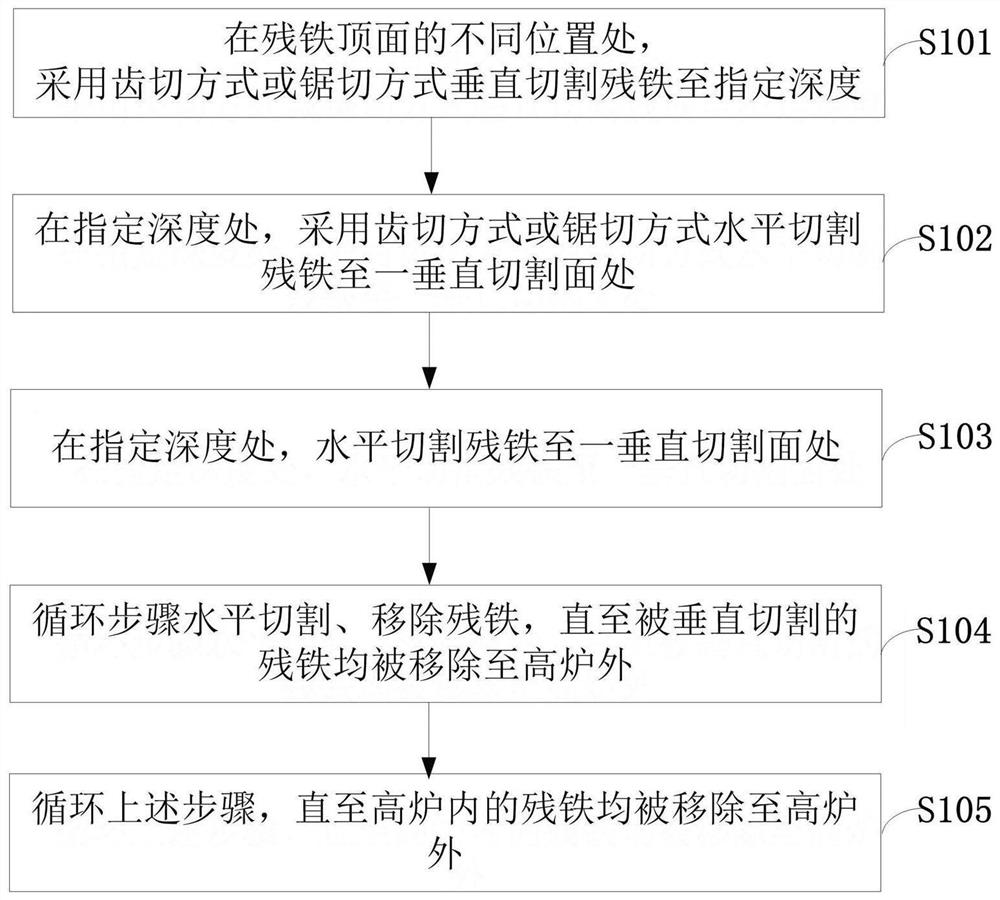

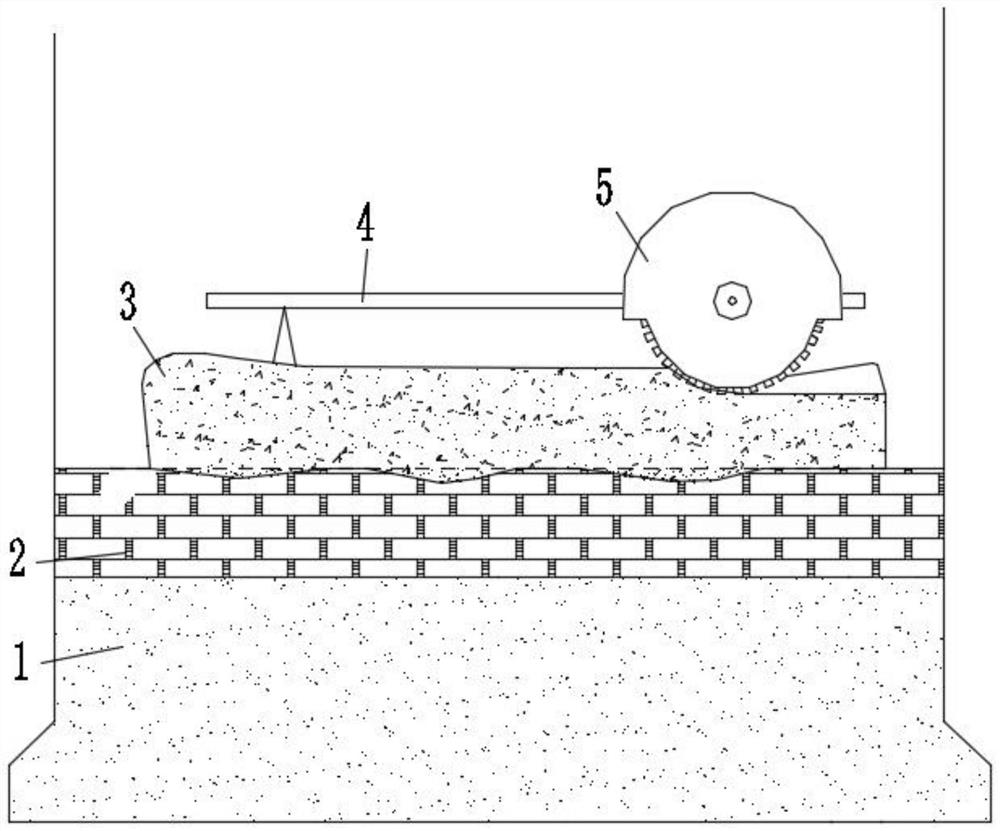

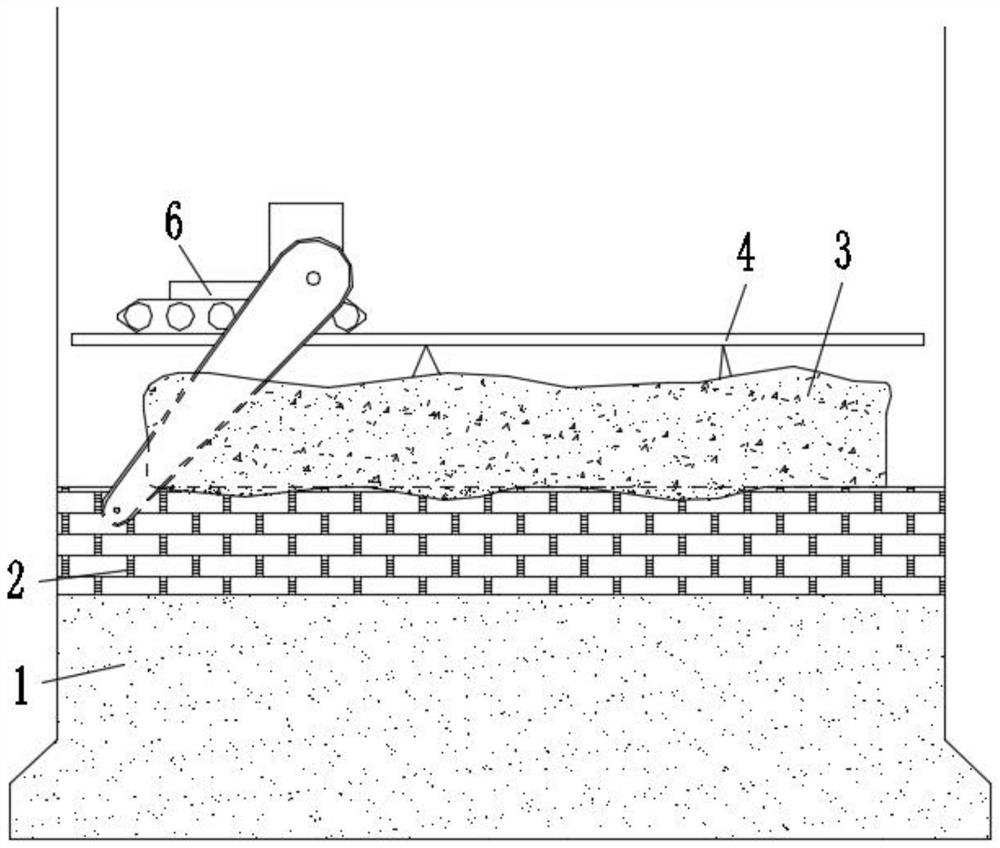

Method for decomposing residual iron of blast furnace

ActiveCN109628673AEasy to installReduce auxiliary workBlast furnace detailsProcess efficiency improvementIron removalHot blast

The invention discloses a method for decomposing residual iron of a blast furnace. The method comprises the steps that vertical cutting is carried out, wherein the residual iron is vertically cut to aspecific depth in a tooth cutting or saw cutting mode at different positions on the top face of the residual iron; horizontal cutting is carried out, wherein at the specific depth position, the residual iron is horizontally cut to a vertical cutting face in a tooth cutting or saw cutting mode; the residual iron is removed, wherein the separated residual iron is removed out of the blast furnace; horizontal cutting and residual iron removal are repeated until the vertically cut residual iron is removed out of the blast furnace completely; and the steps are repeated until the residual iron in the blast furnace is removed out of the blast furnace completely. The invention discloses another method for decomposing the residual iron of the blast furnace. The method includes the steps that vertical cutting is carried out; the residual iron is broken by using external force; the residual iron is removed; the steps of breaking the residual iron by using external force and removing the residualiron are repeated until the vertically cut residual iron is removed out of the blast furnace completely; and the steps are repeated until the residual iron in the blast furnace is removed out of the blast furnace completely. The methods have the advantages that installation is easy, the cutting efficiency is high, and safety is achieved.

