Goat roasting oven

A sheep roasting furnace and furnace body technology are applied in the field of roasting sheep furnaces, which can solve the problems of poor roasting taste, uneven roasting, unfavorable environmental protection, etc., and achieve high rotation reliability, convenient height adjustment and less space occupation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

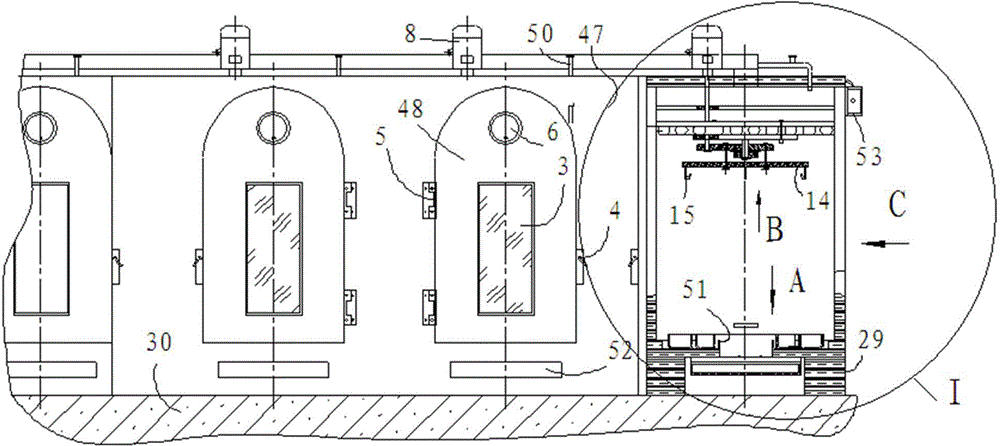

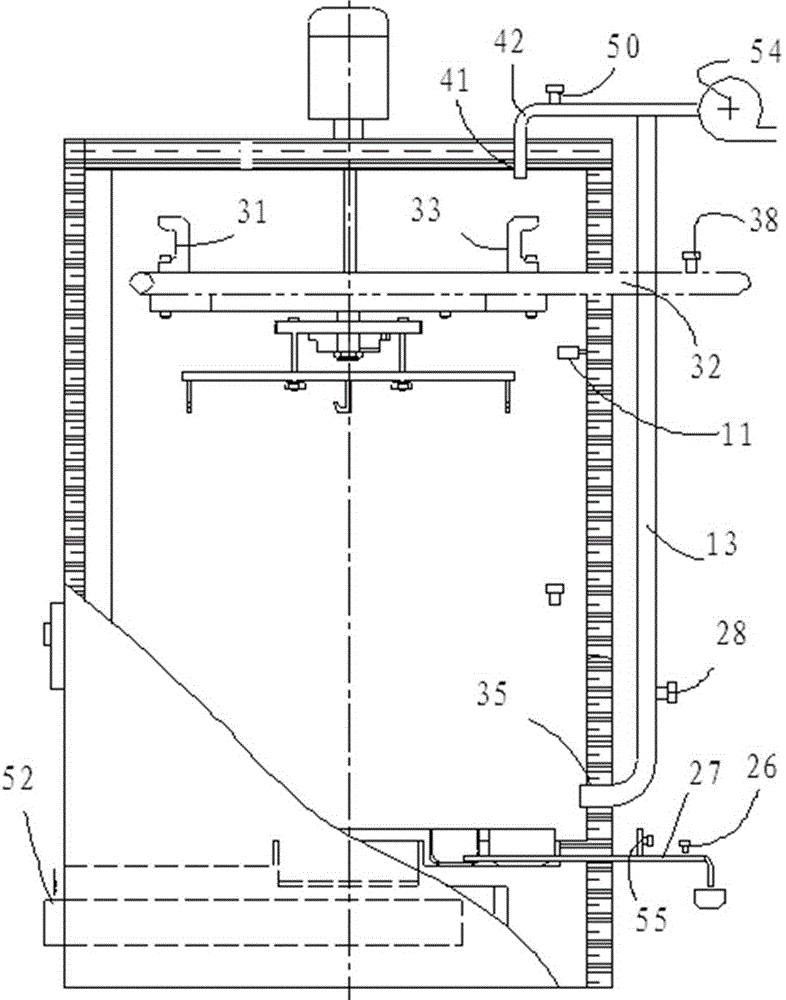

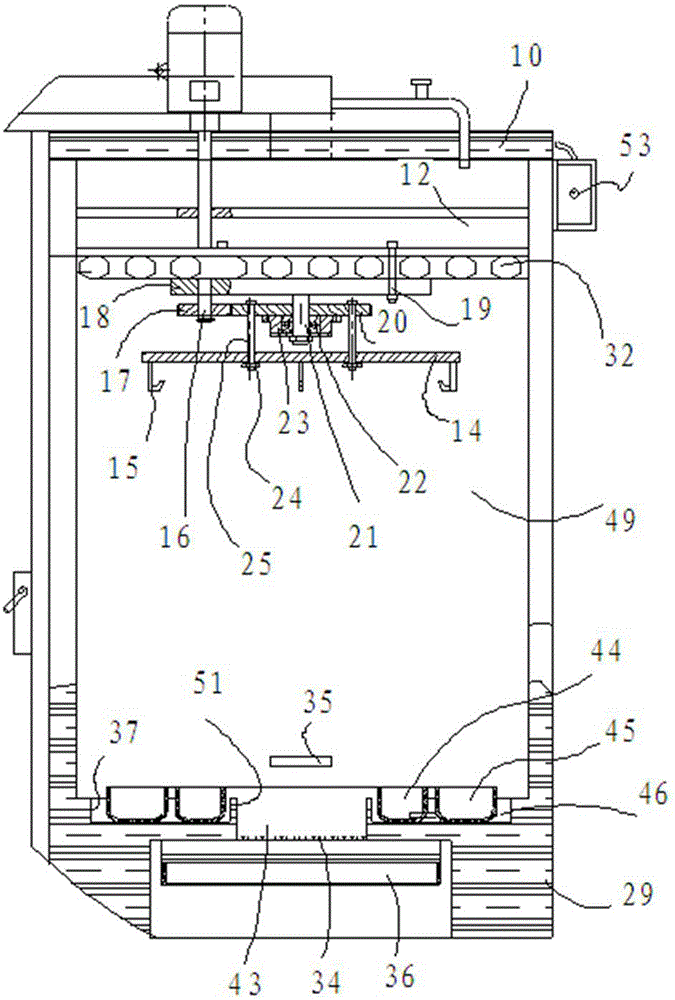

[0028] Such as Figure 1 to Figure 5Shown, a kind of oven for roasting sheep comprises the furnace body 47 that is made by insulating material, and the furnace body adopts refractory wall brick and refractory cement etc. There is a heat preservation furnace door 48, one side of the furnace door 48 is hinged with the furnace body through a loose leaf 5, the other side is provided with a door handle 4, the furnace door 48 is provided with a transparent window 3 made of transparent material, and the upper part of the transparent window 3 is provided with a temperature A display 6 is provided with a thermocouple 11 on the rear side of the body of furnace, and the thermocouple is connected to the temperature display 6. A rotating structure is arranged on the upper part of the inner cavity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com