An Ultrasonic Probe for Wall Thickness Thinning Measurement in Extreme Environments

An ultrasonic probe, wall thickness thinning technology, applied to measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems affecting performance, piezoelectric effect reduction of piezoelectric materials, and has not yet been popularized and applied, etc., to achieve The effect of improving accuracy and reliability and improving practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

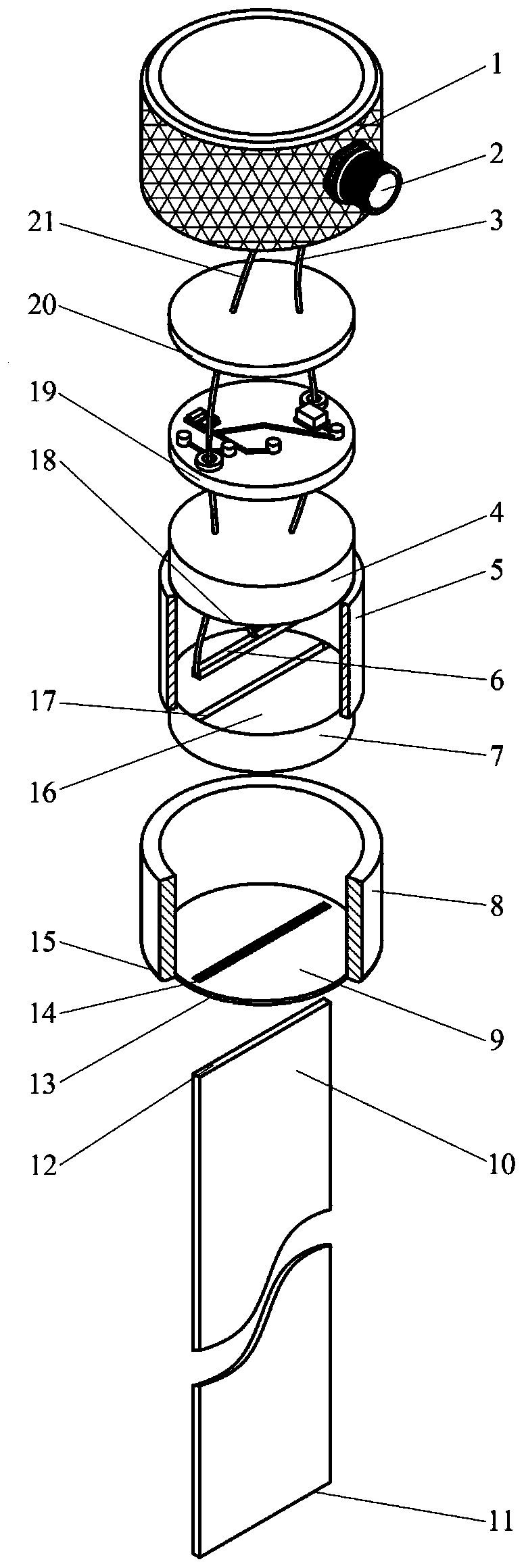

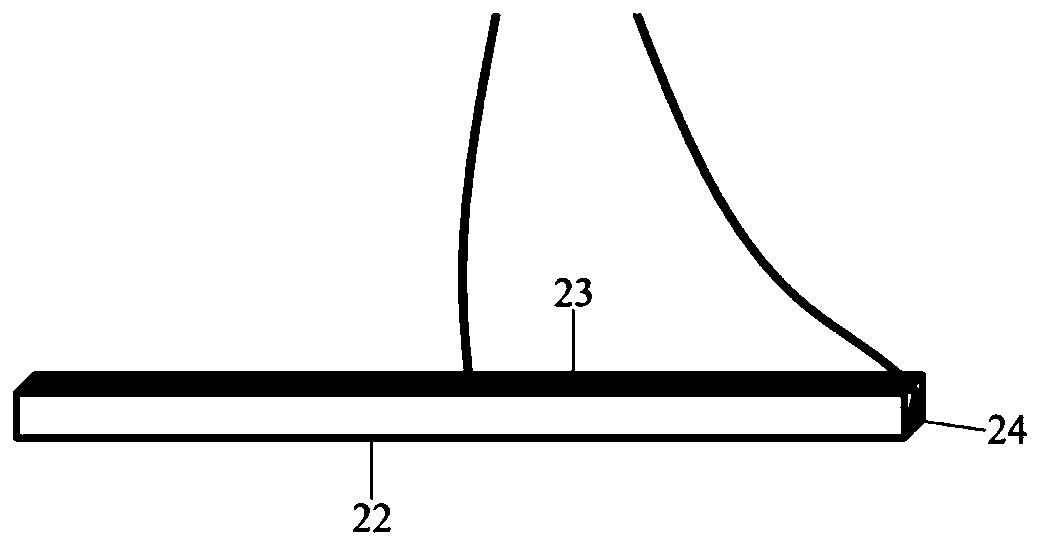

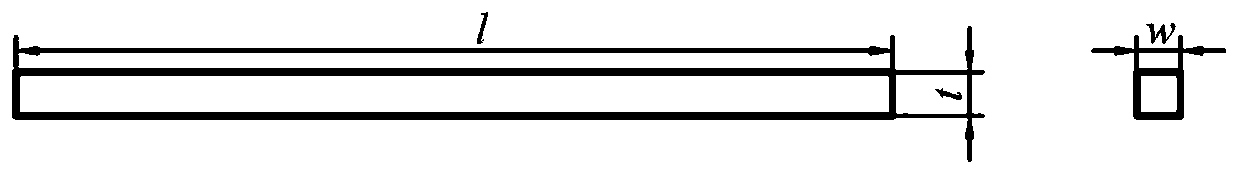

[0057] Design and process an ultrasonic probe for measuring wall thickness thinning under high temperature environment. The piezoelectric chip 6 is made of 2-2 composite material, the outer shell back cover 9 is made of alumina (corundum), the inner shell 5 is made of polytetrafluoroethylene, and the cover shell 1 is made of Hard aluminum alloy 2219, the thickness of the waveguide (10) is 1mm, the width is 20mm, and the length is 300mm, the material is 316L stainless steel, the thickness of the piezoelectric wafer is 1mm, the width is 1mm, the length is 18mm, the circuit board 19 and the pressure The impedance matching of the electric chip 6 is assembled from components such as commercially available resistors and capacitors. We use accessories of Guangdong Fenghua High-tech Co., Ltd. with the following specifications: capacitor, model: CC4‐0805N200J500F3, resistor, model: RC‐MT08W512JT, inductor, model: LGA0204‐221KP52E.

[0058] The tested samples are three flat plates made ...

Embodiment example 2

[0062] Design and process an ultrasonic probe for measuring wall thickness reduction in a low-temperature environment. The piezoelectric chip 6 is made of 2-2 composite materials, the back cover 9 is made of alumina (corundum), the inner shell 5 is made of polytetrafluoroethylene, and the cover-like shell 1 is made of hard Aluminum alloy 2219, the width of the waveguide plate 10 is 20mm, the thickness of the end surface 12 of the waveguide plate is 10mm, the thickness of the lower end surface 11 of the waveguide plate is 1mm, the length is 150mm, the material is 316L stainless steel, and the thickness of the piezoelectric chip is 1mm, a width of 10mm, and a length of 18mm. The circuit board 19 matches the impedance of the piezoelectric chip 6 and is assembled from commercially available resistors and capacitors. We use accessories of Guangdong Fenghua High-tech Co., Ltd. with the following specifications: capacitor, model: CC4‐0805N200J500F3, resistor, model: RC‐MT08W512JT, ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com