Owner:福州天石源超硬材料工具有限公司

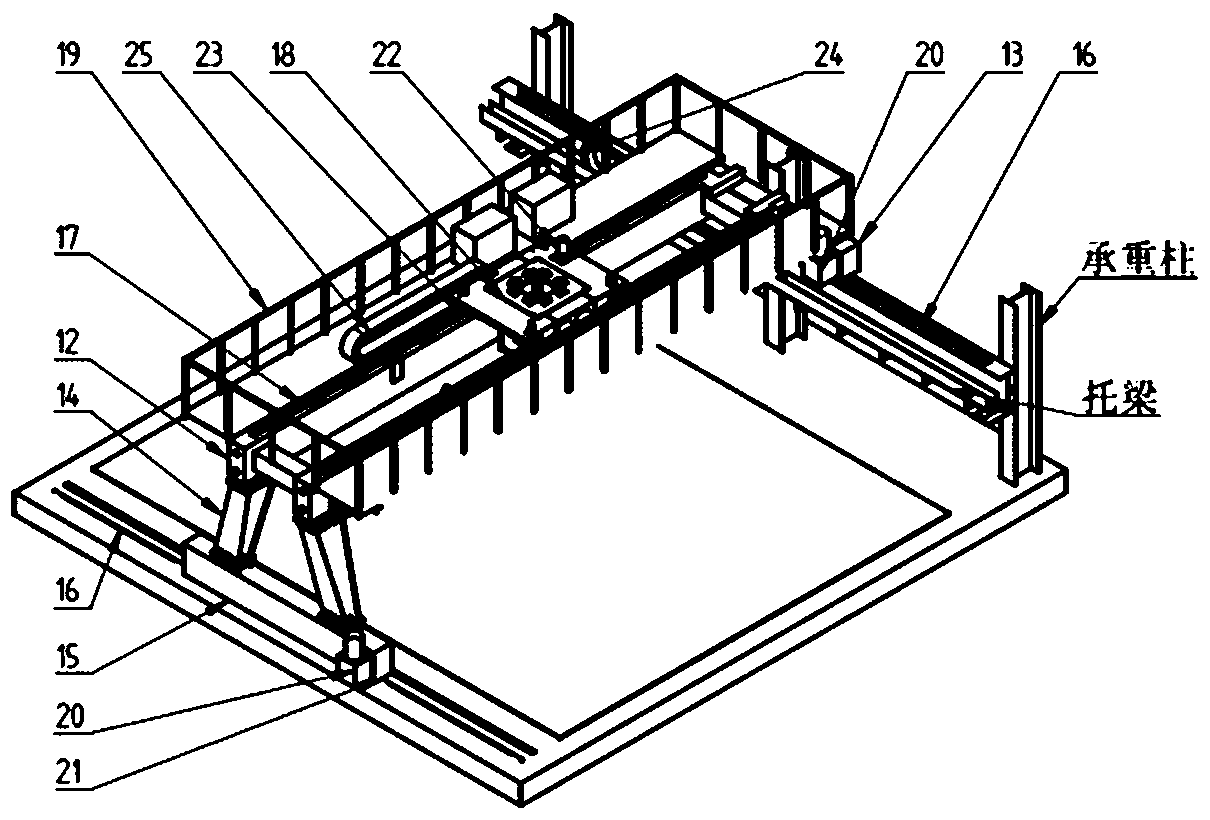

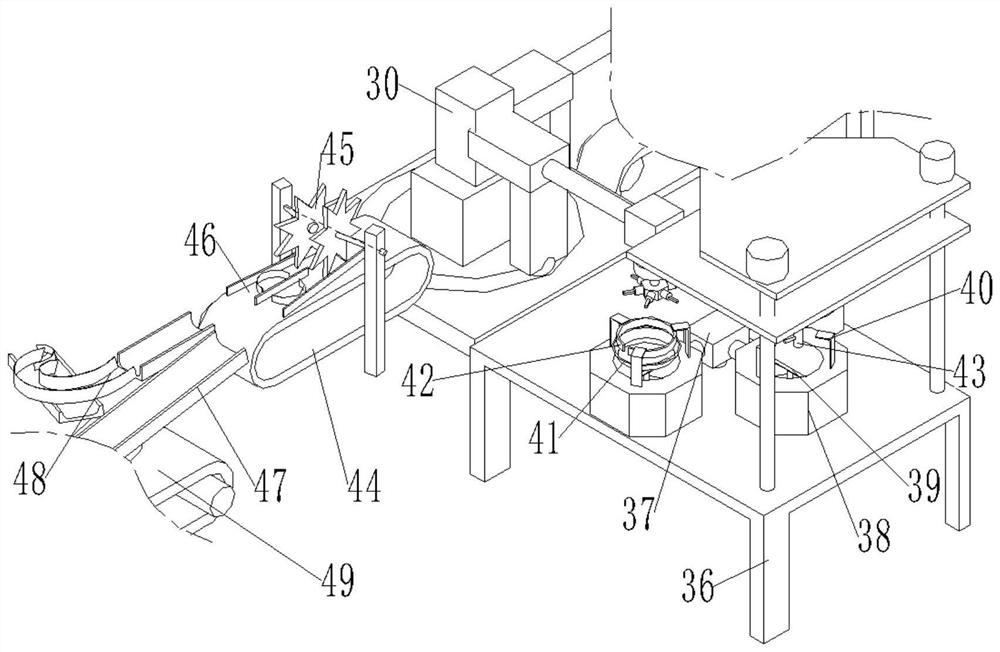

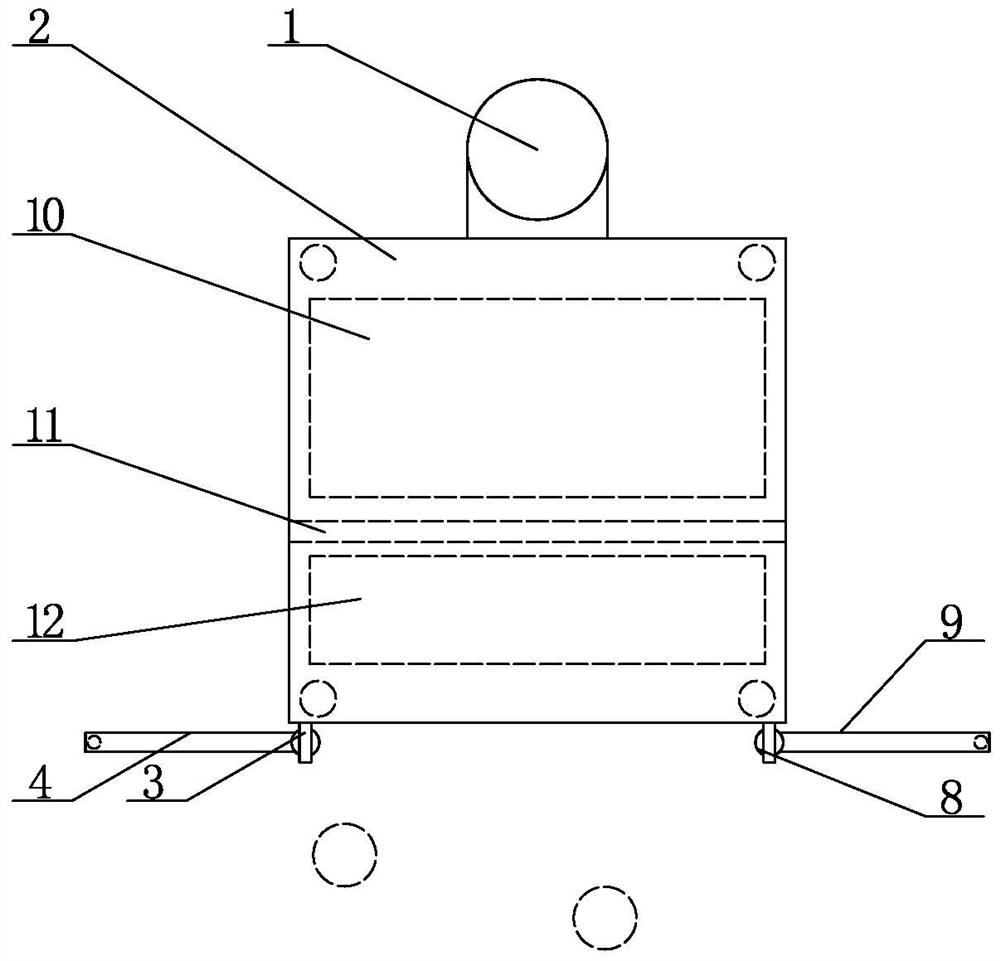

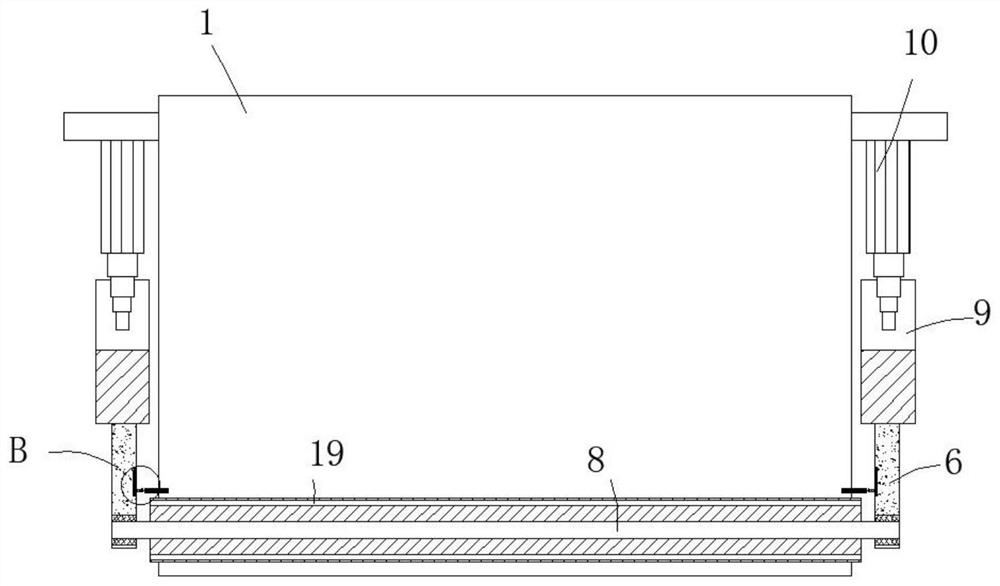

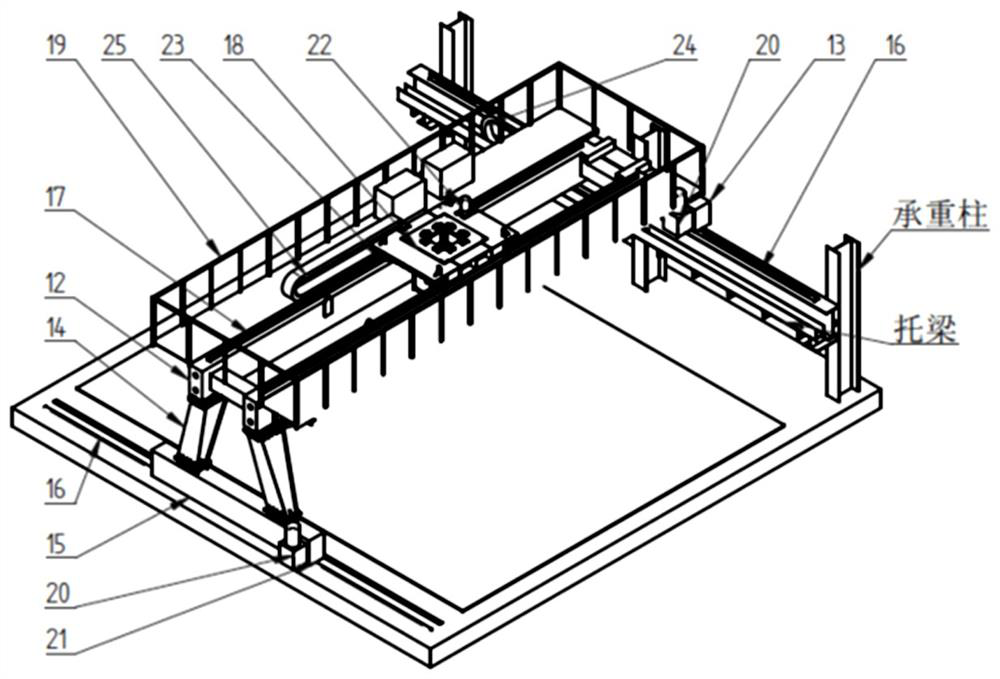

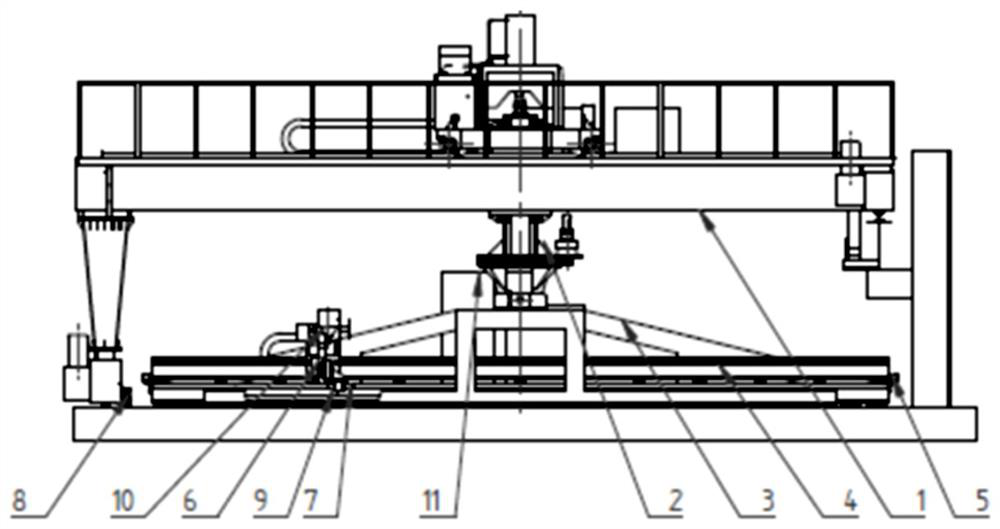

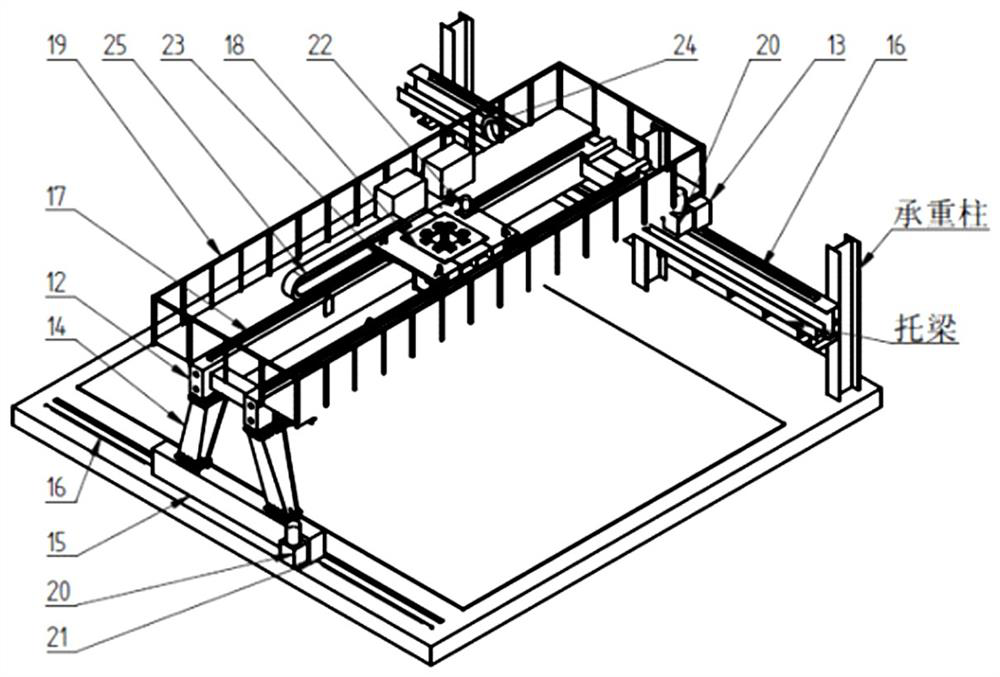

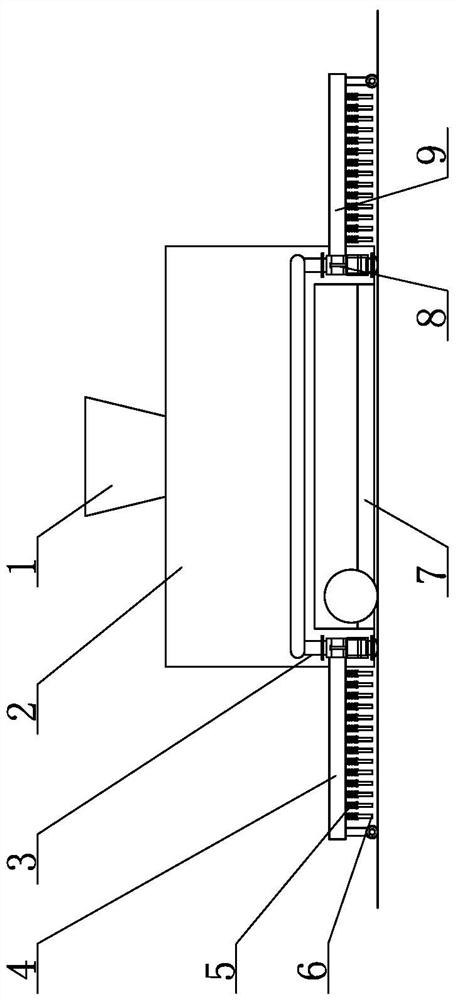

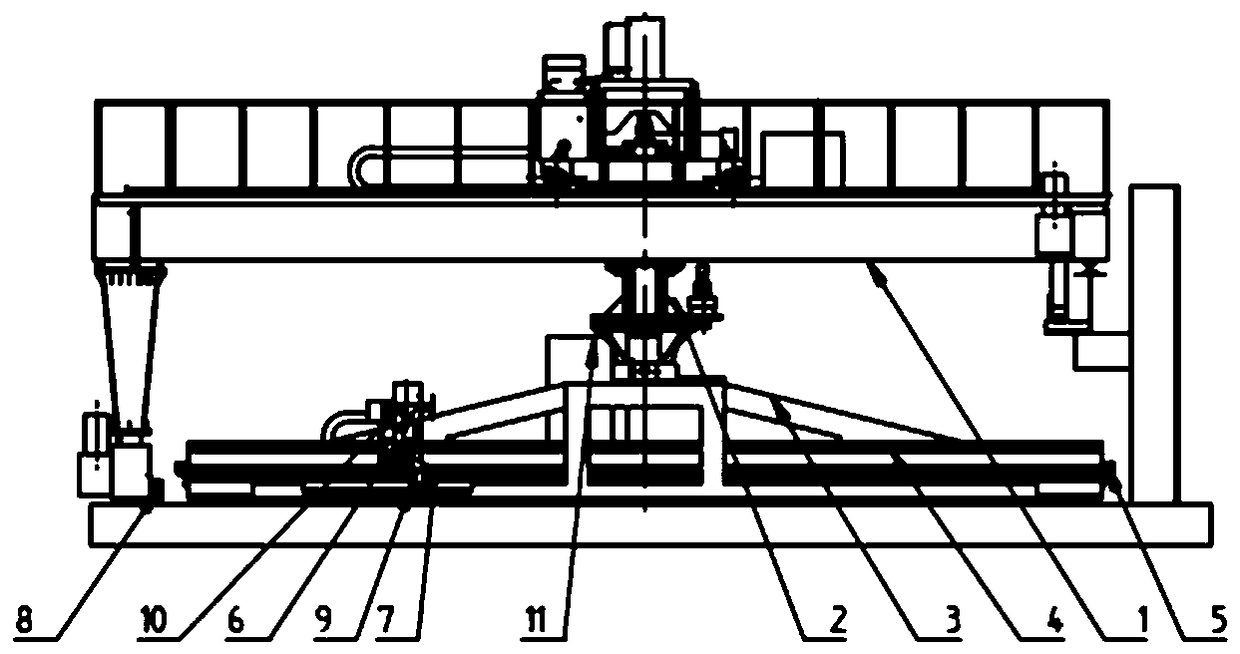

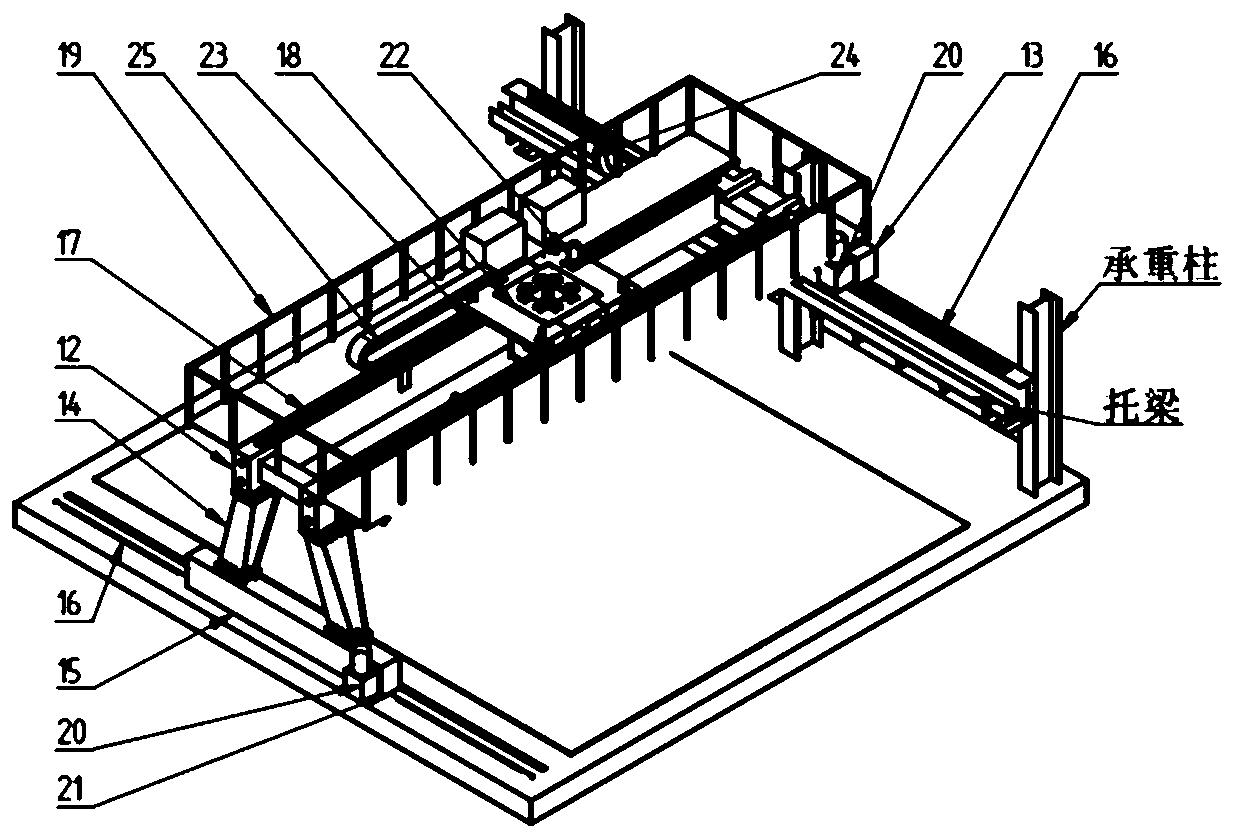

Workpiece positioning auxiliary device for thin plate splicing submerged arc welding machine

