Blade repair positioning device for aeroengine low pressure turbine guide

A technology for aero-engines and low-pressure turbines, applied in auxiliary devices, metal processing equipment, auxiliary welding equipment, etc., can solve the problem of high technical level and experience of workers, manual positioning can not find the center, affect the effect of repair, etc. problems, to achieve the effects of shortening the production cycle, reducing positive deformation and repair procedures, and stable and reliable welding positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

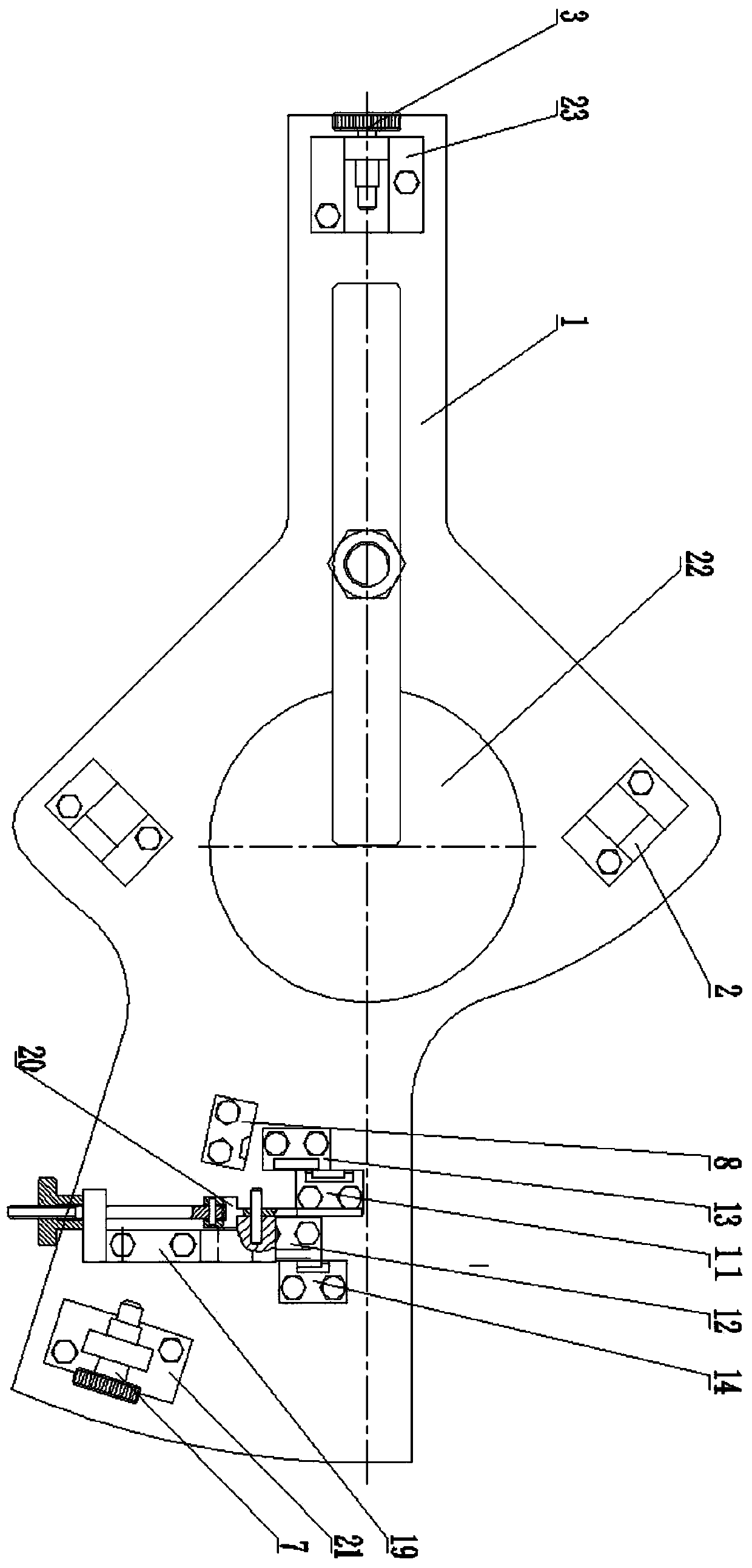

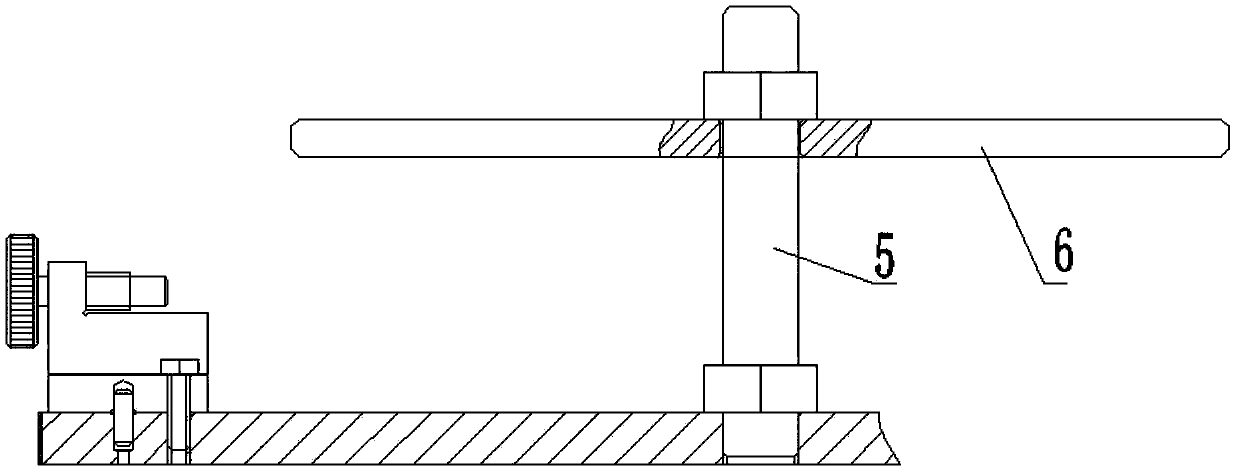

[0027] like Figure 1 to Figure 6 As shown, the blade repair and positioning device for the low-pressure turbine guider of an aeroengine includes a base 1; two side positioning blocks 2 are arranged on the base 1; the two side positioning blocks 2 are arranged symmetrically with respect to the center line of the base 1; The main positioning mechanism, the main positioning mechanism is located on the center line of the base 1, and it forms a triangular positioning group with the two side positioning blocks 2; the triangular positioning group positions the low-pressure turbine guide so that it can be stably fixed, and the center is very clear. It avoids the situation that manual positioning cannot find the exact center and requires high technical level and experience of workers.

