Garbage truck bucket assembly tailor welding tooling and assembly process

A technology of garbage trucks and assemblies, applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve the problems of dimensional accuracy and shape and position tolerance, affecting assembly quality, easy damage, etc., to ensure parallelism and coaxiality. , The effect of reducing maintenance service costs and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with accompanying drawing:

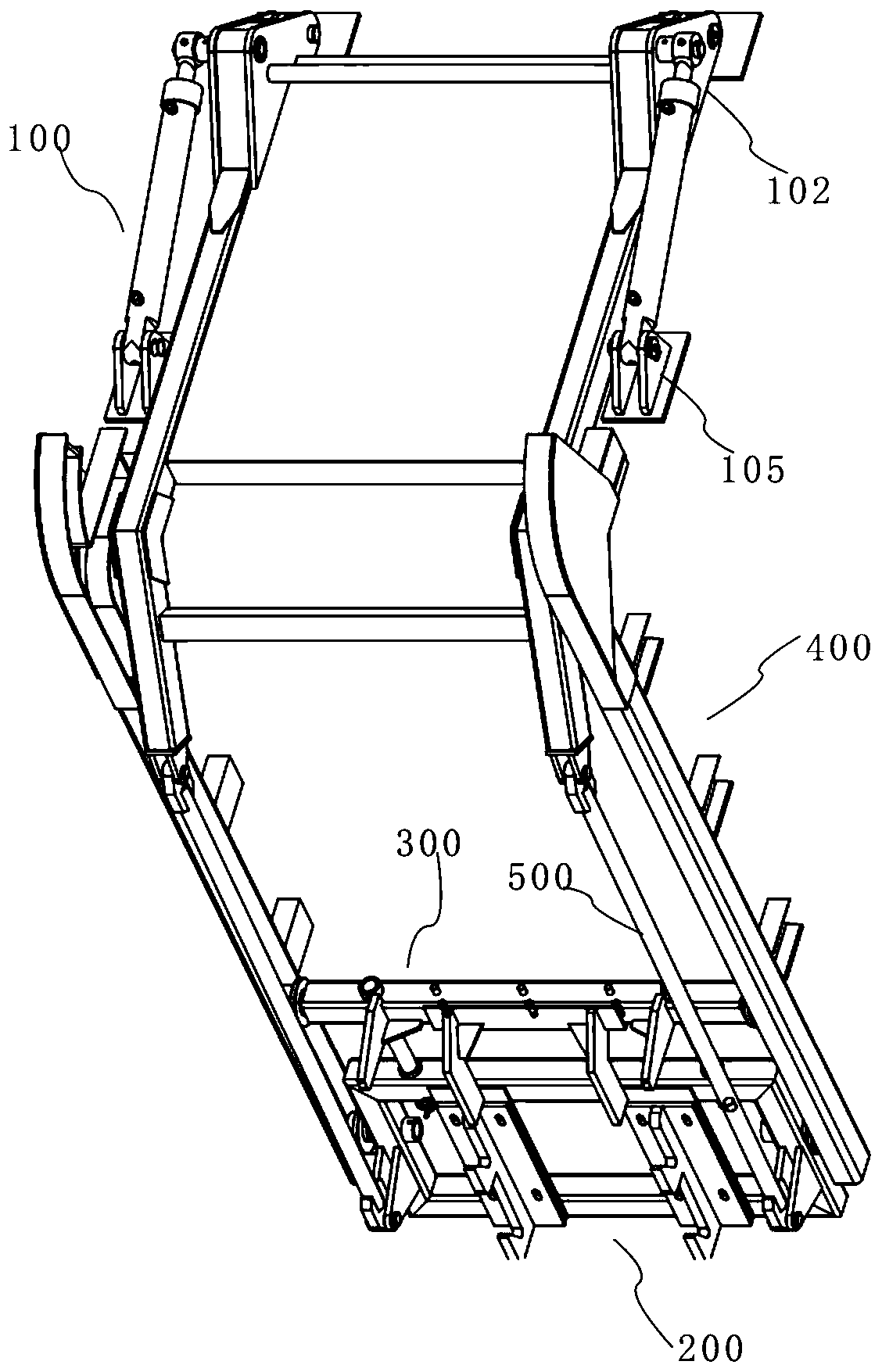