The invention relates to a workpiece positioning auxiliary device for a thin plate splicing submerged arc welding machine. The workpiece positioning auxiliary device comprises a bilateral pressure frame device, weld seam alignment and fine adjustment devices disposed at both ends of the bilateral pressure frame device and a grounding device disposed on a half gantry frame body. The bilateral pressure frame device comprises a main pressure frame and an auxiliary pressure frame which are arranged in parallel for simultaneously pressing two steel plates to be spliced, and the bilateral pressure frame device is provided with an adjusting beam and a welding trolley device. The weld seam alignment and fine adjustment devices are disposed at both ends of the adjusting beam for driving the adjusting beam to rotate clockwise or counterclockwise, so that a weld seam is parallel to a track of a welding trolley. The operation of the half gantry frame body is more precise by using auxiliary devices, the auxiliary devices are perfectly matched with the welding trolley and workpieces, and the precise control is achieved; and the welding work of the workpieces is realized at any position within the movement coverage area of a half gantry frame assembly, no position requirement is proposed for welding stations, and the logistics and transportation are convenient and the site utilization rate ishigh.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

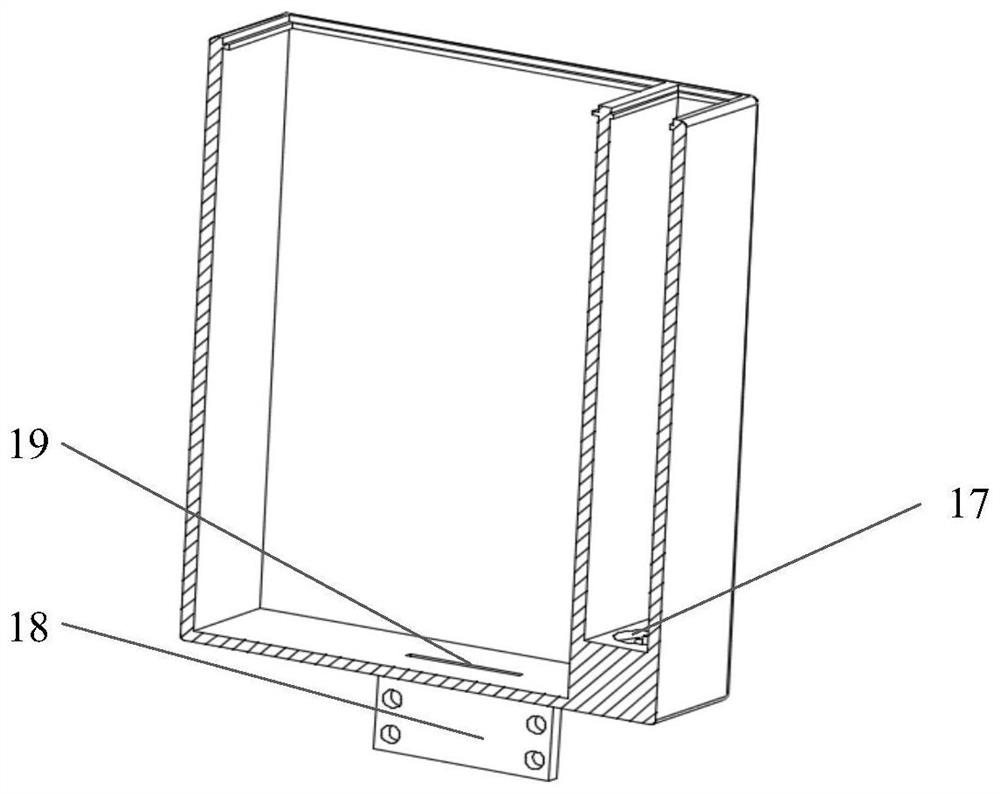

Buried pipeline leakage on-line monitoring system and monitoring method

ActiveCN111664364AReduce the burden onReduce difficultyDetection of fluid at leakage pointPipeline systemsMicrocontrollerEngineering

The invention relates to a buried pipeline leakage on-line monitoring system and monitoring method. In the system, N buried pipeline leakage on-line monitoring devices are parallelly located in a slave station, at least one commercial signal transmission module 4G / 5G server end is located in a master station, the slave station is in wireless communication with the master station, the commercial signal transmission module 4G / 5G server end is connected with a commercial server, narrow-strip piezoelectric wafers of the on-line monitoring devices are installed on the near end faces of strip-shapedwaveguide rods, and ultrasonic signal transmitting / receiving modules are connected with the narrow-strip piezoelectric wafers through positive wires and negative wires; the ultrasonic signal transmitting / receiving modules, signal conditioning modules, signal sampling modules and microcontroller modules are integrated on circuit boards, and the ultrasonic signal transmitting / receiving modules, thesignal conditioning modules and the signal sampling modules are controlled by the microcontroller modules; and the far end faces of the strip-shaped waveguide rods extend out of shells and are inserted into soil around pipelines. According to the system and the method, during leakage monitoring, signals generated by the monitoring devices are transmitted to the commercial server, and a data processing module installed in the commercial server compares changes of the signals so as to judge the leakage degree of the pipelines.

