Drying device for environmental-protection production sintering of ferrite magnetic powder

A technology of drying device and sintering iron, applied in drying, drying machine, heating device and other directions, can solve problems such as heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

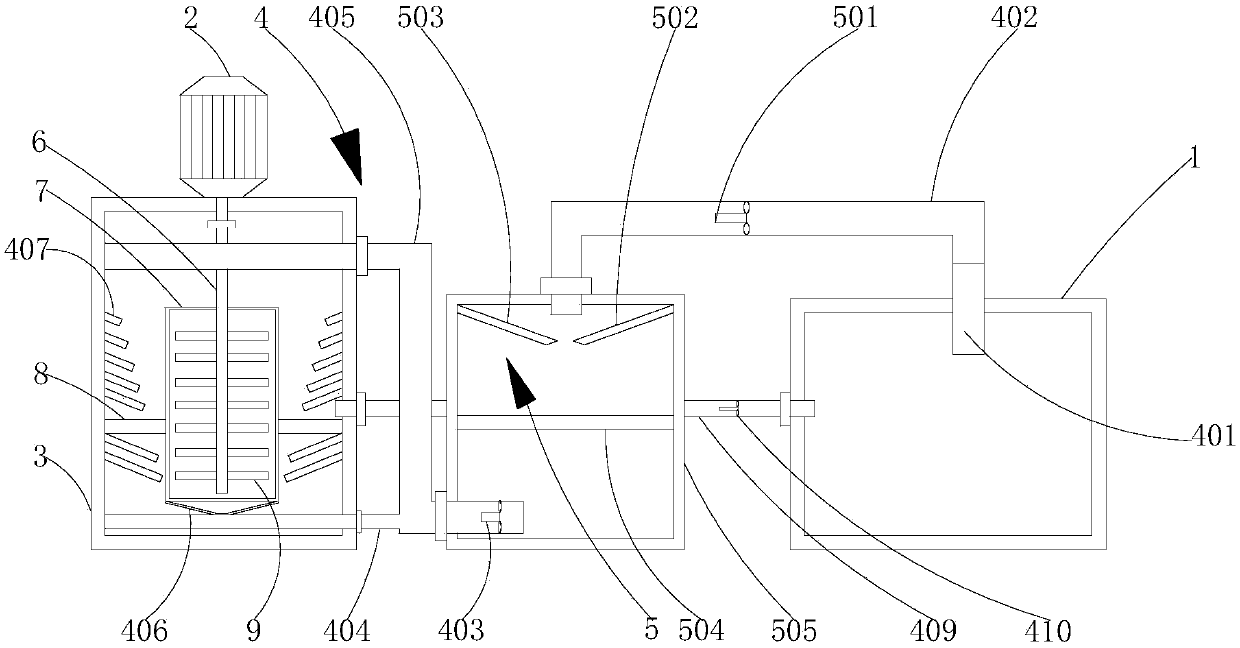

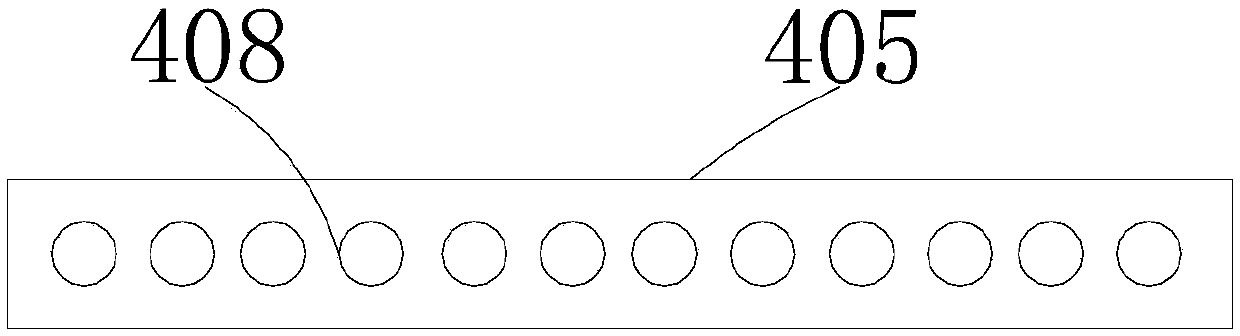

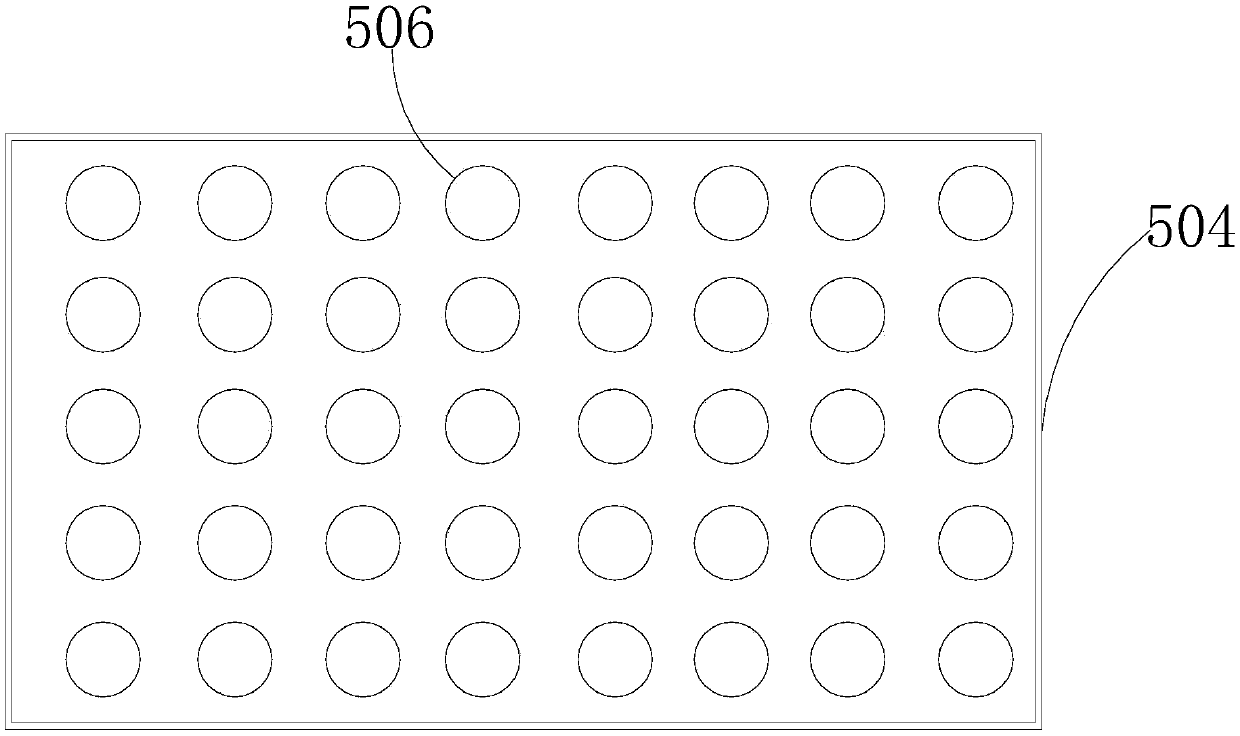

[0023] Such as Figure 1-3 As shown, the present invention provides a technical solution: an environmentally friendly drying device for producing sintered ferrite magnetic powder, including a sintering box 1, a waste heat recovery device 4, a drying box 3 and a dust removal device 5, and the waste heat recovery device 4 includes Exhaust pipe 401, air pipe 1 402, suction fan 1 403, air pipe 2 404, air pipe 3 405, air outlet cover 406, baffle plate 407, air outlet 1 408, air pipe 4 409 and suction fan 3 410, dust removal The device 5 includes the second suction fan 501, the positive plate 502, the negative plate 503, the separator 504, the dust box 505 and the second air outlet 506. The second suction fan 501 is an electrostatic fan, and the exhaust pipe 401 is located inside the sintering box 1. The top of 401 penetrates the top of the inner wall of the sintering box 1 and extends above the sintering box 1, and the top of the exhaust pipe 401 is connected with one end of the ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com