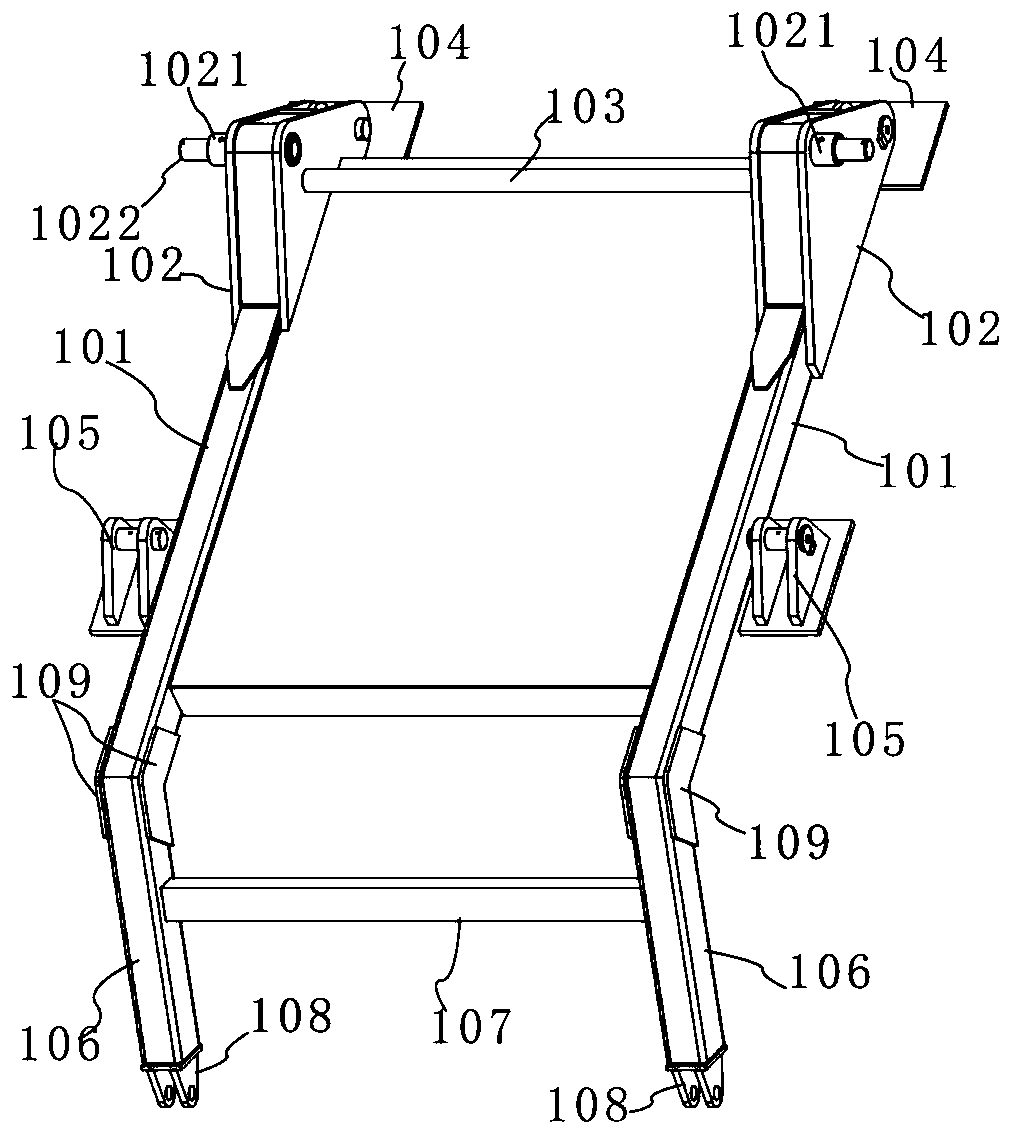

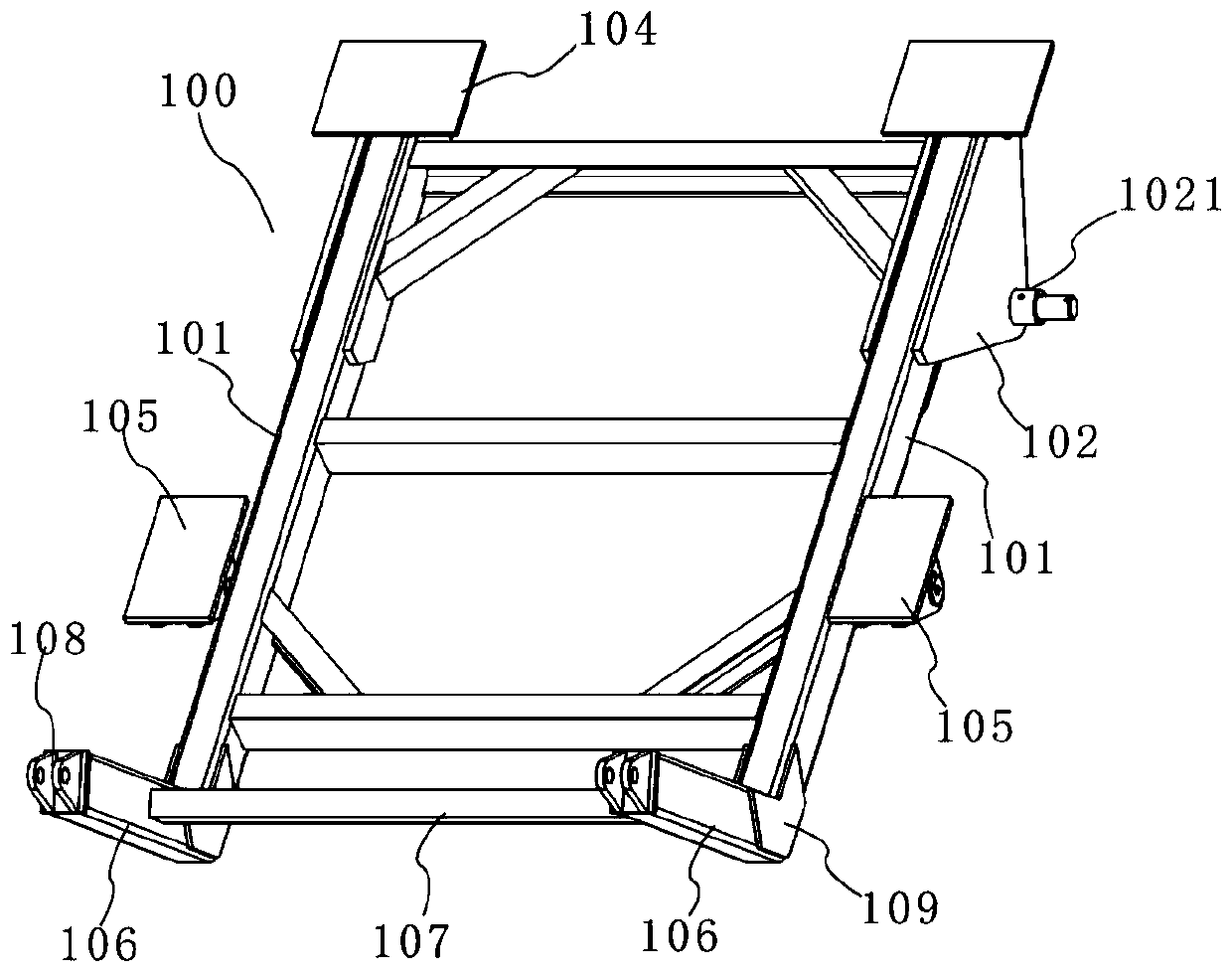

[0058] Such as Figure 1-16 As shown, this embodiment provides a garbage truck bucket assembly tailor welding tool for positioning the tailor welded bucket assembly. In this embodiment, the bucket assembly includes a top cover assembly 100, a guide rail assembly 400, a bucket frame assembly 200 and a bucket press assembly 300, and the connection between the top cover assembly 100 and the bucket frame assembly 200 are movably connected by a tie rod 500, and the corresponding tailor welding tooling of this embodiment includes three sub-tools for supporting use, which are the upper cover sub-tool A for positioning the tailor welding upper cover assembly 100, the tailor welding guide rail for positioning The guide rail division tooling C of the assembly 400, and the hanging bucket division tooling B used for positioning the tailor-welded hanging bucket frame assembly 200 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com