Owner:EAST CHINA UNIV OF SCI & TECH

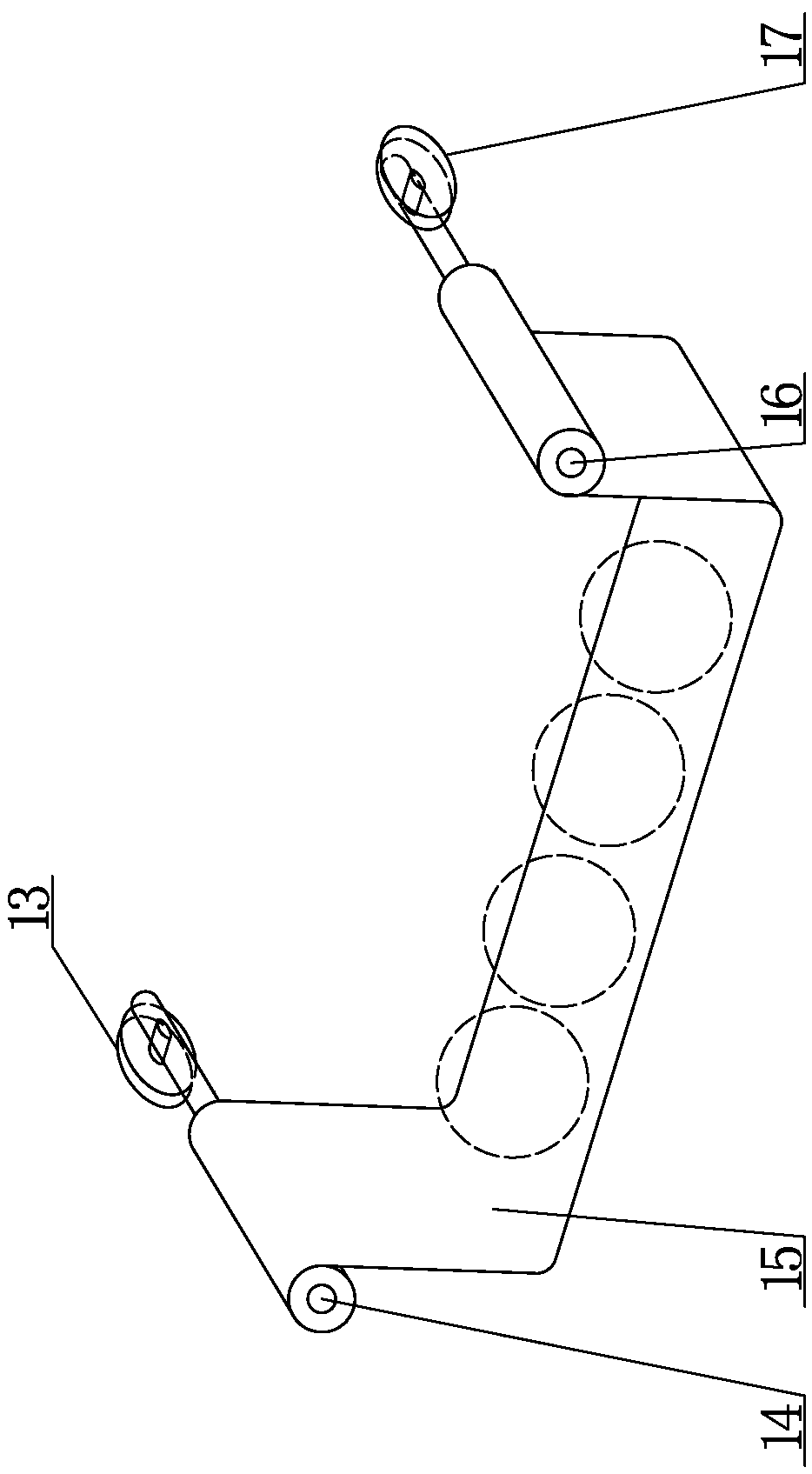

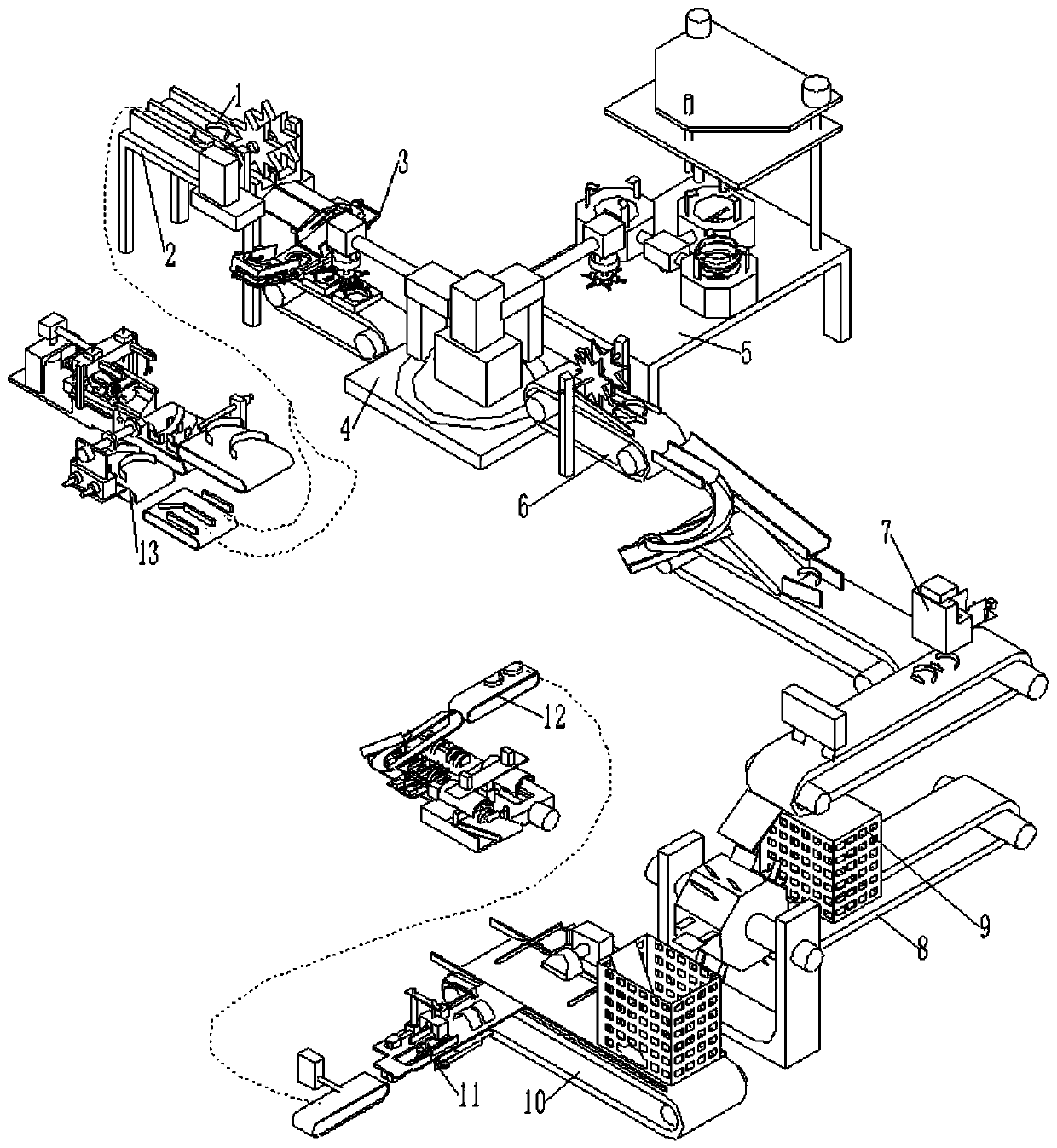

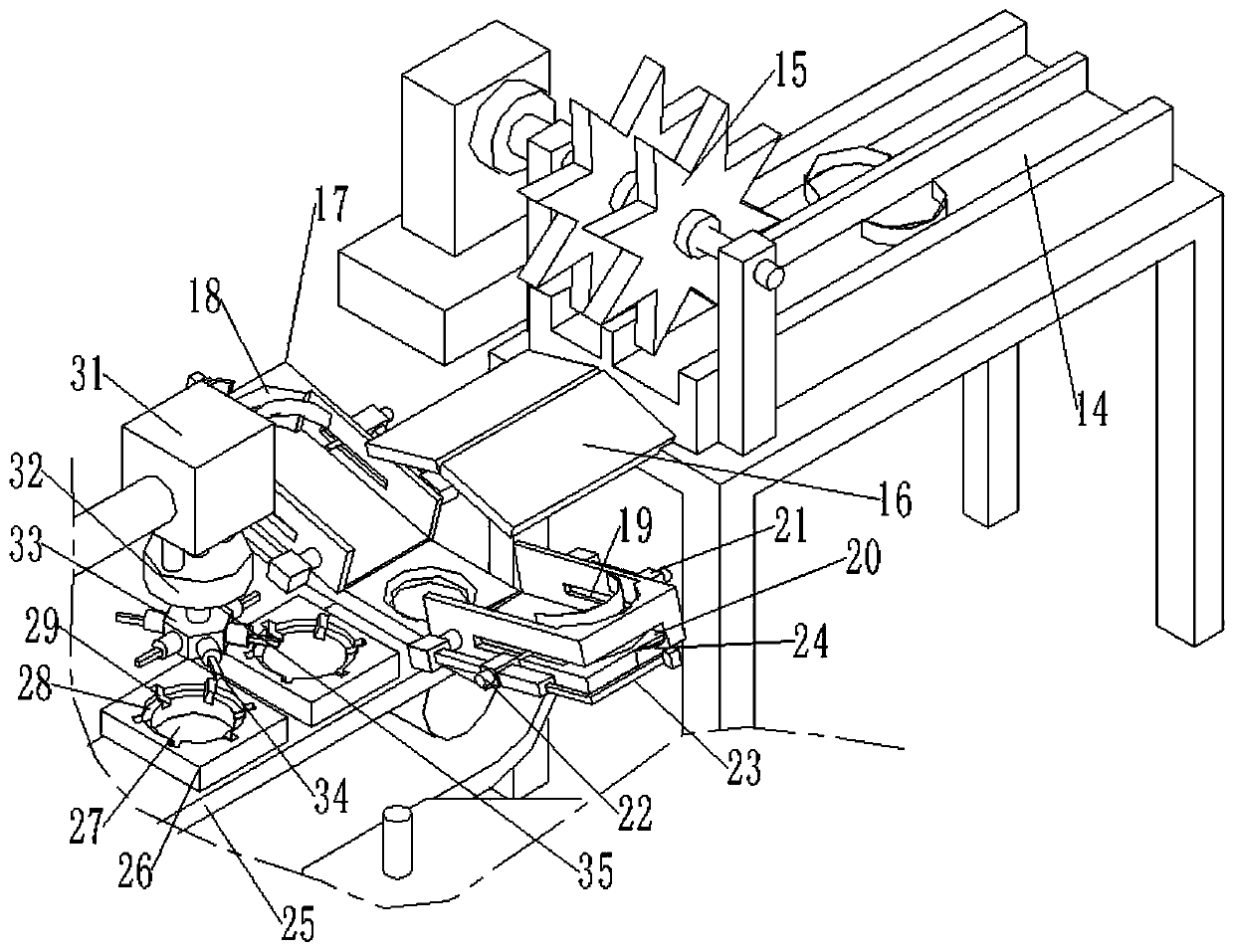

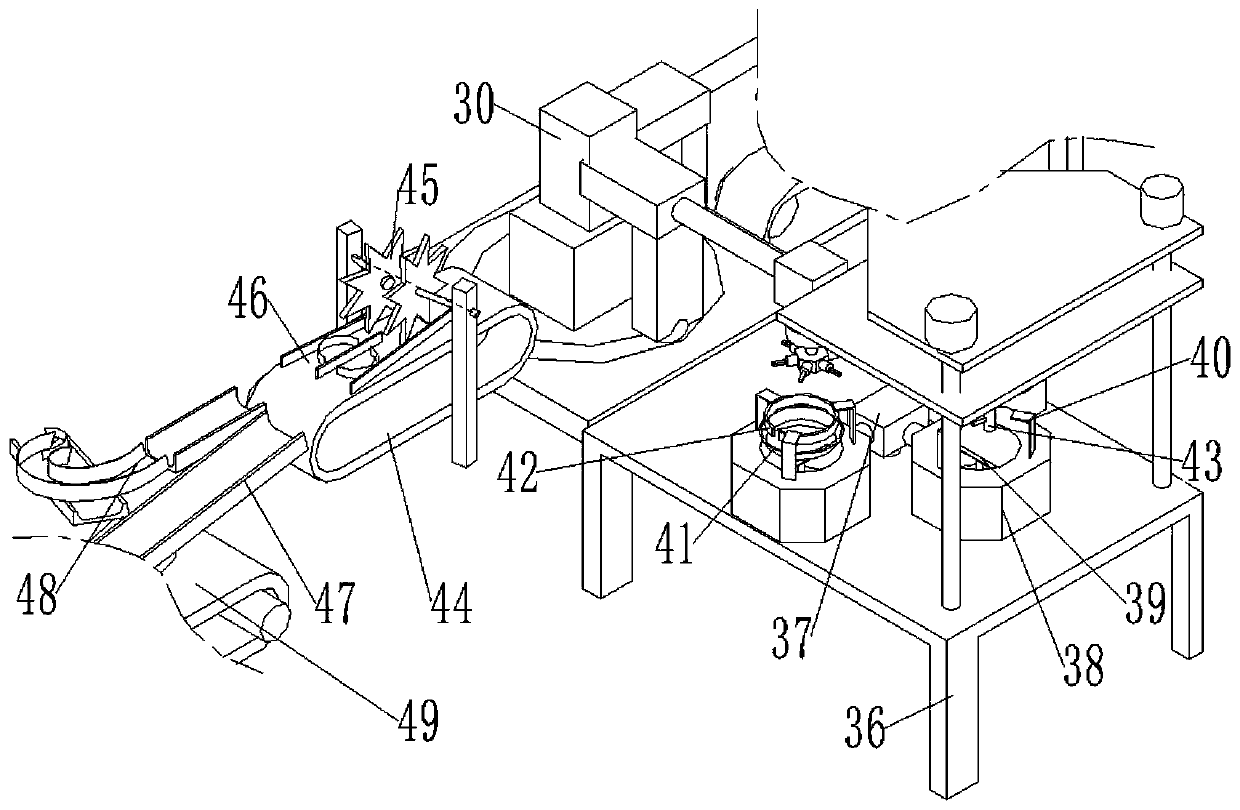

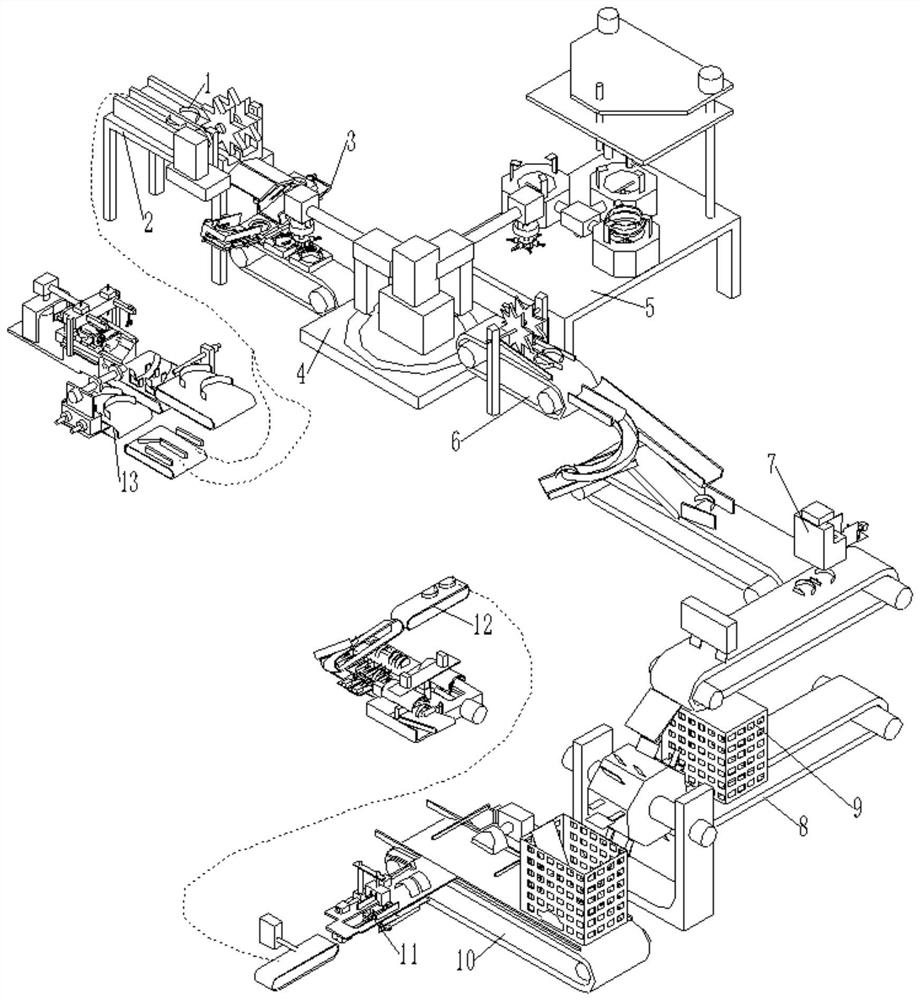

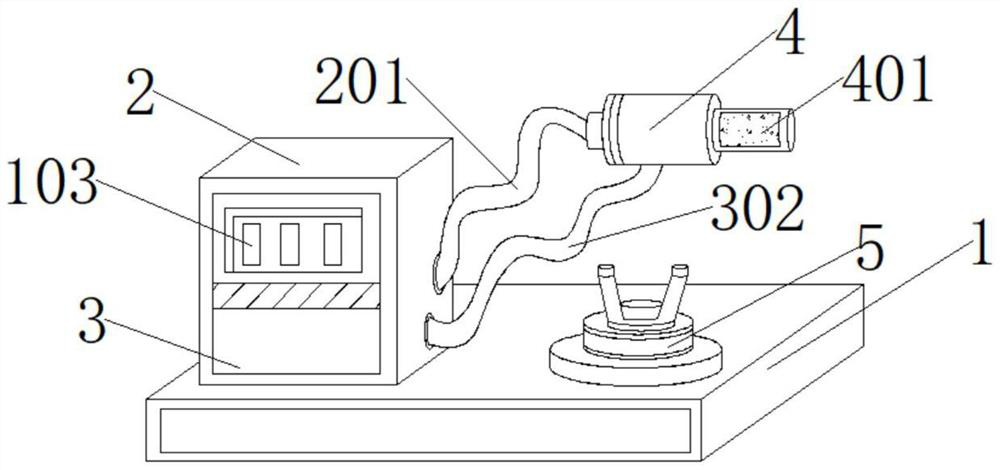

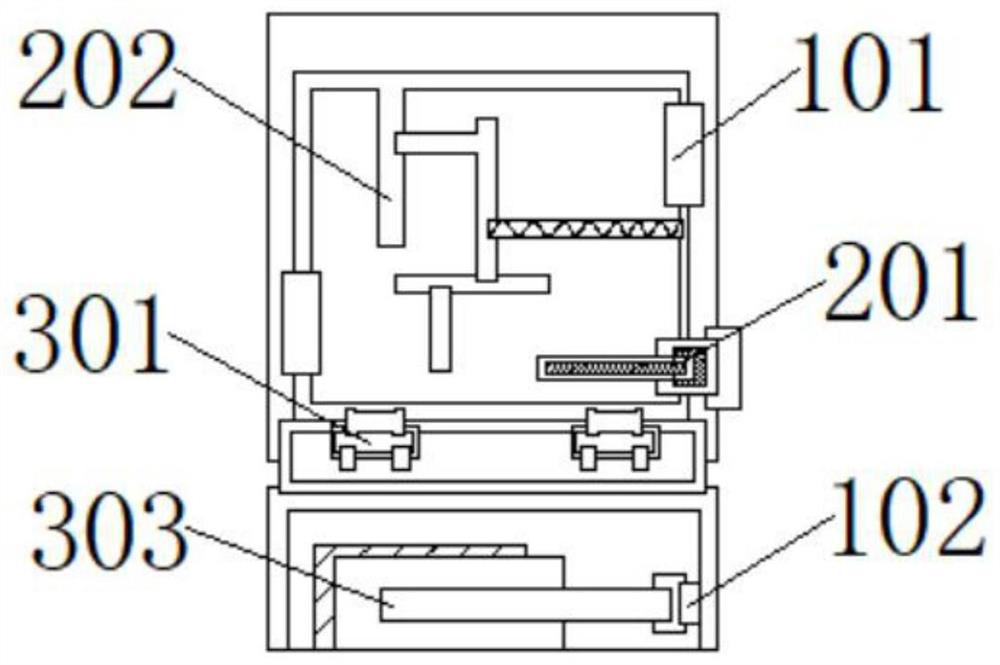

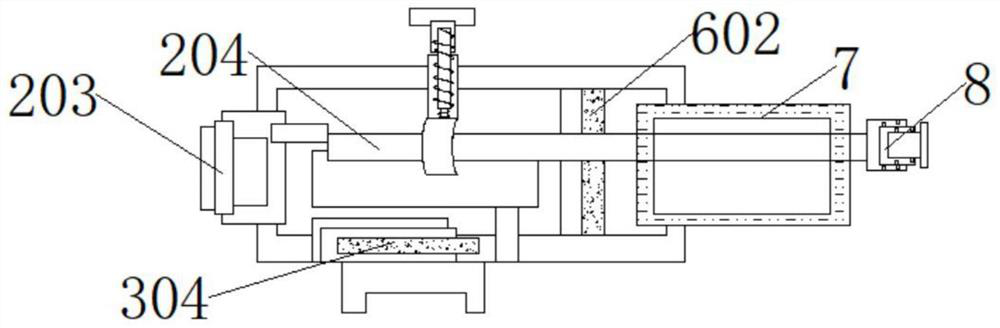

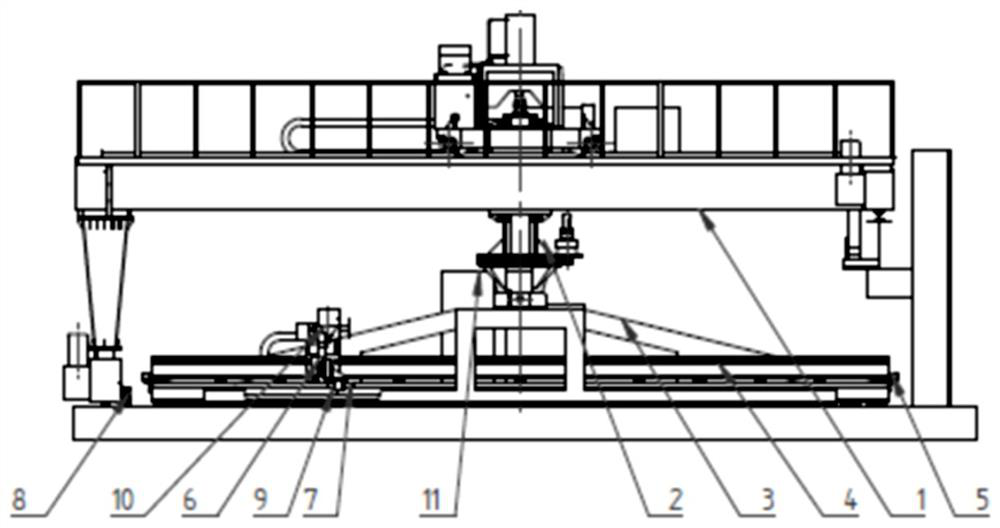

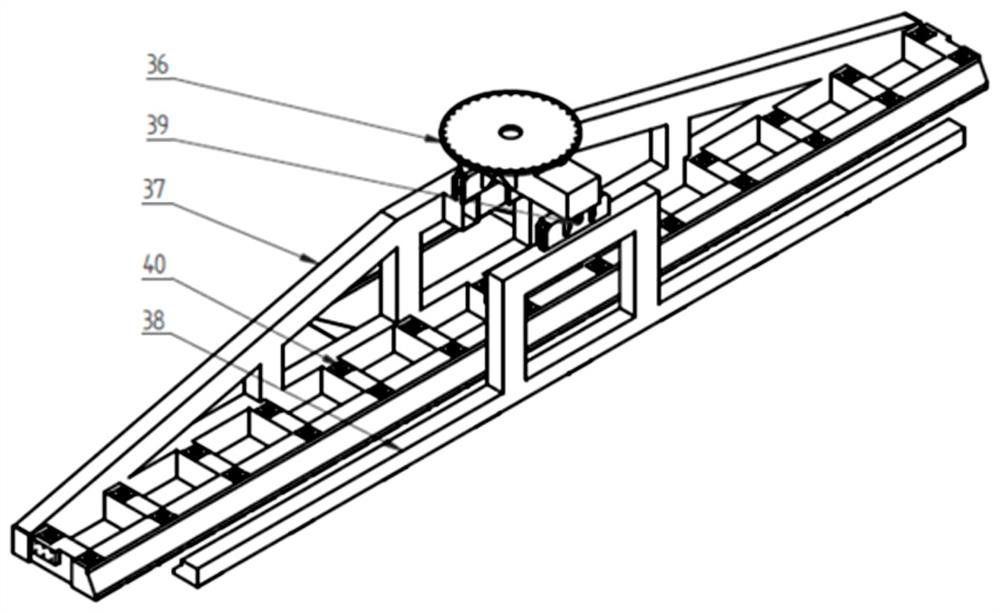

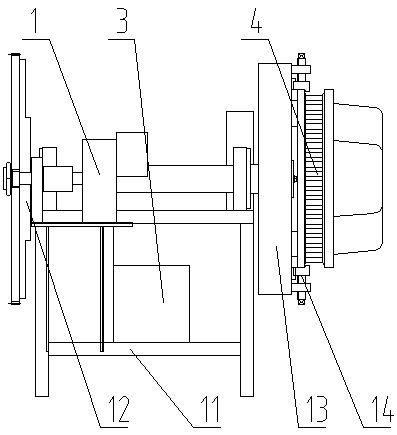

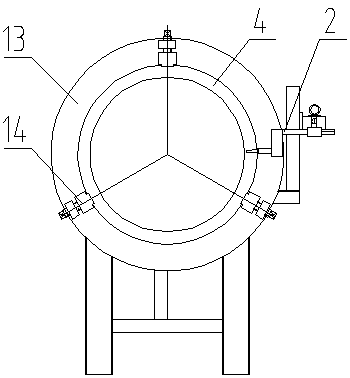

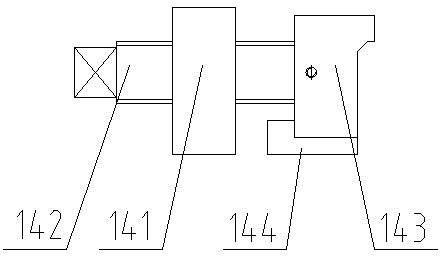

Automatic bearing bush machining and conveying assembly line and process

ActiveCN110394661ARealize automatic unmanned connectionReduce auxiliary workOther manufacturing equipments/toolsMetal working apparatusManipulatorAssembly line

The invention relates to an automatic bearing bush machining and conveying assembly line which is arranged on a machine frame assembly and is used for process linkage between bearing bush positioninglip opening milling equipment and bearing bush inner hole milling equipment. The automatic bearing bush machining and conveying assembly line comprises a first conveying device (2), a first separatingand combining device (3), a first feeding manipulator (4) and a second conveying device (6), wherein the input end of the first conveying device (2) is in process linkage with the output end of the bearing bush positioning lip opening milling equipment, the input end of the separating and combining device (3) is in process linkage with the output end of the first conveying device (2), the first feeding manipulator (4) is used for achieving the process linkage between the separating and combining device (3) and the bearing bush inner hole milling equipment, and the input end of the second conveying device (6) is in process linkage with the output end of the first feeding manipulator (4). The automatic bearing bush machining and conveying assembly line is reasonable in design, compact in structure and convenient to use.

