Tailored Welding Tooling and Technology for Sub-beam Assembly of Hook-arm Car

A sub-beam and assembly technology, which is applied in the field of tailor-welding tooling and technology of the hook-arm car sub-beam assembly, can solve the problems of difficult assembly, poor interchangeability of components, and inability to guarantee the dimensional accuracy of components, reducing the number of tooling, The effect of avoiding space occupation and facilitating positioning and tailoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with accompanying drawing:

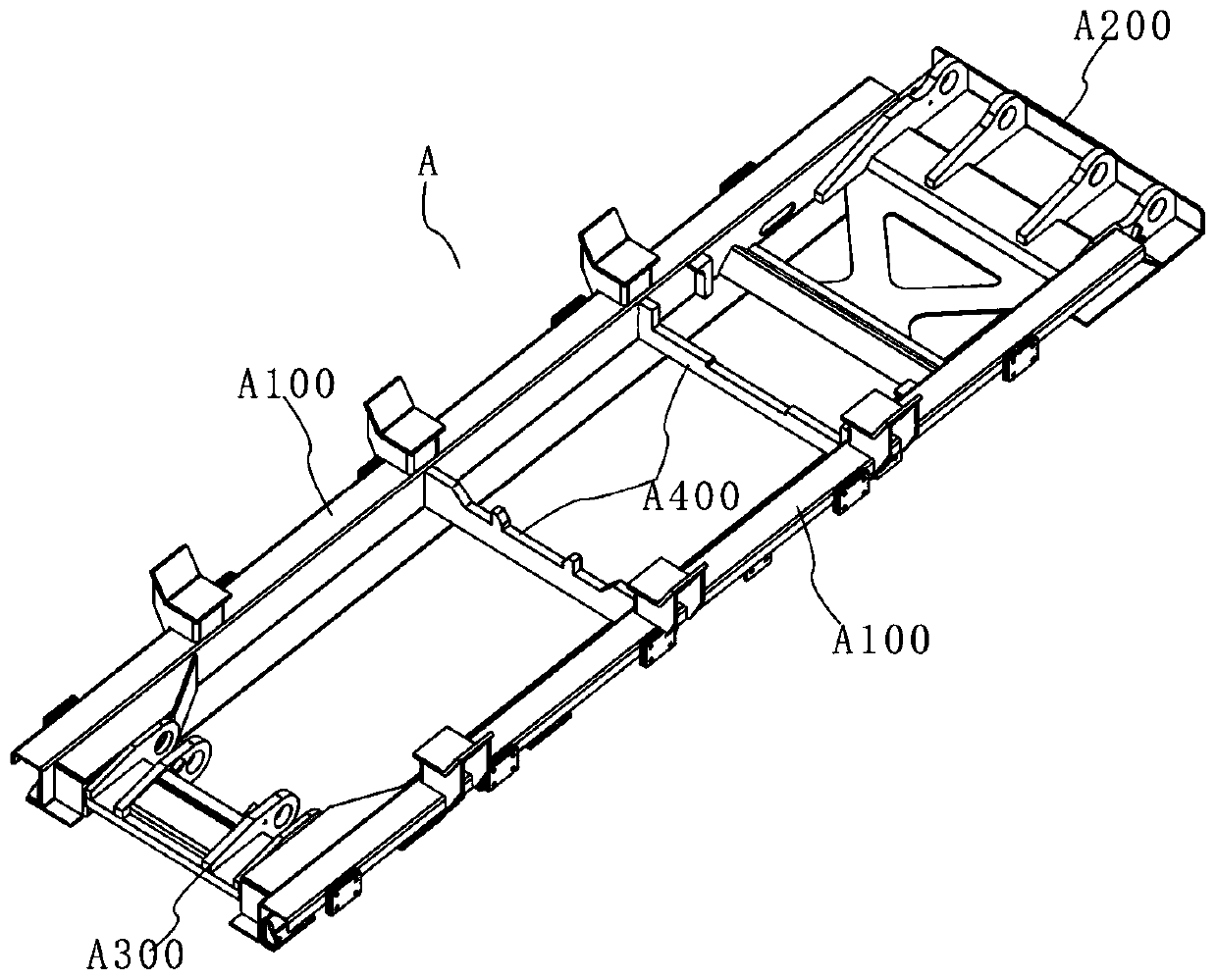

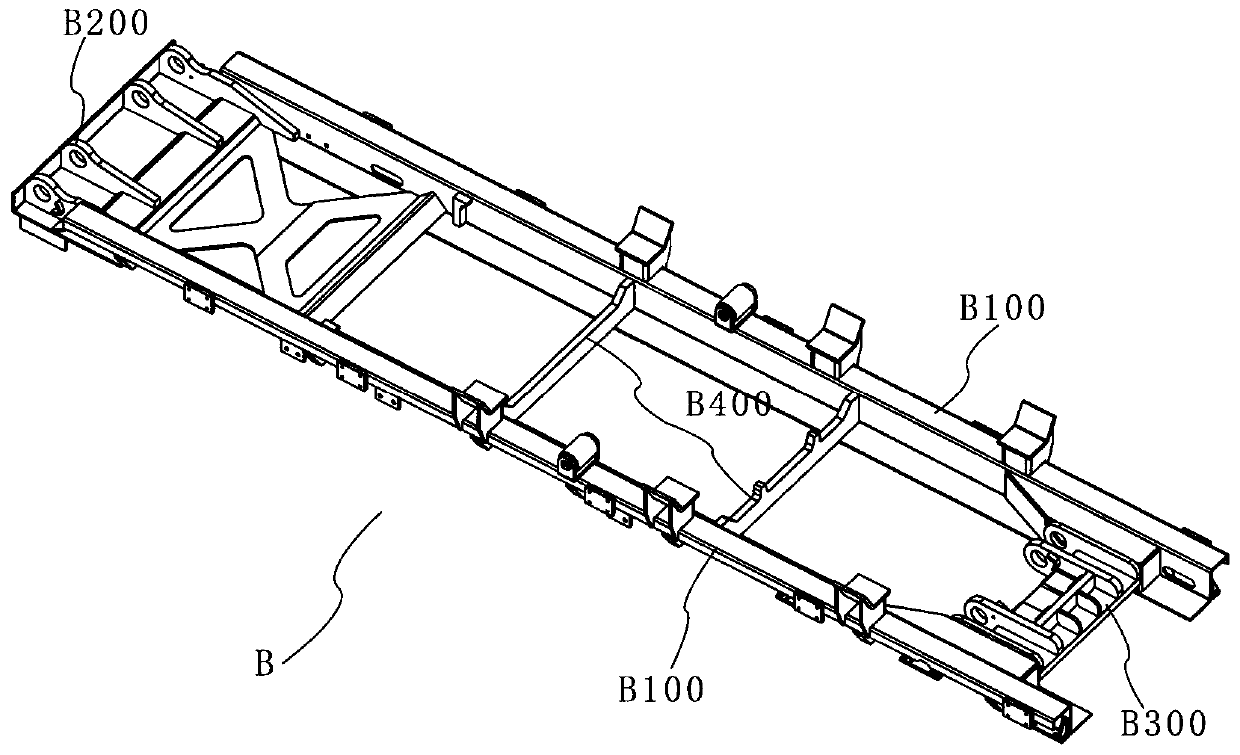

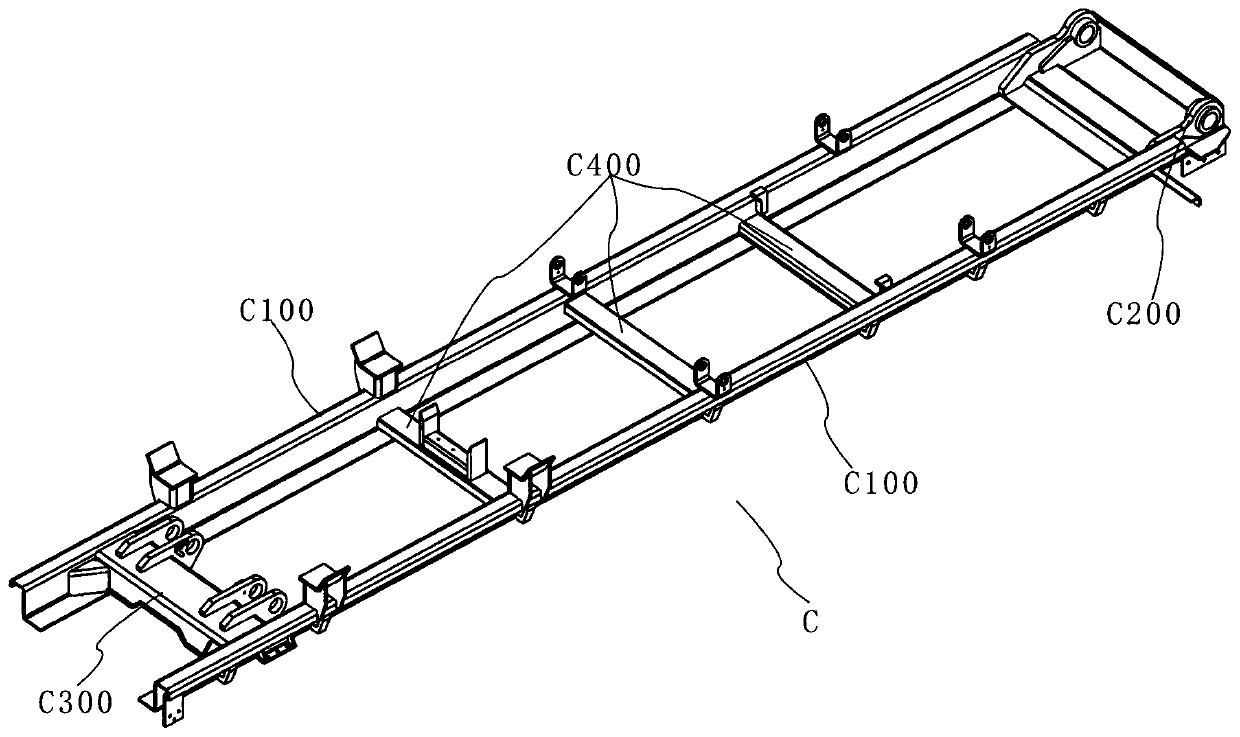

[0055] This embodiment provides a tailor-welding tool for the sub-frame assembly of the hook-arm vehicle, which is suitable for the positioning and tailor-welding of three product specifications of the sub-frame A, B, and C, wherein the specification of the sub-frame A is the smallest, and the specification of the sub-frame C is the largest , the sub-beams A, B, and C respectively include two parallel and opposite longitudinal beams A100, B100, C100 and hinged seats A200, B200, C200 combined with the front ends of the longitudinal beams A100, B100, C100 and Cylinder blocks A300, B300, C300 at the rear of C100, and longitudinal beams A100, B100, C100 include the central vertical plate, the inner horizontal plate connecting the bottom of the central vertical plate and stretching inward, connecting the top of the central vertical plate and extending outward The outer horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com