[0028] Wherein, the main positioning mechanism includes a main positioning block 23 and a compression screw 3 connected with the main positioning block 23 for locking the low-pressure turbine guide; th...

Embodiment 2

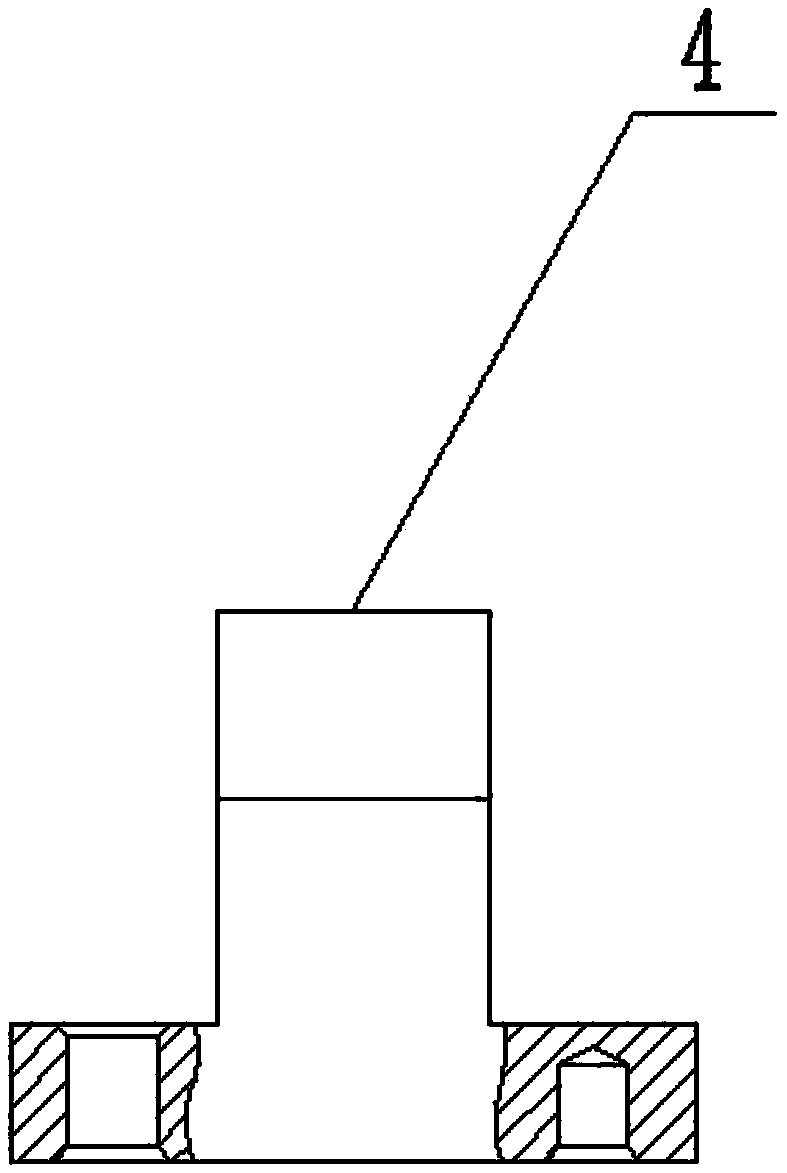

[0034] like Figure 1 to Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the base 1 is provided with an edge plate positioning block 8 located on one side of the center line; the edge plate positioning block 8 includes a bottom plate 10 arranged on the base 1 and an The positioning column 9 on the bottom plate 10; the edge plate positioning block 8 is used to fix the edge plate of the low-pressure turbine guider.

[0035] In a preferred embodiment of the present invention, the base 1 is provided with a first leading edge positioning block 11 and a second leading edge positioning block 12 for positioning the leading edge of the low-pressure turbine guide; the first leading edge positioning block 11 and the second The leading edge positioning block 12 is located between the edge plate positioning block 8 and the center line; the first leading edge positioning block 11 and the second leading edge positioning block 12 are arranged radially relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com