Owner:烟台大丰轴瓦有限责任公司

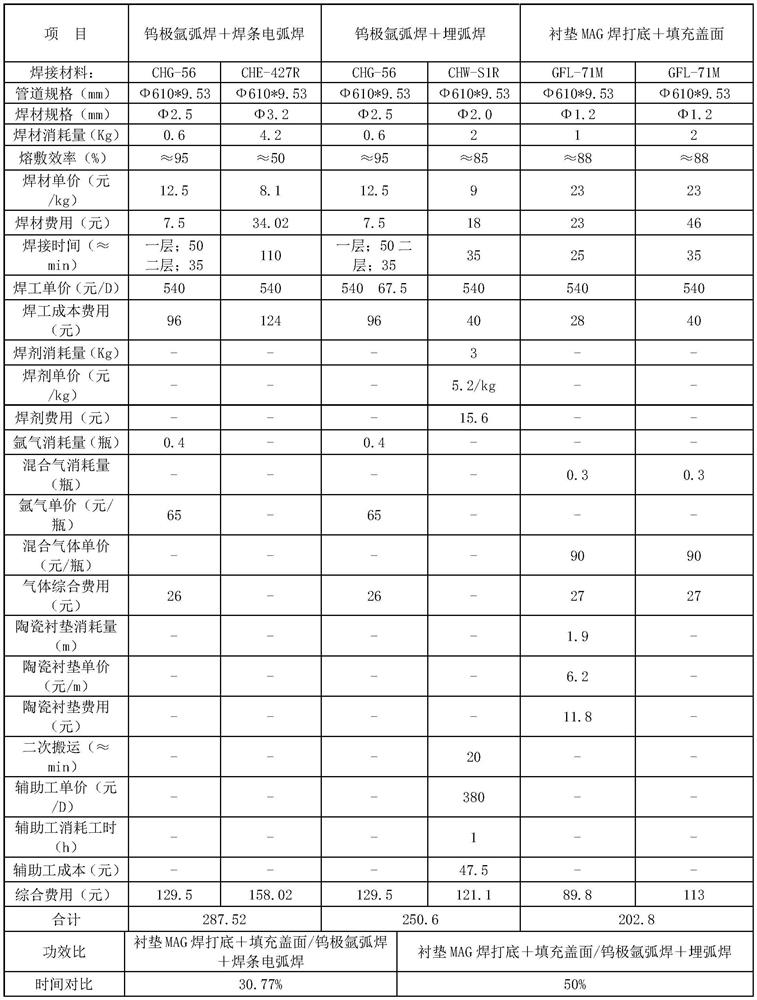

Carbon steel pipeline flux-cored wire all-position motorized welding MAG backing welding process

The invention relates to the technical field of carbon steel pipeline backing welding, in particular to a carbon steel pipeline flux-cored wire all-position motorized welding MAG backing welding process. The carbon steel pipeline flux-cored wire all-position motorized welding MAG backing welding process comprises the steps that appropriate welding parameters are set on a welding power source; through a power supply, a wire and a contact tube, welding current and welding voltage trigger an electric arc with a welding bead through a flux-cored wire for welding; the flux-cored wire is automatically conveyed from a wire reel through a wire feeding wheel; the flux-cored wire forms a welding seam on the pipeline through electric arc melting, and then welding of the next welding seam continues; and after the welded junction is assembled, a ceramic gasket on the back of the root weld of a round pipe is tightly attached to the center of the inner wall weld of the welded junction, and a U-shaped groove is formed in the middle of the ceramic gasket. According to the carbon steel pipeline flux-cored wire all-position motorized welding MAG backing welding process, the construction cost can be reduced, the welding efficiency is improved, the adaptability is high, the welding quality and efficiency are remarkably improved, and the labor intensity of operators is relieved.

Owner:SINOPEC TENTH CONSTR

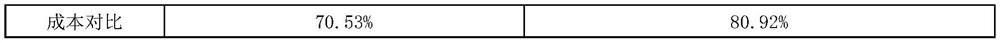

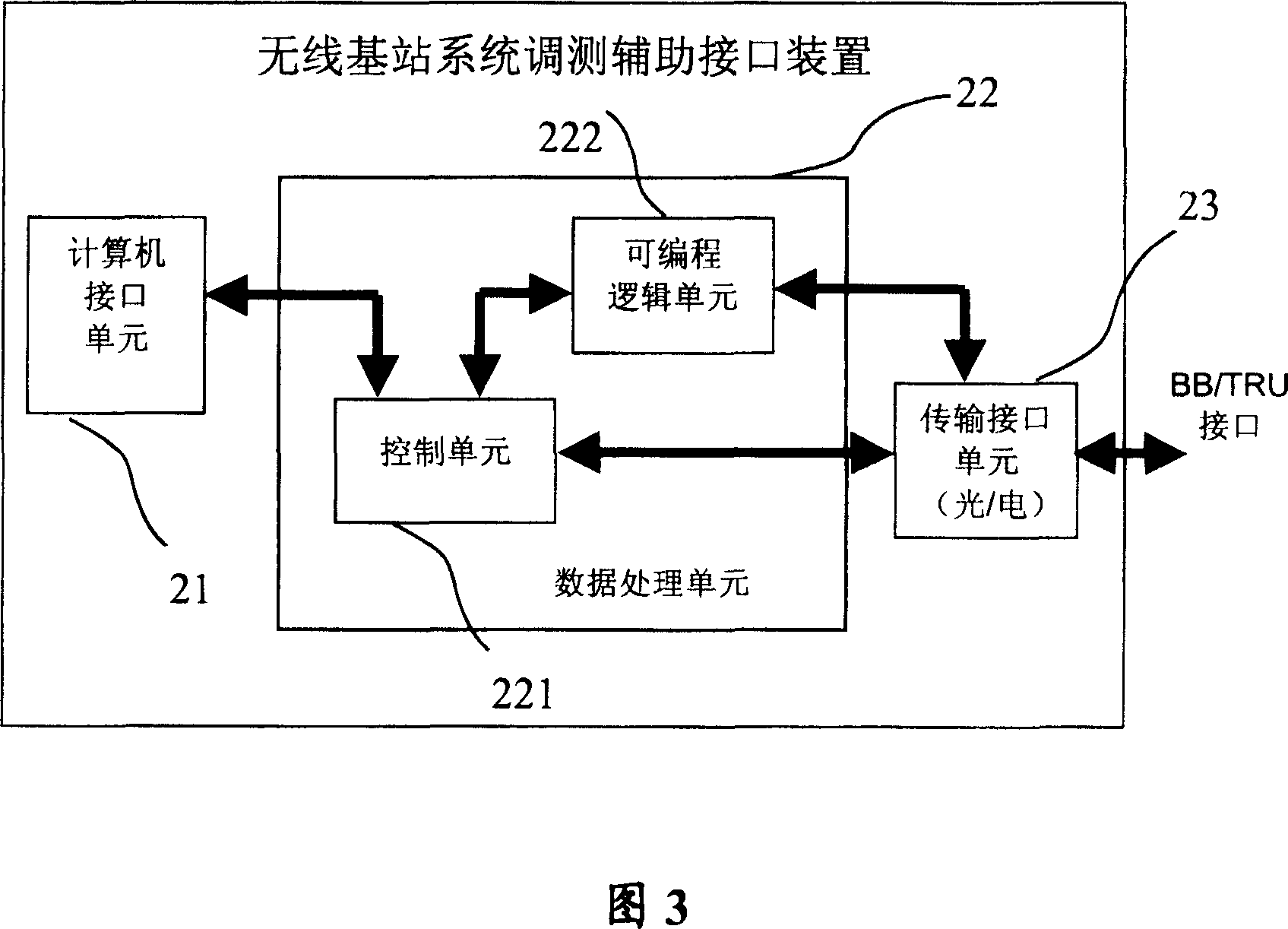

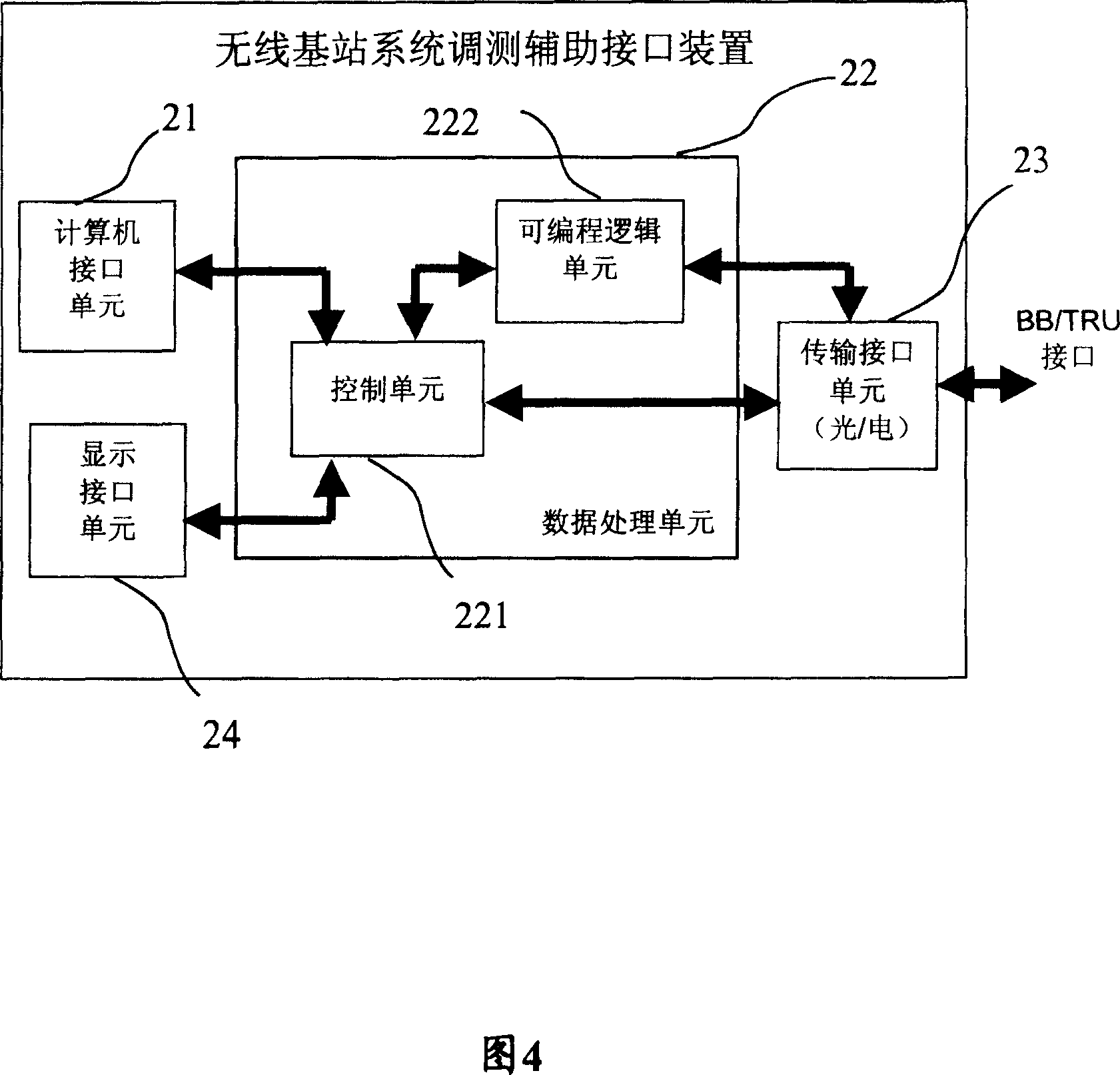

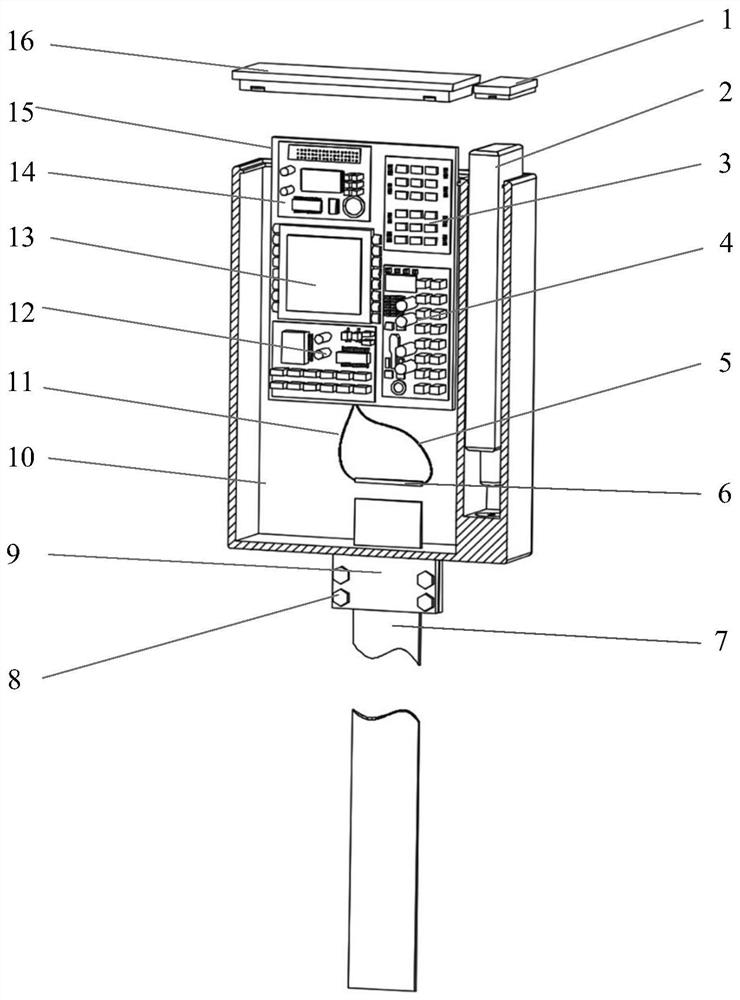

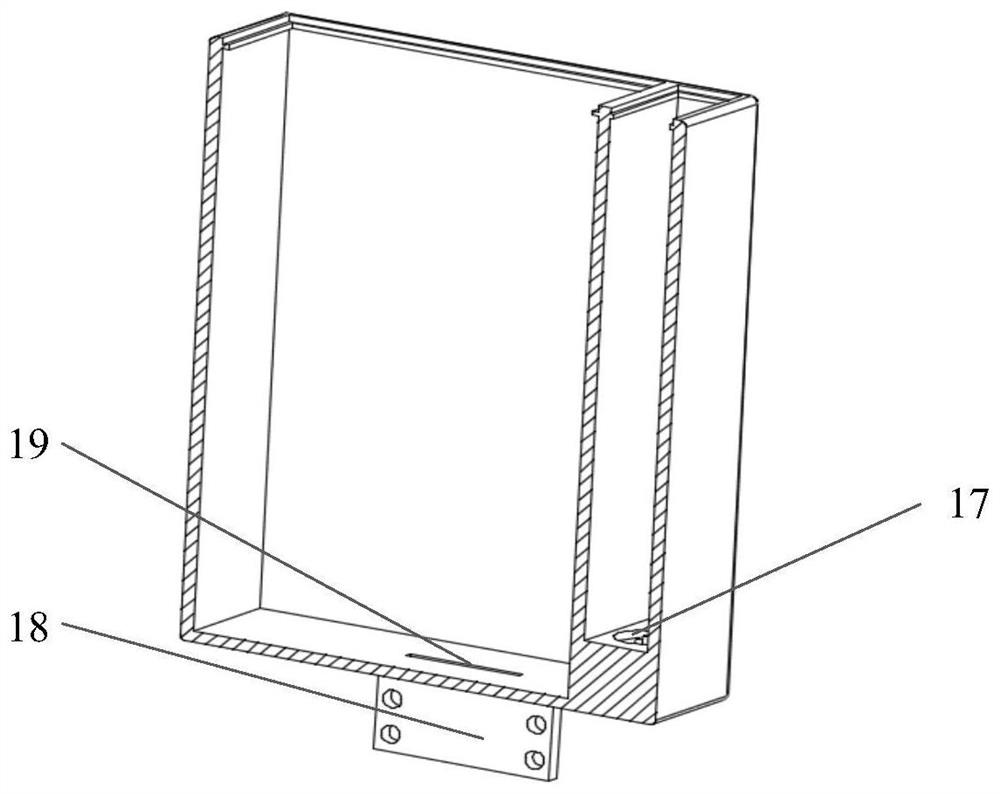

Reglation testing axiliary interface device of radio base station and testing system using it

InactiveCN100359971CReduce auxiliary workReduce complexityRadio/inductive link selection arrangementsTransmission monitoringInterface standardNetwork integration

A device of debugging auxiliary interface on radio base station consists of transmission interface unit coupled on baseband processing unit or radio frequency unit coupled of radio base station for receiving interface data of baseband processing unit or radio frequency unit, data processing unit coupled with transmission interface unit for processing interface data received by transmission interface unit, computer interface unit coupled with data processing unit for receiving the debugging command of user. The test system applying said device can debug base station system with different interface standard and different network integration conveniently and simply.

Owner:HUAWEI TECH CO LTD

An on-line monitoring system and monitoring method for buried pipeline leakage

ActiveCN111664364BReduce the burden onReduce difficultyDetection of fluid at leakage pointPipeline systemsMicrocontrollerWaveguide

The invention relates to a buried pipeline leakage online monitoring system and monitoring method. In the system, N buried pipeline leakage online monitoring devices are located in the slave station in parallel, at least one commercial signal transmission module 4G / 5G server is located in the master station, and the slave station and The main station adopts wireless communication, the 4G / 5G server side of the commercial signal transmission module is connected to the commercial server, the narrow piezoelectric chip of the online monitoring device is installed on the proximal surface of the strip waveguide, and the ultrasonic signal transmitting / receiving module is connected to the wire through the wire The negative is connected to the narrow piezoelectric wafer. The ultrasonic signal transmitting / receiving module, the signal conditioning module, the signal sampling module and the microcontroller module are integrated on the circuit board and controlled by the microcontroller module. The distal face of the ribbon waveguide sticks out of the housing and is inserted into the soil surrounding the pipe. During leakage monitoring, the signal generated by the monitoring device is sent to the commercial server, and the data processing module installed in the commercial server compares the changes of the signal to judge the leakage degree of the pipeline.

Owner:EAST CHINA UNIV OF SCI & TECH

Bearing bush automatic processing transmission line and technology

ActiveCN110394661BRealize automatic unmanned connectionReduce auxiliary workOther manufacturing equipments/toolsMetal working apparatusRobot handControl engineering

The invention relates to an automatic bearing bush processing and transmission line, which is arranged on a frame assembly, and is used for linking the bearing bush milling and positioning lip equipment with the bearing bush milling inner hole equipment; the bearing bush automatic processing and transmission line includes an input end and a bearing bush milling and positioning lip. The first transmission device (2) for the process connection of the output end of the equipment, the first separation and coupling device (3) for the process connection between the input end and the output end of the first transmission device (2), and the first separation and coupling device for process connection (3) The second conveying device (6) connected with the first feeding manipulator (4) used for the bearing bush inner hole milling equipment, and the input end and the output end of the first feeding manipulator (4). The invention has reasonable design, compact structure and convenient use.

Owner:烟台大丰轴瓦有限责任公司

Special multifunctional aspirator for cerebral surgery

PendingCN113633833APerfect attraction structureImprove efficiencyMedical devicesCatheterBiomedical engineeringLight source

The invention discloses a special multifunctional aspirator for cerebral surgery. The special multifunctional aspirator comprises a device body, suction equipment and a cold light source device, wherein the cold light source device is fixedly connected to the top of the device body, the suction equipment is fixedly connected to the top of the cold light source device, a support is fixedly connected to the other side of the top of the device body, a mounting plate is fixedly connected to one side of the interior of the suction equipment, a mounting rod is fixedly connected to one side of the interior of the cold light source device, and a display screen is connected to the dead front of the surface of the suction equipment in an embedded mode. The convenience of the aspirator is excellently improved through the display screen, the flexibility of the aspirator is excellently improved through a rotary connecting groove, a suction head is convenient to replace, the service life of a suction tube is excellently maintained through a rubber sleeve, the adjustability of the aspirator is excellently improved through an adjusting connecting valve, the practicability of the aspirator is excellently improved through a suction mechanism, the multifunctional convenience of the aspirator is excellently improved through a cold light connecting mechanism, and the aspirator is suitable for being used in medical instruments and has wide development prospects in the future.

Owner:王举磊

An Ultrasonic Probe for Wall Thickness Thinning Measurement in Extreme Environments

ActiveCN108613644BHigh precisionImprove reliabilityUsing subsonic/sonic/ultrasonic vibration meansWaferingEngineering

The invention relates to an ultrasonic probe for wall thickness reduction measurement under an extreme environment. A piezoelectric wafer is embedded in a circular upper damping block, and a positiveelectrode and a negative electrode located on the piezoelectric wafer are connected with a positive wire and a negative wire respectively, and the positive wire and the negative wire pass through theupper damping block to be connected with a threaded joint on a cover-shaped outer shell; the upper damping block and a lower damping block with the same size are closely fit and are closely fixed by an inner shell, and the inner shell is embedded in the cover-shaped outer shell and a cylindrical outer shell; the upper end surface of a guided wave plate passes through the back cover of the cylindrical outer shell and the lower damping block to be connected with the piezoelectric wafer, and the lower end surface of the guided wave plate is contacted with a tested piece; the thickness and the width of the guided wave plate have to enable single-mode zero-order horizontal shear waves to pass in a non frequency dispersion mode; and the piezoelectric wafer can excite and receive transverse wavesignals, and the cross section is matched with that of the guided wave plate. Long-term online monitoring or offline multi-point measurement on ultrasonic guided waves under extreme environments can become possible.

Owner:EAST CHINA UNIV OF SCI & TECH

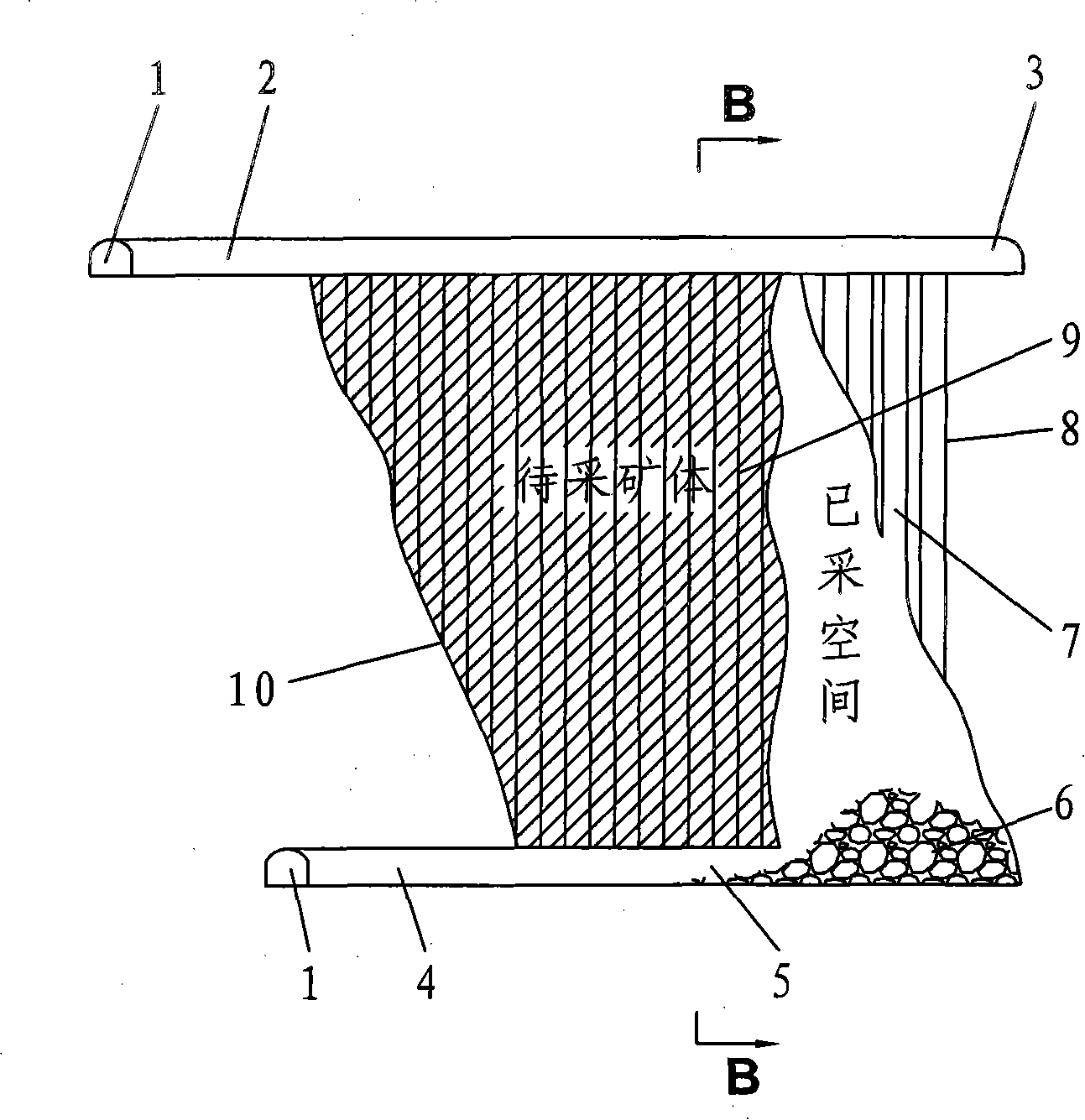

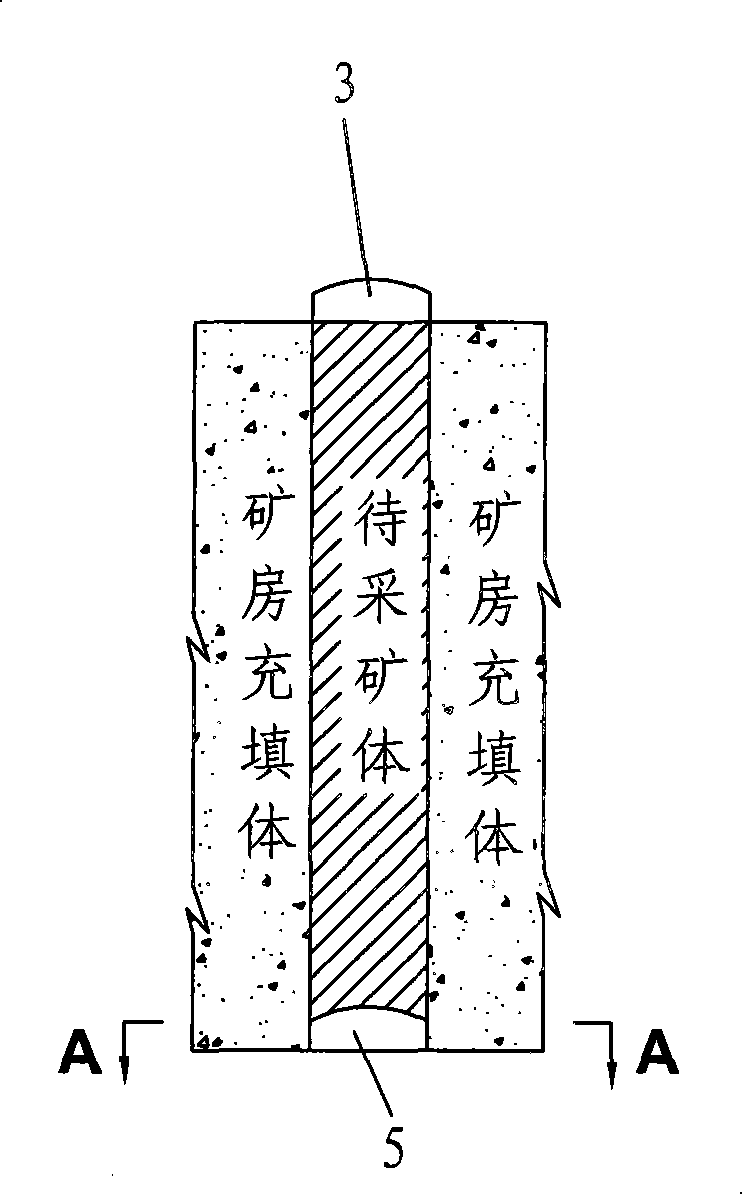

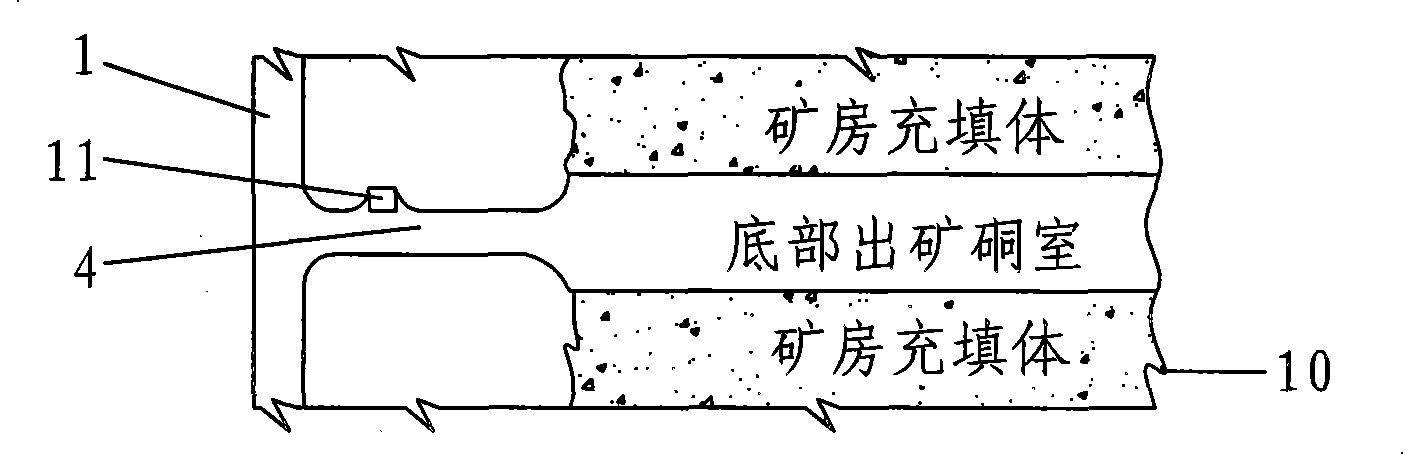

Non-bottom pillar deep hole falling-back type mining method

The invention relates to a non-pillar deep-hole backing-type mining method. The method is suitable for that: the digging height is between 10 and 50 m; the length of a stope is between 40 and 80 m; the width of the stope is between 7 and 9 m; the dip angle of an ore body is between 68 and 90 degrees; the height of a bottom ore removal chamber is between 2.5 and 3.5 m; the height of an upper part rock drilling chamber is between 3.4 and 3.8 m; meanwhile, an explosive charge structure, an explosion initiating sequence, stope side lacing and top plate control are determined according to the conditions of the stope, and a remote-control scraper and a remote-control crushing trolley are jointly used to treat large ore materials for ore removal. The mining method has the advantages of small mining-cutting engineering quantity, simple mining-cutting process, high rock drilling efficiency, good blasting effect, safe and efficient ore removal process, can effectively improve the wide-spacing stoping safety for underground metal mines nationwide, can upgrade the mining technical level for the underground metal mines in China, can promote the development of nationwide underground metal mine mining technology, and can reduce the dilution rate and loss rate of nationwide underground metal mine spacing stoping stopes, so as to promote the maximal recycling of metal resources.

Owner:深圳市中金岭南有色金属股份有限公司凡口铅锌矿

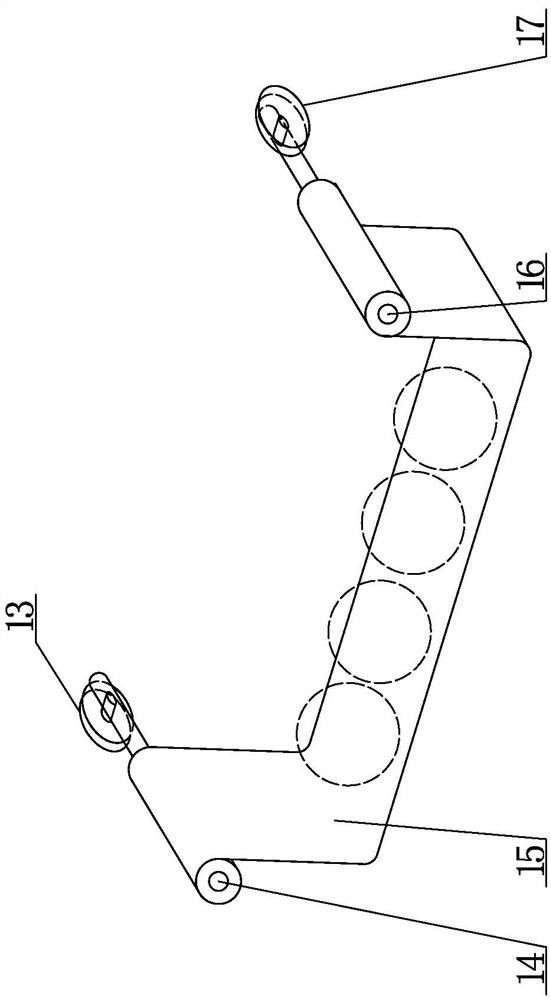

Indoor intelligent basketball collection companion training device

InactiveCN109045637BReduce auxiliary workImprove the efficiency of individual trainingBall sportsPhysical medicine and rehabilitationSports equipment

An indoor intelligent basketball collection training device belongs to the field of sports equipment. It is characterized in that it includes a box-shaped storage bin, a walking device is installed at the bottom of the storage bin, a collecting device is arranged on the front side of the storage bin, a flexible lifting conveying device and a cleaning and disinfection device are installed in the storage bin, and a cleaning and disinfection device is installed on the back side of the storage bin A directional projection device is set; the directional projection device includes an ejector and an automatic projector, and a communication hole is opened on the rear side wall of the storage bin, and a projection bin is set at the rear of the storage bin; between the first and second cleaning belts The ejector is arranged in the lower part of the ejector gap, the directional projection device is arranged in the projection chamber, and the ejector can eject the basketball between the first and second cleaning belts. Lift it up and put it into the projection bin through the communication hole. The invention can assist team members to practice catching and shooting basketballs, and can also collect, clean and maintain indoor basketballs in time.

Owner:XIAN TECH UNIV

An artificial lawn laying device

ActiveCN112458844BIncrease contact forceStable layingRoads maintainenceAgricultural engineeringMechanical engineering

The invention discloses an artificial lawn laying device, which relates to the technical field of lawn laying devices. Aiming at the existing problems that cannot be well adjusted, the following scheme is proposed, which includes a connection box, and the connection box is fixedly connected with a partition The partition board is provided with winding rollers, the outer side of the winding rollers is wound with turf, and the bottom of the partition board is rotatably connected with an electric door, and one side of the turf is provided with a The blocking device for the fixed connection of the box, one side of the connection box is rotationally connected with a symmetrically arranged pneumatic cylinder, the invention has a simple structure and is easy to use, and can adjust the lawn during the laying process, reducing labor input and labor intensity. At the same time, it can be adjusted in real time to reduce the possibility of skew, reduce subsequent auxiliary work, reduce procedures, and increase the quality and work efficiency of laying.

Owner:湖北绿之行人造草坪有限公司

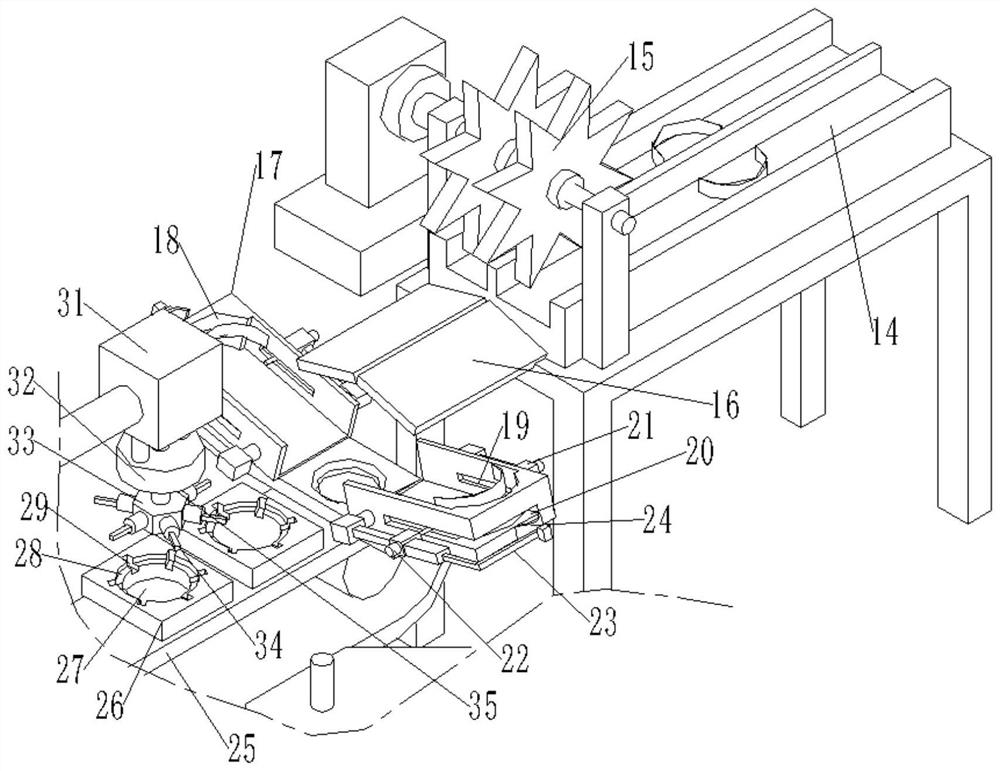

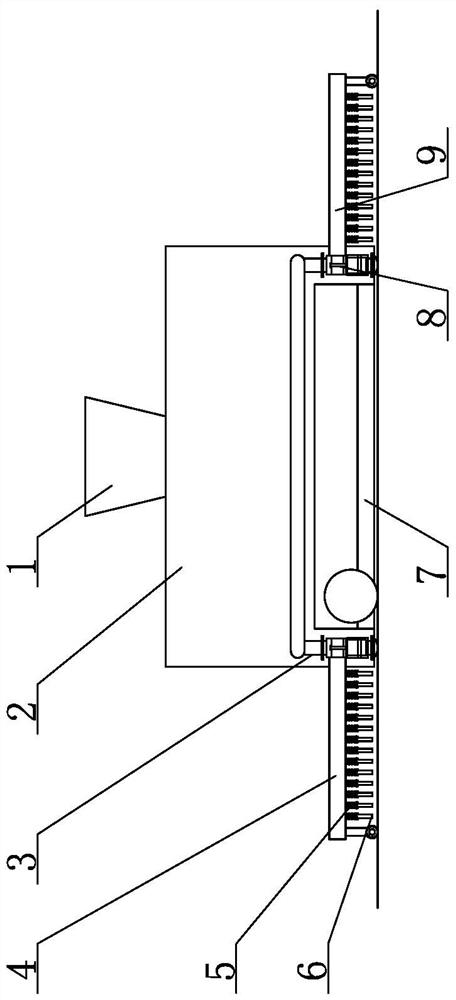

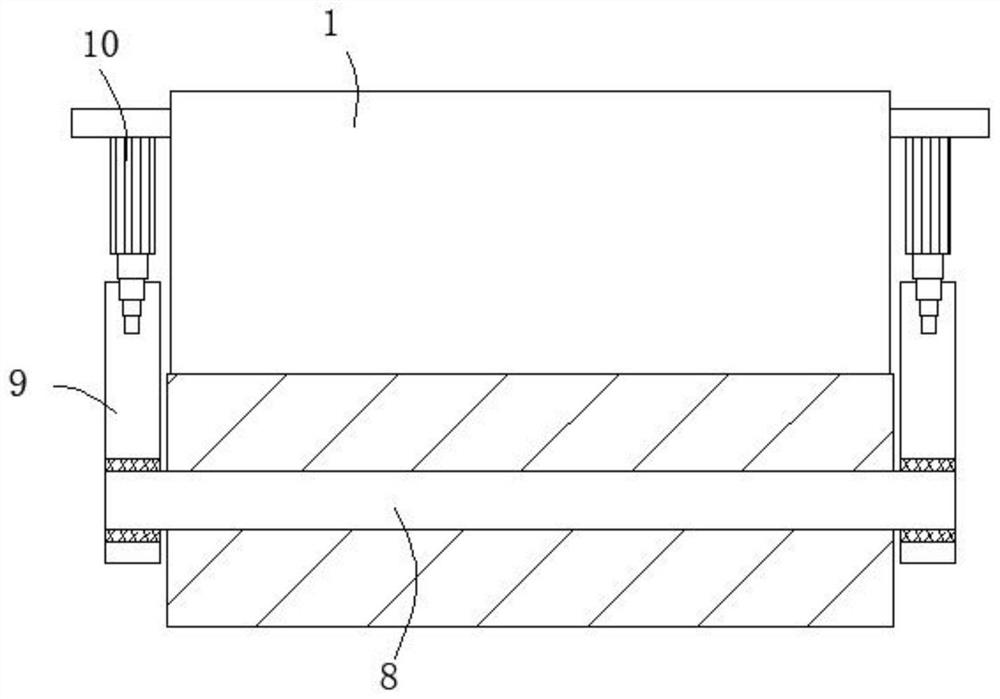

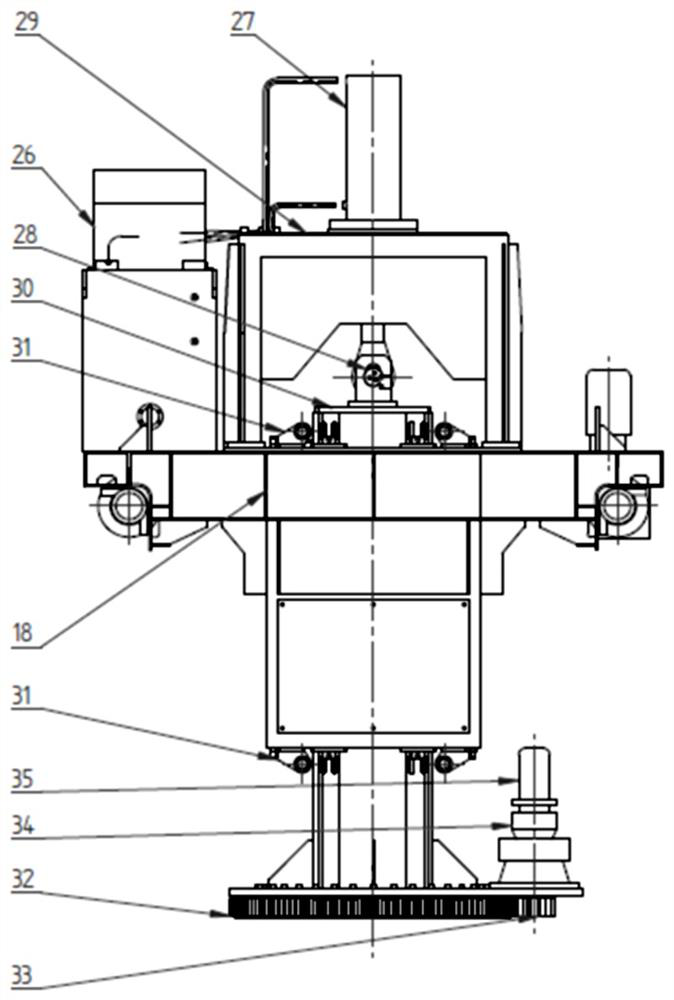

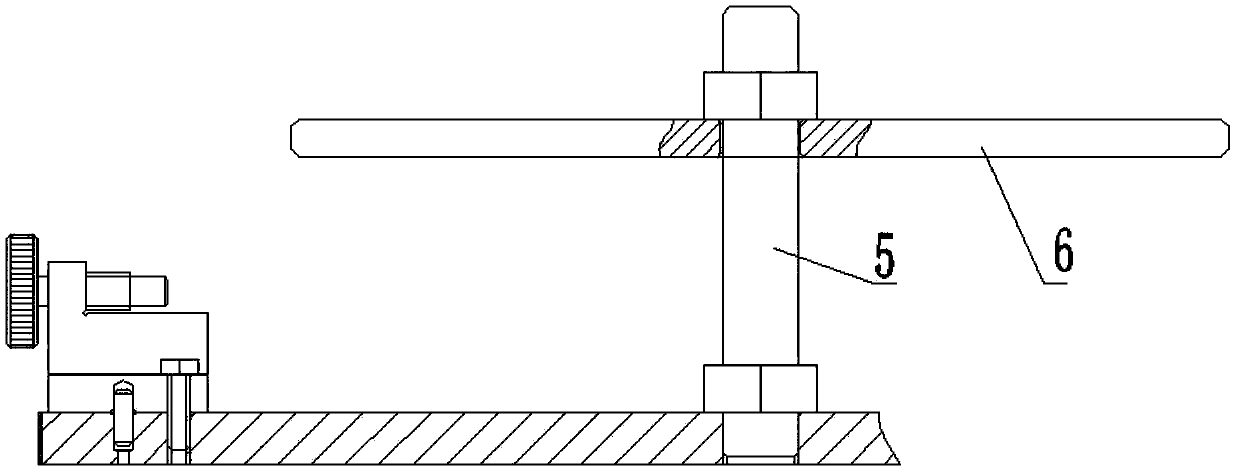

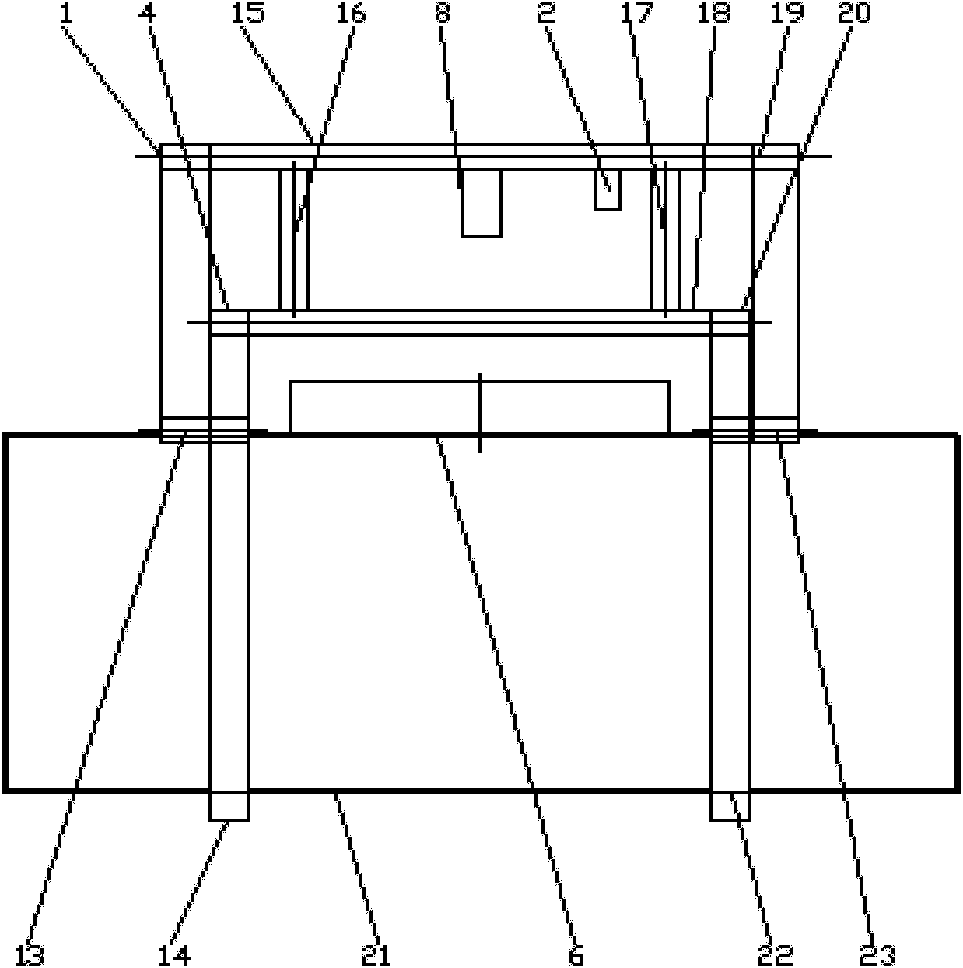

A pressure frame for thin plate splicing submerged arc welding machine

ActiveCN108326398BConvenient for logistics and transportationImprove site utilizationWelding/soldering/cutting articlesMetal working apparatusReduction driveThin slab

The invention relates to a pressure frame for submerged arc welding machine for thin plate splicing, which includes a half-gantry device, a lifting and rotating device and a double-sided pressure frame device; Guide rail, longitudinal motor reducer, longitudinal wheel set, trolley, transverse guide rail, transverse motor reducer, transverse wheel set, etc., can realize the longitudinal and transverse travel of the pressure frame; the lifting and rotating device consists of a hydraulic station, an oil cylinder, a lifting It is composed of pin shaft, oil cylinder frame, lifting column, guide wheel, slewing bearing, pinion, cycloid reducer, motor, etc., which can realize the lifting and rotating motion of the pressure frame. The longitudinal and lateral movement of the semi-gantry device, the lifting and rotating movement of the lifting and rotating device, and the placement of workpieces in any position and direction are all within the scope of the invention. The two-sided pressure frame is effective and reliable for the two steel plates that need to be spliced. Pressing and cooperating with related welding devices not only ensure the convenience of welding operation and high efficiency, but also ensure the quality of welding.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

A workpiece positioning auxiliary device for thin plate splicing submerged arc welding machine

The invention relates to a workpiece positioning auxiliary device for thin plate splicing submerged arc welding machine, which includes a double-sided pressure frame device, a weld seam alignment fine-tuning device arranged at both ends of the double-sided pressure frame device, and a grounding device arranged on the half-gantry frame body device; the double-sided pressure frame device includes two main and secondary pressure frames arranged in parallel, which are used to simultaneously compress the two steel plates to be spliced; the double-sided pressure frame device is provided with an adjustment beam and a welding trolley device. The welding seam alignment fine-tuning device is arranged at both ends of the adjusting beam, and is used to drive the adjusting beam to rotate clockwise or counterclockwise, so that the welding seam remains parallel to the track of the welding trolley. These auxiliary devices make the operation of the semi-gantry body more precise, and the cooperation with the welding trolley and the workpiece is more perfect, achieving precise control, so that the welding work of the workpiece can be realized at any position within the movement coverage area of the semi-gantry assembly, and the welding station No location requirements, convenient logistics and transportation, and high site utilization.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

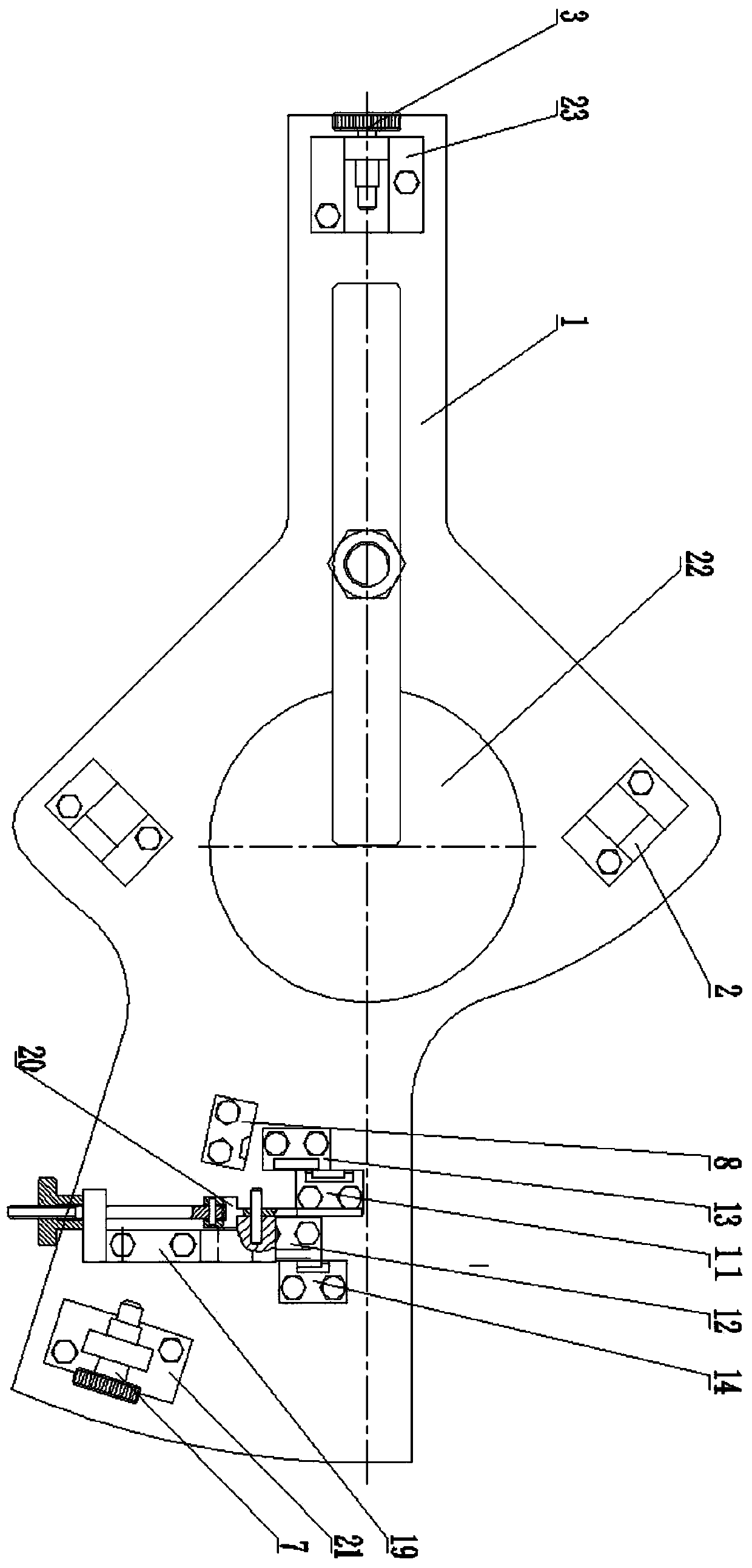

Blade repair positioning device for aeroengine low pressure turbine guide

ActiveCN106956100BPrevent and reduce welding deformationReduce welding distortionWelding/cutting auxillary devicesAuxillary welding devicesAviationMaterial resources

The invention discloses a vane repair and positioning device for an aero-engine low-pressure turbine stator, and mainly aims to solve the problems that a true center can not be found through the existing manual positioning, requirements for the skill level and experience of workers are high, a lot of manpower and material resources are wasted, and mistakes and defects are liable to occur, with influence on the effect after repair in the prior art. The vane repair and positioning device for the aero-engine low-pressure turbine stator comprises a base; the base is provided with two edge positioning blocks which are arranged symmetrically by taking a center line of the base as an axis; and the base is provided with a main positioning mechanism located on the center line of the base, and the main positioning mechanism and the two edge positioning blocks form a triangle location group. Through the above scheme, the purpose of accurately positioning the low-pressure turbine stator is achieved, and the vane repair and positioning device has high practical value and popularization value.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD +1

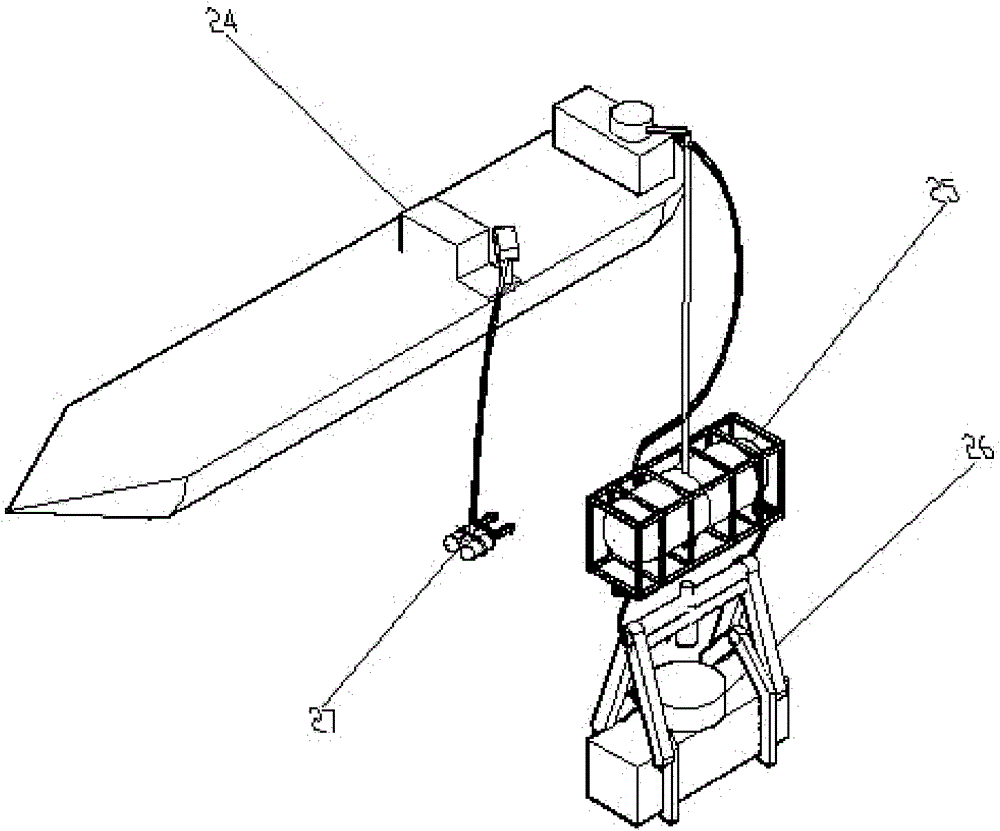

Deepwater electromagnetic chuck container spreader

InactiveCN102114904BReduce auxiliary workImprove securityVessel salvagingLoad-engaging elementsHydraulic cylinderUnderwater

The invention discloses a deepwater electromagnetic chuck container spreader which mainly comprises a spreader framework, a container fixture, an electromagnetic chuck, a hydraulic cylinder and an underwater camera, wherein the spreader framework comprises a first ledge, a second ledge and a first cross beam which are connected through a first twisting point and a fifth twisting point; the container fixture is of a grab bucket and comprises a second cross beam, a first rotating shaft, a second rotating shaft, a third ledge and a fourth ledge, the first rotating shaft is connected with the second rotating shaft through a twisting point, the first rotating shaft is connected with the third ledge through a twisting point, the second rotating shaft is connected with the fourth ledge through atwisting point; the spreader framework is connected with the container fixture together through a first bracket and a second bracket, the spreader framework is positioned at the outer side of the container fixture; the bottoms of the third ledge and the fourth ledge are used for clamping a container fallen into water from two sides of the container; and the electromagnetic chuck is positioned over the container. The spreader is cooperatively matched with the electromagnetic chuck by adopting the container fixture and clamping and fixing the container underwater, thereby ensuring that the sinkcontainer is salvaged from the deepwater safely.

Owner:WUHAN UNIV OF TECH

Indoor intelligent basketball collection cleaning and directional projection device

InactiveCN108970042BReduce auxiliary workImprove the efficiency of individual trainingBall sportsEngineeringMechanical engineering

Owner:杨智楷

Pressure frame used for thin plate splicing submerged arc welding machine

ActiveCN108326398AConvenient for logistics and transportationImprove site utilizationWelding/soldering/cutting articlesMetal working apparatusMotor speedReducer

The invention relates to a pressure frame used for a thin plate splicing submerged arc welding machine. The pressure frame comprises a half portal frame device, a lifting and rotating device and a dual-side pressure frame device; the half portal frame device is composed of dual transverse beams, a vertical column, an upper end frame, a lower end frame, a longitudinal guide rail, a longitudinal motor speed reducer, a longitudinal wheel set, a trolley, a transverse guide rail, a transverse motor speed reducer, a transverse wheel set and the like, longitudinal and transverse walking of the pressure frame can be achieved, the lifting and rotating device is composed of a hydraulic station, an oil cylinder, a lifting pin shaft, an oil cylinder frame, a lifting vertical column, a guide wheel, a rotation support, a small gear, a cycloidal pin gear speed reducer, a motor and the like, lifting and rotating of the pressure frame can be achieved, and through longitudinal and transverse motion of the half portal frame device and lifting and rotating motion of the lifting rotating device, placing of the workpiece at any position and any direction is in the work range; the dual-side pressure frame device can achieve effective and reliable pressing of two steel plates required to be spliced, and is matched with related welding devices and the like, it is ensured that welding work operation isconvenient, and efficiency is high, and welding quality is ensured.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

Flame cutting tool

InactiveCN109047986ARealize automatic cuttingImprove cutting efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlame cutting

The invention provides a flame cutting tool. The flame cutting tool comprises a frame part, an air cutting part, a casting blank and a control part; the frame part comprises a bracket, a power part, aworking platform and a clamping part; the power part penetrates through the left and right ends of the bracket, and is fixedly connected with the bracket; the working platform is vertically arranged,is positioned at the right end of the bracket, and is fixedly connected with the power part; and the clamping part is fixedly mounted on the right end surface of the working platform. The flame cutting tool adopts a cooperating mode of the frame part, the air cutting part and the casting blank to realize automatic cutting of the casting blank; and through vertical arrangement of the working platform, an unfixed end of the casting blank automatically falls under the effect of gravity after cutting to prevent bonding of a fixed end and the unfixed end through high cutting temperature, so that the separation auxiliary work after cutting is reduced, the cutting efficiency of the casting blank is improved, and the labor intensity of operators is reduced.

Owner:常州戚墅堰机车车辆配件工业有限公司

A method for decomposing residual iron in a blast furnace

ActiveCN109628673BEasy to installReduce auxiliary workBlast furnace detailsProcess efficiency improvementIron removalBlast furnace

Owner:福建天石源科技股份有限公司

A kind of manipulator automatic spraying camouflage camouflage paint and preparation method thereof

The invention discloses automatic spraying camouflage coating for manipulators and a method for preparing the automatic spraying camouflage coating. The method includes (1), adding 35.00-42.00 parts of acrylic resin, 0.50-1.00 part of dispersing agents, 1.00-3.00 parts of anti-sagging agents, 1.50-2.50 parts of extinction powder, 0.10-5.00 parts of electrically conductive optical materials, 7.00-18.00 parts of pigment, 17.00-23.00 parts of fillers and 6.00-8.50 parts of mixed solvents into an accessory tank and uniformly stirring the acrylic resin, the dispersing agents, the anti-sagging agents, the extinction powder, the electrically conductive optical materials, the pigment, the fillers and the mixed solvents to obtain first mixtures; (2), grinding the first mixtures by the aid of a sand mill until the fineness of the first mixtures reaches 18-22 micrometers; (3), adding 4.00-6.00 parts of special modified polyester compounds, 3.00-5.00 parts of silicon dioxide nanometer composite materials and 6.00-8.50 parts of mixed solvents into paste and uniformly stirring the special modified polyester compounds, the silicon dioxide nanometer composite materials, the mixed solvents and the paste to obtain second mixtures; (4), regulating the viscosity of the second mixtures until the viscosity of the second mixtures reaches coating-4 cup 65-80 S; (5), filtering and packaging the automatic spraying camouflage coating. The automatic spraying camouflage coating and the method have the advantages that the automatic spraying camouflage coating is reasonable in design and has tone which is consistent with natural backgrounds, anti-infrared camouflage effects of spectral reflection curves can be realized by the automatic spraying camouflage coating, and problems in the aspects of sagging, drying speeds, surface smoothness and the like in automatic paint spraying procedures can be solved.

Owner:CHANGZHOU JIAERKE SIMULATION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com